How to avoid supply chain disruption with reordering rules¶

In supply chain management, depending on the type of product, businesses will need to plan for stock picking and re-supply to ensure the supply chain is in a continuous operation. To support that need, the Viindoo software support you to actively control the amount of stock and order the right amount of products at the right time.

Requirements

This tutorial requires the installation of the following applications/modules:

First of all, you need to create a product. Refer to Steps to create a new product.

Note

You need to set up a Vendor for this product, or else the reordering rule will not work.

Setup purchase supply routes in product detail¶

To setup purchase supply routes, follow the steps below:

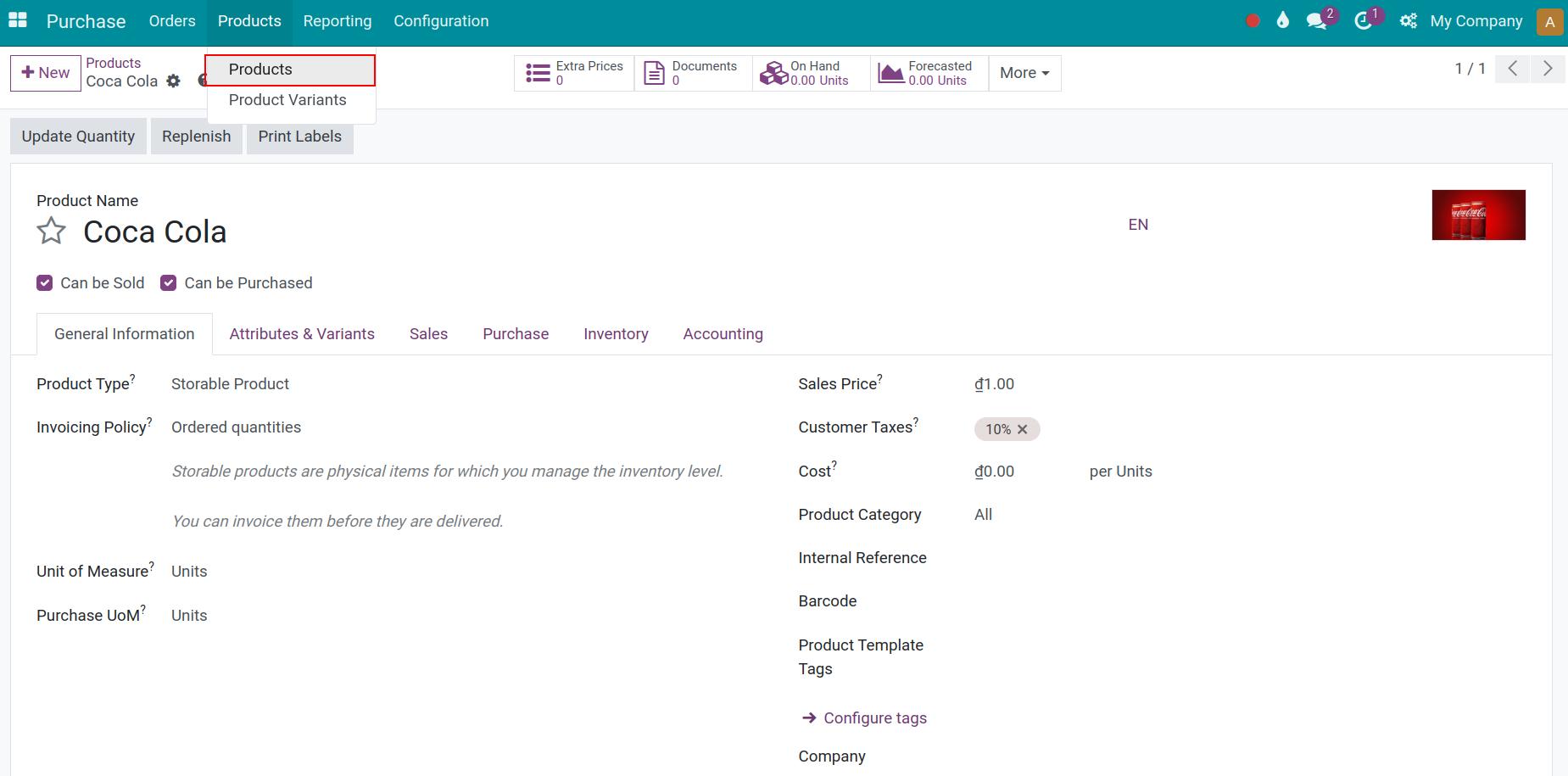

Navigate to Purchase > Products > Products, select the product.

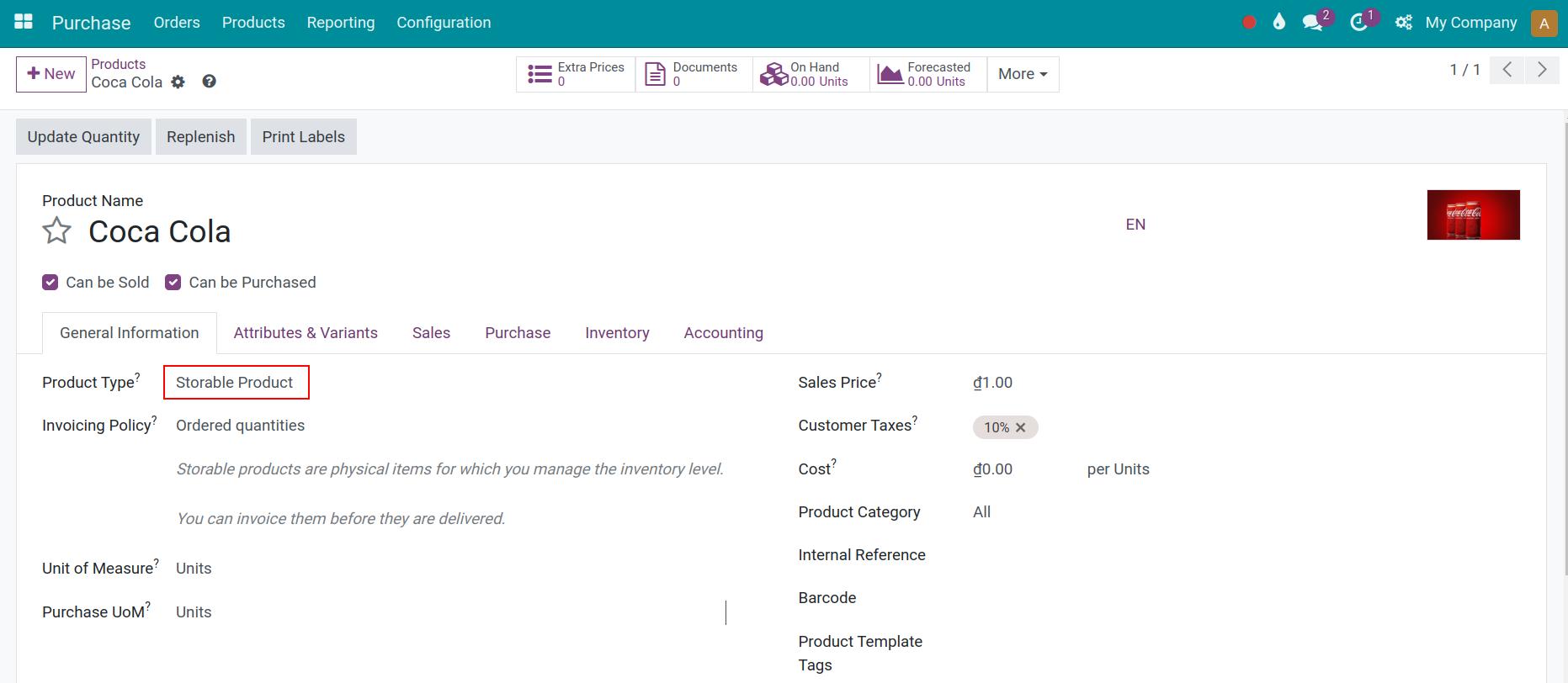

At the General information tab, select product type as Storable product.

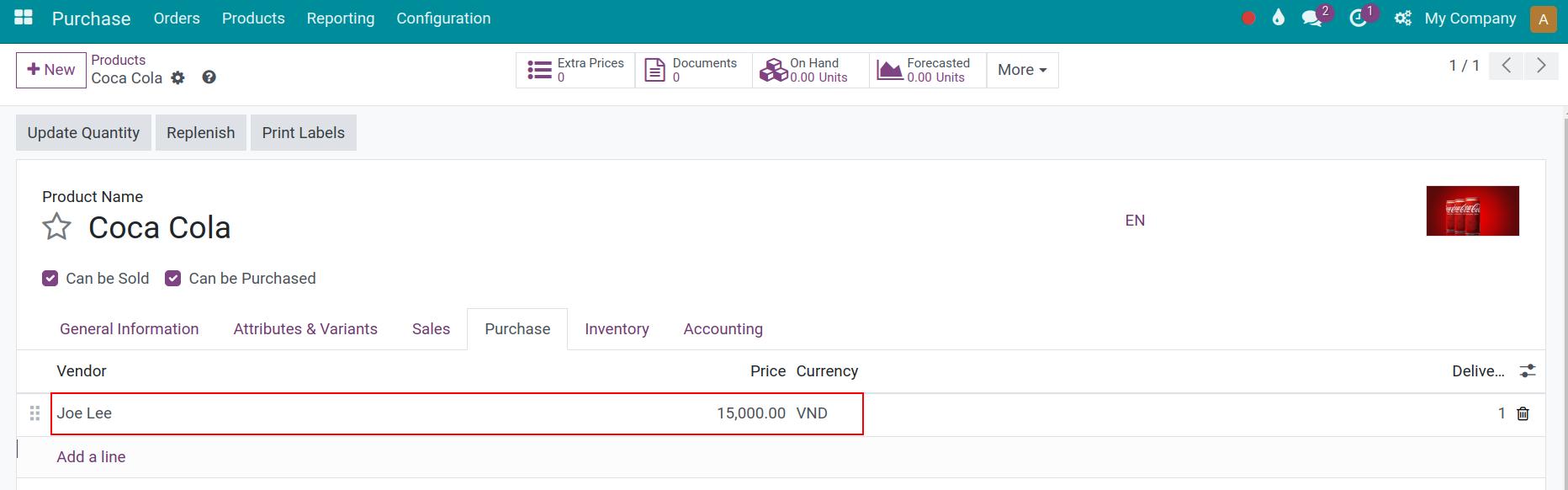

At the Purchase tab, set up a vendor for this product.

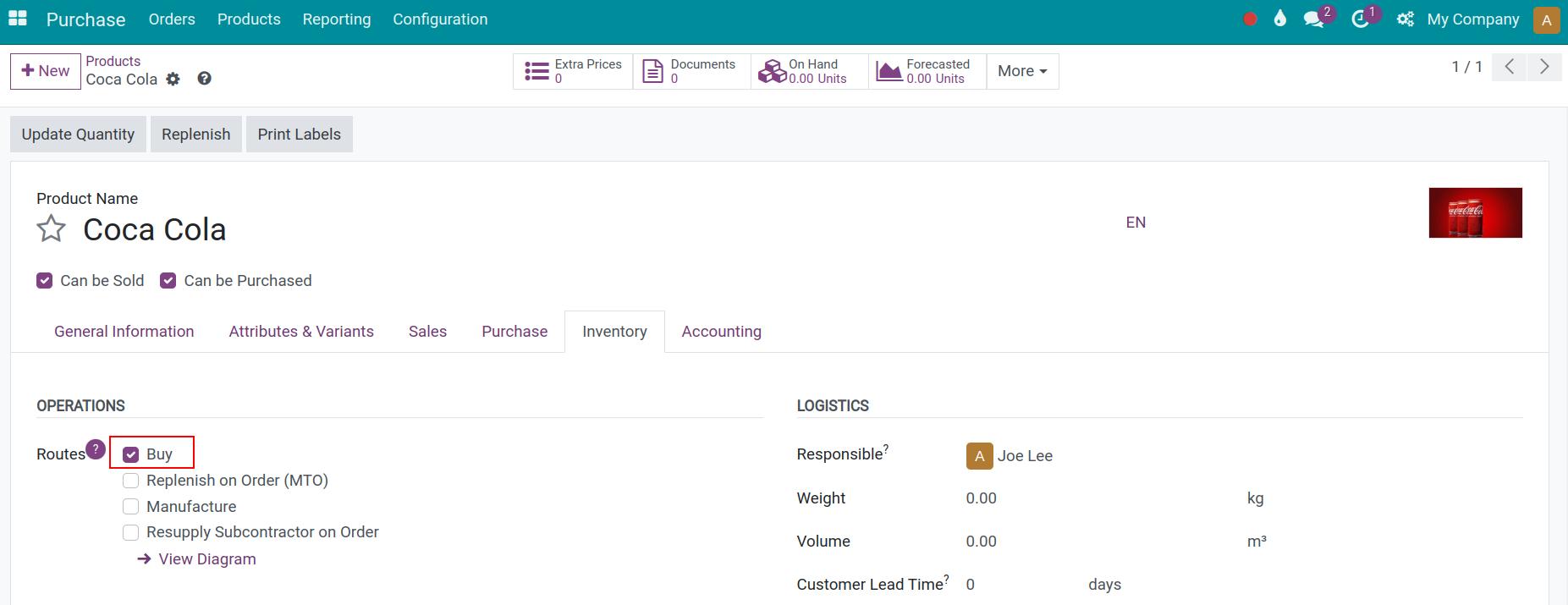

Next, at the Inventory tab, select the Buy route.

Set up reordering rule¶

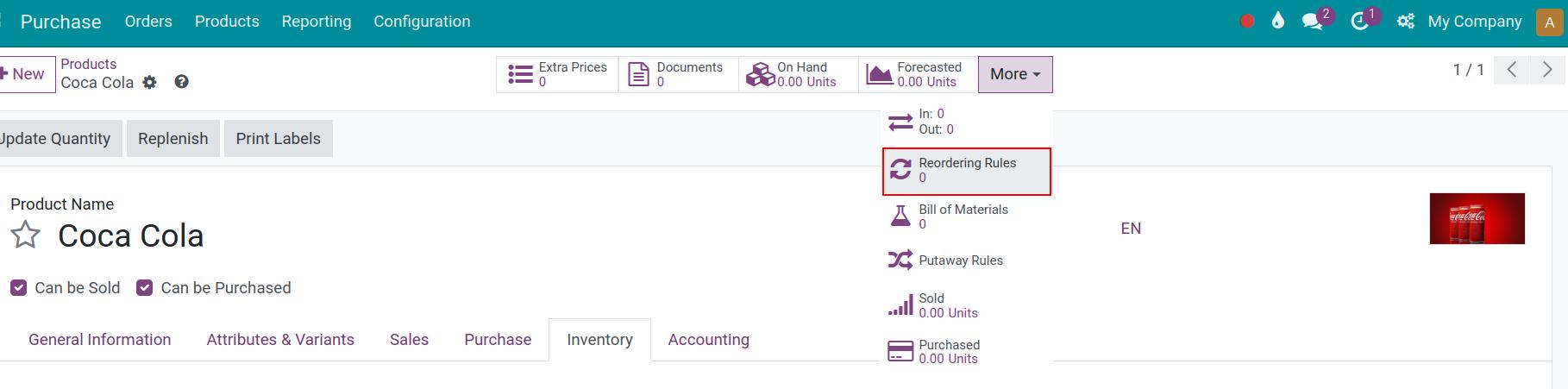

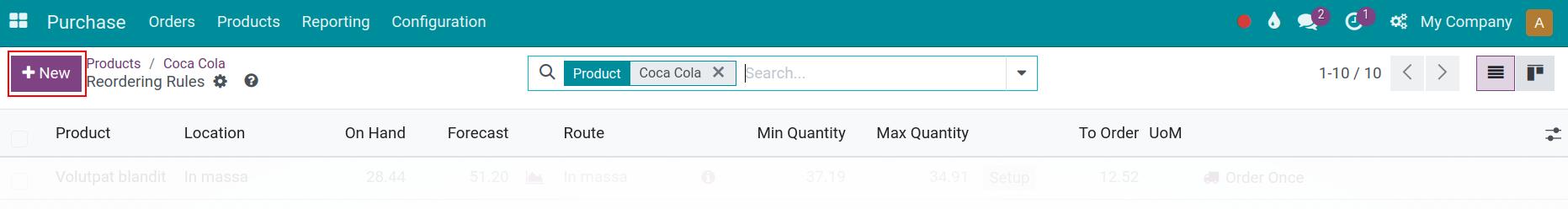

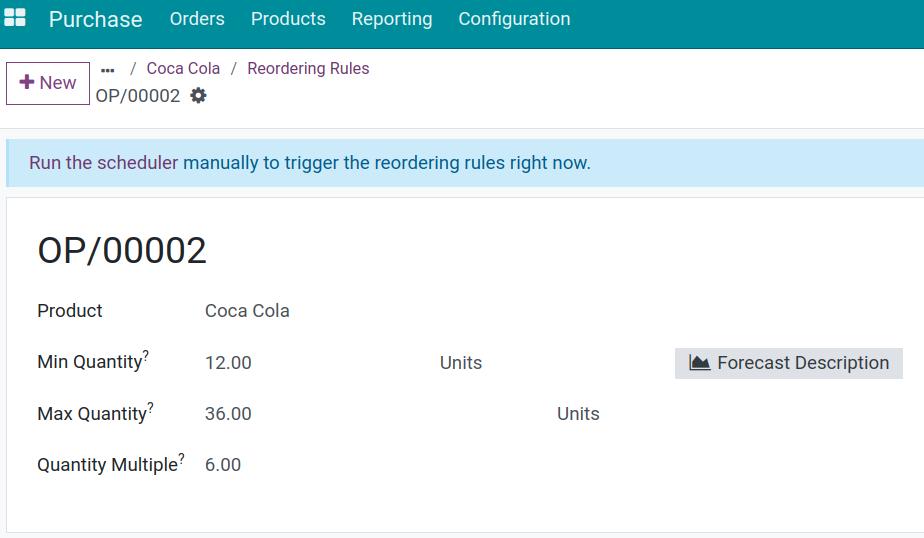

At the product information menu on the product record, select Reordering Rules and press New.

Here, fill in the following information:

Preferred Route: Choose a route for this supply method of the product;

Trigger: Decide whether the reordering rule will run automatically or manually;

Min Quantity: The minimum quantity required for this product in the inventory;

Max Quantity: The maximum quantity required for this product;

Multiple Quantity: The procurement quantity will be rounded up to this multiple. If the quantity multiple is 0 then the exact quantity will be used.

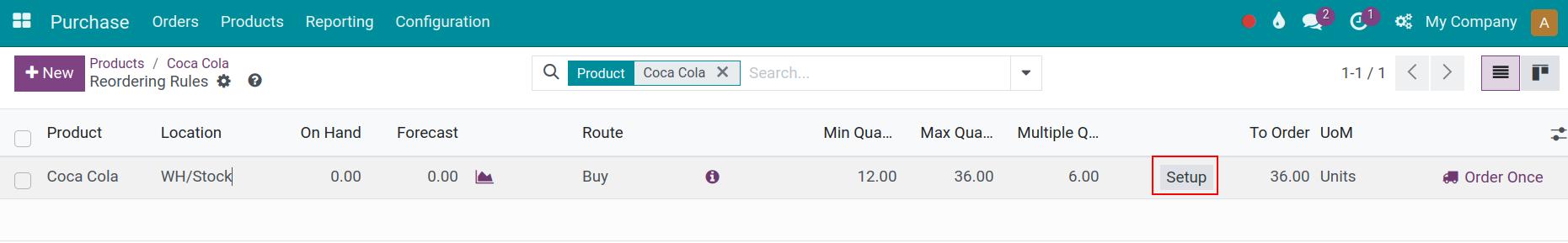

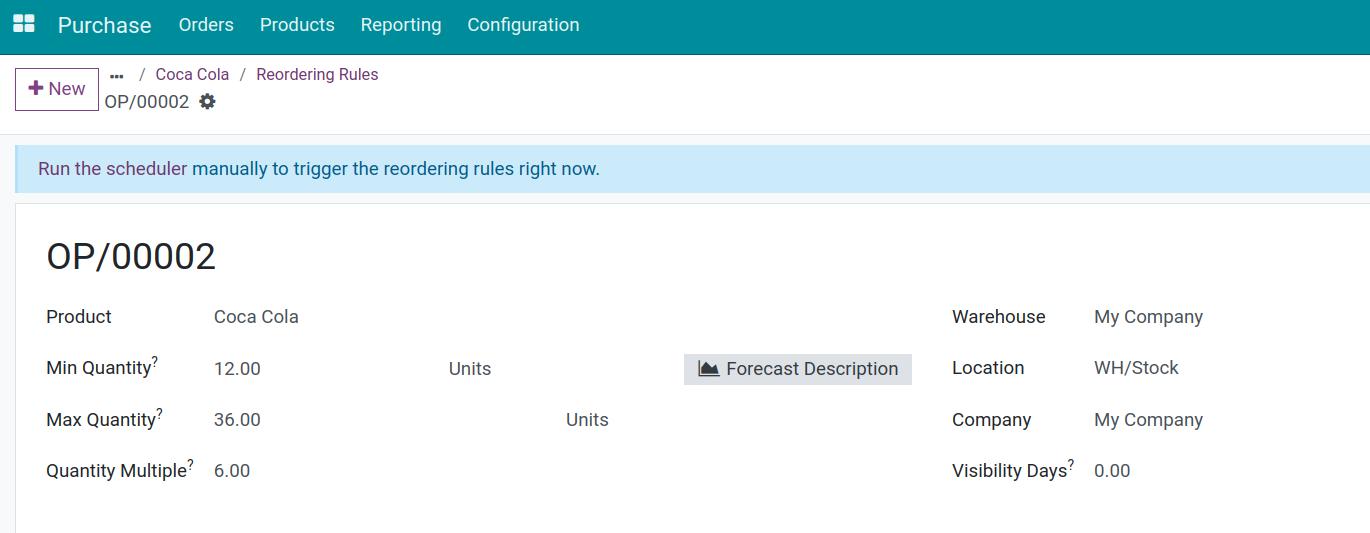

After setting up the reordering rule, click on Setup to see details.

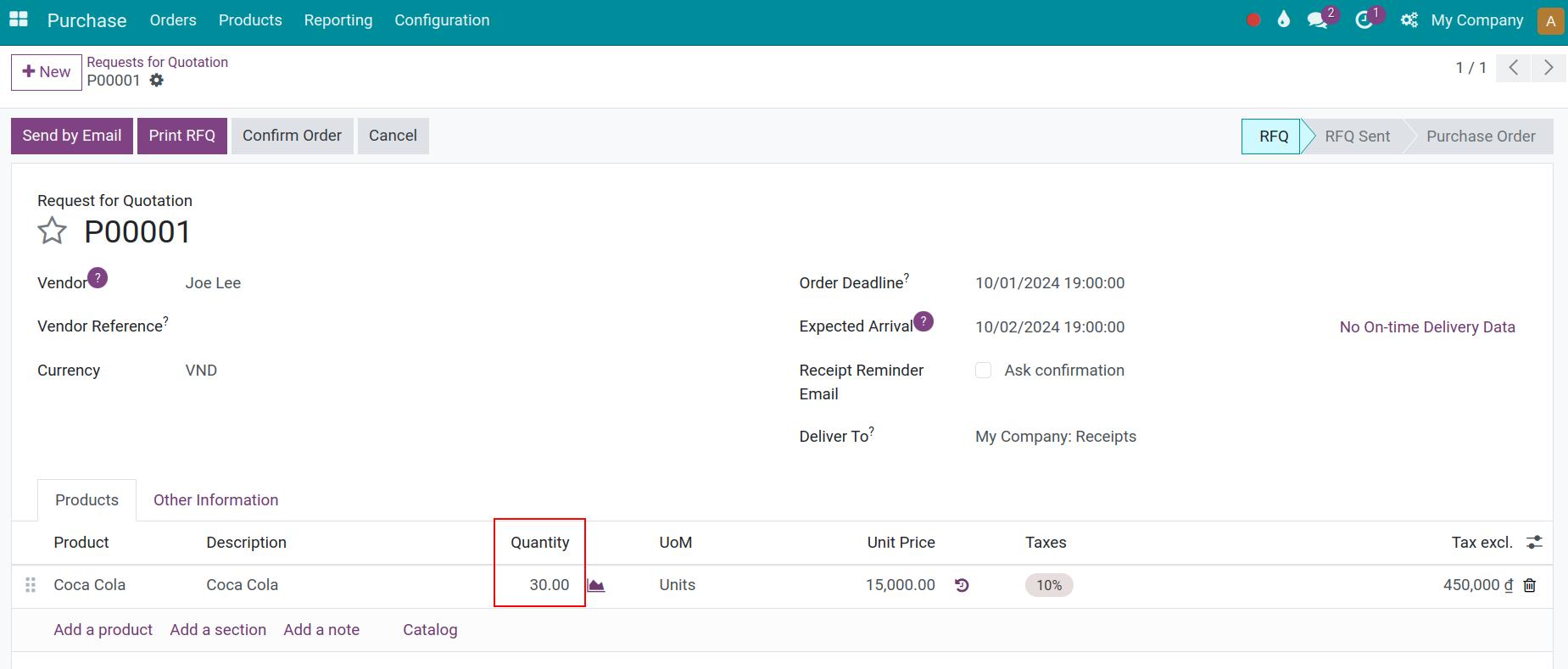

Depending on the setup (by days or hours), the software will collect all the requirements in the system, generate purchasing orders and attach them to the pre-set vendor of each product. This will prevent breaking the continuity of the supply chain.

Note

When applying reordering rules, the software will prioritize the vendors that are set on top of the vendor list.

Example¶

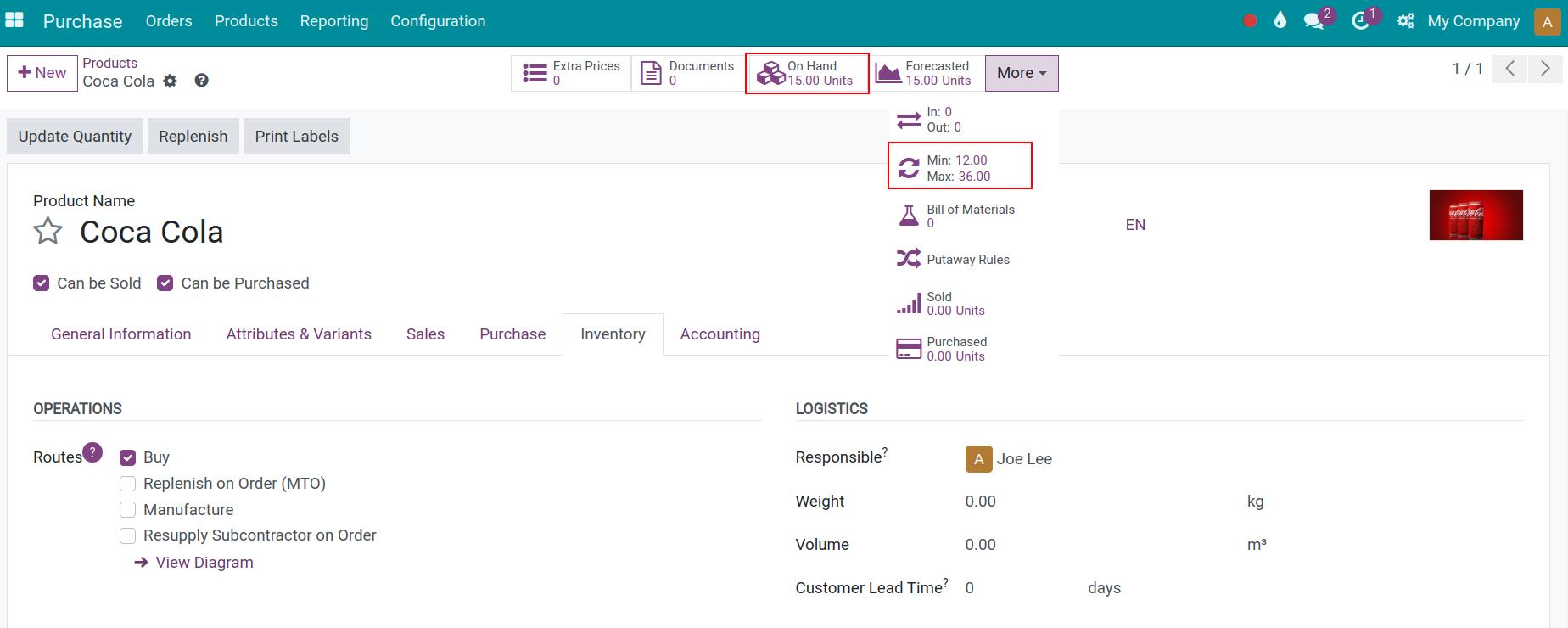

Your storable product is Coca-cola which has the on-hand quantity is 15 bottles.

Set up the reordering rule as follow:

Min Quantity: 12 bottles

Max Quantity: 36 bottles

Quantity Multiple: 6 (purchased with packs of 6 bottles)

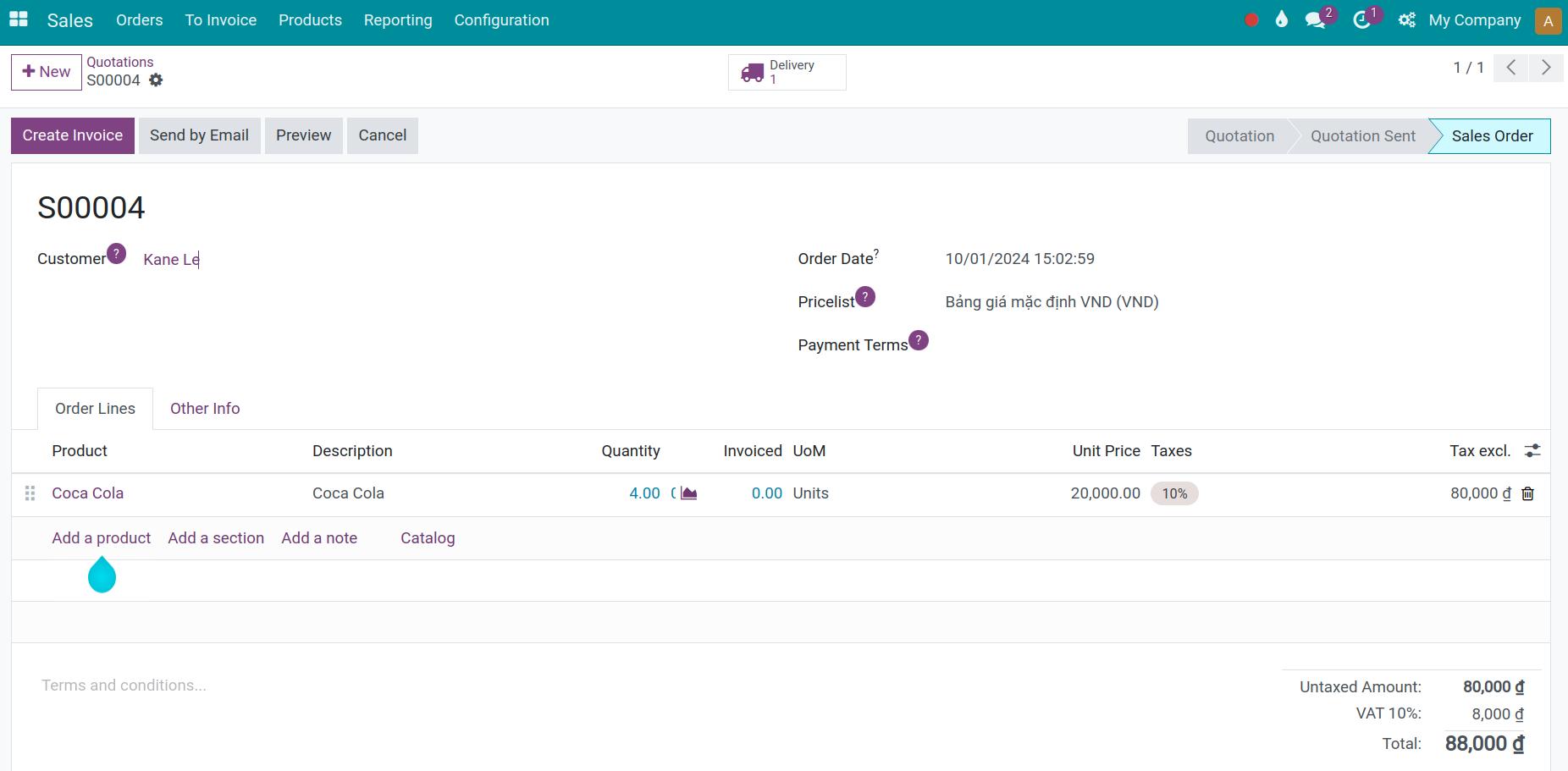

A customer purchased 4 bottles today. That makes the inventory after-sale drop to 11 bottles.

Now, the software will generate a draft purchase order with the quantity that satisfied the reordering rule. In our example, the purchased quantity will be 30 bottles, in which:

Rule 1: Guarantee the max quantity = 36 - 11 = 25 bottles.

Rule 2: Guarantee the purchasing quantity is the multiples of 6 according to the setup in the reordering rule.

See also

Related article

Optional module