Nowadays, companies strive to enhance operations and efficiency. The Master Production Schedule (MPS) plays a crucial role in optimizing production schedules for timely delivery and cost reduction.

MPS is a planning tool that helps manage production by detailing what, when, and how much to produce. This post will explore MPS, its implementation, benefits, and integration into Viindoo software for improved effectiveness.

Introduction to Master Production Schedule (MPS)

Master Production Schedule is a critical component of the overall production planning process. It is a detailed plan that outlines the quantity and timing of production for each finished product. The main objective of MPS is to balance the demand for products with the available resources and capacity of the company. By doing so, it ensures that the right products are produced at the right time, in the right quantities, and with the right resources.

The MPS is typically created based on the sales forecast, customer orders, and inventory levels. It takes into account factors such as lead time, production capacity, and resource availability to create a realistic and achievable production schedule. This allows businesses to better manage their inventory levels, reduce lead times, and meet customer demands efficiently.

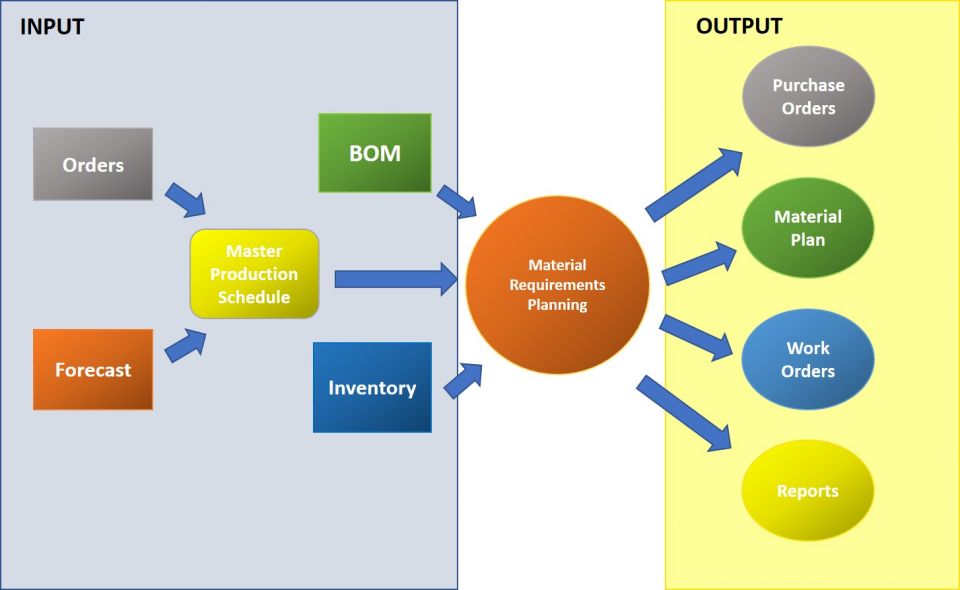

Master Production Schedule is the source of many activities in the production process

Benefits of Implementing Master Production Schedule

- Improved Customer Satisfaction: With a well-planned and efficient production schedule, businesses can meet customer demands on time, leading to increased customer satisfaction.

- Reduced Inventory Costs: MPS helps in optimizing inventory levels, reducing the need for excess stock and minimizing inventory costs.

- Increased Efficiency: By streamlining the production process, MPS helps in increasing efficiency and reducing lead times.

- Better Resource Management: With a detailed production schedule, businesses can better manage their resources and avoid over or under utilization.

- Cost Savings: By minimizing waste and improving efficiency, MPS can help businesses save costs in the long run.

Implementing Master Production Schedule

Implementing MPS requires careful planning and coordination across different departments within a company. It involves a series of steps that need to be followed to ensure a successful implementation. Let's take a look at some general guidelines for implementing MPS.

General Guidelines for Implementing Master Production Schedule

- Understand your business needs: Before implementing MPS, it is essential to understand the specific needs and goals of your business. This will help in creating a customized MPS that aligns with your business objectives.

- Involve all stakeholders: MPS implementation involves various departments such as sales, production, and inventory management. It is crucial to involve all stakeholders in the process to ensure their buy-in and cooperation.

- Set realistic goals: Setting achievable goals is critical for the success of MPS implementation. Unrealistic goals can lead to frustration and failure of the entire process.

- Train employees: Proper training of employees is necessary to ensure they understand the MPS and their role in its implementation. This will also help in smooth adoption and integration of MPS into daily operations.

- Monitor and review: Regular monitoring and review of the MPS is essential to identify any issues or bottlenecks and make necessary adjustments. This will help in continuously improving the effectiveness of the MPS.

Key Components of Master Production Schedule

To better understand how MPS works, let's take a look at its key components:

- Production Plan: This is the main component of MPS and outlines the quantity and timing of production for each finished product.

- Bill of Materials (BOM): BOM is a list of all the materials and components required to produce a finished product. It is an essential part of MPS as it helps in determining the availability of resources and raw materials.

- Inventory Levels: MPS takes into account the current inventory levels to determine the amount of production needed to meet customer demands.

- Lead Time: Lead time refer to the time taken to procure raw materials, manufacture products, and deliver them to customers. MPS considers these lead times to create a realistic production schedule.

- Capacity Planning: Capacity planning is a crucial aspect of MPS as it ensures that the production schedule is aligned with the available resources and capacity of the company.

Implementing Master Production Schedule in Viindoo software

Now that we have a better understanding of MPS and its benefits, let's explore how it can be implemented in an ERP system, specifically Viindoo software.

Introduction to Viindoo software

Viindoo is an all-in-one business management software that offers a wide range of modules to manage various aspects of a business, including sales, accounting, inventory, and production. It is highly customizable and can be tailored to meet the specific needs of a business.

Enabling Master Production Schedule in Viindoo

Navigate to Manufacturing > Configuration > Settings, and under the Planning section, activate the Master Production Schedule option. Here, you can fine-tune the time range, specifying whether you prefer monthly, weekly, or daily granularity. Additionally, define the number of periods to be displayed for comprehensive planning. Save your configurations, and voila! MPS is now at your disposal.

Navigating the MPS feature

Upon enabling MPS, head to the Planning menu to access the Master Production Schedule. Here, a comprehensive layout awaits, featuring 12 columns representing the upcoming periods. Customization options abound, allowing you to tailor the displayed rows to your specific requirements.

Let's decipher the rows on the screen:

- Starting Inventory: The initial stock on hand at the beginning of the period.

- Demand Forecast: Estimated demand for the period.

- Indirect Demand Forecast: Projected demand for components influenced by primary product demand.

- To Replenish: Quantity slated for replenishment via manufacturing or purchase orders.

- Actual Replenishment: Quantity replenished based on generated orders.

- Forecast Stock: Estimated stock quantity at the period's end.

- Available To Promise: Quantity committed for future sales.

By using the ADD A PRODUCT button, you can define replenishment rules tailored to each item's characteristics. Set safety stock targets, minimum and maximum replenishment quantities, ensuring meticulous control over inventory levels.

MPS automates replenishment processes, triggered by predefined rules and forecast demand. Whether it's generating purchase orders or manufacturing orders, Viindoo MPS ensures timely action to maintain optimal stock levels.

Discover Viindoo Manufacturing Software

Viindoo Manufacturing empowers businesses with efficient production scheduling and inventory management through its MPS feature.

Optimizing Viindoo MPS

To take full advantage of the power of Viindoo MPS, there are several strategies you can apply:

- Accurate Demand Forecasting: Invest in robust demand forecasting mechanisms to predict future demand accurately. Utilize historical data, market trends, and customer insights to refine forecasting models.

- Fine-Tune Replenishment Parameters: Customize replenishment rules based on product characteristics, demand patterns, and lead times. Set optimal safety stock levels, minimum and maximum replenishment quantities to prevent stockouts and excess inventory.

- Streamlined Order Processing: Automate order processing workflows to expedite replenishment activities. Integrate MPS with procurement and manufacturing processes to ensure timely order generation and fulfillment.

- Real-Time Monitoring and Adjustment: Monitor MPS performance in real-time and make adjustments as needed. Stay agile to respond to changes in demand, supplier availability, or production constraints promptly.

- Collaborative Supply Chain Management: Foster collaboration with suppliers and partners to optimize supply chain dynamics. Share demand forecasts, production schedules, and inventory levels to synchronize activities and minimize disruptions.

Conclusion

Master Production Schedule is a powerful tool that helps businesses optimize their production process and improve efficiency. By creating a detailed schedule of what needs to be produced, when, and in what quantities, MPS ensures timely delivery of products while minimizing costs. By integrating MPS into an ERP system like Viindoo, businesses can further enhance its effectiveness and reap the benefits of streamlined operations, increased efficiency, and cost savings.

FAQ

MPS focuses on the production of finished products, while MRP (Material Requirements Planning) focuses on the procurement of raw materials and components needed for production.

Yes, MPS can be implemented in businesses of all sizes and across different industries.

Yes, Viindoo software is highly customizable and can be tailored to meet the specific needs of small businesses. It is also cost-effective, making it an ideal solution for small businesses.

Yes, MPS can be integrated with other systems such as MRP, CRM, and accounting software to streamline the entire production process.