Optimizing Inventory Management by MTS in Viindoo¶

In today’s fast-paced business environment, efficient inventory management is crucial for maintaining smooth operations and minimizing costs. One effective approach to achieve this is by implementing a Make-to-Stock (MTS) strategy. Viindoo, an advanced ERP solution, offers a powerful platform for optimizing inventory management by MTS. With its integrated features, Viindoo enables businesses to efficiently track stock levels, forecast demand, and automate replenishment processes, ensuring that the right products are available at the right time. In this article, we will explore how Viindoo’s MTS functionality can streamline inventory management and drive greater efficiency across your supply chain.

Requirements

This tutorial requires the installation of the following applications/modules:

In Viindoo, the Minimum-Maximum Stock (MTS) rule can be trigger either automatically or manually. The choice of which method to use depends on the characteristics and inventory management needs of the business.

Automatic MTS trigger: Automatic trigger of MTS is suitable for businesses with stable and predictable supply chains, where product demand and supply routes are highly stable. This is ideal when:

Demand forecasts are clearly defined: Products with consistent demand and predictable supply, such as consumer goods or basic raw materials.

Supply routes are stable: Suppliers, markets and logistics processes are stable, with minimal changes over time.

Automatic MTS trigger will automatically trigger inventory replenishment when stock levels fall below the minimum threshold, ensuring the business always has enough stock to meet production or sales needs. It also mean, users will not involved and control the process.Manual MTS trigger: Manual trigger of MTS is more appropriate when the business needs better control over the inventory process:

Need for better control at each location or warehouse: If a business has multiple warehouses or sales points, each location may have different inventory needs, and manual activation allows users to adjust replenishment based on real-time requirements at each location.

Situations requiring flexibility: In cases of sudden market fluctuations or supply chain disruptions, manual control allows businesses to quickly adjust their replenishment plans, avoiding overstocking or stockouts.

Set the product’s reordering rules¶

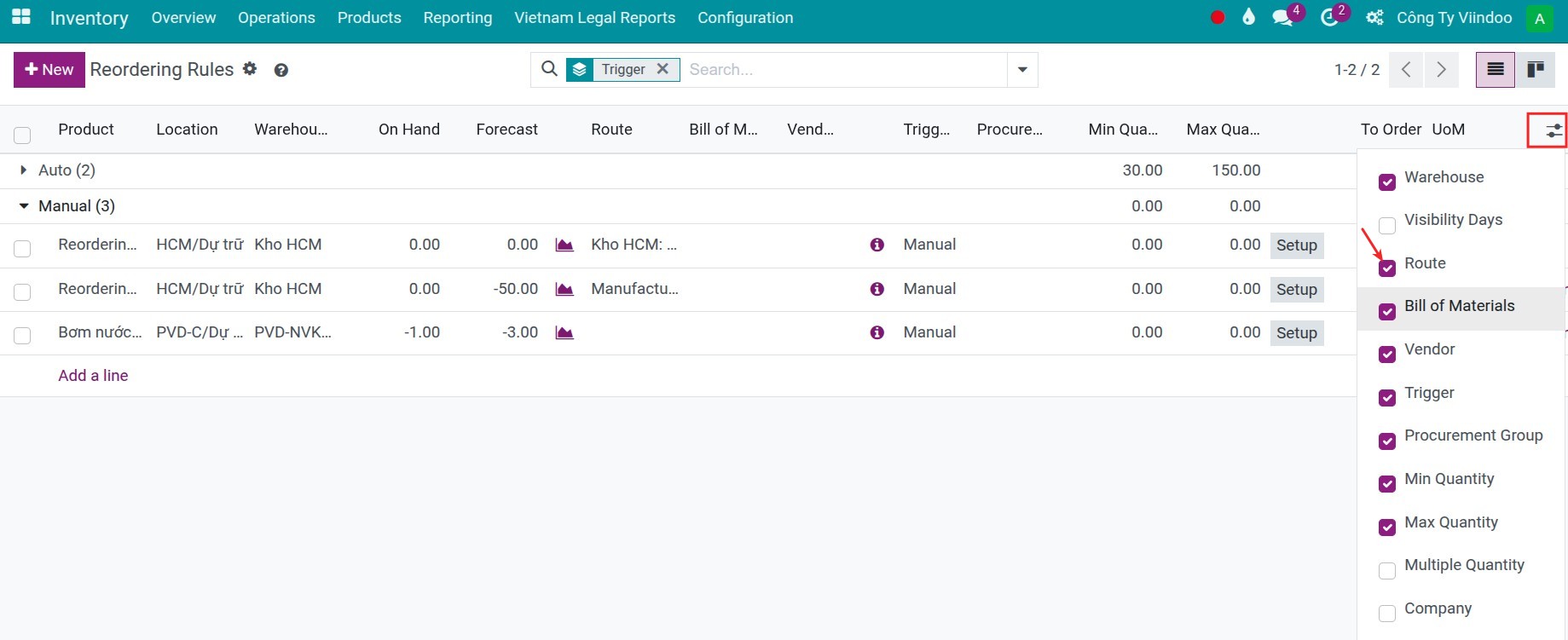

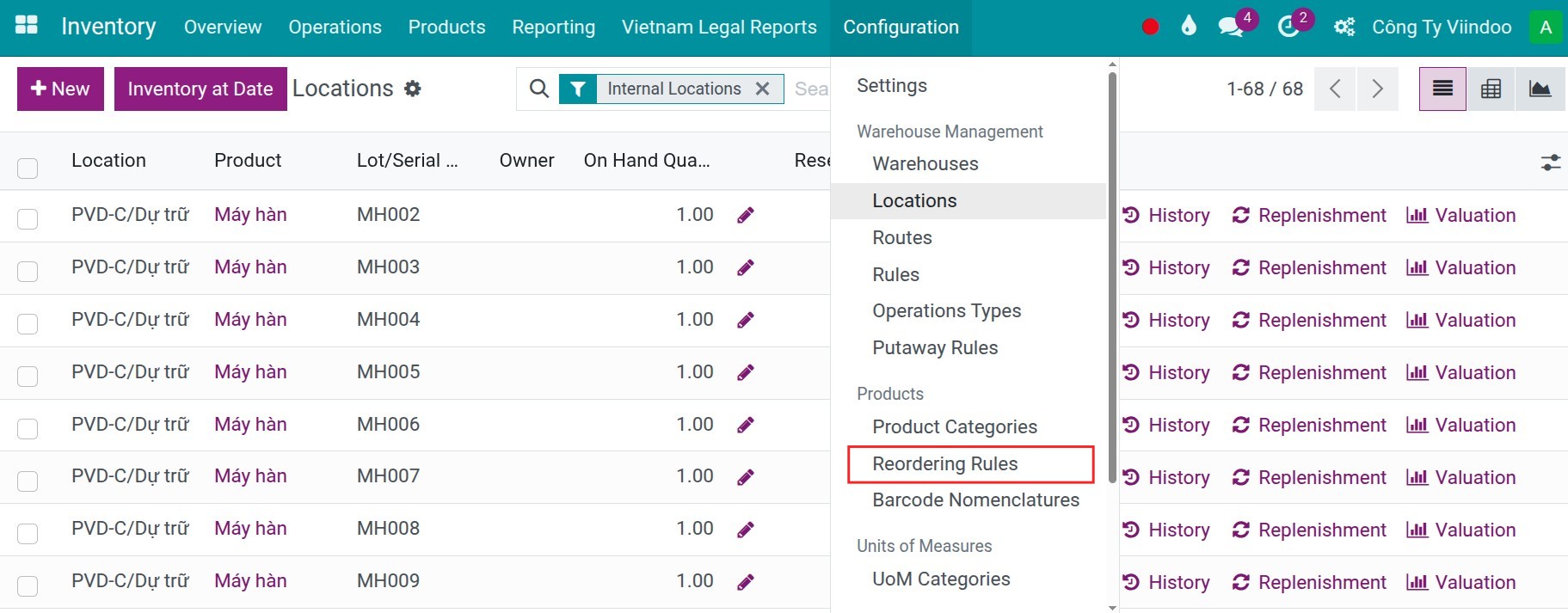

Navigate to Inventory > Configuration > Reordering Rules to create a new reordering rule:

Tip

Reordering rules can also be created from the Reordering Rules smart button on the product form.

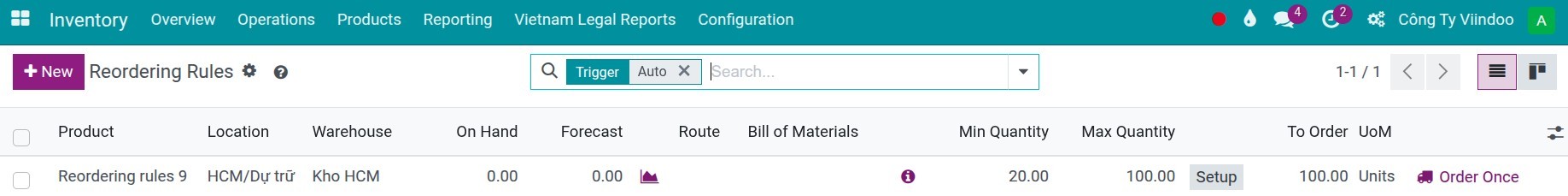

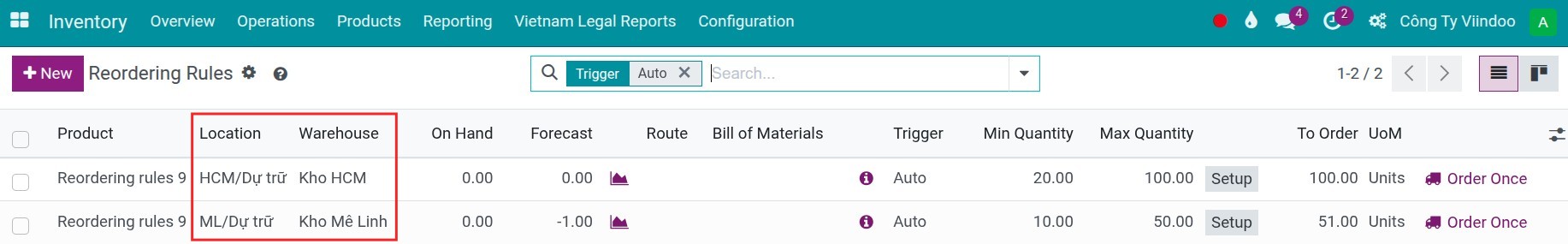

In cases where a product must be replenished from a different warehouse, you can set up reordering rules for each warehouse to ensure proper supply flow between them.

Automatic reordering rules¶

To enable automatic reordering rules, you need to configure the following elements:

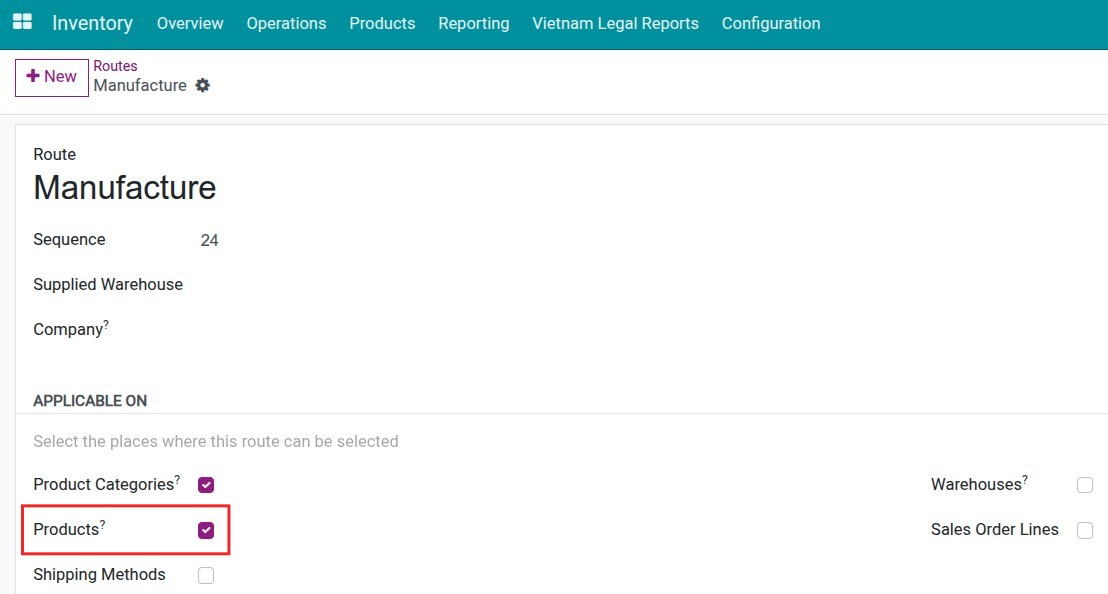

Routes on the product form or its product category.

A list of vendors on the product form (if the Buy route is applied).

A valid Bill of Materials (BoM) for the product (if the Manufacture route is applied).

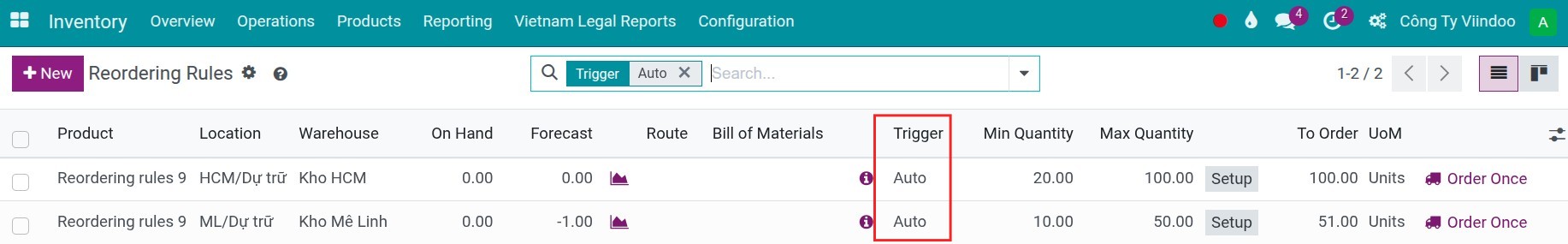

By default, when a reordering rule is created, its trigger is set to Auto. This means that whenever the forecast quantity falls below the defined minimum, the system will automatically trigger a replenishment action. This could be a purchase order, manufacturing order, internal transfer, or a combination, depending on the configured routes for each product.

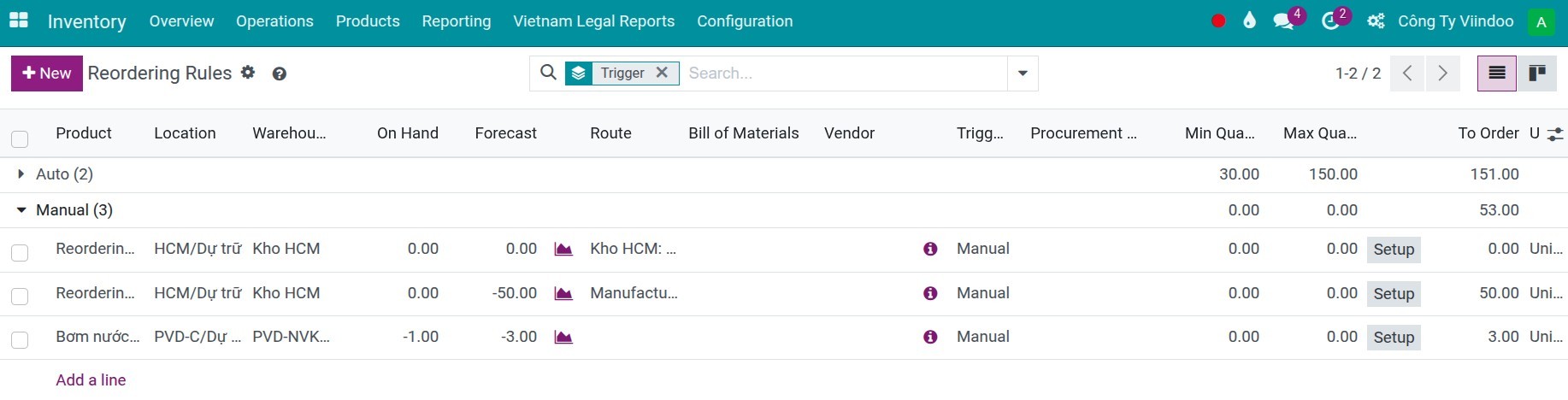

Manual reordering rules¶

To allow more involvement, flexibility, and control over the replenishment process, you can set the reordering rule’s trigger to Manual.

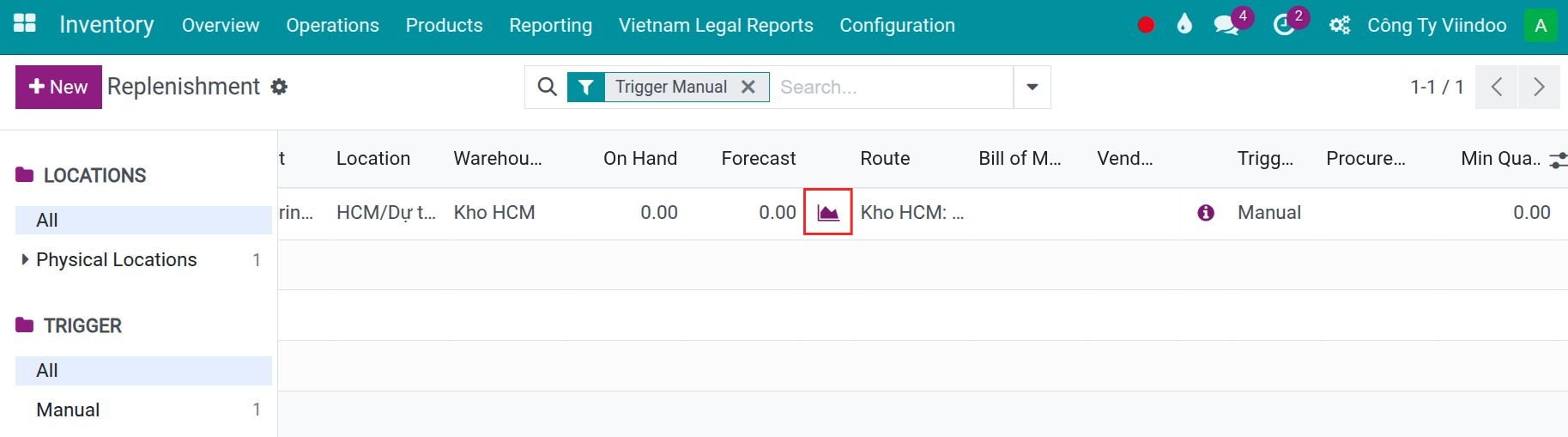

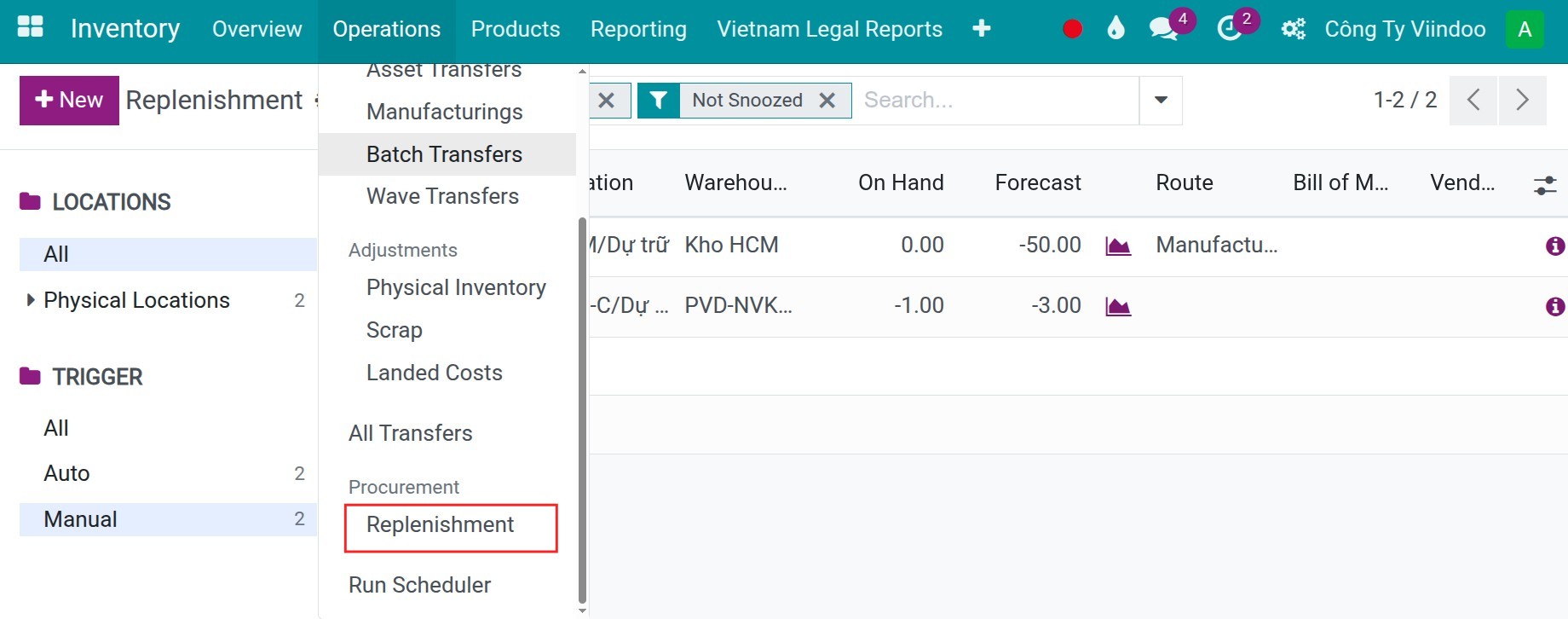

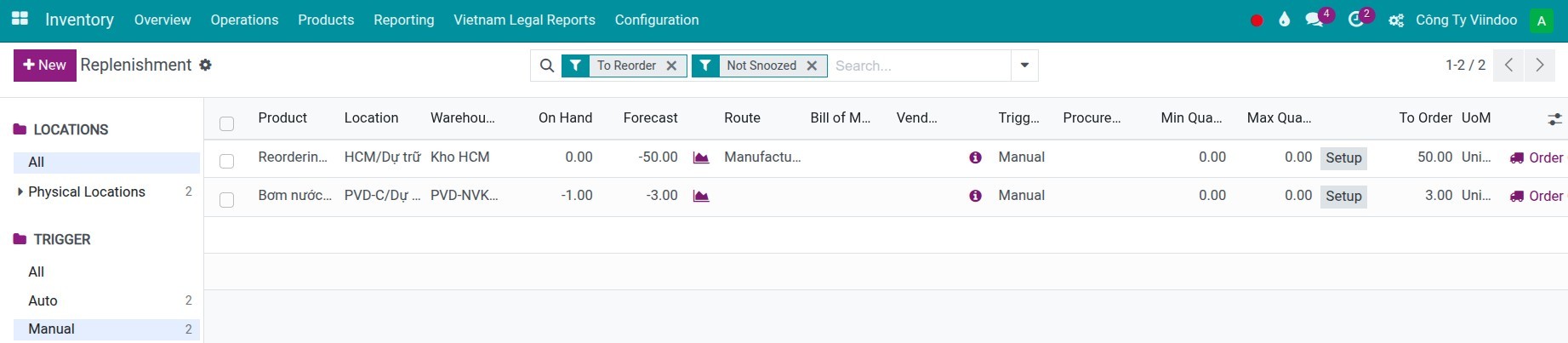

To manually control and manage product replenishment, navigate to Inventory > Operations > Replenishment. This dashboard allows you to monitor and manually trigger replenishment actions based on current stock levels and demand. Whenever the forecast quantity falls below the minimum threshold, the corresponding reordering rule will be displayed on this dashboard for your review and action:

Here, Viindoo provides several features to help you control and adjust replenishment operations:

Forecast Report: Click the forecast report icon next to the forecast quantity. This will display the detailed forecast, including expected receipts and demand operations. It also helps identify which Procurement Group to assign in order to link the replenishment with a specific operation.

![Forecast report]()

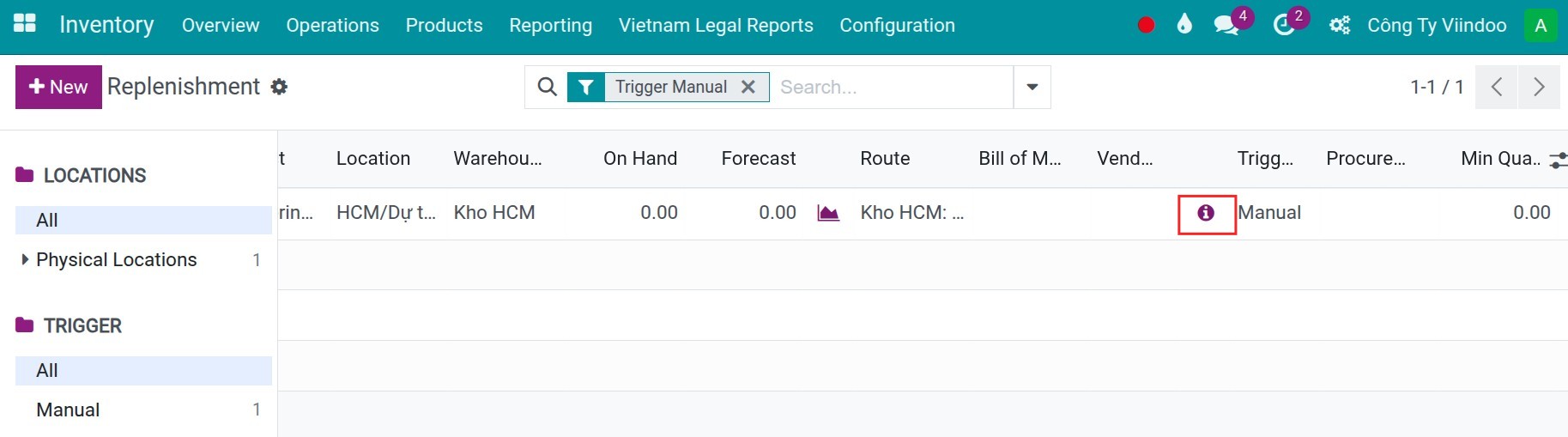

The Replenisment information: Click the information icon to open the replenishment details dashboard. Here, you can view key data such as:

![Replenishment information]()

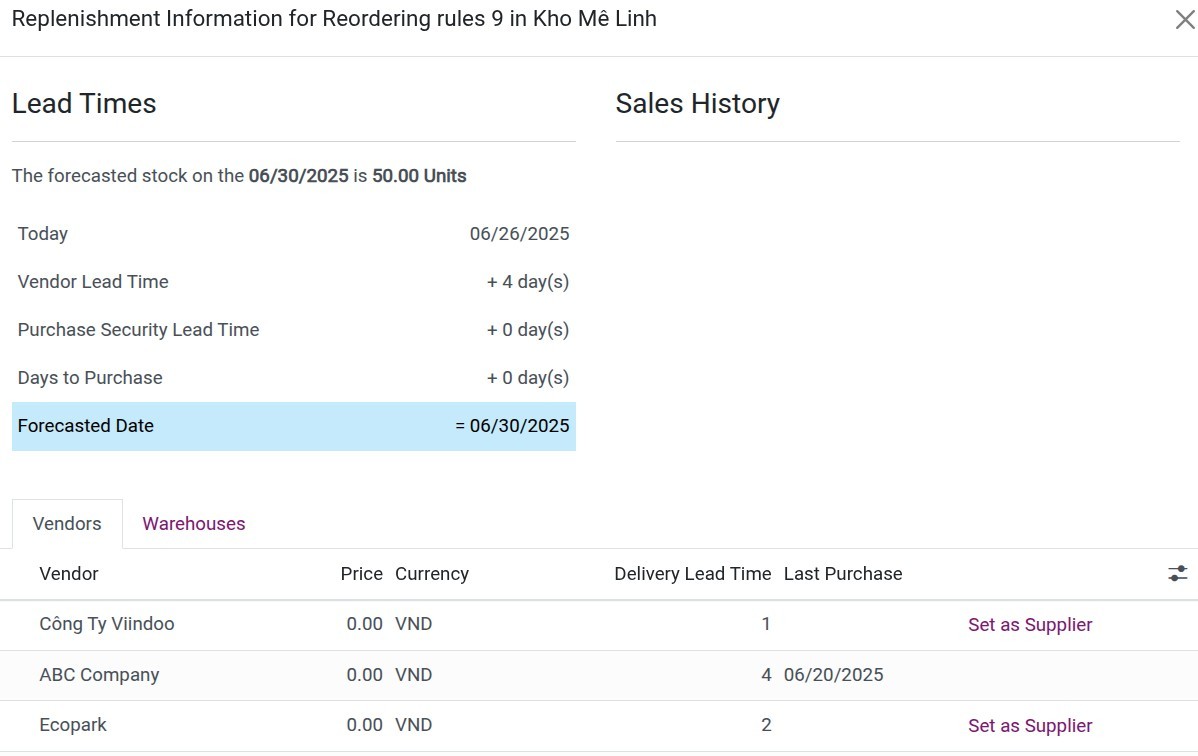

Lead times: Based on the lead times configured for the product and the selected preferred route, the system will display either the purchase lead time or manufacturing lead time, accordingly. This information is used to estimate the forecasted replenishment date for the product, helping ensure timely fulfillment of demand.

![Replenishment information]()

Vendor: You can also view the product’s vendor list in this section. Based on criteria such as Delivery Lead Time, Last Purchase Date, and Last Purchase Price, you can select or switch to a different vendor as needed by clicking Set as Supplier.

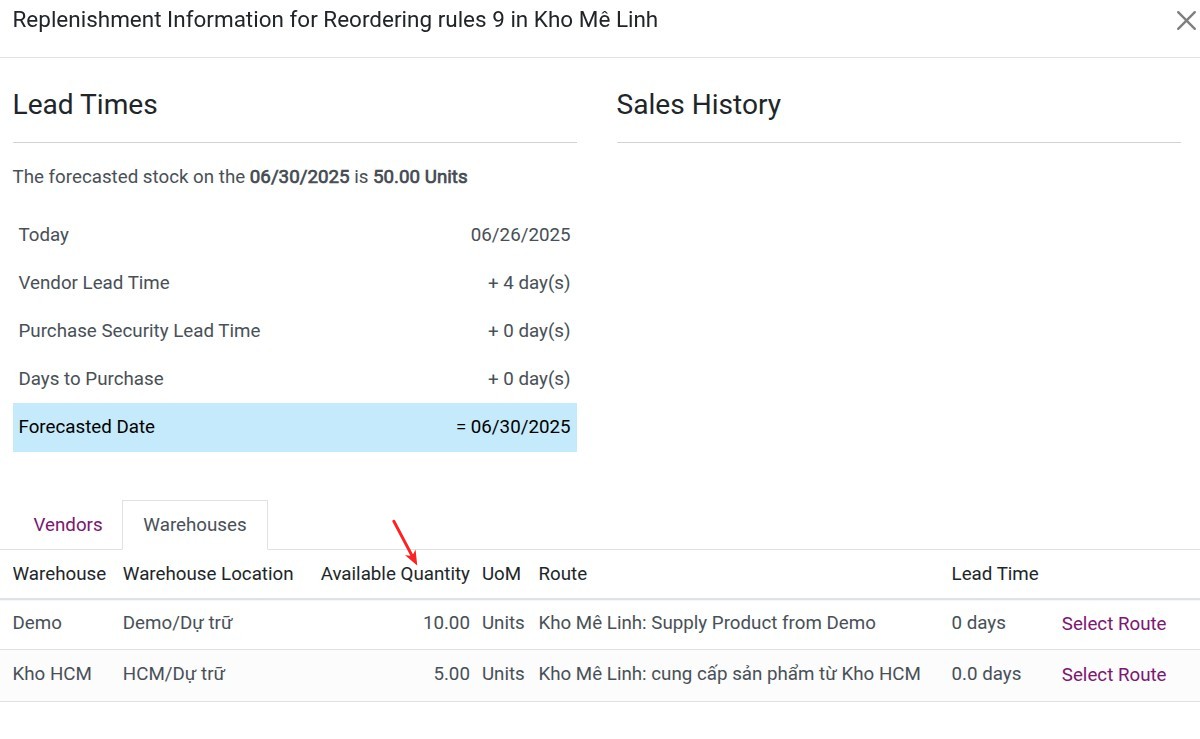

Warehouse: On this tab, you can view the available quantity of the product in other warehouses. Based on this information, you can choose to use or switch the route to replenish from another warehouse by clicking the Select Route button.

![Replenishment information]()

Sales History: This information helps you review the sales history of the product, supporting better decision-making regarding replenishment and demand planning.

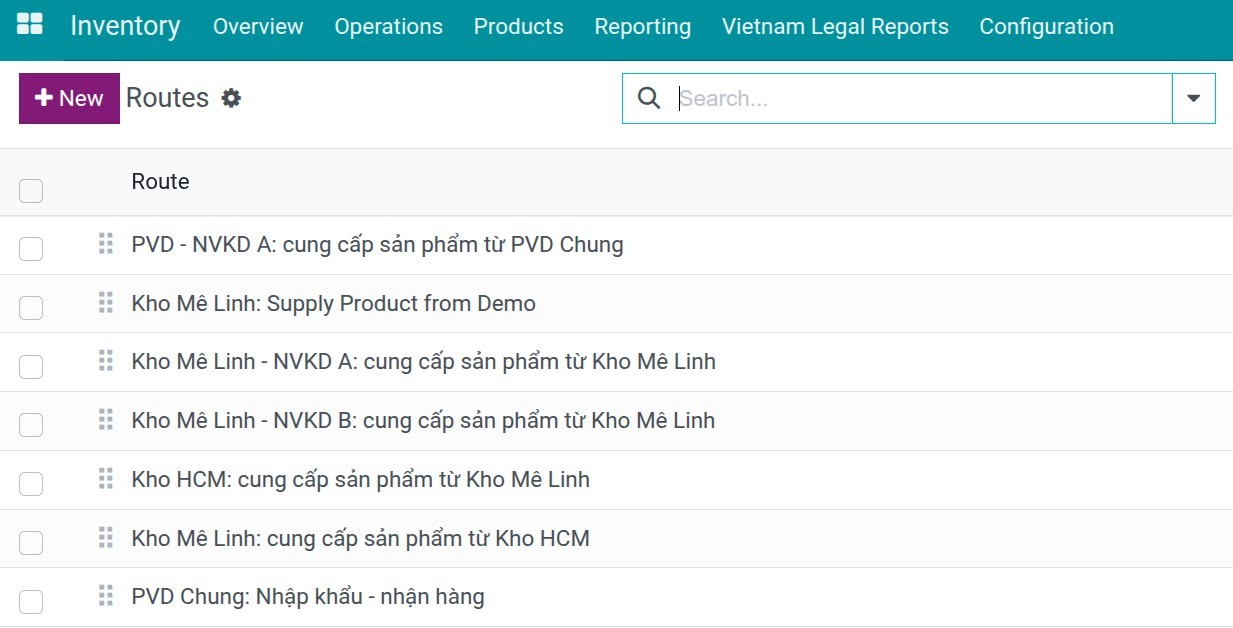

Route: Specify the preferred route for this reordering rule. In Viindoo, multiple routes can be configured on the Inventory tab of the product form or under the Routes field on the product category. When a specific route is set in the reordering rule, it will take priority over other available routes.

Vendor: If the preferred route is Buy, select the vendor to be used. This vendor must already be listed in the product’s vendor list.

Bill of Materials (BoM): If the preferred route is Manufacture, select the appropriate BoM. If no BoM is selected here, the system will automatically use the first BoM listed for the product.

Procurement Group: Assign a procurement group to group and track replenishment operations associated with a specific demand source. For example, if the procurement group is set to SO0001, the resulting purchase orders (POs), manufacturing orders (MOs), or stock pickings will be linked to sale order SO0001.

Note

By default, these columns are hidden. To reveal them, click the Adjust Settings icon and select the desired columns from the drop-down menu.

![Create a new reordering rule]()

This can be done by enabling the relevant routes under Inventory > Configuration > Routes, and ensuring they are set to be selectable on products.

If multiple routes are selected for a product but no preferred route is defined in its reordering rule, the system will apply the route with the lowest sequence number from the list of available routes.

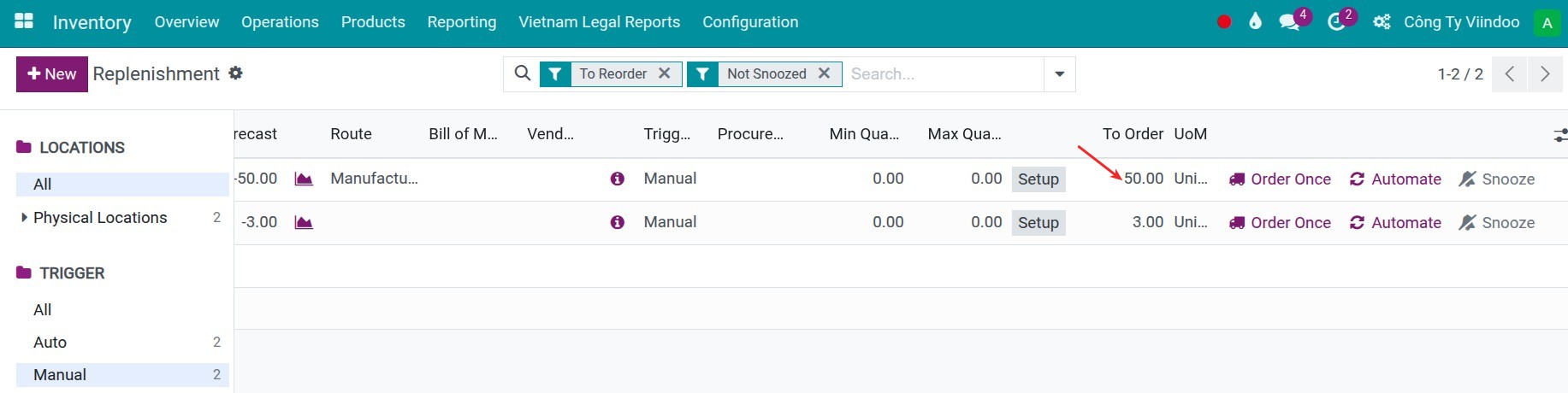

You can also adjust the quantity in the To Order column based on the quantity already suggested by the system.

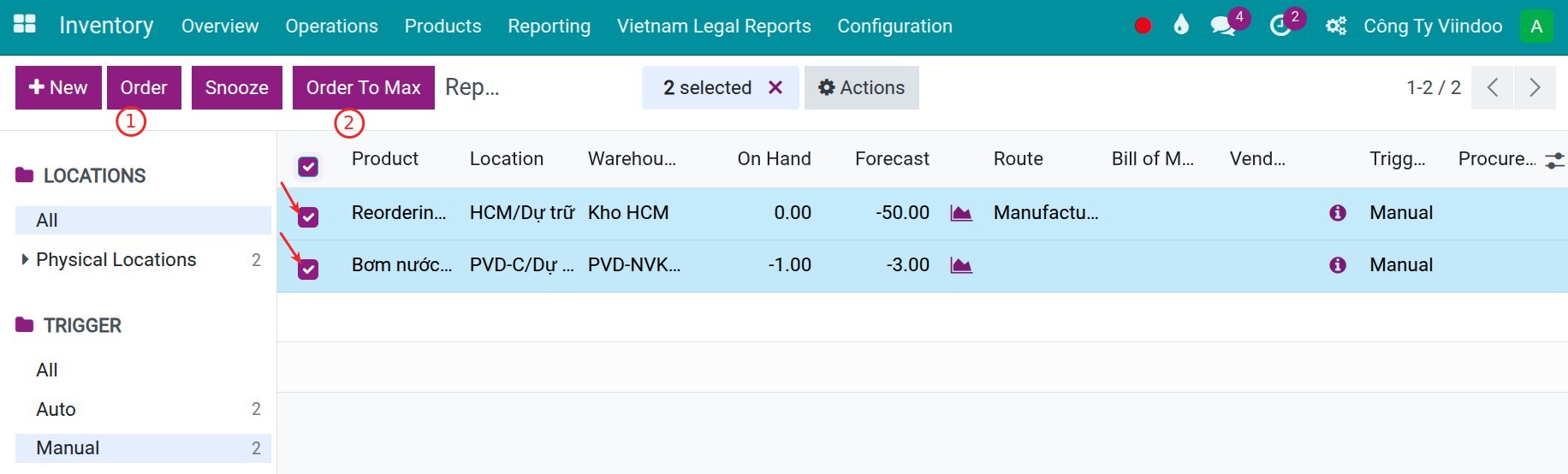

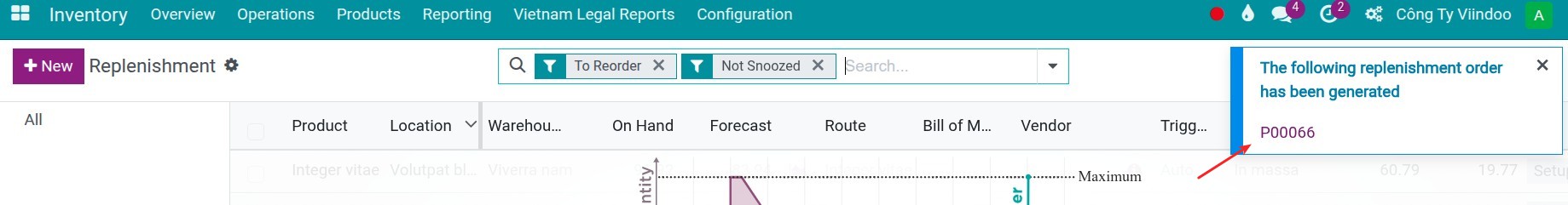

After flexibly managing how to replenish the required products, simply select the relevant lines and click:

Order button: If you want to generate the operations with the To order quantity.

Order to Max button: If you want to generate the operations to meet the Maximum quantity.

The system will notif the operations are generated, you can access right from the notification.

Tip

On the dashboard, you can use the filters on the right-hand panel to quickly select specific locations or trigger types, allowing for faster filtering and streamlined replenishment operations.

Warning

When using manual reordering rules, you need to manually trigger the operation for each reordering rule. This is especially important when multiple reordering rules are configured, as the system will not process them automatically.

See also

Related articles

Optional modules