Manage Loss components in Manufacturing¶

Material consumption management is the process of managing and controlling the use of materials in the production process. The main objective of material consumption management is to ensure that materials are used efficiently, and economically, and can be reused when necessary.

The Manufacturing module of Viindoo software provides features to help businesses control the amount of material losses in the manufacturing process, enabling them to make decisions in order to:

Minimize manufacturing costs;

Control the supply planning of materials;

Optimize the manufacturing process.

General setting¶

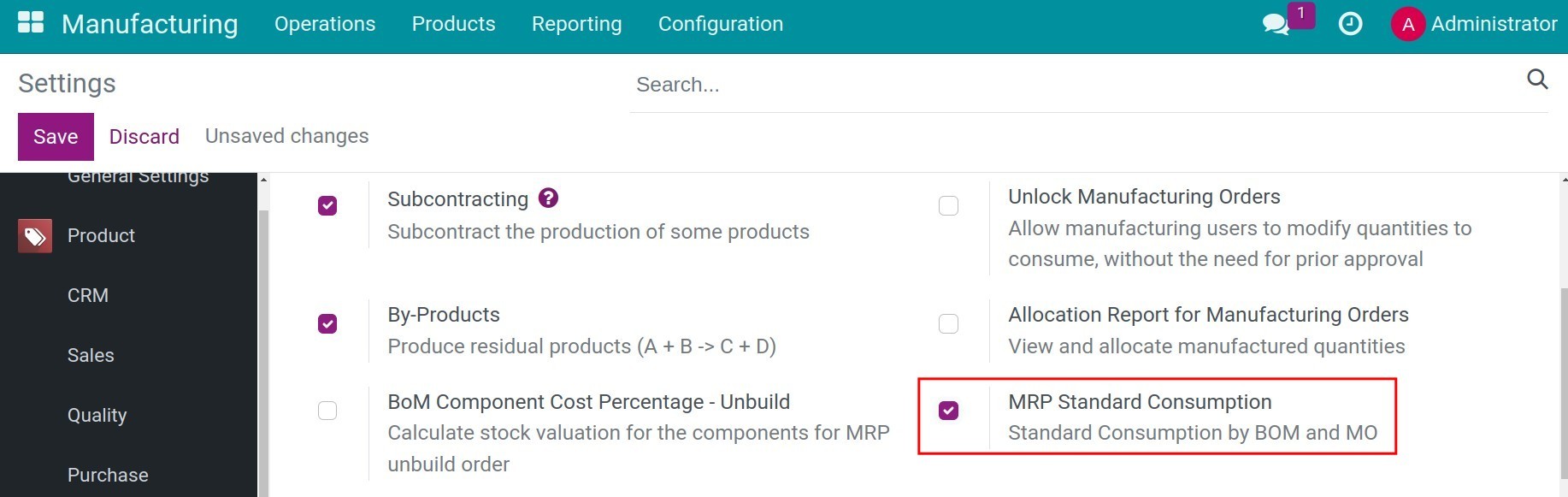

Activate the Standard Consumption feature¶

Access the application Manufacturing > Configuration > Settings, check the option MRP Standard Consumption, and click Save.

Configure the material consumption quantities in the BoM¶

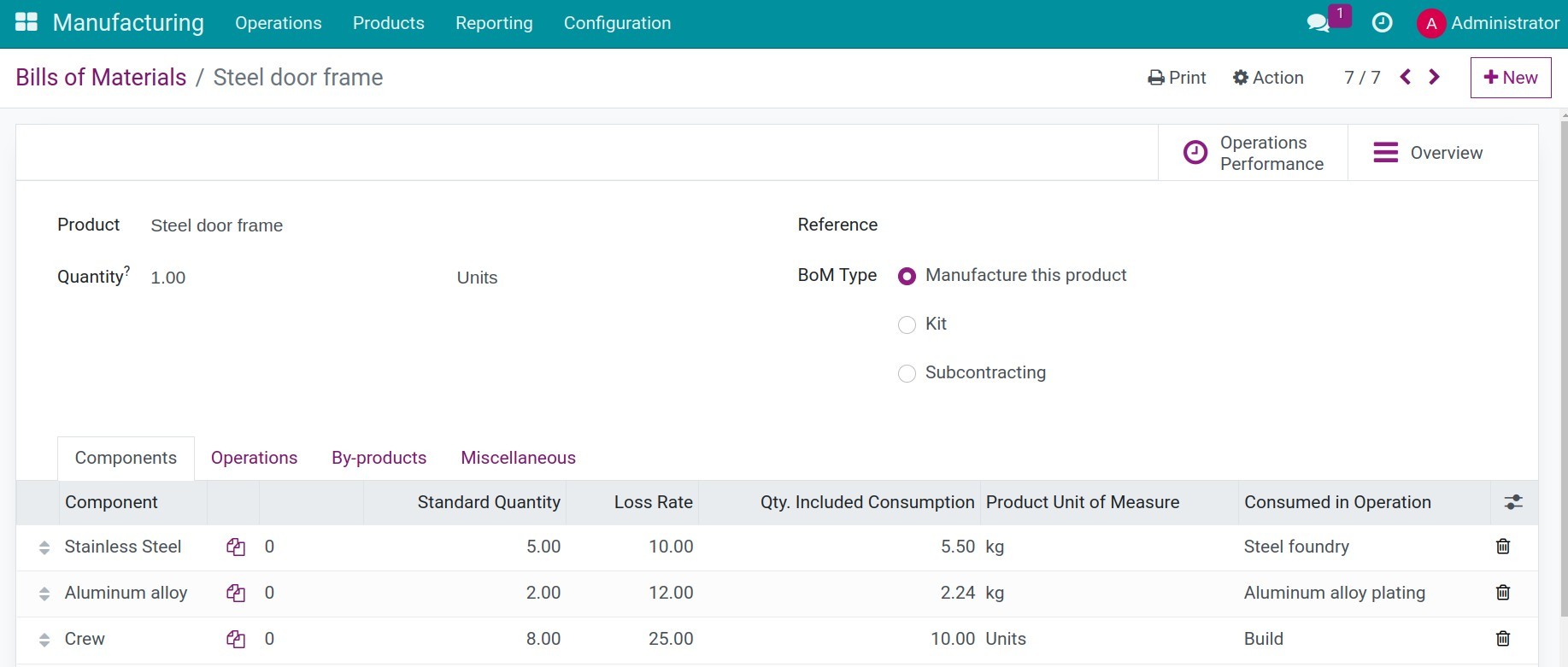

After activating the MRP Standard Consumption feature, the software allows configuring the material consumption quantities that the business has tracked during the manufacturing process.

Fill in the Standard Quantity and Loss Rate, and the system will automatically calculate the demand quantity of materials to be used for manufacturing (= Standard Quantity + Standard Quantity x Loss Rate).

This calculation serves the following purposes:

At the start of manufacturing, instead of supplying materials based on the Standard Quantity, the system will request the demand quantity of materials to be supplied.

During the manufacturing process, businesses can track the expected material loss and compare it with the actual loss, providing a basis for adjusting the Loss rate for future manufacturing orders.

Tracking consumption in manufacturing¶

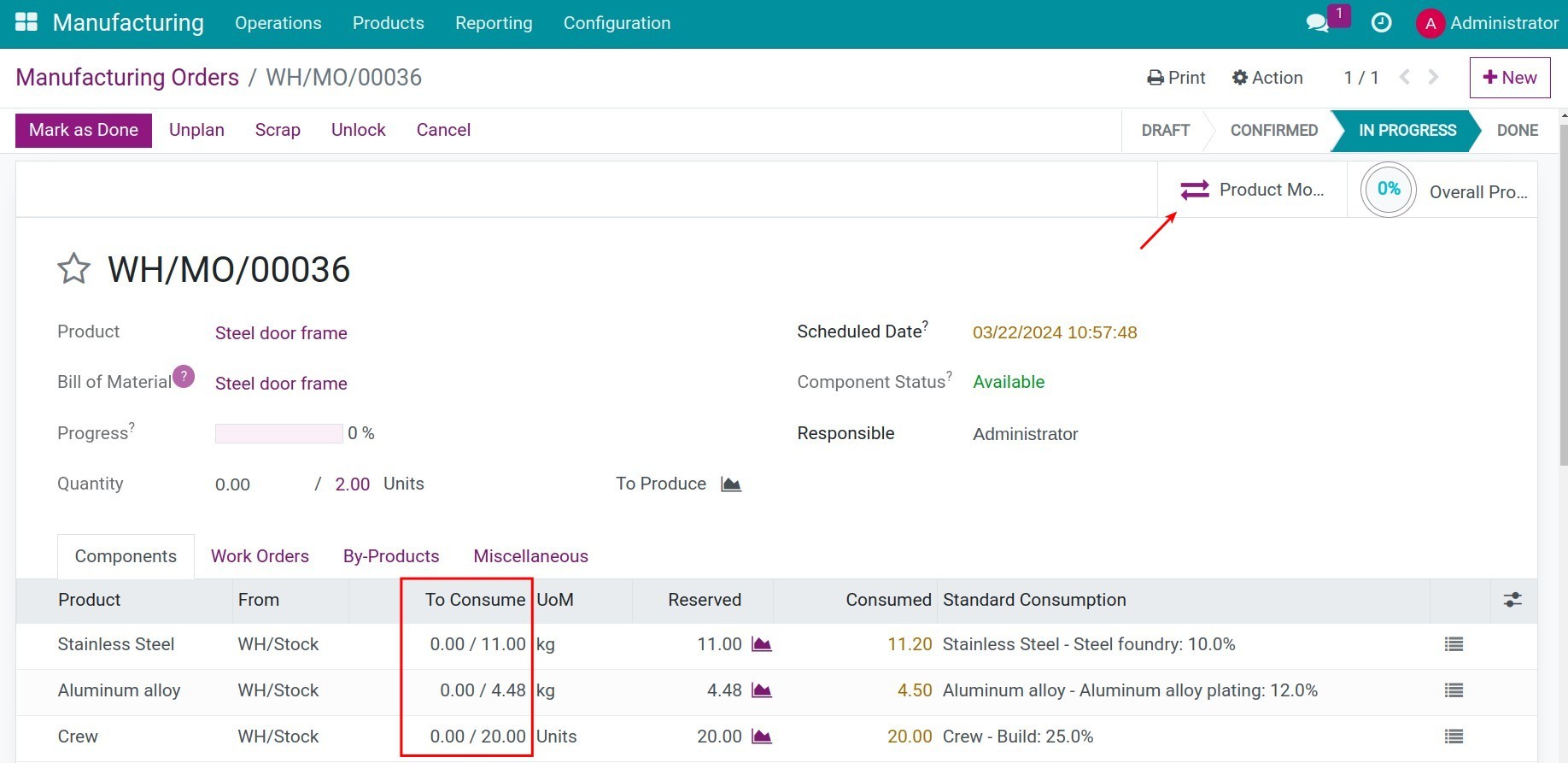

Access the Manufacturing application, create a Manufacturing Order, and then click Confirm to start the manufacturing. The demand quantity of components is included the loss rate.

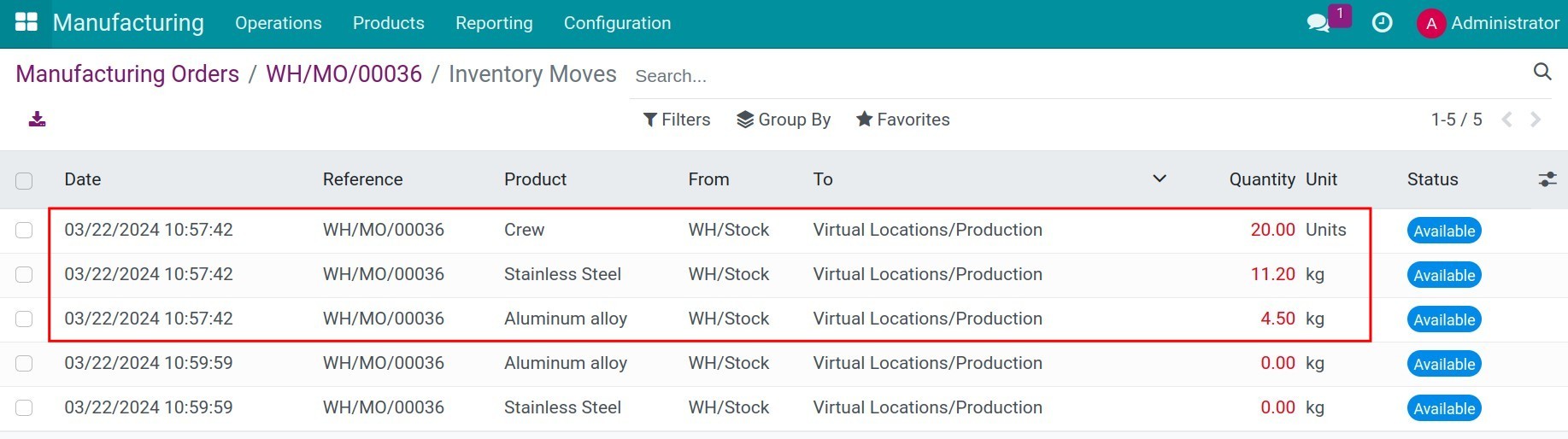

At the end of the manufacturing process, you can input the actual consumption of each component. The quantity of the transfers corresponds to the actual consumption on the manufacturing order.

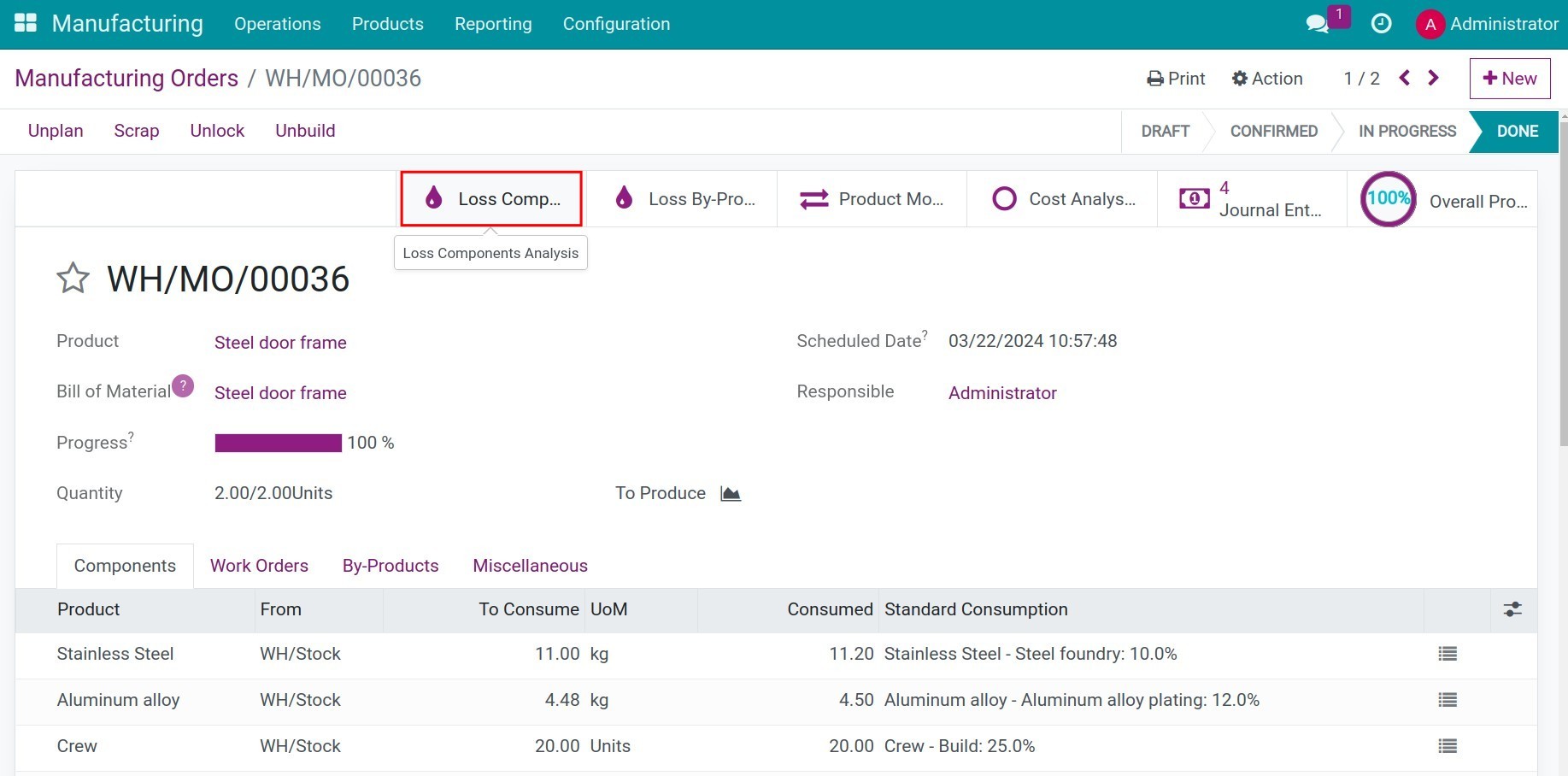

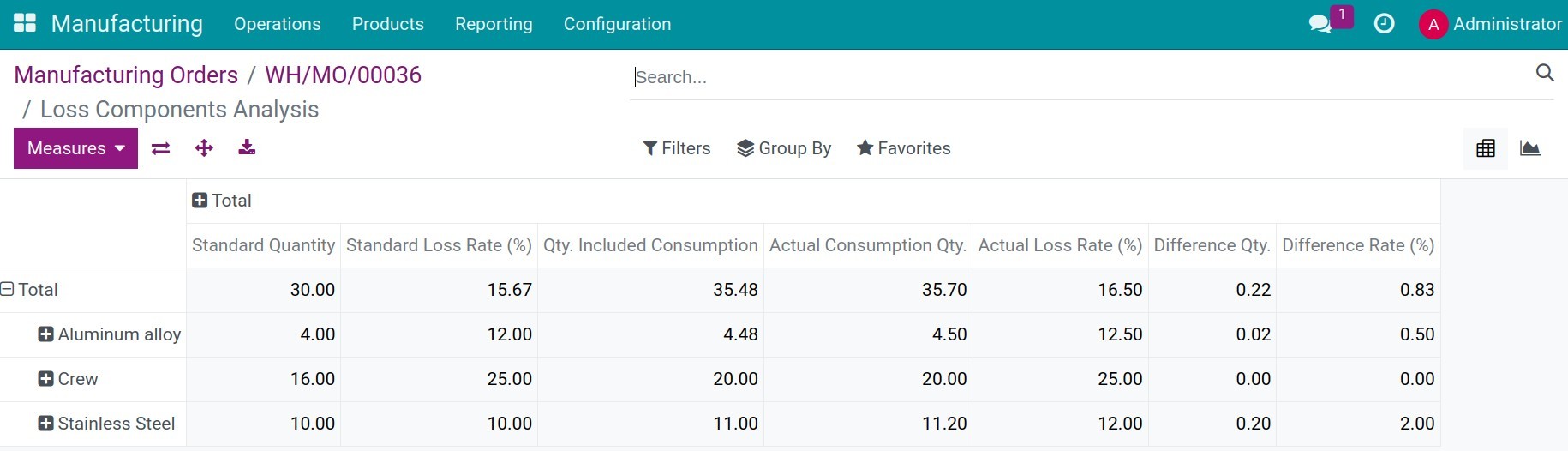

After completing the manufacturing order, click the Mark as Done button to finish the manufacturing order. You can also click the Loss Components Analysis button directly on the manufacturing order to track:

The quantity of materials according to the Bill of materials;

The variance between the expected and actual quantity of components in this manufacturing order;

The variance between the expected and actual material loss rates.

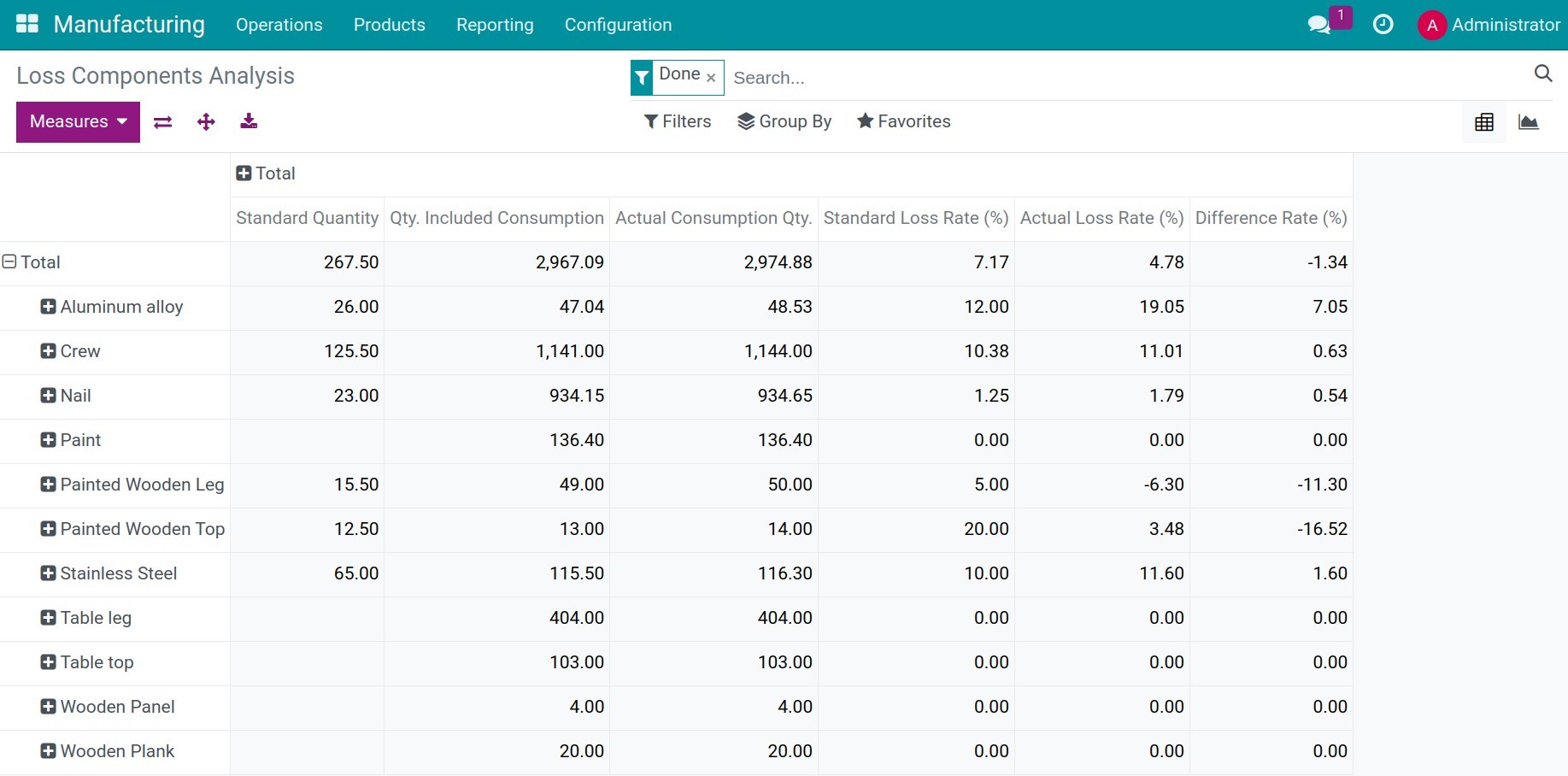

Besides, you can navigate to Manufacturing > Reporting > Loss Components Analysis to see and analyze the total variance of each product through all the manufacturing orders. Here you can have the comparison time by time, and orders by orders. If you see inconsistent and abnormal data, you can find the reason and make some adjustments to BoM or the manufacturing process.

See also

Related article

Optional module