Why Multiple Disconnected Tools when One System Does It All?

Total Integration. Total Control. All you need for your factory.

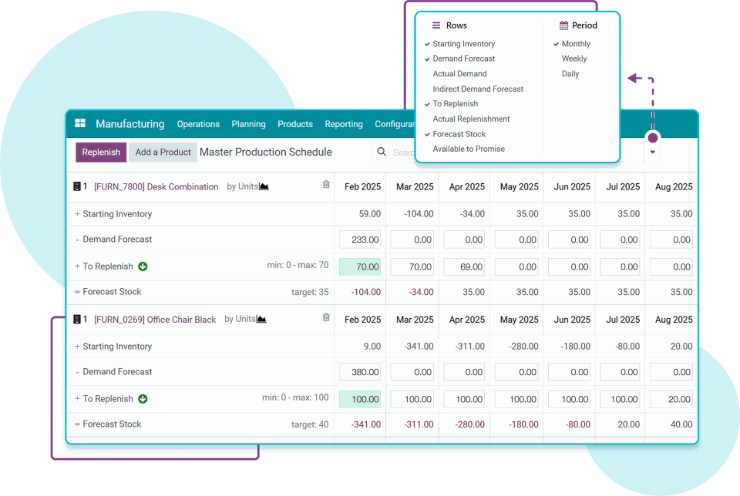

Proactive production planning

Comprehensive planning and scheduling, easy adjustments and clear visibility in:

- Gantt chart

- Kanban chart

- Pivot chart

- Column, pie chart

- ..

Organizing work orders, work centers efficiently with resource availability for proactive production.

Monitoring availability of Bill of Materials (BOM) and production timelines.

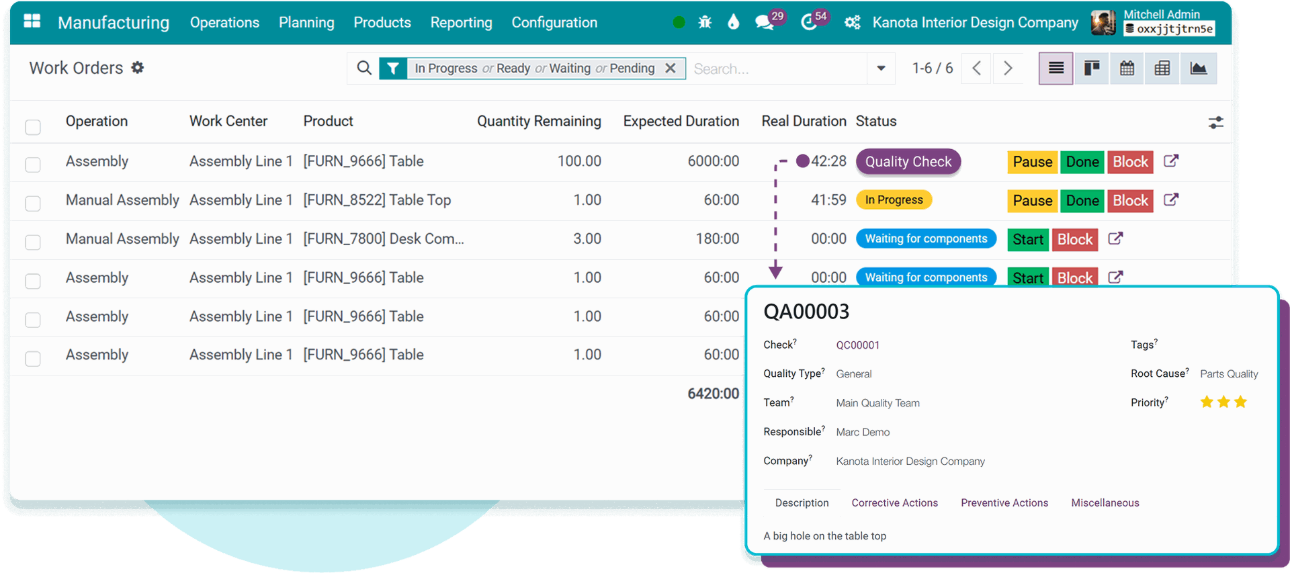

More than a MES, real-time tracking of manufacturing operation

Shop floor operations are never easy, but with real-time tracking of manufacturing operations, it becomes more manageable.

Material Availability: Checking if all required parts and materials are available for production.

Just-in-Time Replenishment: Providing suggestions on when and how to restock materials to minimize storage costs.

Fulfillment Options: Choosing whether to produce in-house, purchase externally, subcontract, or transfer materials from another location to fulfill production needs.

Labor and Machine Allocation: Monitoring the availability and utilization on the shop floor to minimize downtime and delay.

Manufacturing progress: ensure visibility of manufacturing orders, which orders are in progress, completed, or delayed.

Outsourcing tracking: efficiently manage subcontract manufacturing, from materials, timeline, quality control, performance tracking, etc.

Moving Towards the Smart Factory

Ready to optimize your operation with IoT integration, unlock new opportunities for optimization, efficiency, and innovation.

Production cost and Manufacturing cost

BoM cost structure and Cost Estimation

Actual Material Consumption, Material Loss

Difference Between Planned and Actual

Discover more in Viindoo Webinar (Vietnamese version): Technology application in Manufacturing cost

Real-time and comprehensive reports

Get more optimized with an intuitive, multi-dimensional, and flexible reporting system. All information about the production process and performance are fully and instantaneously aggregated, enabling faster and more accurate decision-making.

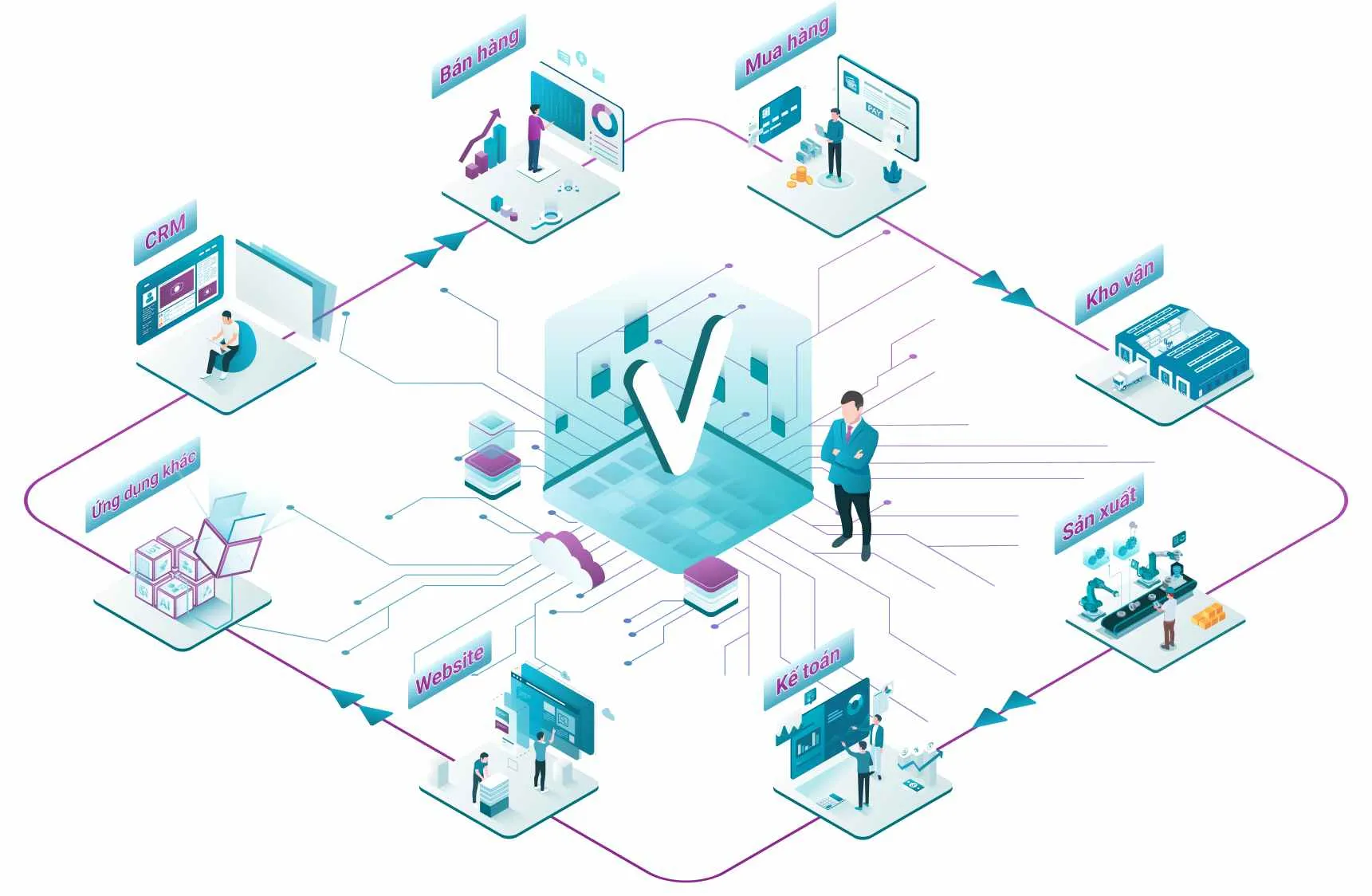

Fully integrated with other parts of Viindoo ERP

Together with Viindoo Manufacturing, businesses can handle a broader range of tasks and processes to improve overall efficiency and effectiveness.

Enable Just-In-Time Production, reduce cost and waste.

Bring products to customer through every channel.

Ensures efficient workforce management.

Real-time cash flow, revenue, cost control, reports

No credit card required

Trusted by Industry Leaders

Scalable enterprises that choose Viindoo Enterprise Management Software for efficient work.

Start with Viindoo to increase the competitiveness of the Enterprise