Choose the right inventory flow to handle your delivery¶

Similar to the stock receipt process, the stock delivery process to customers can also be configured to transfer goods to other locations such as output, quality control, or not. This process is designed according to the management needs and the characteristics of each product.

The Inventory Management System of Viindoo All-in-one Enterprise Management Solution can fulfill that demand by providing three types of the stock delivery process:

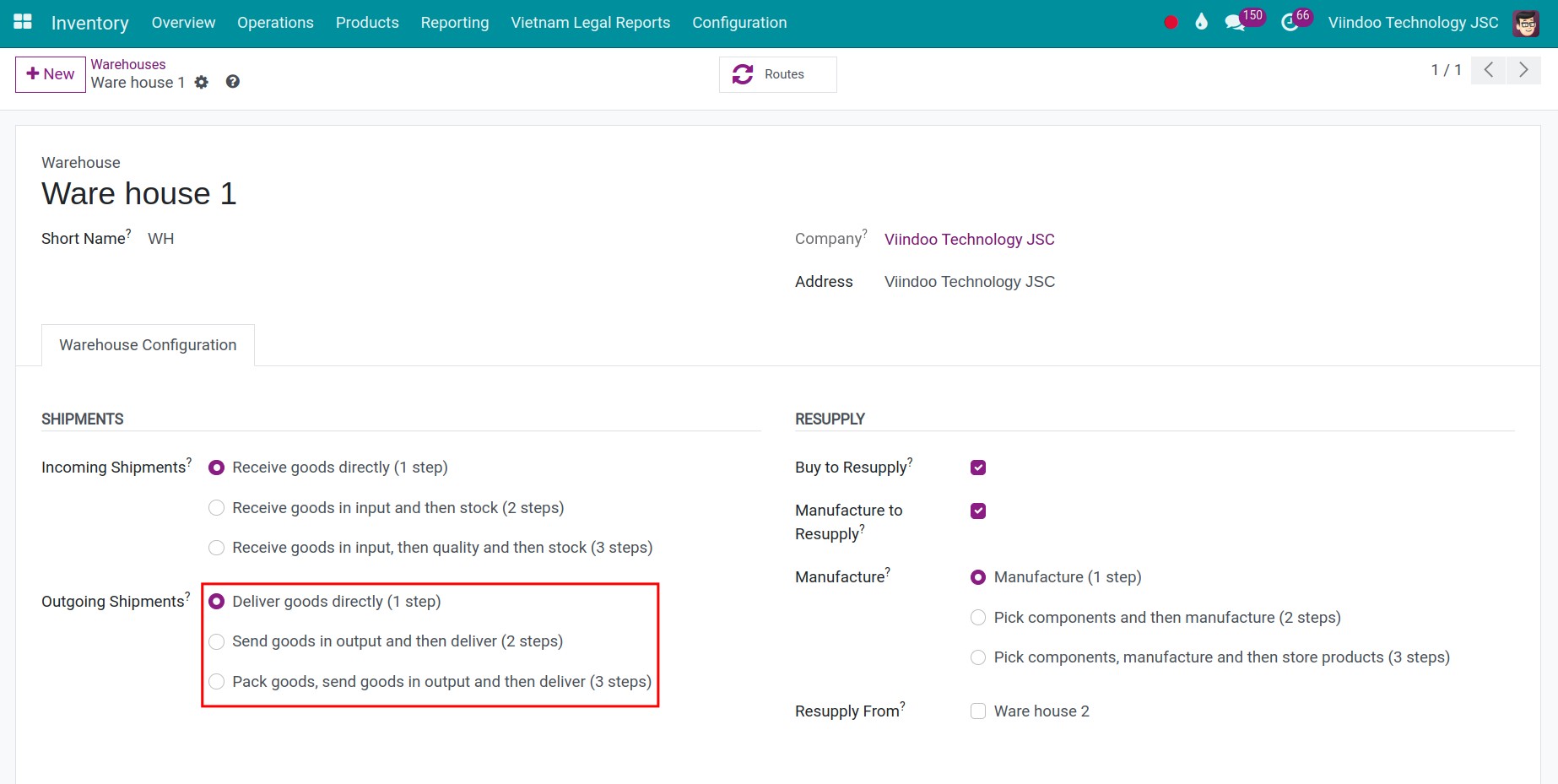

Delivery goods directly (1 step): Delivering the goods to customers directly from the warehouse.

Send goods in output and then deliver (2 steps): Transferring the goods from the stock location to the output location, then the delivery will be performed.

Pack goods, send goods in output and then deliver (3 steps): Transferring the goods from the warehouse to the packing zone for packing. Next, creating the stock move to the output location. Finally, performing the delivery of goods to customers.

Requirements

This tutorial requires the installation of the following applications/modules:

Steps to activate the stock delivery process¶

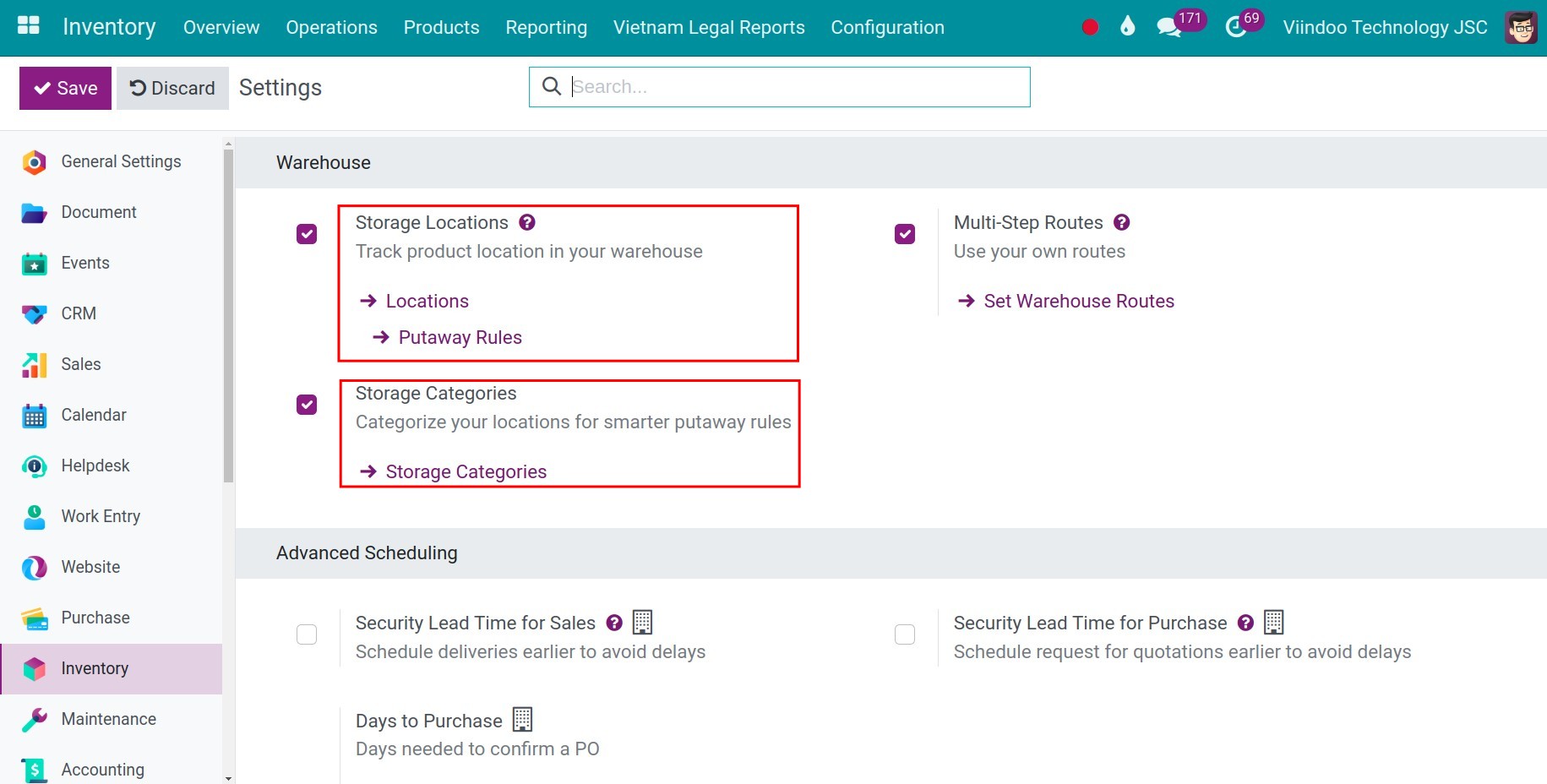

To activate the stock delivery process, you navigate to Inventory ‣ Configuration ‣ Settings, at the Warehouse section, enable Multi-step Routes ‣ Save.

To configure the stock delivery process, you access to Inventory ‣ Configuration ‣ Warehouse, choose the needed warehouse to set up, and the system will display the information of that warehouse.

In the outgoing shipments section on the Warehouse Configuration tab, you check on the suitable stock delivery process and save it to record the changes.

The above is an overview of selecting a stock delivery process. Depending on the characteristics of your company’s products, you can choose the process that suits your needs.