How to excute the internal replenishment in Viindoo¶

Internal Replenishment is a critical operation in modern warehouse management, especially for businesses with multiple storage locations or distributed inventory systems. In Viindoo ERP, the Internal Replenishment feature automates the transfer of products between internal warehouses or locations to maintain optimal stock levels at each point. Proper configuration and execution of this process help minimize stockouts, enhance inventory visibility, and improve the overall efficiency of internal supply chain operations.

Requirements

This tutorial requires the installation of the following applications/modules:

In Viindoo, you can excute the internal replenishment on some ways:

Using Make to order (MTO) method.

Using Make to stock (MTS) method.

Using manual replenishmnet.

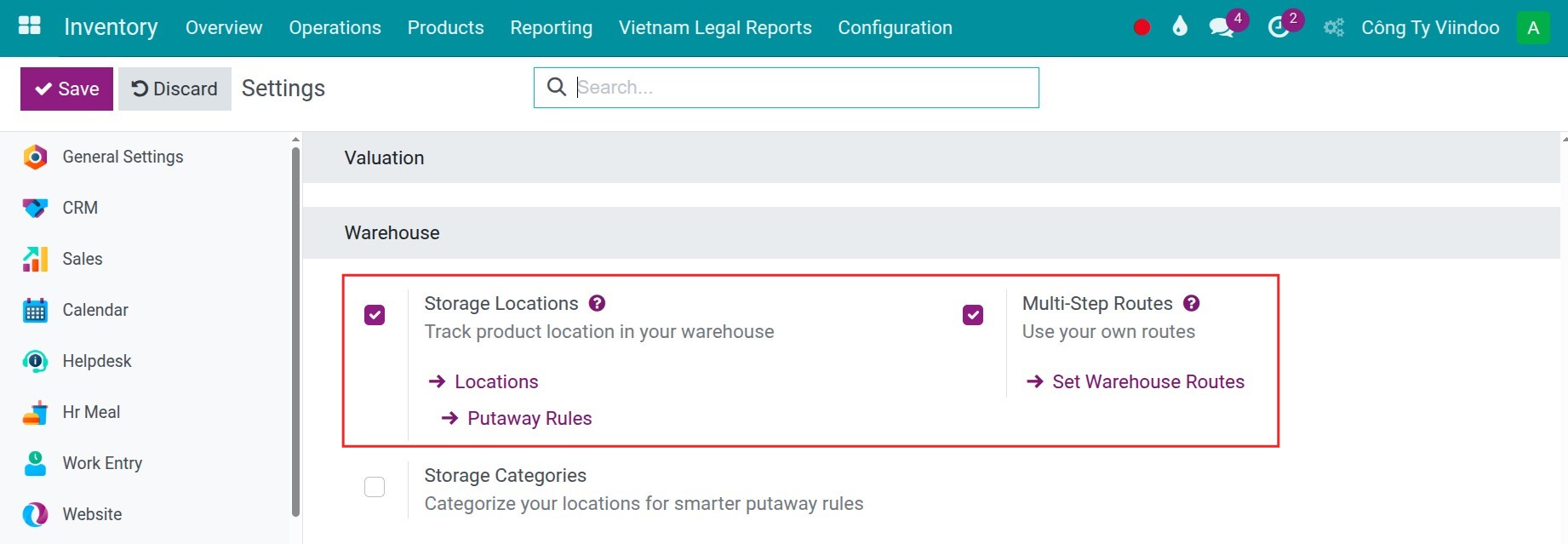

Initial configuration¶

Navigate to Inventory > Configuration > Settings, activate the Storage Locations and Multi-Step Routes features.

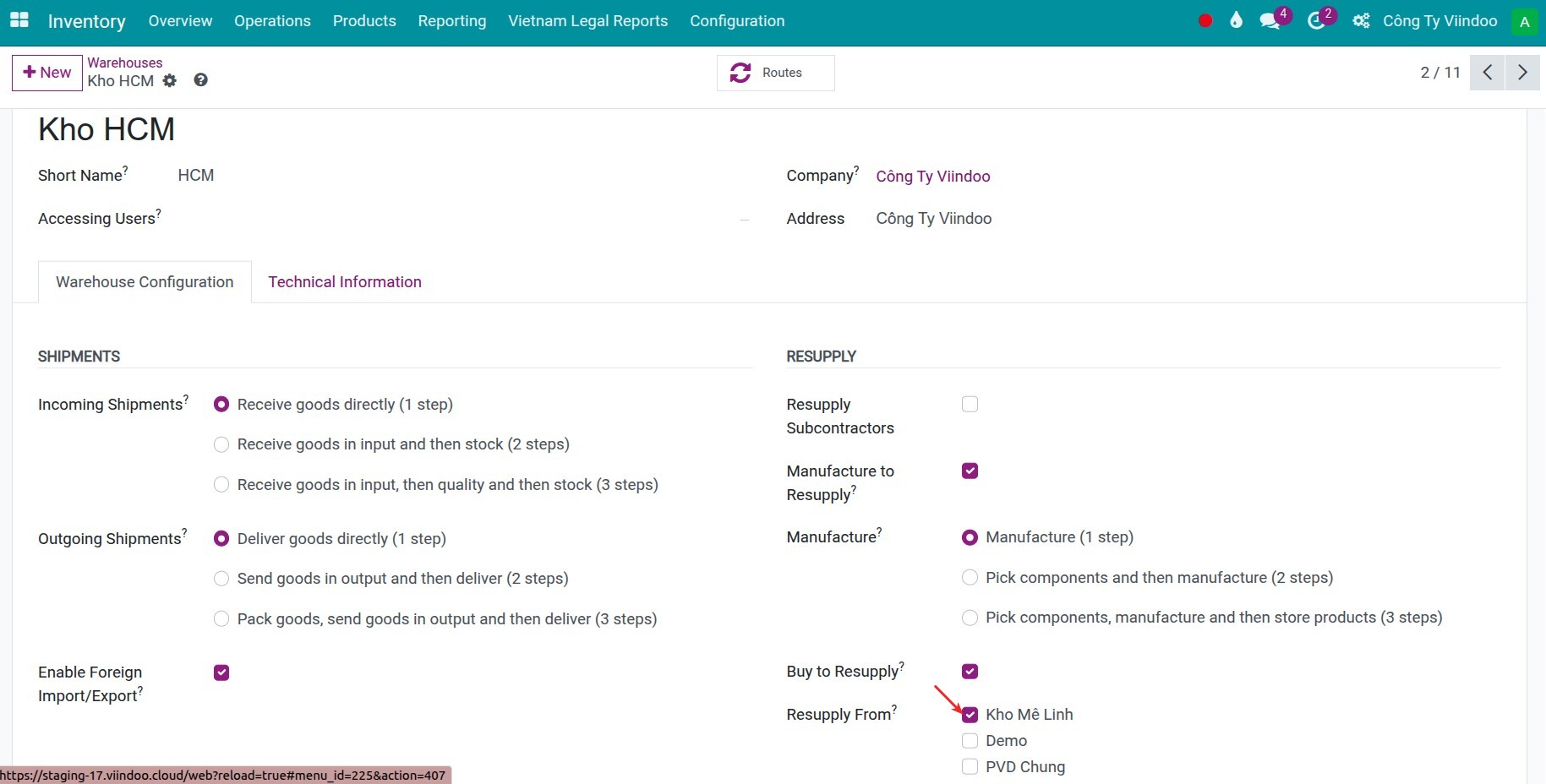

Navigate to Inventory > Configuration > Warehouses, create multi warehouses, select the specific warehouse(s) that will be used to resupply this warehouse in the Resupply From field:

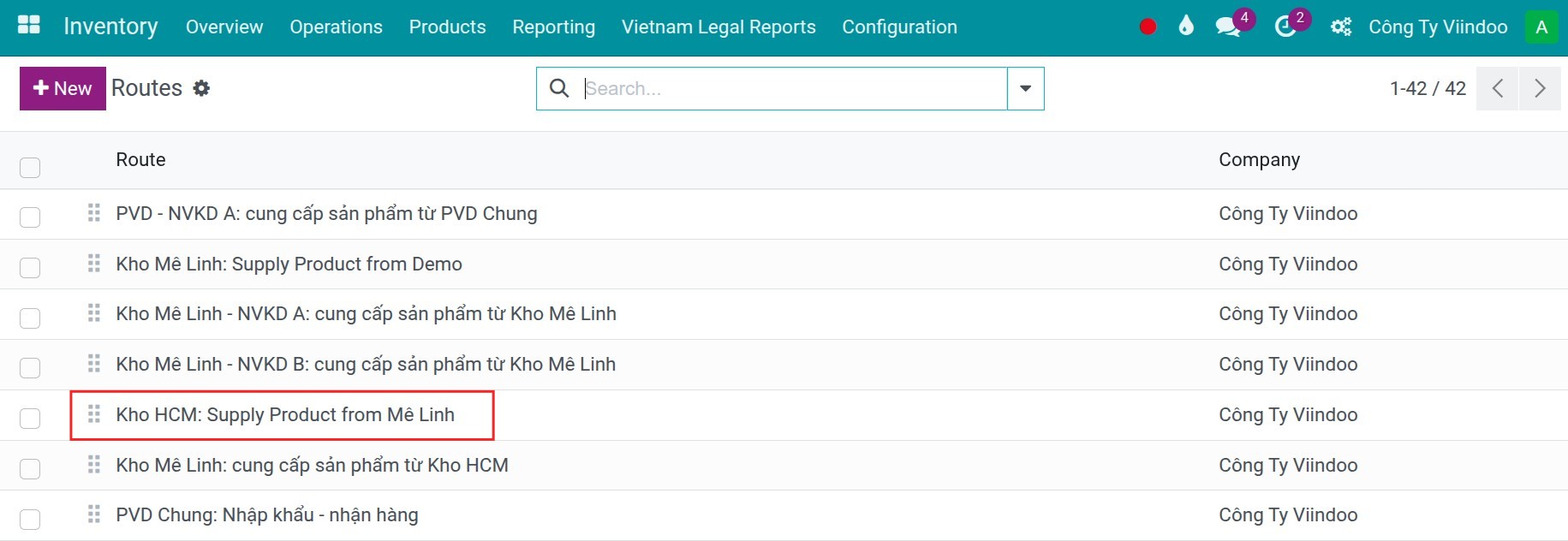

Once done, the system will automatically generate the related routes under Inventory > Configuration > Routes:

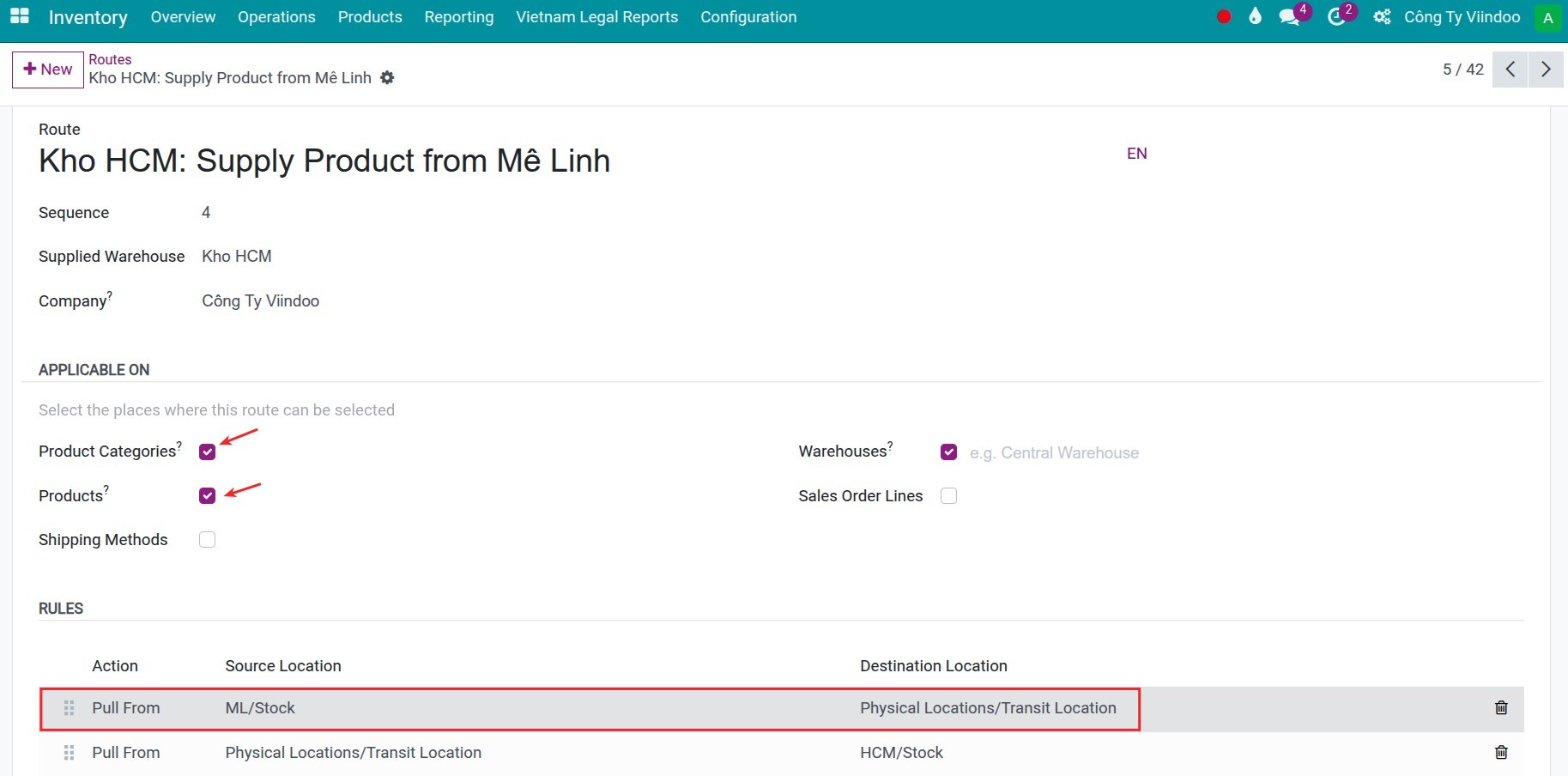

Some key features you need to note as follows:

Applicable on: Select the places where this route can be selected.

Product Categories: Select this if you want the route to apply at the product category level.

Products: Select this if you want the route to apply at the individual product level.

Both Options: If both are selected, the system will prioritize the route defined on the product first. However, if the route settings on the product and the product category conflict, it may cause operational issues. It is recommended to select either Product Categories or Products to avoid configuration conflicts.

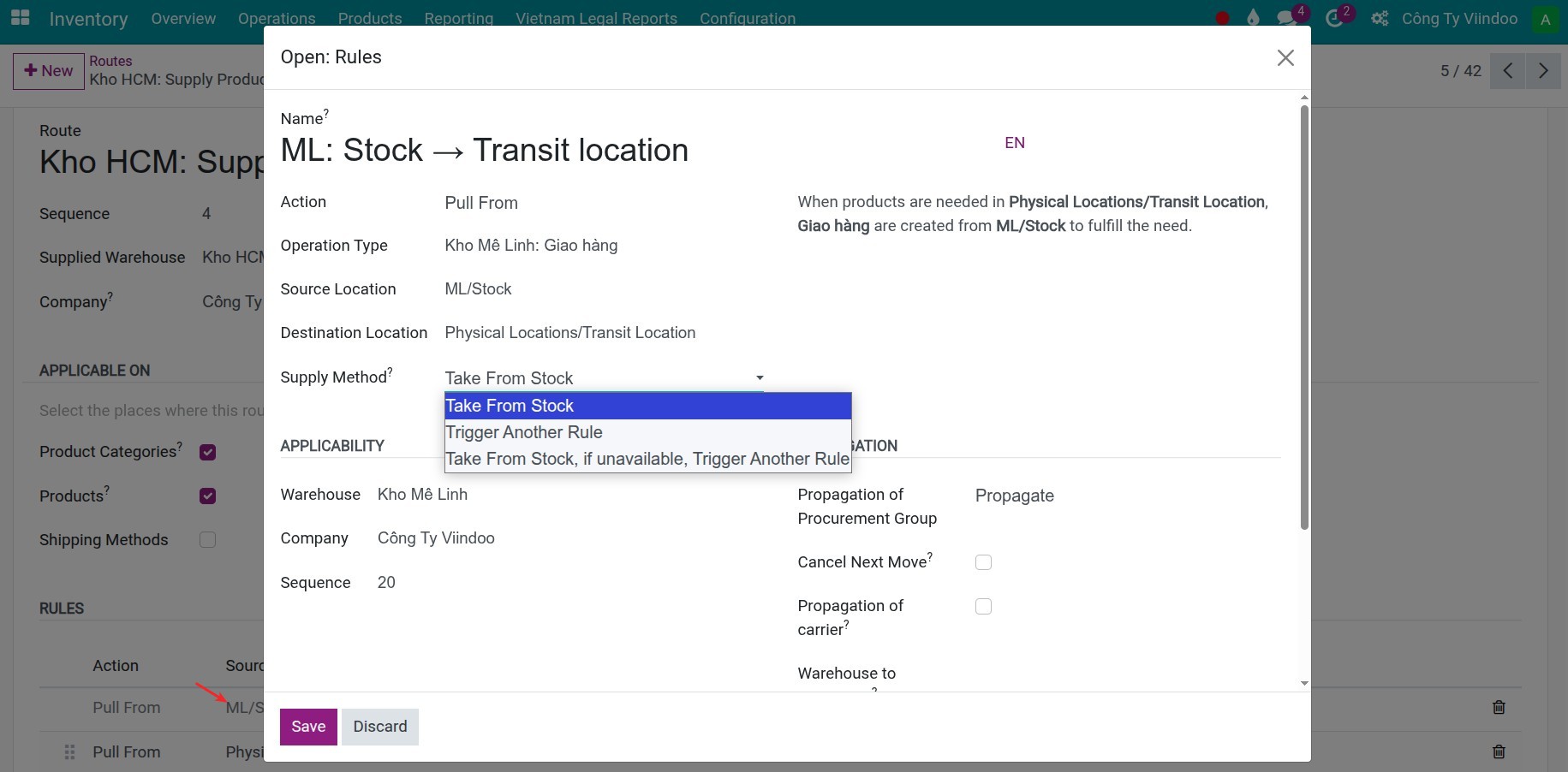

Rules: Choose the rules Pull from Physical Locations/Transit location to Stock. Within the Supply Method field, you can choose one of those following options:

Take From Stock: The system will only take products from the current stock. If the required quantity is not available, no further procurement or production action will be triggered.

Take From Stock, if unavailable, trigger another rule: The system first attempts to pull from stock. If the quantity is insufficient, it will activate the next route to generate the resupply operations (e.g., purchase order, manufacture order, or internal transfer) to fulfill the requirement.

![Configure rules]()

Warning

When using Take From Stock, if unavailable, trigger another rule, please note: If stock is insufficient, the triggered operation (e.g., a purchase or production order) will request the entire required quantity, regardless of how many units are available in stock. Example: If the route requires 10 units and only 5 are in stock, the subsequent route (e.g., Buy) will still generate a purchase order for 10 units, not just the shortfall of 5.

Internal replenishment by MTO¶

This method triggers internal stock transfers only when a specific sales order or manufacturing order is confirmed. Products are moved internally to fulfill the exact demand of that order. It is ideal for businesses that prioritize inventory precision and aim to reduce carrying costs by avoiding overstock.

Configuration¶

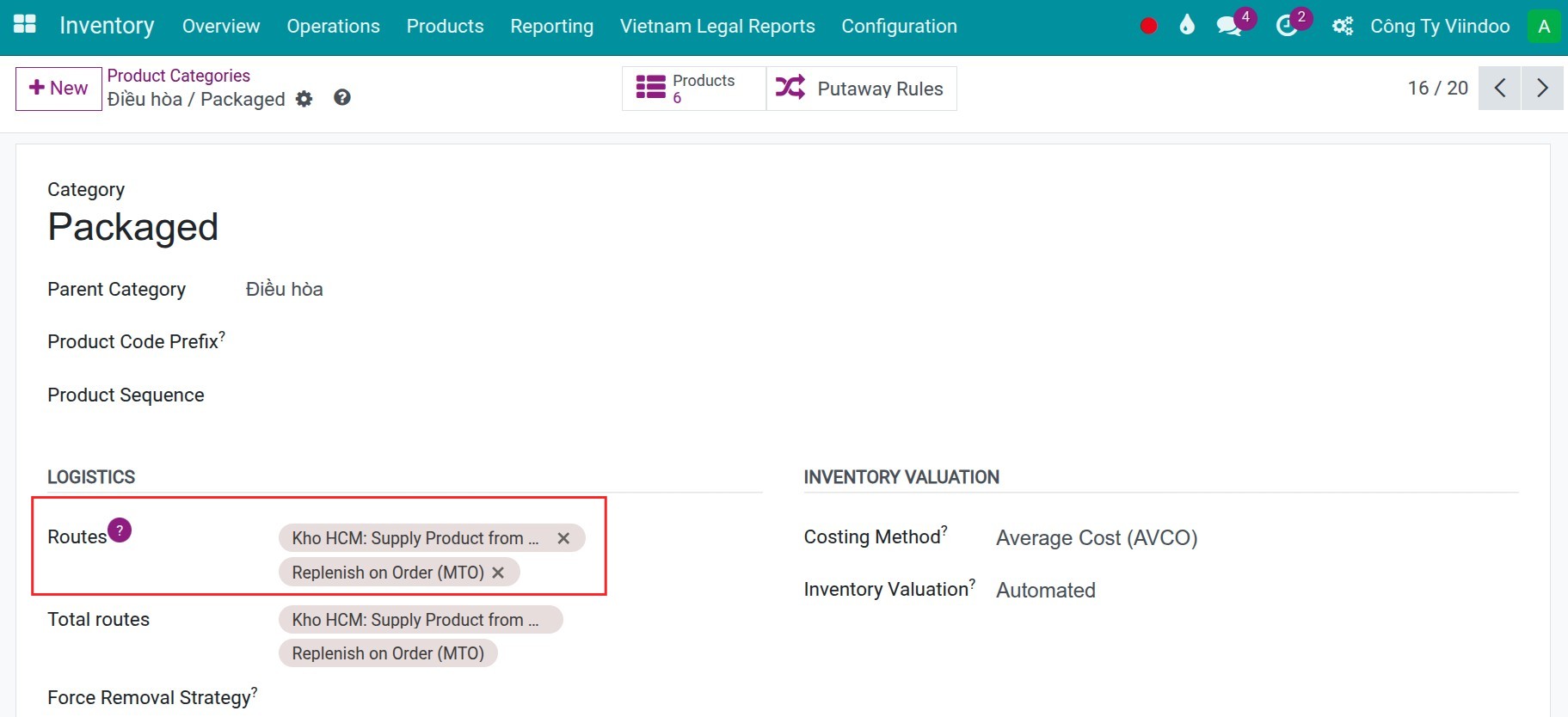

Navigate to Inventory > Configuration > Product Categories to both internal warehouses replenishment route and MTO:

Replenishment execution¶

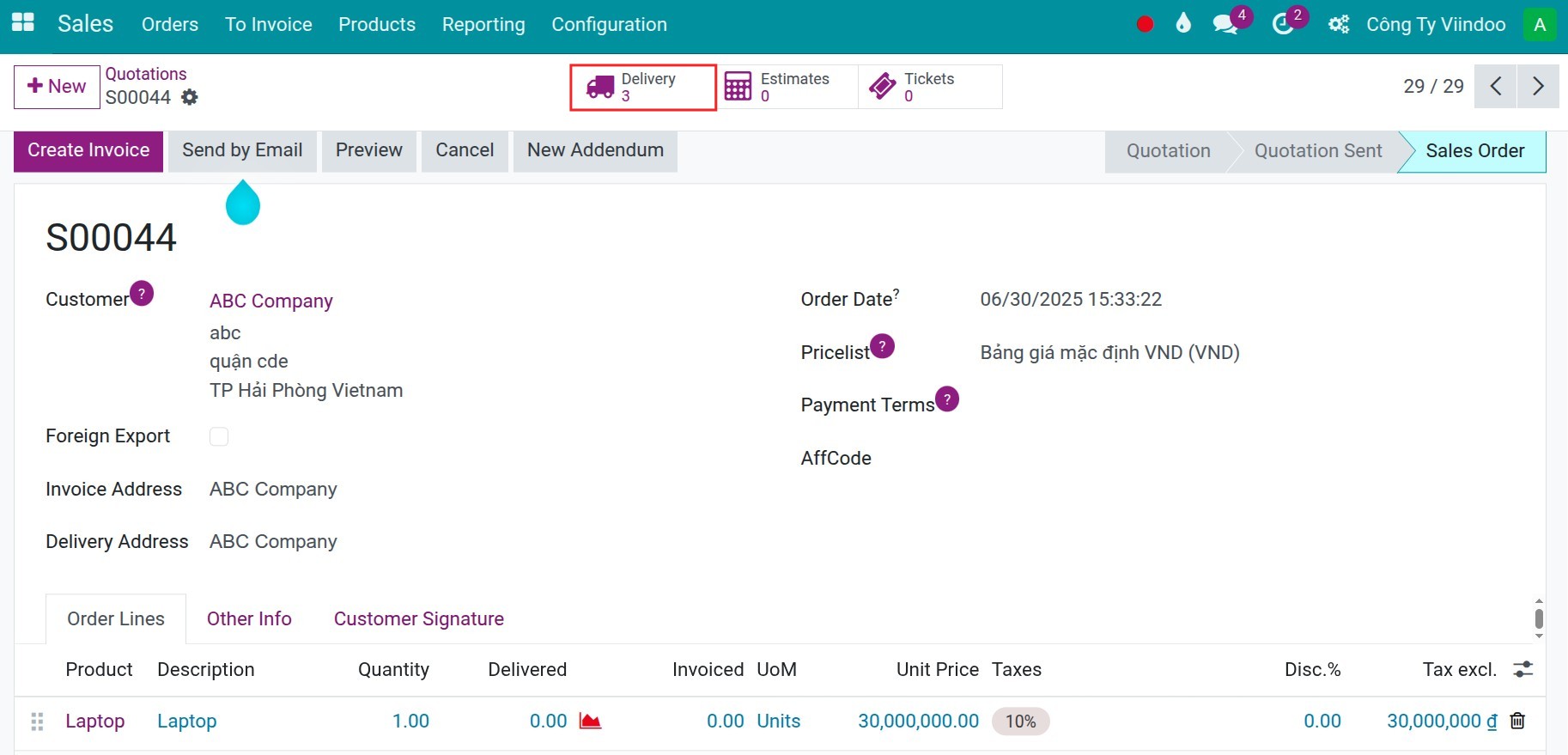

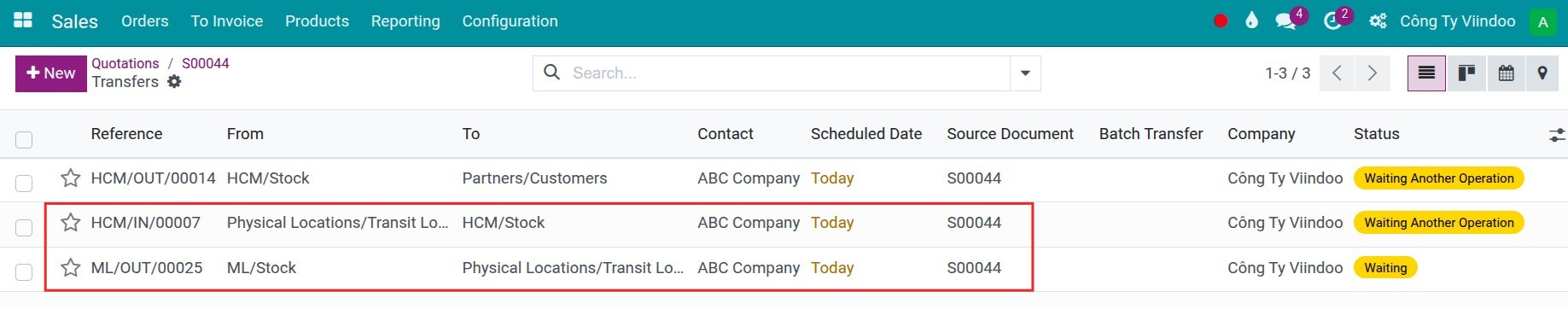

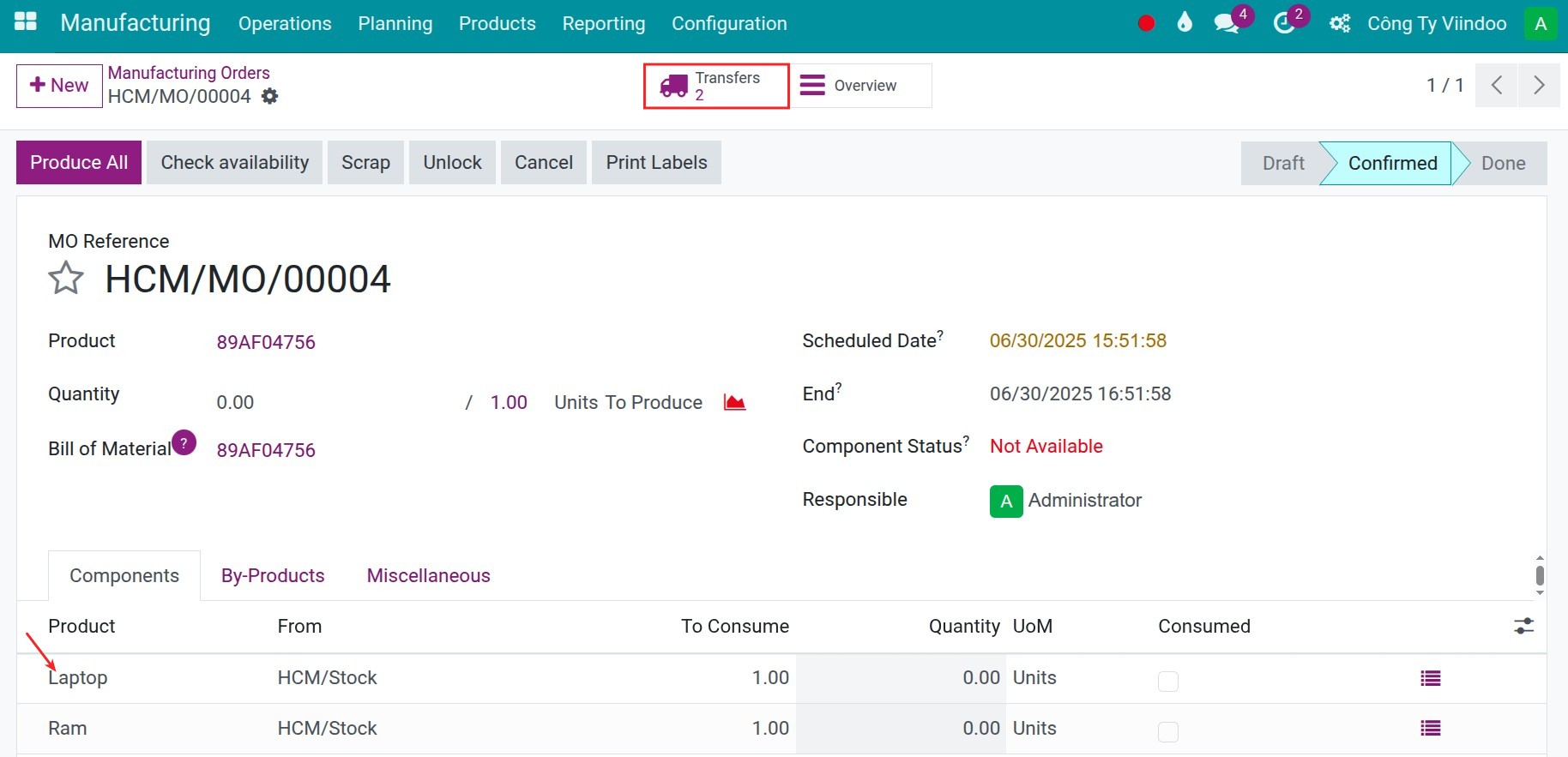

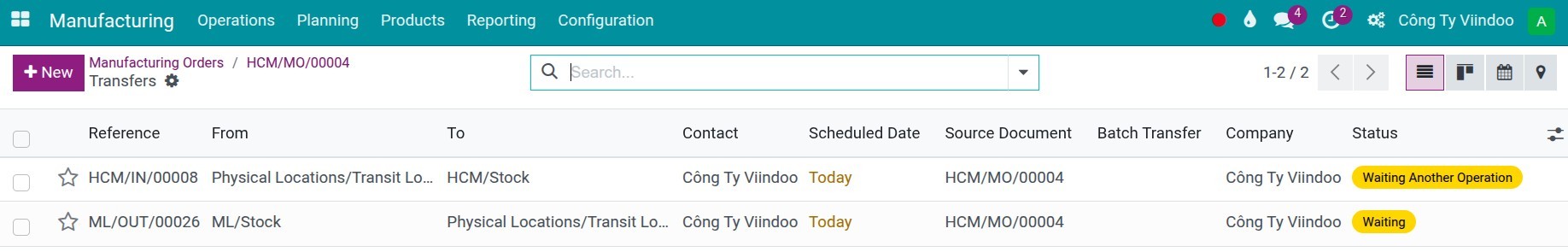

Whenever a Sales Order or Manufacturing Order is confirmed, the system will automatically generate an Internal Transfer to move products from the source warehouse to the destination warehouse. This internal replenishment operation always involves two pickings, passing through a Transit Location, which acts as an intermediary step:

Picking 1: From Source Warehouse to Transit Location. This represents the outbound movement of products from the originating warehouse.

Picking 2: From Transit Location to Destination Warehouse. This represents the inbound movement of products into the receiving warehouse.

This two-step process ensures that internal stock transfers are traceable, controlled, and aligned with actual logistics operations, especially useful for businesses operating across multiple warehouses or sites.

Sale order is confirmed

Manufacturing order is confirmed

As actual, when you finish to tranfer products, you Validate those pickings.

Internal replenishment by MTS¶

This approach automates internal transfers based on predefined minimum and maximum stock rules. When stock at a location drops below the minimum threshold, Viindoo generates an internal replenishment request to restock up to the maximum level. This is suitable for fast-moving goods or high-demand environments.

Configuration¶

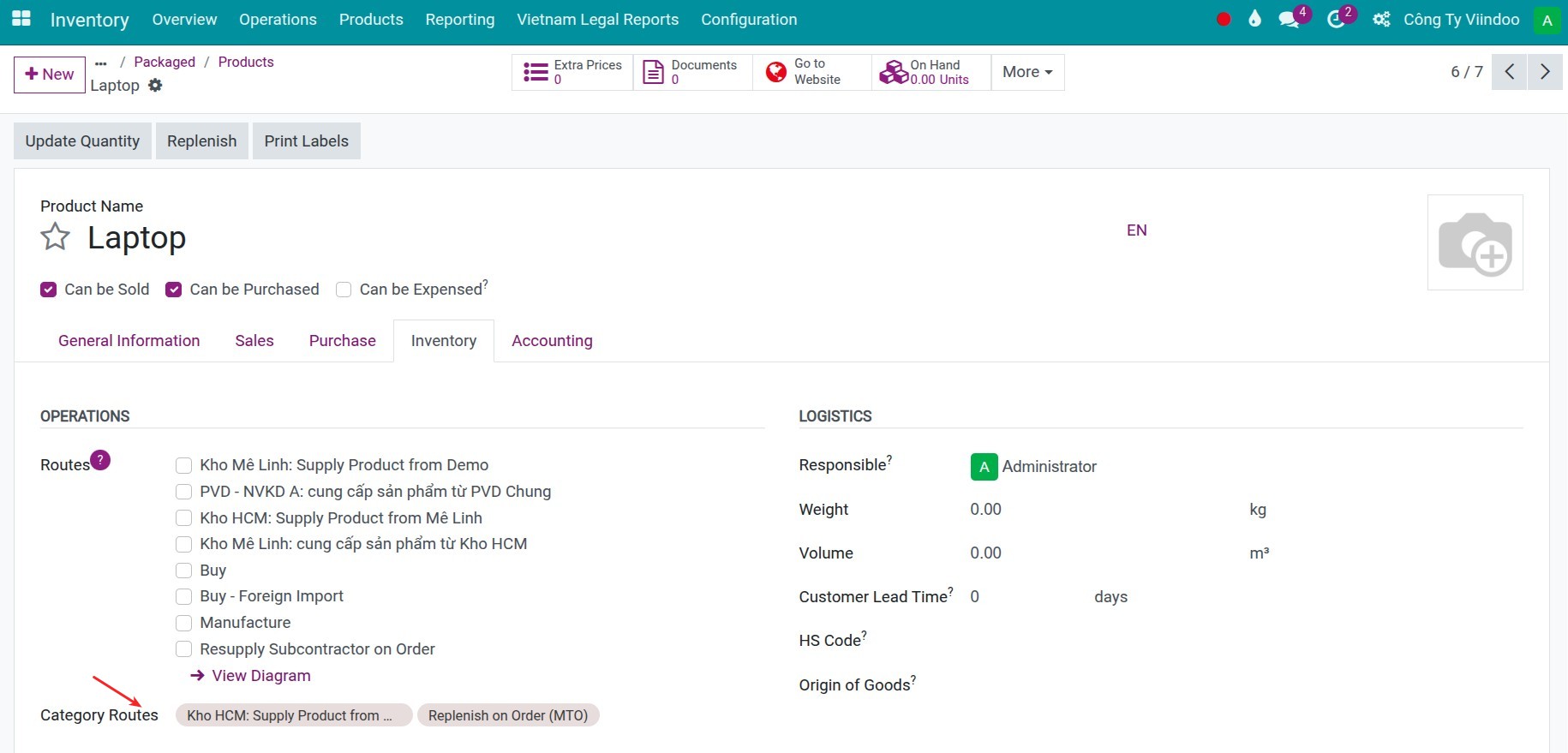

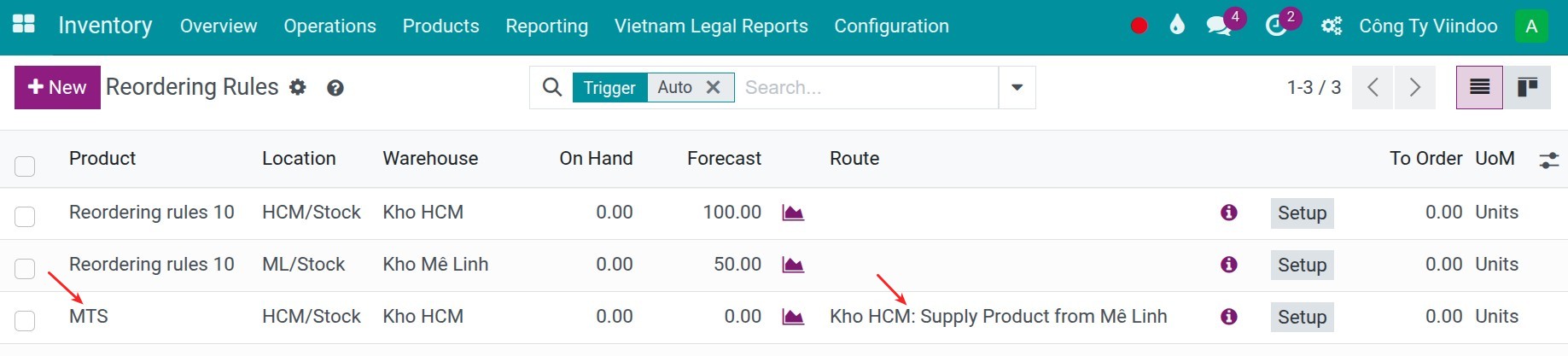

Configure the MTS rules for the product. In the product or on the reordering rule, only configure the route between internal warehouses:

Replenishment execution¶

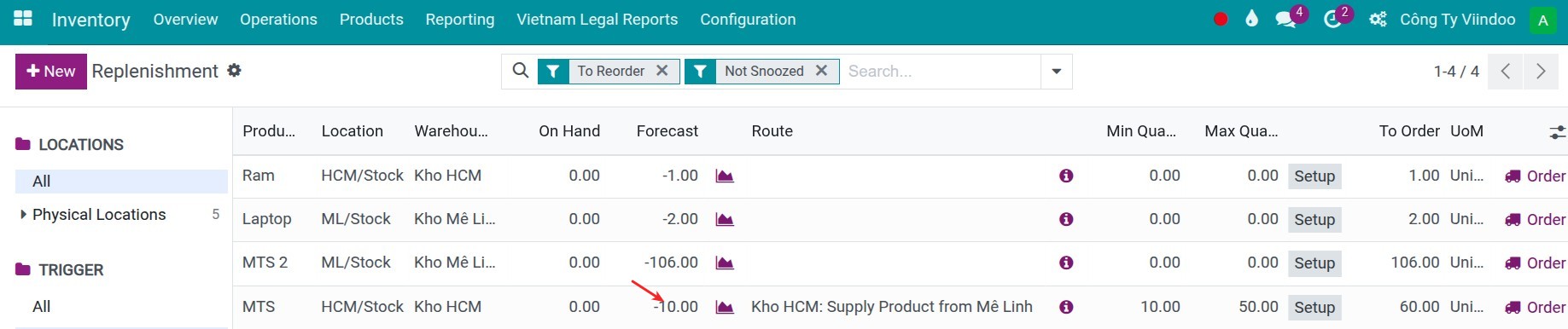

Whenever stock at a destination location fall down below the minimum threshold, Viindoo generates an internal replenishment request to restock up to the maximum level.

When using the Make to Stock (MTS) method, there is a potential issue to consider: If there are already existing the transfer orders between these same locations (in an unconfirmed state), the system will add new transfer lines to those existing pickings instead of generating a new pair of pickings. This behavior may impact traceability or workflow expectations if not properly managed.

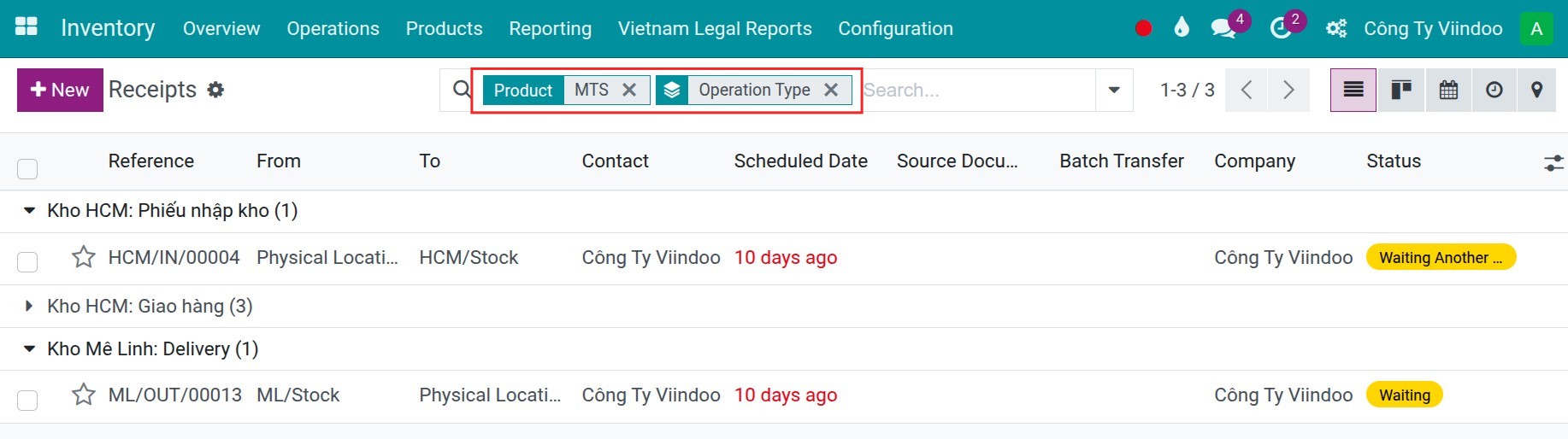

To operate and validate, you navigate to Inventory > Operations > Receipts or Inventory > Operations > Deliveries and search the pickings by Product name and Operation type.

Internal replenishment by manual operation¶

In this mode, internal transfers are initiated manually by warehouse or supply chain personnel. It offers full control and flexibility, often used in exceptional cases, or when automated methods are not yet configured.

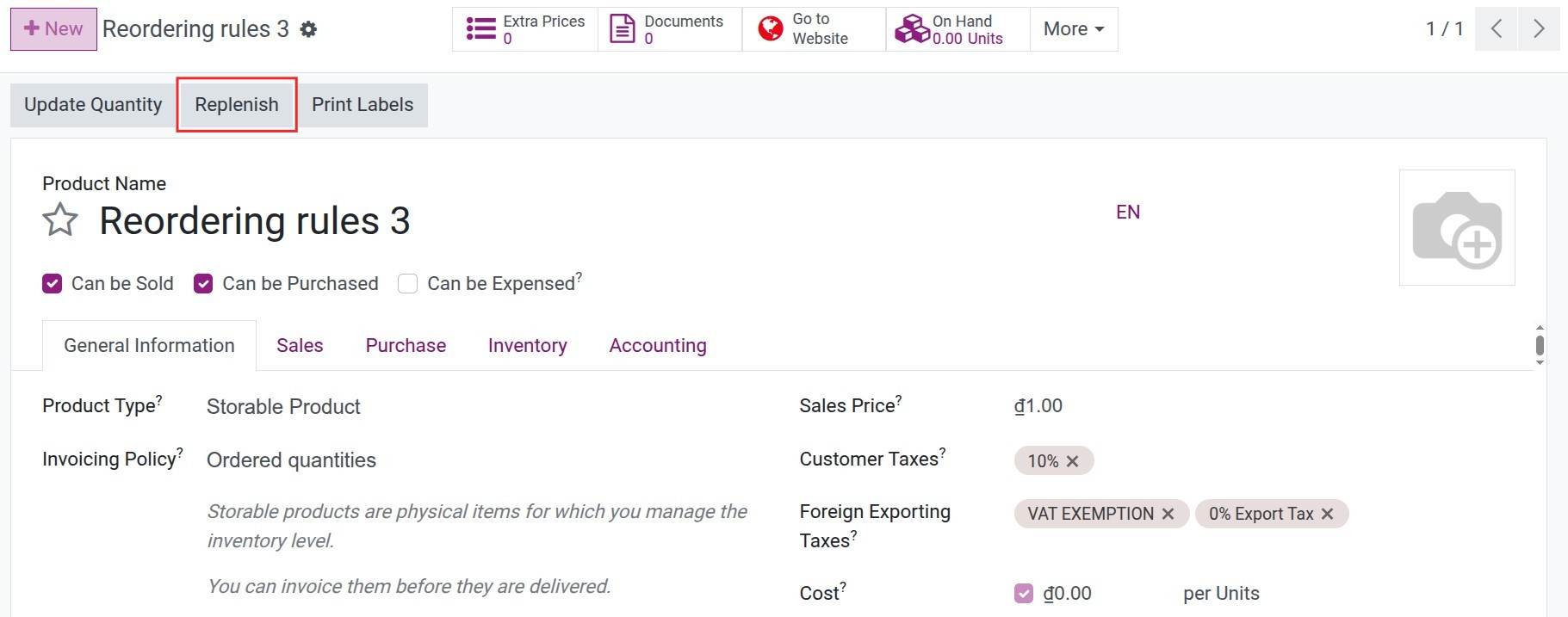

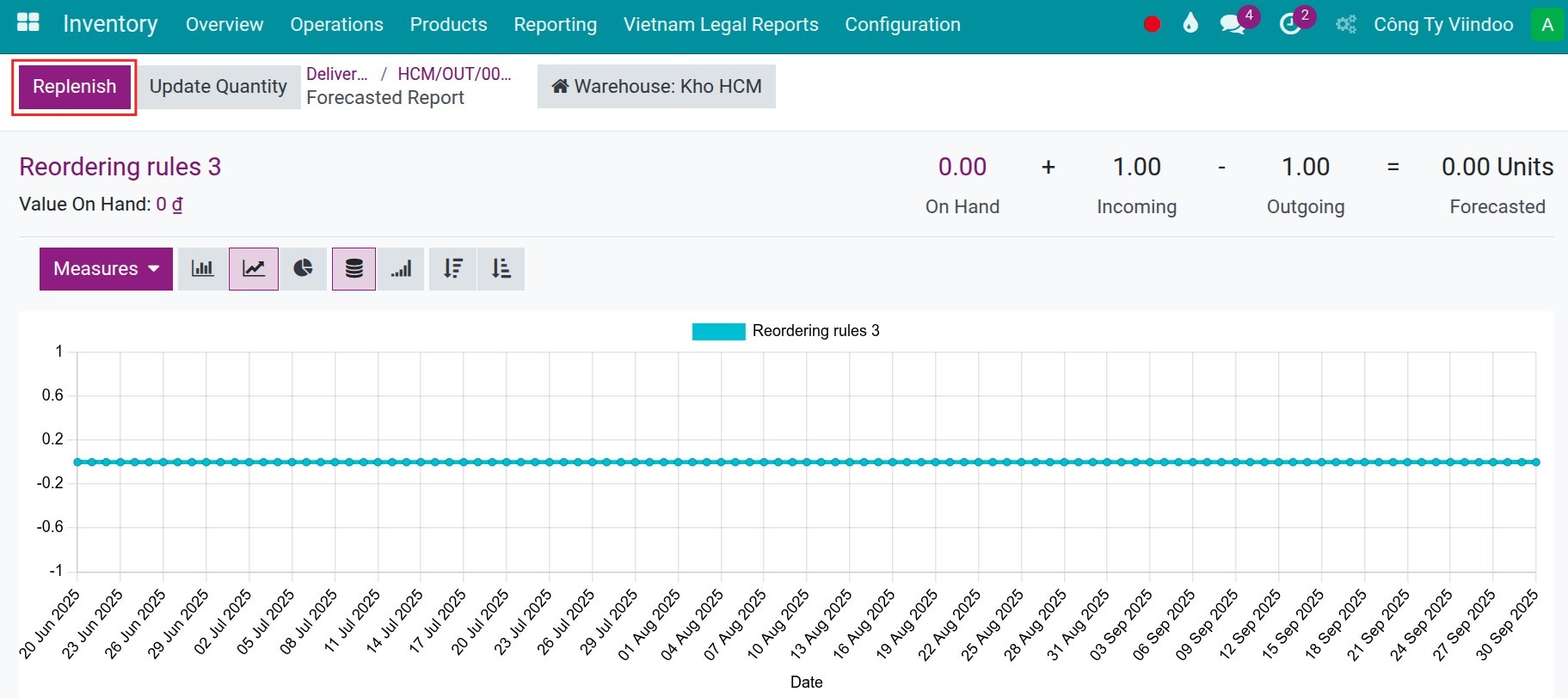

On each operation, you will see the product forecast report. Open this report, press Replenish:

Tip

You also can request to replenish from product form.

![Replenish on product form]()

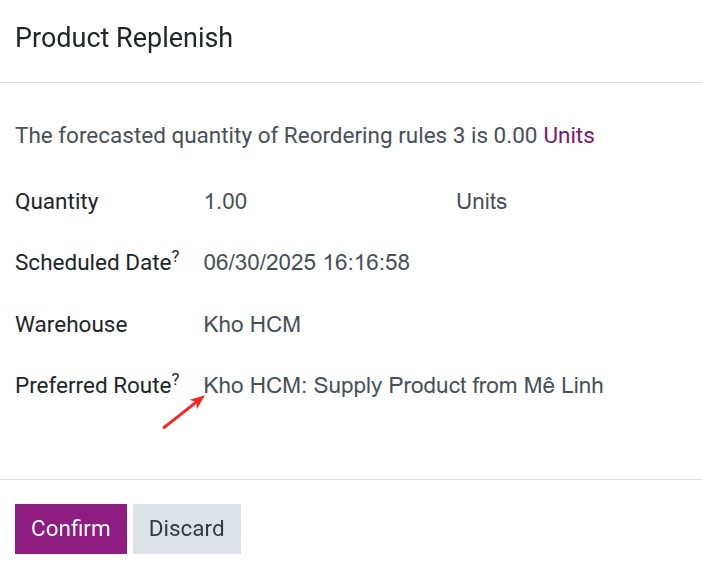

In the meantime, you can select the route:

Note

The route can be selected here need to be enable to display on Product.

Once you press Confirm, two pickings will be generated to tranfer product between two warehouses. Similar with replenishment by MTS, you can go to the Inventory > Operations > Receipts or Inventory > Operations > Deliveries to search the pickings by product name and operation type.

See also

Related article

Optional module