How to understand the Product Forecase Report¶

The inventory forecast report provides real-time insights into stock levels, helping businesses optimize management, planning, and decision-making. This report ensures product availability for sales, production, and timely replenishment.

Requirements

This tutorial requires the installation of the following applications/modules:

Overview¶

The Product Forecast Report is essential for managing product supply within the supply chain. By leveraging this report, businesses can proactively control stock movements, ensuring a balanced inflow and outflow of products.

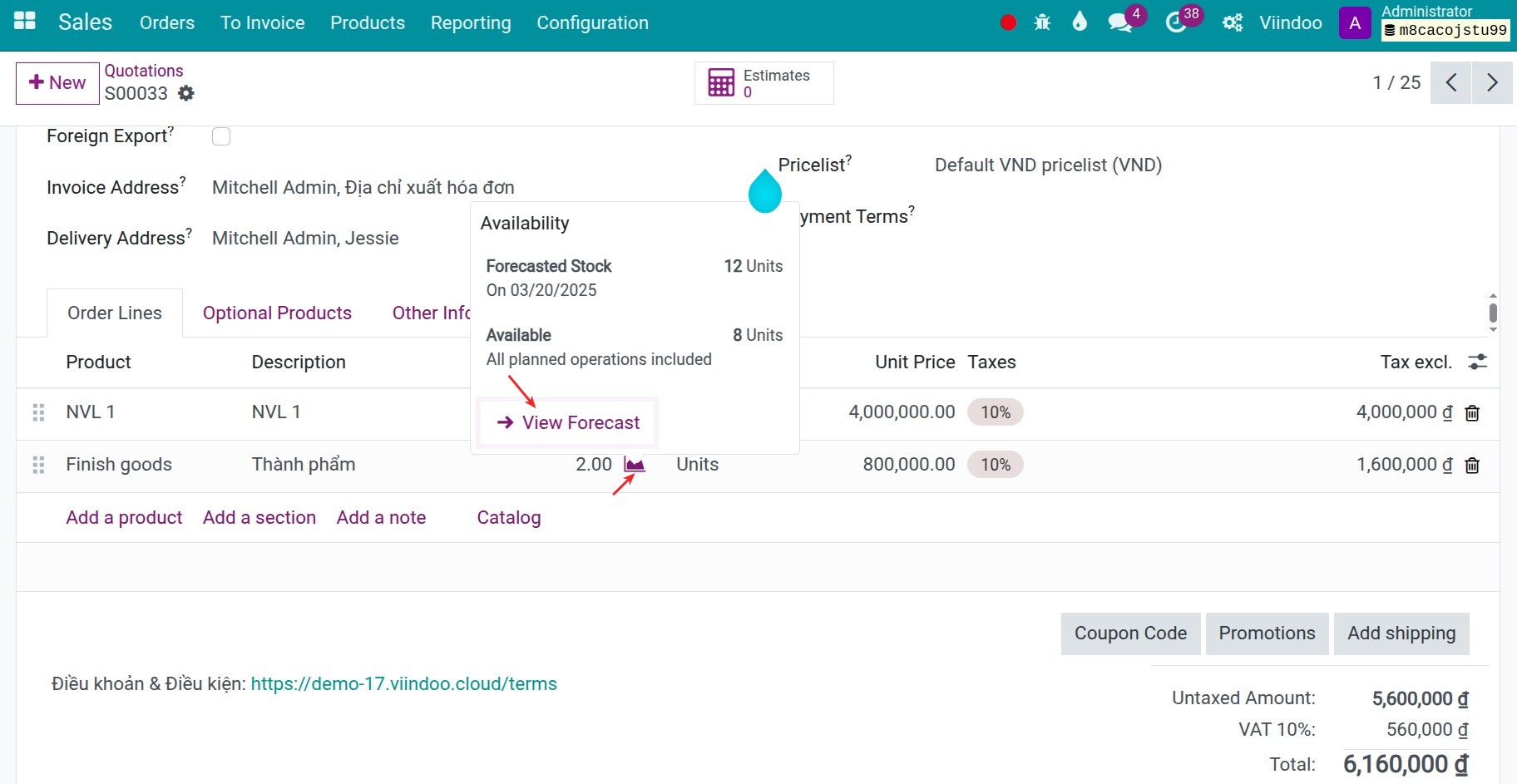

You can access this forecast report via the Inventory, Purchase, Manufacturing and Sales apps. On the product form, the sales orders, the purchase order, the manufacturing order, the transfer notes, the inventory reports, etc, to access this report, click the Forecast smart button, then press View Forecast.

Note

This report is only available for Storable products.

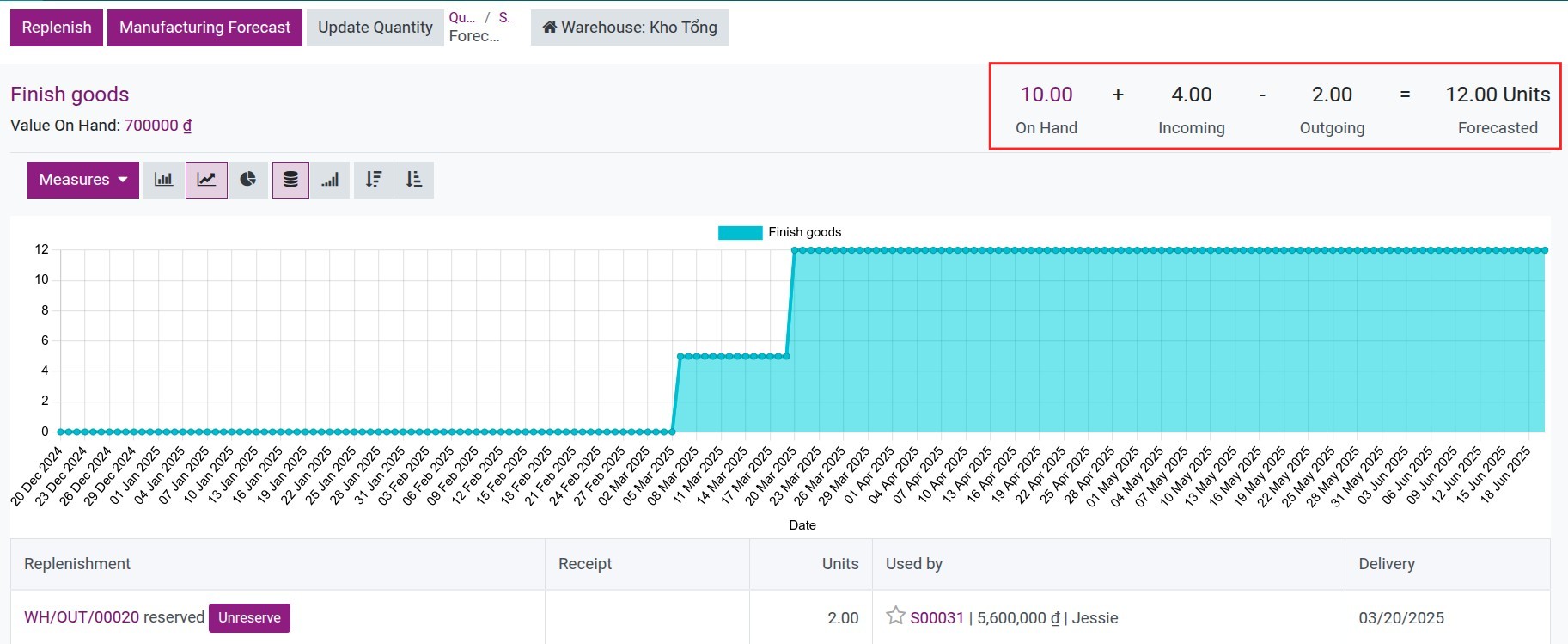

The Forecasted Report provides a graph and a table to visualize stock movements over time. It includes:

On Hand: Current stock physically available in the warehouse.

Incoming: Quantities expected from confirmed purchase orders (the incoming operations) or manufacturing orders.

Outgoing: Quantities reserved for sales orders or other outgoing operations.

Forecasted: The forecast stock levels based on confirmed and planned operations.

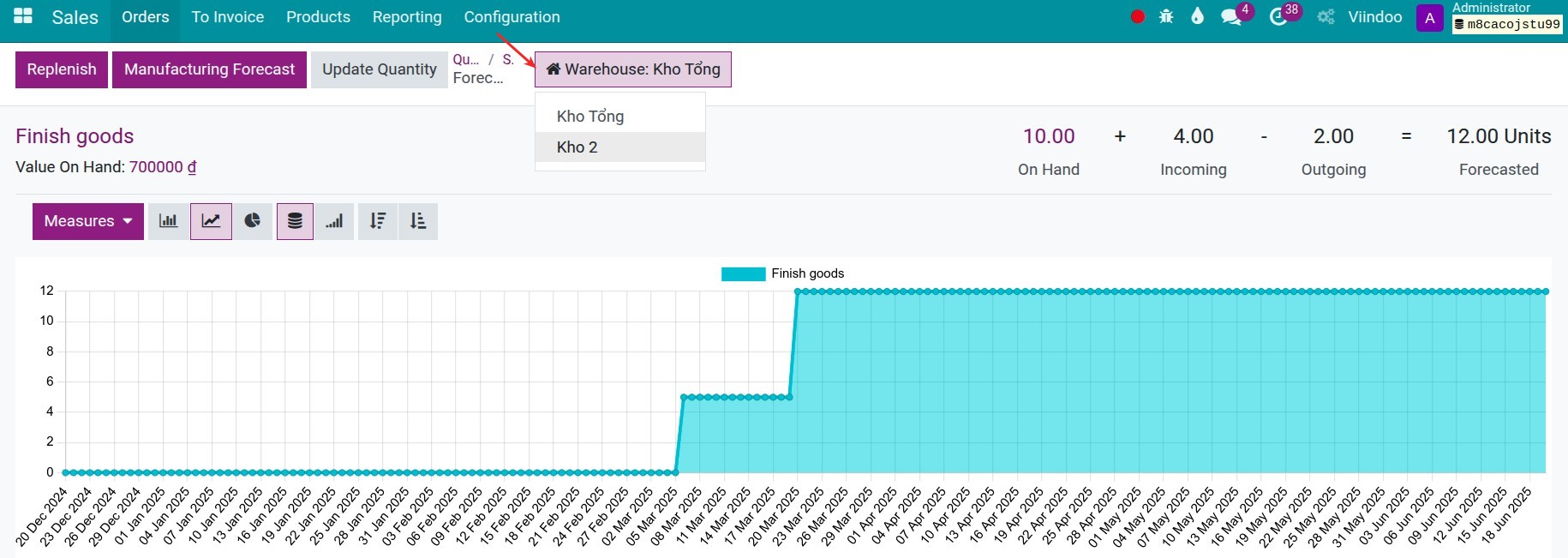

You also can see the forecast report for each warehouse by changing to the specific one.

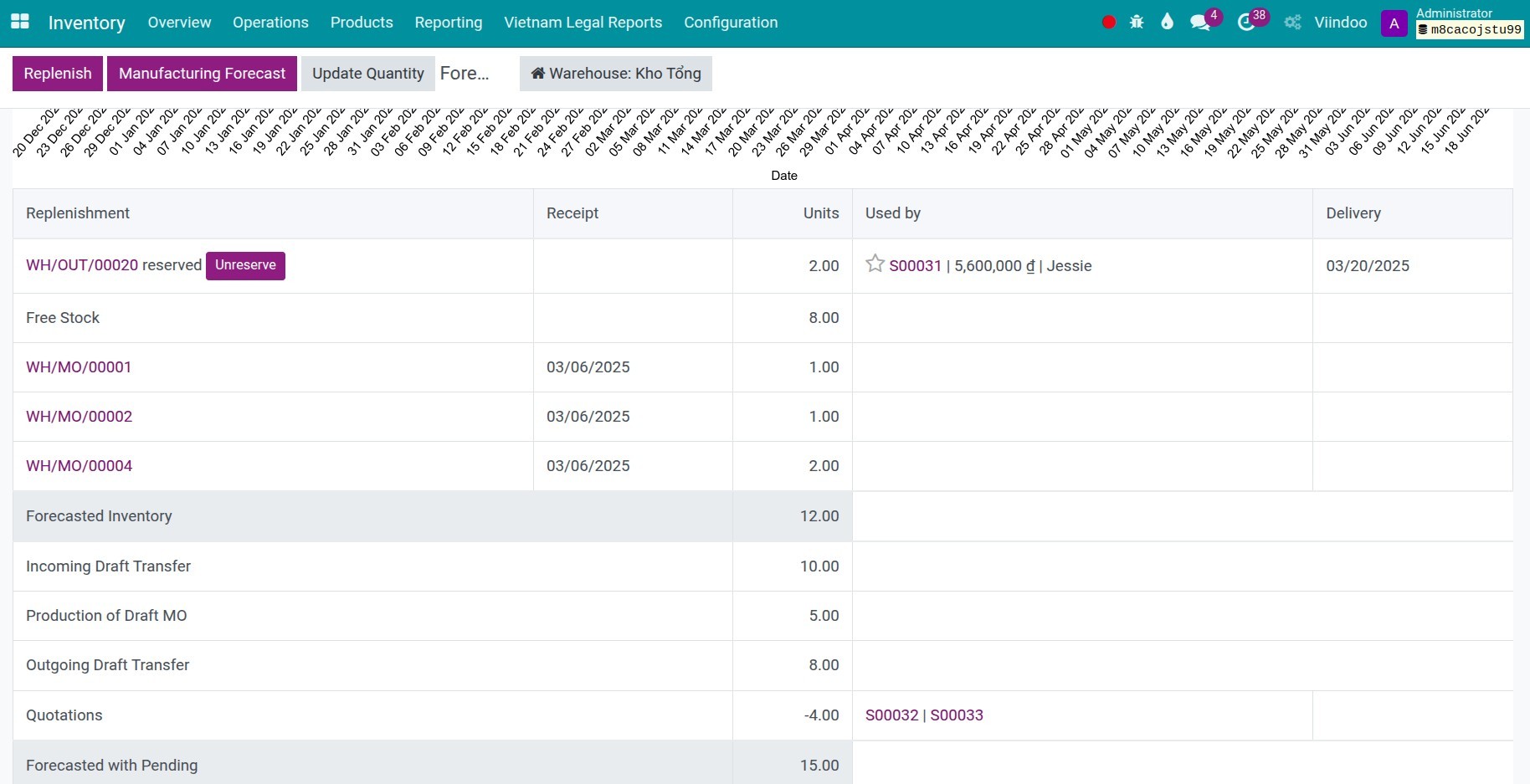

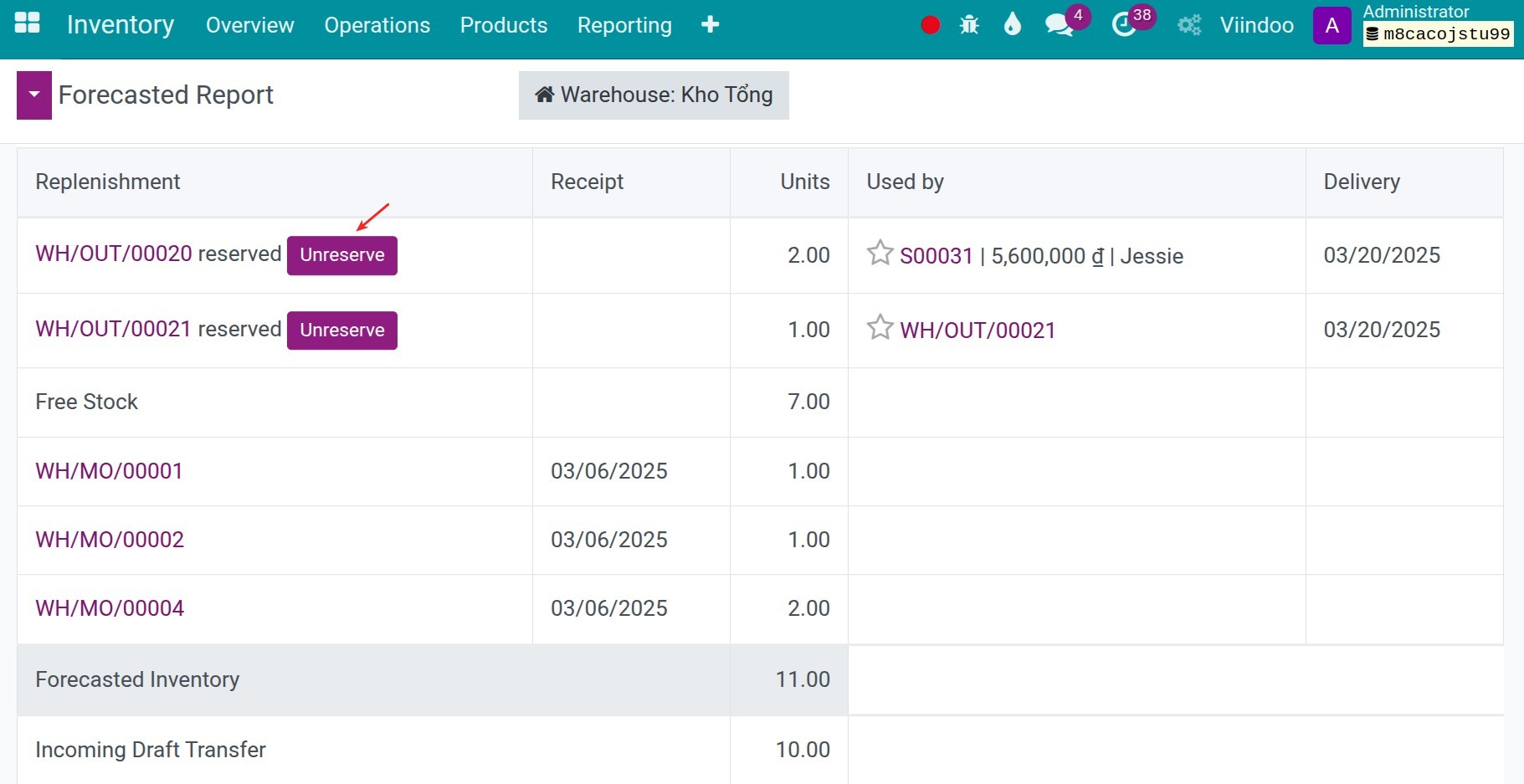

To see detailed planned operations affecting the forecast report, you can check the forecasted table.

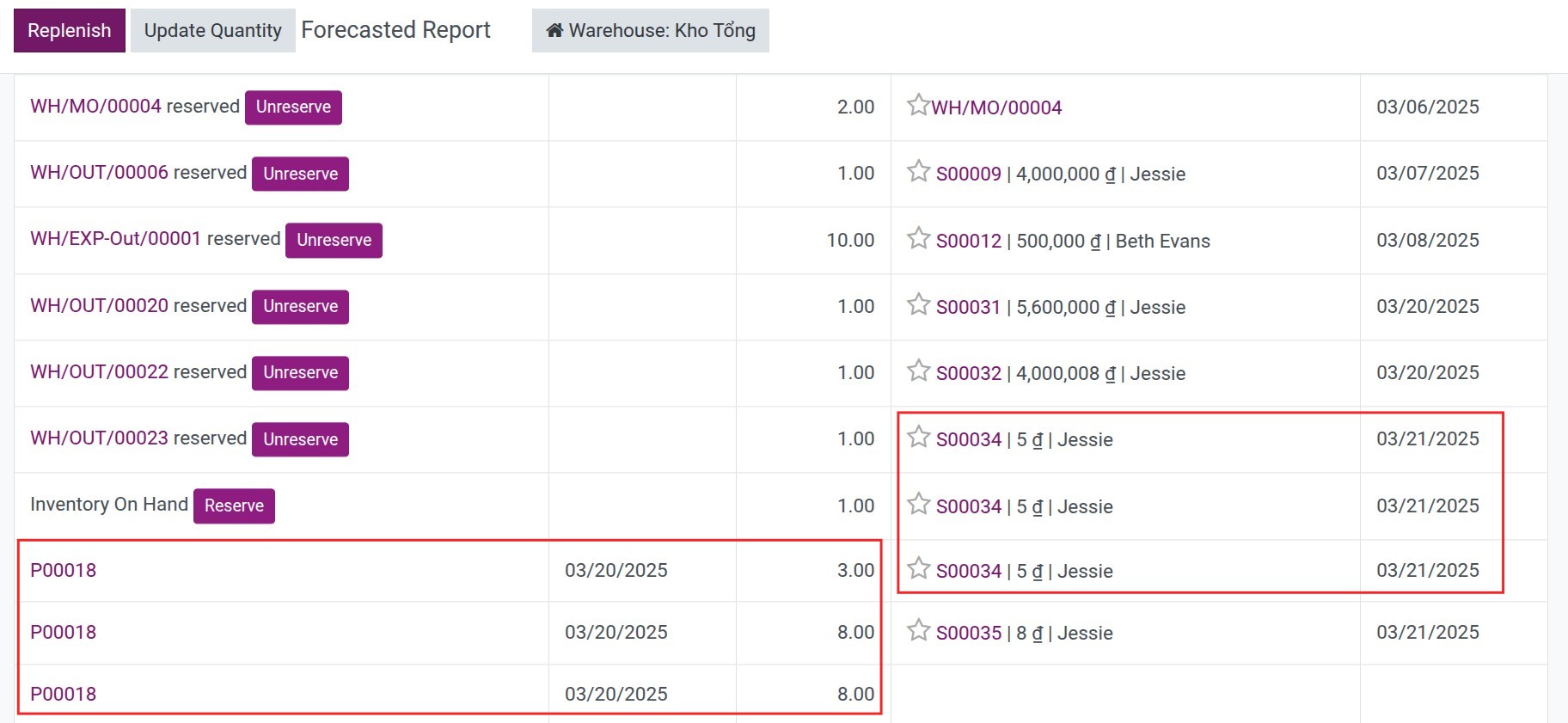

Replenishment: Lists reserved and planned receiving operations.

Receipt: Displays the planned date of receiving operations.

Units: Shows the quantity for both incoming and outgoing operations.

Used by: Lists planned delivery operations.

Delivery: Displays the planned date of delivery operations.

Free Stock: The number of available products in stock.

Forecasted Inventory: Calculated as On-hand quantity + Incoming quantity - Outgoing quantity.

Incoming Draft Transfer: Product quantity from incoming draft transfers (receipts in draft status).

Production of Draft MO: Product quantity from draft manufacturing.

Outgoing Draft Transfer: Product quantity from outgoing draft transfers (deliveries in draft status).

Quotations: Displays product quantities from quotations, with a list available for review.

Forecasted with Pending: Calculated as Forecast Inventory + Incoming Draft Transfer + Production of Draft MO - Outgoing Draft Transfer - Quotations.

Reserve and unreserve products¶

Users with inventory access rights can reserve or unreserve products directly from the Forecasted Report, ensuring optimized stock allocation for operational needs.

Product Forecast Report in Replenishment¶

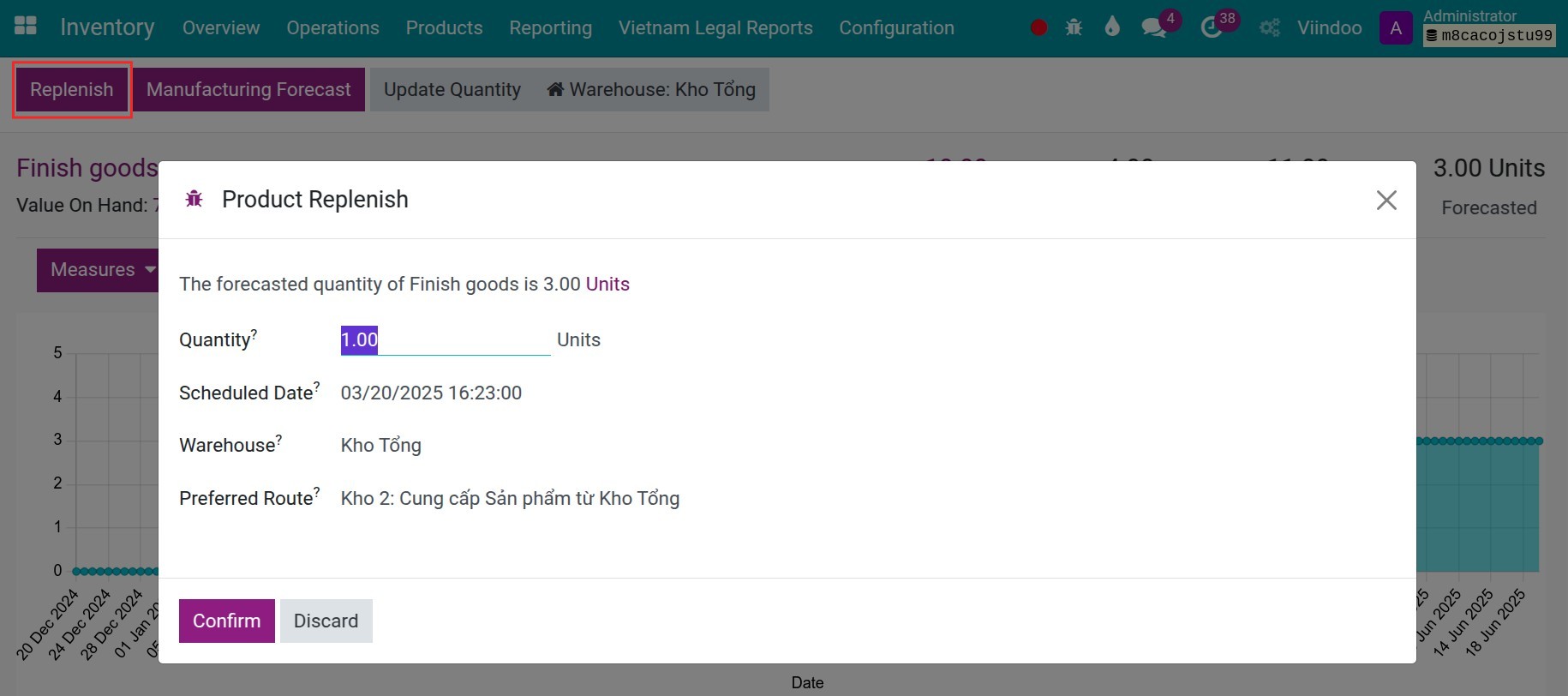

In this report, you can take actions to replenish stock and ensure business continuity. To do so, click the Replenish button.

Quantity: Enter the required quantity for this product..

Scheduled Date: Specify the planned date when this quantity is needed.

Warehouse: Select the warehouse that needs replenishment.

Preferred Route: Choose the replenishment method, such as Buy, Manufacture, or Transfer from another warehouse.

Press Confirm to complete the replenishment request.The system will automatically generate the necessary operations, such as purchase orders, manufacturing orders, or stock transfers, to fulfill the demand.

Product Forecast Report in Manufacturing¶

Note

This feature is only available with the product that has bill of materials (BoM).

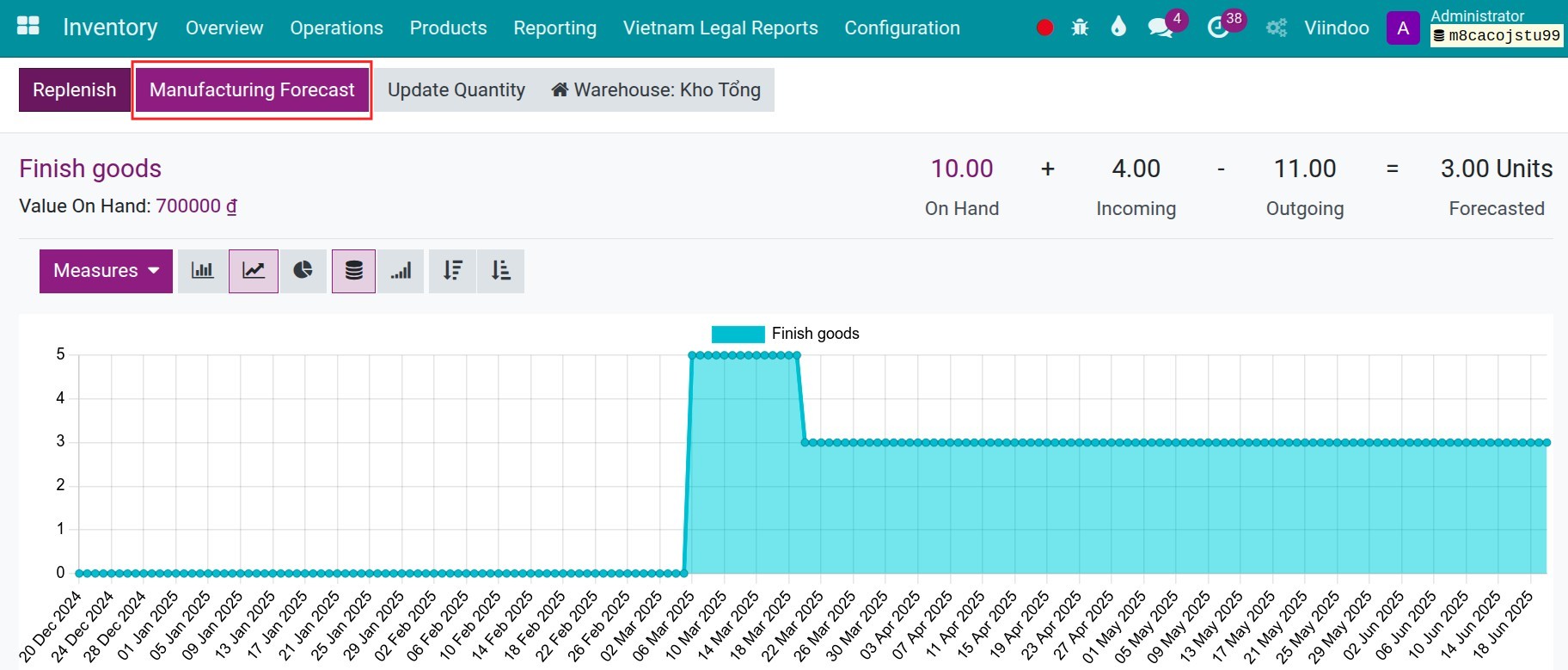

A manufacturing company can use this report to forecast the demand for raw materials based on planned production orders, ensuring a smooth workflow without delays. To do so, click to Manufacturing Forecast:

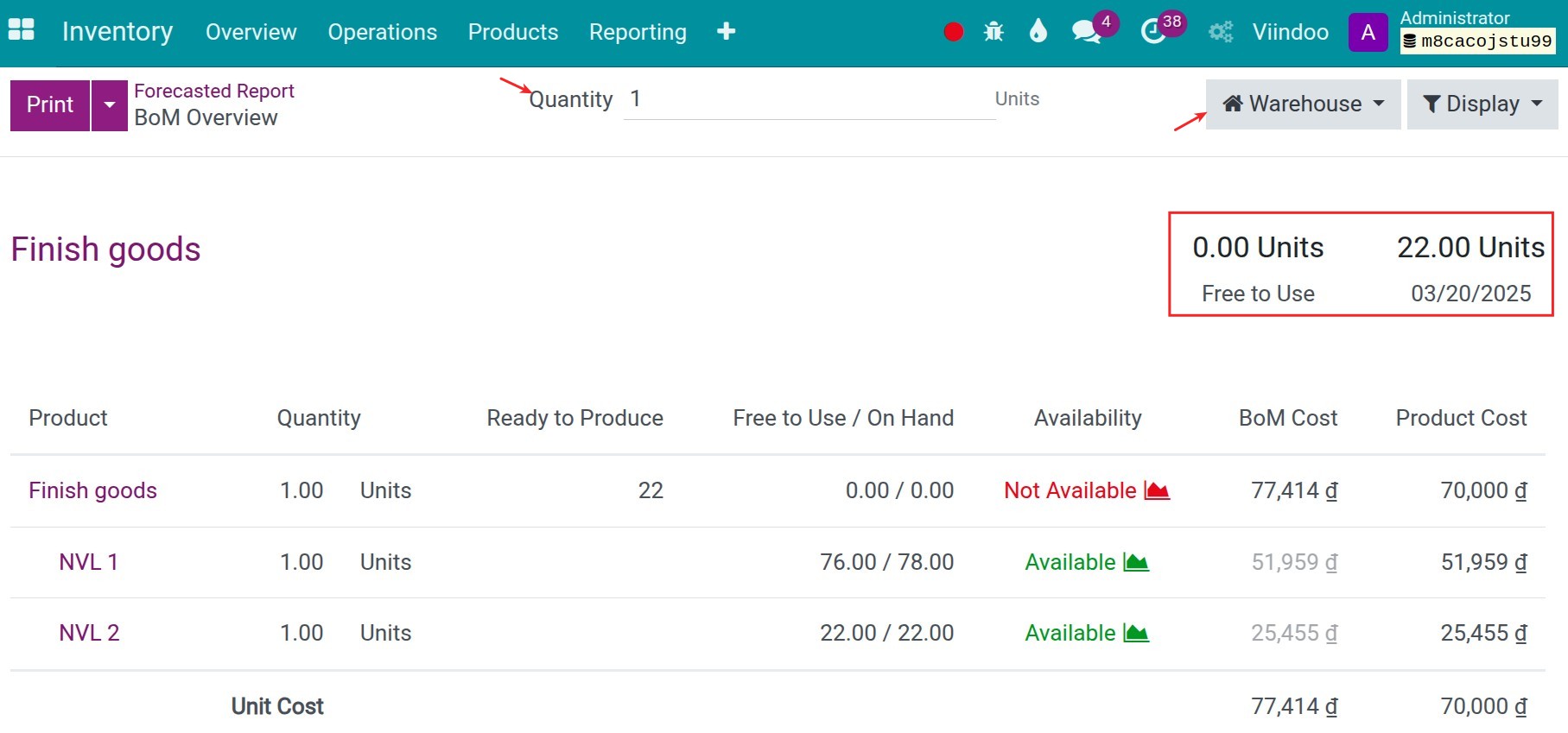

Quantity: Enter the expected number of products; ingredient quantities will be calculated based on the Bill of Materials (BoM).

Warehouse: Select the warehouse to check the stock status.

Free to Use: Displays the available quantity of this product.

Estimate quantity: Shows the number of products ready for production, depending on the available stock of its ingredients.

Additional Forecast Information:

Ready to Produce: Displays the number of products ready for production, based on the available stock of components.

Free to Use / On Hand: Shows both the available quantity and the on-hand stock of this product and its components.

Availability: Indicates the stock status of the product and its components.

BoM Cost: Calculates the product cost based on the Bill of Materials (BoM) structure.

Product Cost: Calculates the product cost based on the number in the Cost field on the product interface.

This Manufacturing Forecast gives you an overview of the production feasibility for this product.

Use cases¶

Split order¶

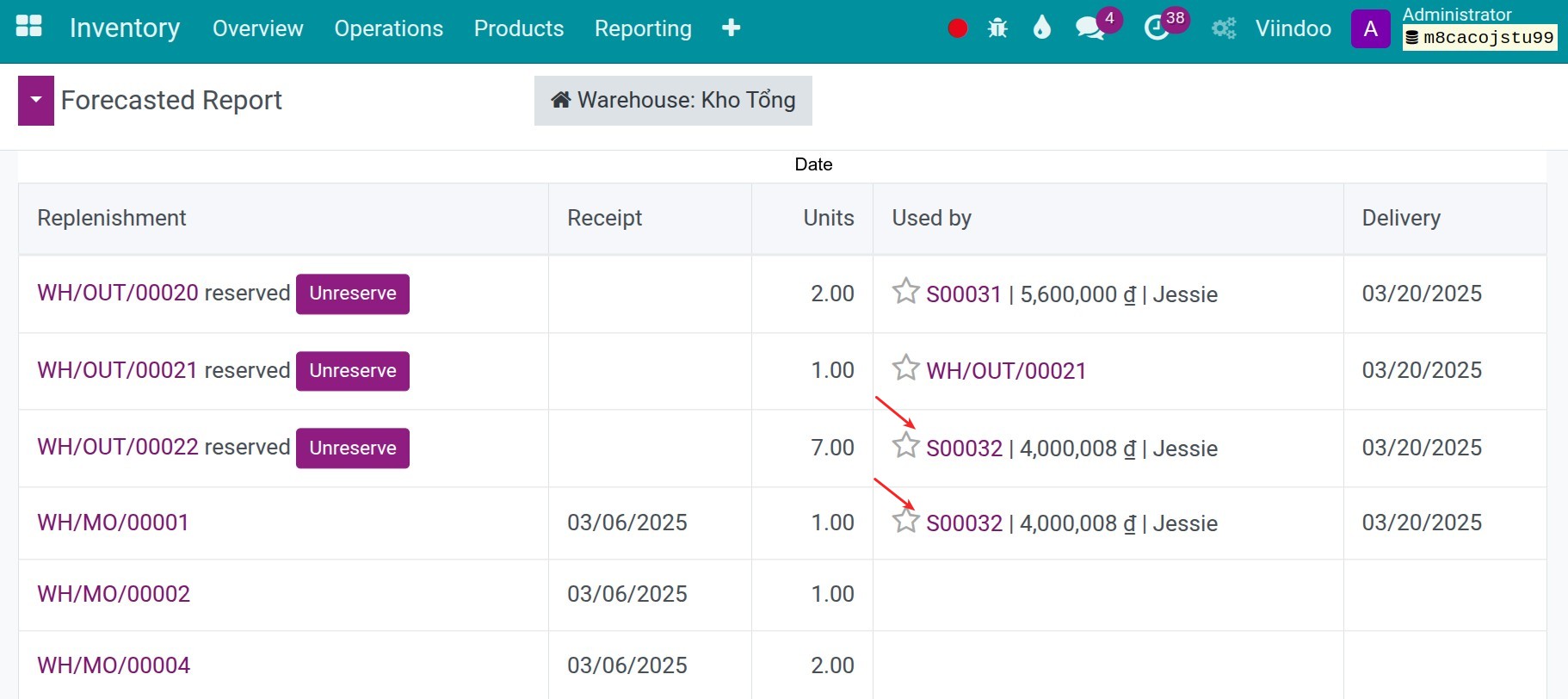

In the example below, there is not currently enough stock of a product to fulfill the multiple sales orders and the Sales order (S00032) and its corresponding transfer has been split between the two orders. The current stock has been reserved for a shipment WH/OUT/00022, the remaining is expected with WH/MO/00001.

In some cases, a single receiving operation may be split into multiple delivery operations to forecast stock reserved for those deliveries. This is only a forecast at that moment and can change anytime based on future transactions.

Negative quantity¶

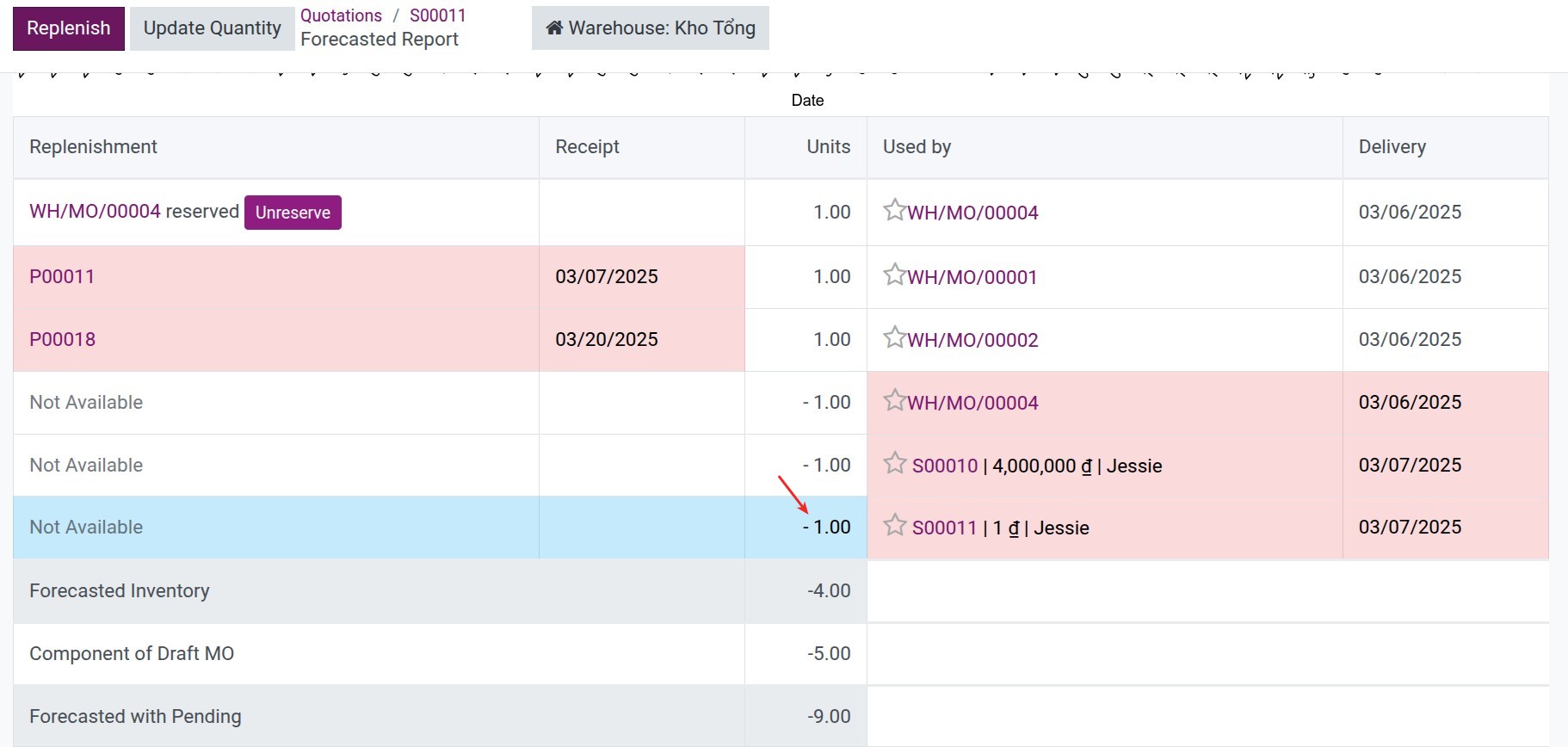

A negative forecasted quantity indicates that demand exceeds available and incoming stock at a specific point in time. This can occur due to:

Sales Orders (SOs) or Manufacturing Orders (MOs) requiring more stock than what is currently available or expected.

Delays in shipping or manufacturing, disrupting the expected stock flow.

When negative numbers appear in the Forecast Report, they serve as early warning signals, prompting businesses to act swiftly and strategically:

Prioritize critical sales and production orders to meet urgent demands.

Accelerate procurement by expediting purchase orders and adjusting sourcing strategies.

Proactively manage customer expectations by communicating potential delays in advance.

By closely monitoring forecasted quantities, businesses can stay ahead of disruptions, maintain operational stability, and optimize supply chain performance.

See also

Related article

Optional module