Track your products with serial numbers¶

The serial number is a unique code that identifies a specific product, allowing to track its transfer history and post-sale activities. Viindoo software allows you to manage and track products with serial numbers with ease.

Requirements

This tutorial requires the installation of the following applications/modules:

Configure inventory management by serial numbers¶

Application configuration¶

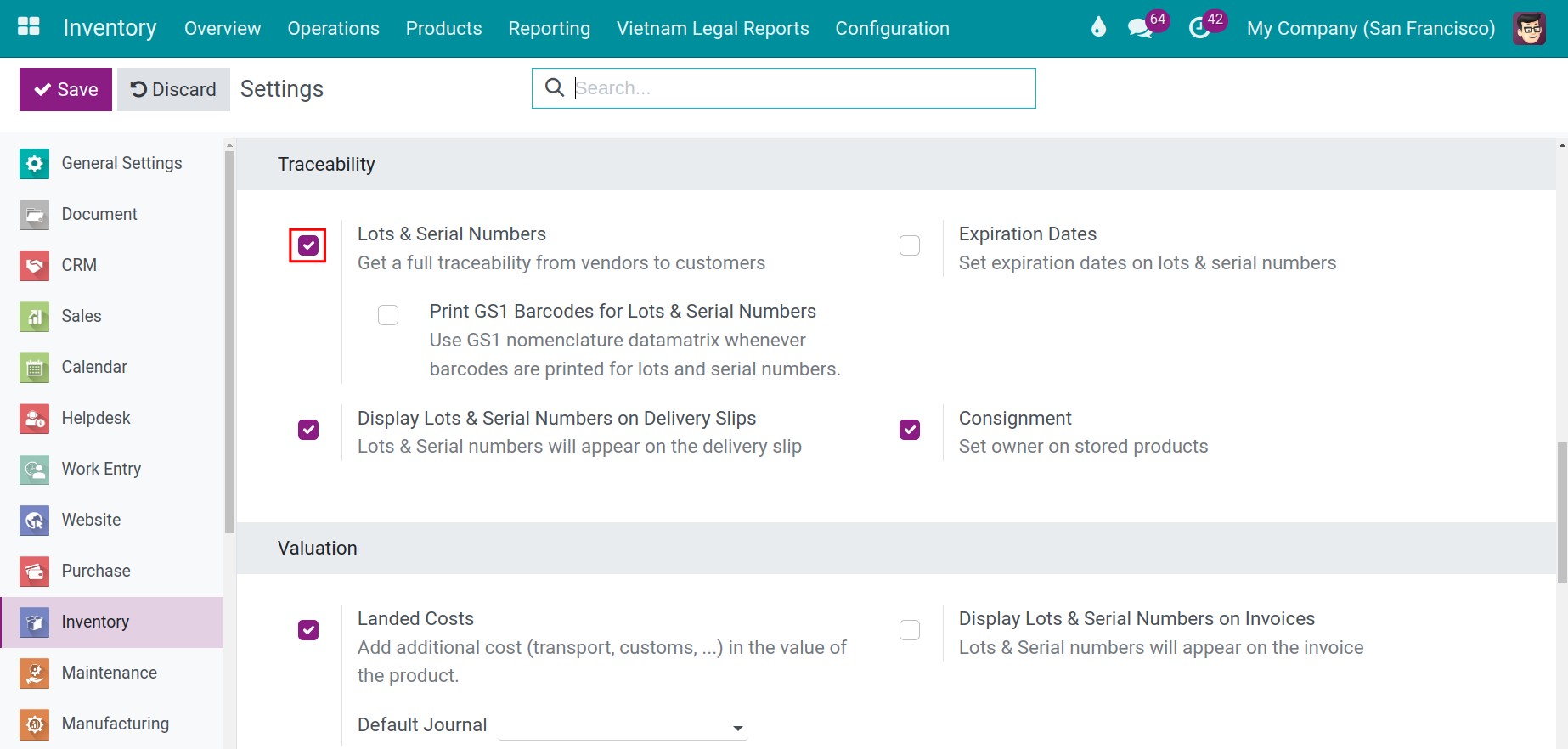

To configure Inventory management software by serial numbers, you need to navigate to Inventory > Configuration > Settings > Traceability. After that, activate the Lots & Serial Numbers feature and click Save.

Product configuration¶

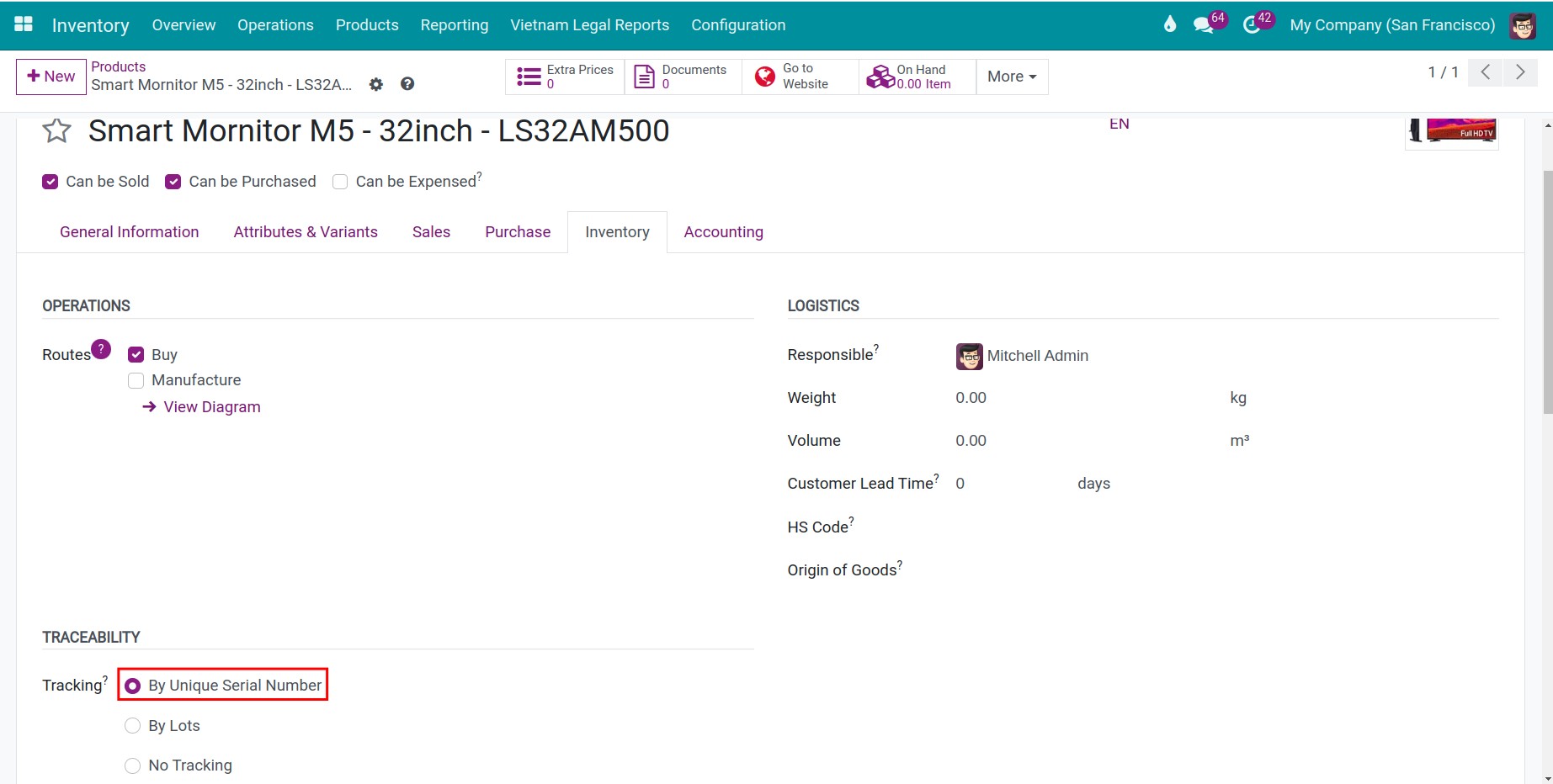

To manage goods by serial numbers, you need to activate the serial number tracking feature on products by navigating to Inventory > Products > Products and opening the product you want to configure, and then select tracking By Unique Serial Number at the Inventory tab. Next, click Save to save the settings.

See also

Manage Serial numbers¶

Receipts¶

To stock a product traced by serial number, you need to specify its serial number by:

Assigning serial numbers manually;

Multi-assigning serial numbers;

Copying and assigning serial numbers from an Excel file.

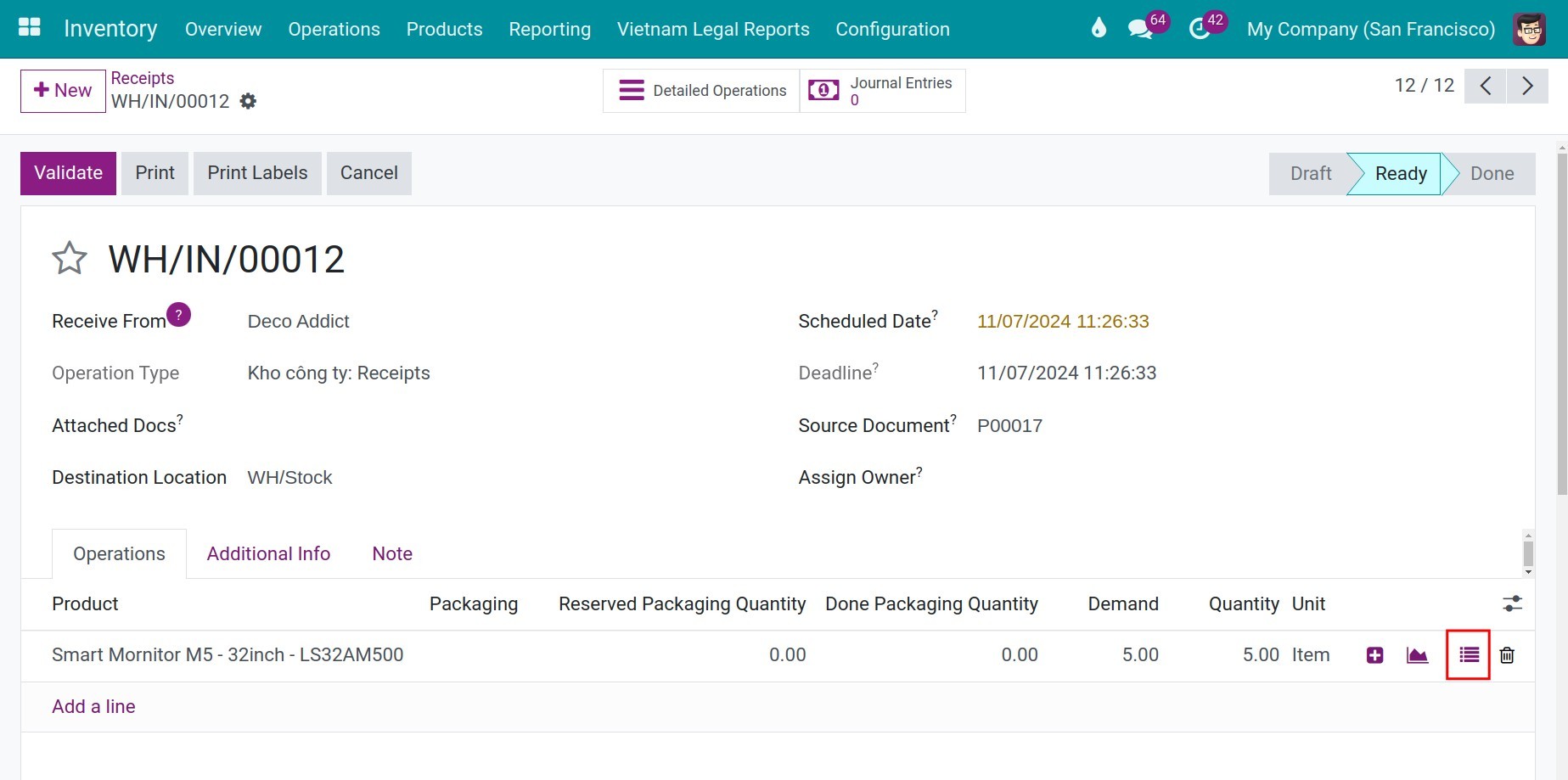

First, you need to open the details operations of the receipt slip:

Below are details on how to assign serial numbers to products.

Manually assign different serial numbers¶

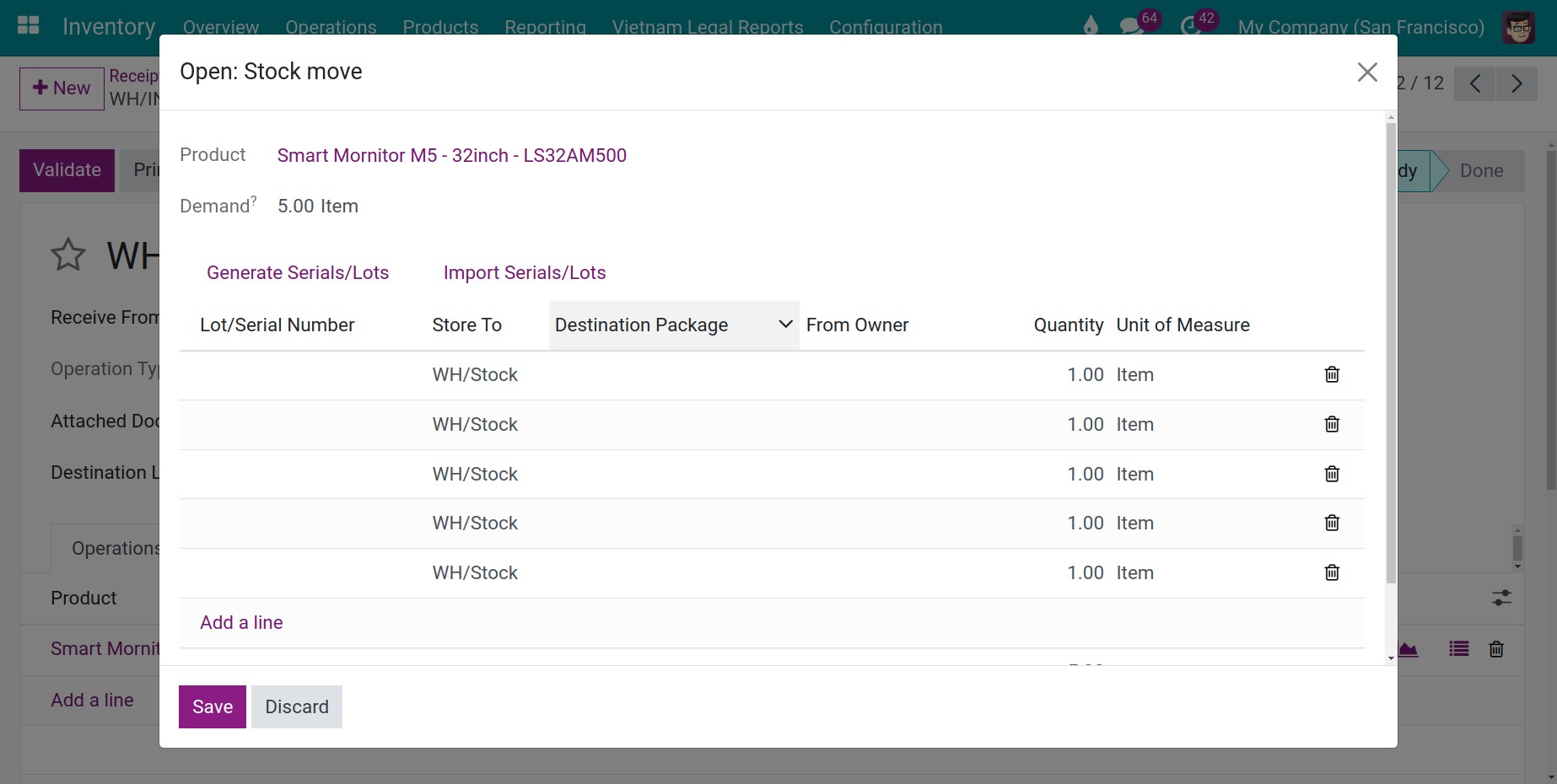

You click 4-line icon, then press Add a line to enter the product’s serial number in Lot/Serial Number field. You can keep doing that until you have entered all the serial numbers.

Multi-assign serial numbers¶

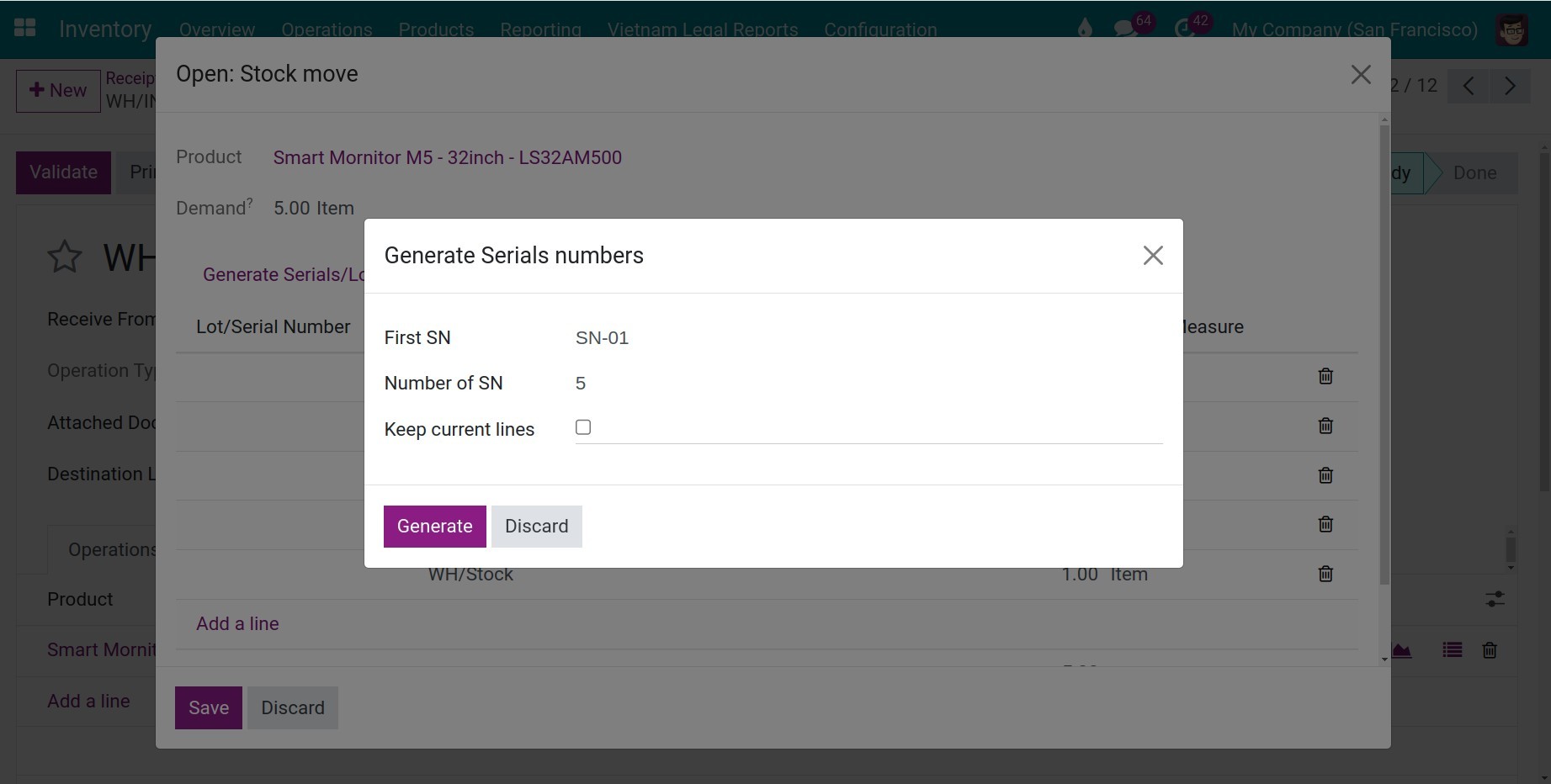

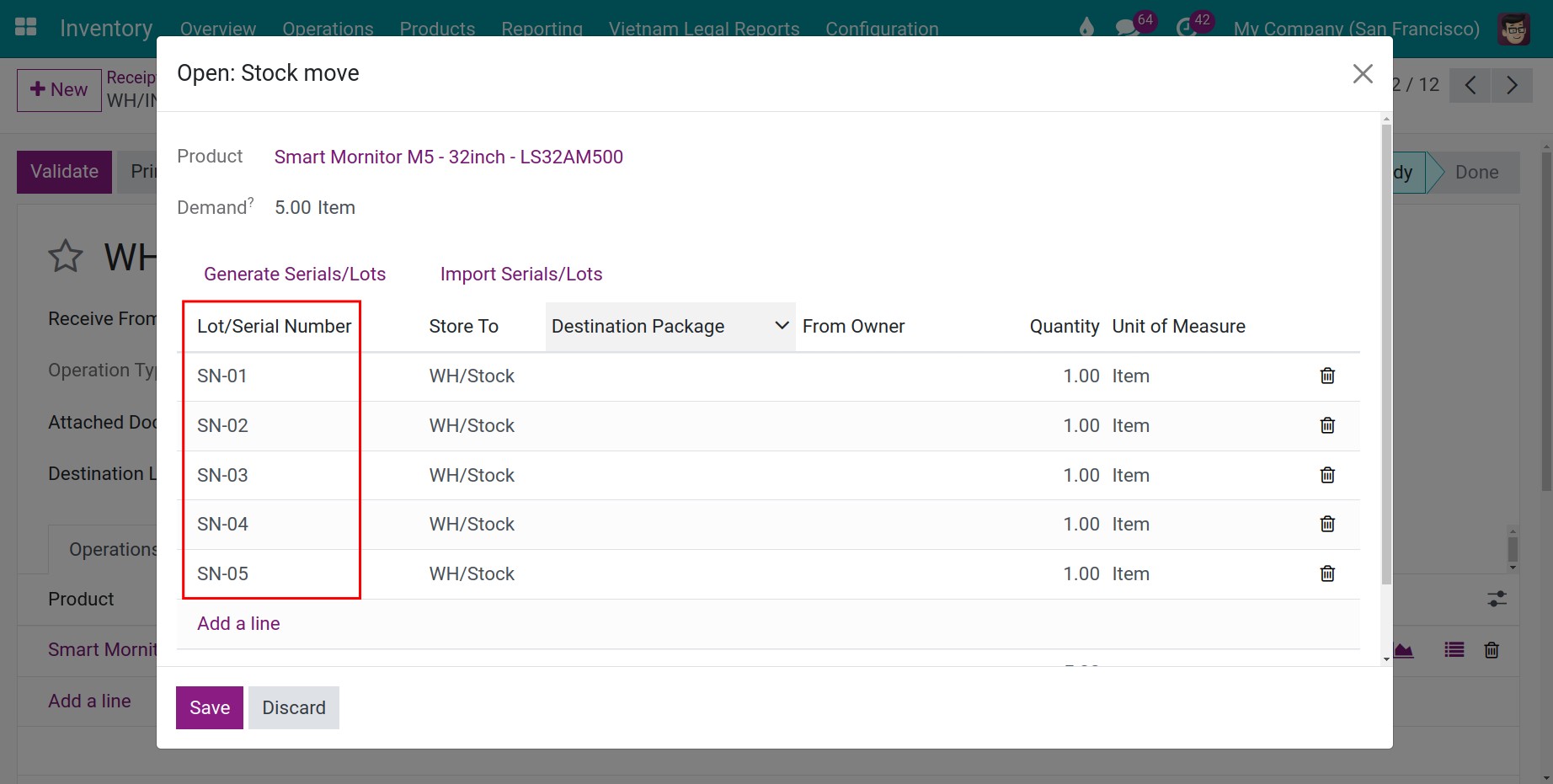

To assign multiple serial numbers, you need to lick Generate Serial/Lots button, and enter the starting serial number in First SN and the number of products you want to assign in Number of SN. After entering the above data, click Generate.

The system will automatically generate serial numbers in order based on the first serial number and assign them to the products.

Note

With this input method, there should be at least 1 number anywhere in the serial code. The purpose is for the system to automatically increment by that number.

You can select the Keep current lines feature if you want to set up new products with a specified serial number.

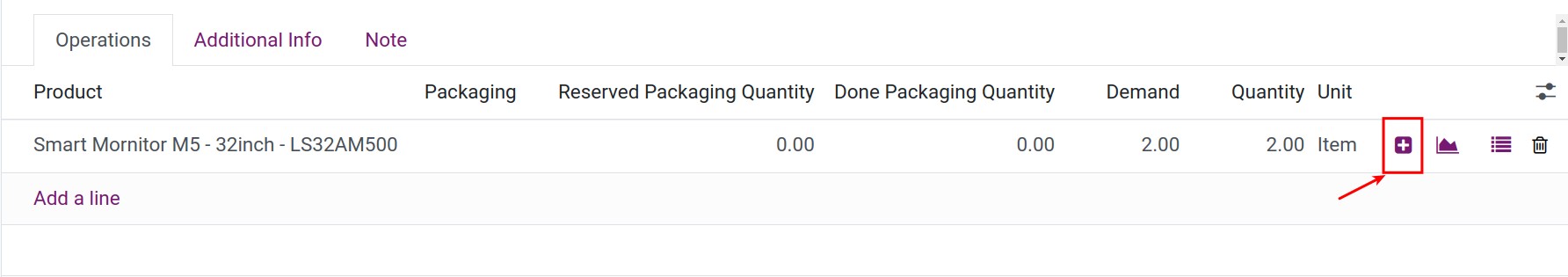

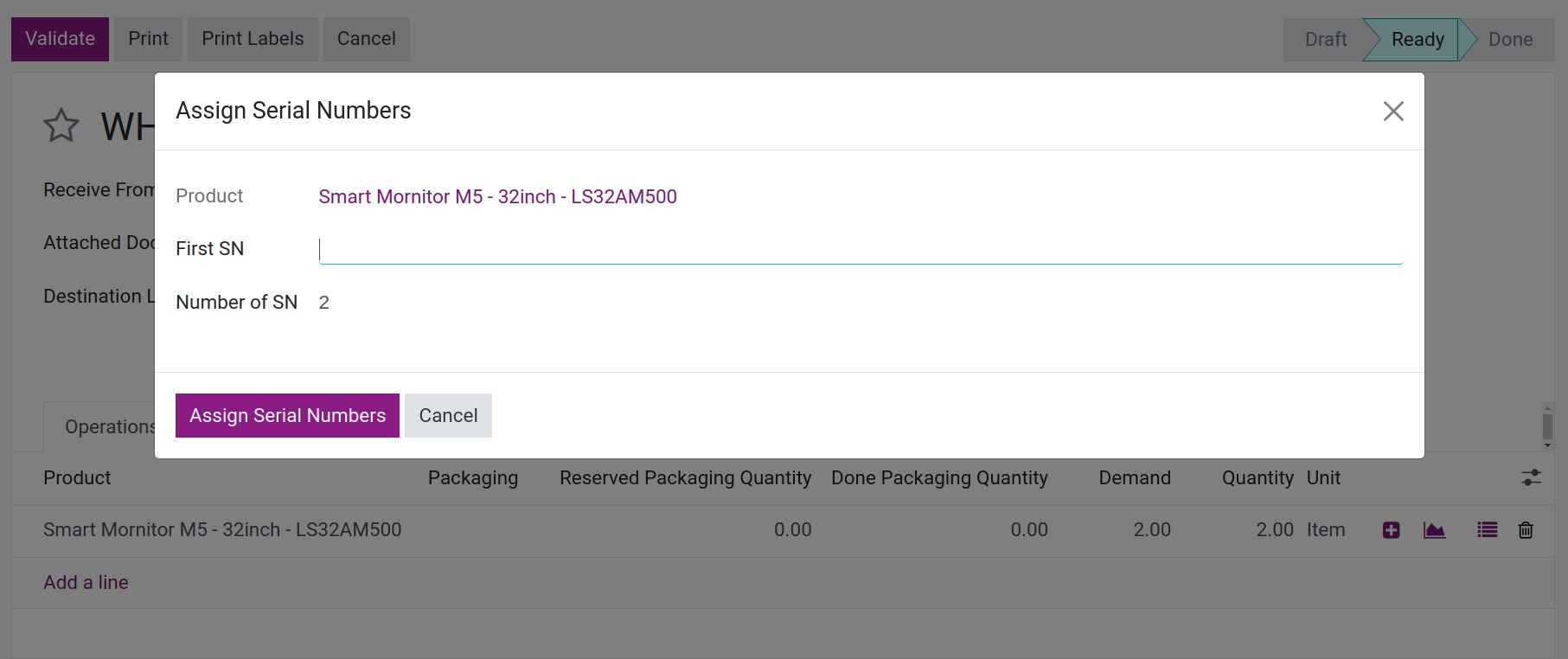

On the other hand, if you don’t want the pop-up window to appear, you can quickly proceed by clicking the + icon. Then, type the starting serial number in First SN line and click the Assign Serial Number button. However, you should use this method only when receiving a small quantity of products. This is because you are more likely to need to verify the product’s serial numbers when dealing with a large quantity of products.

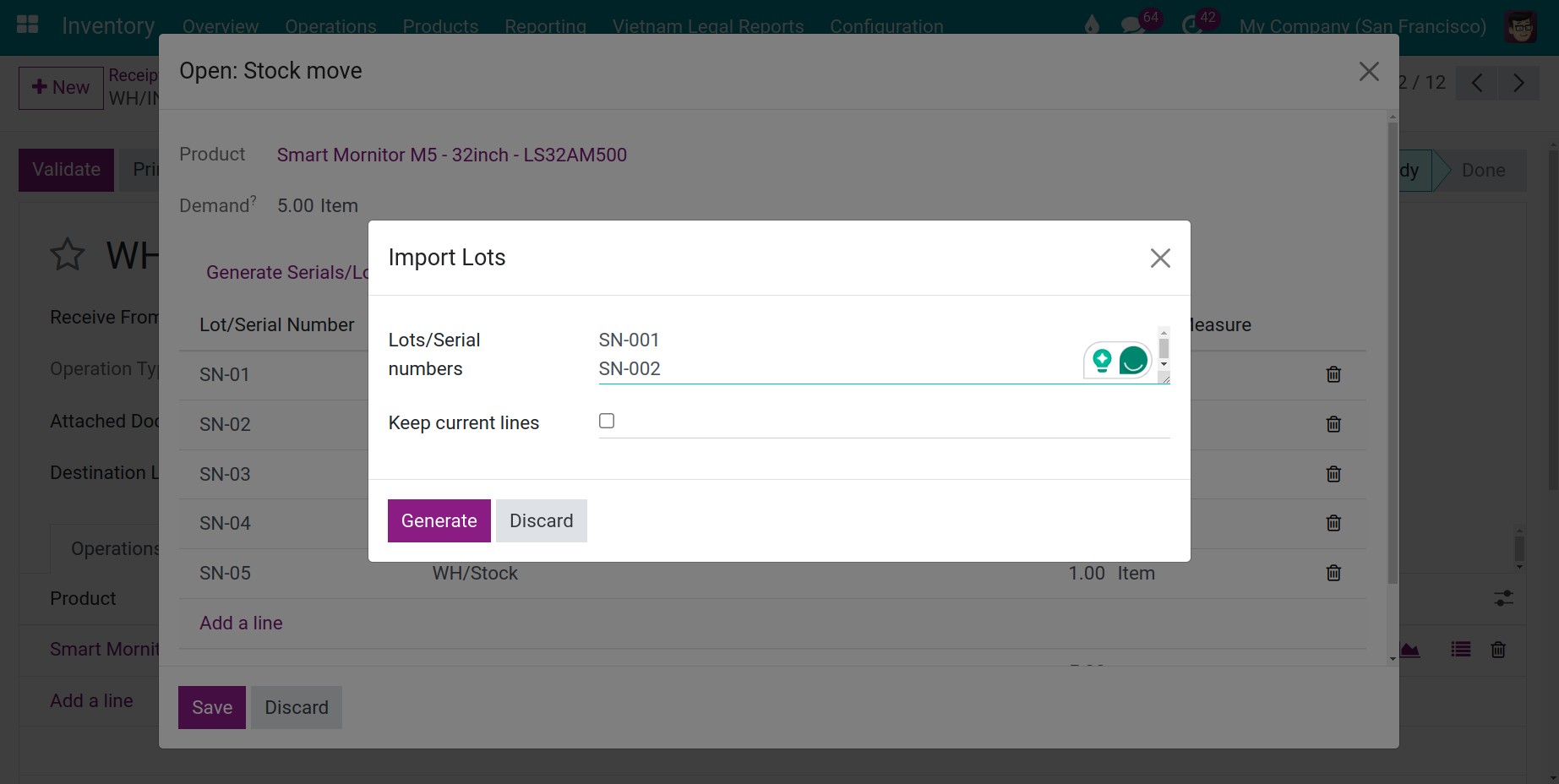

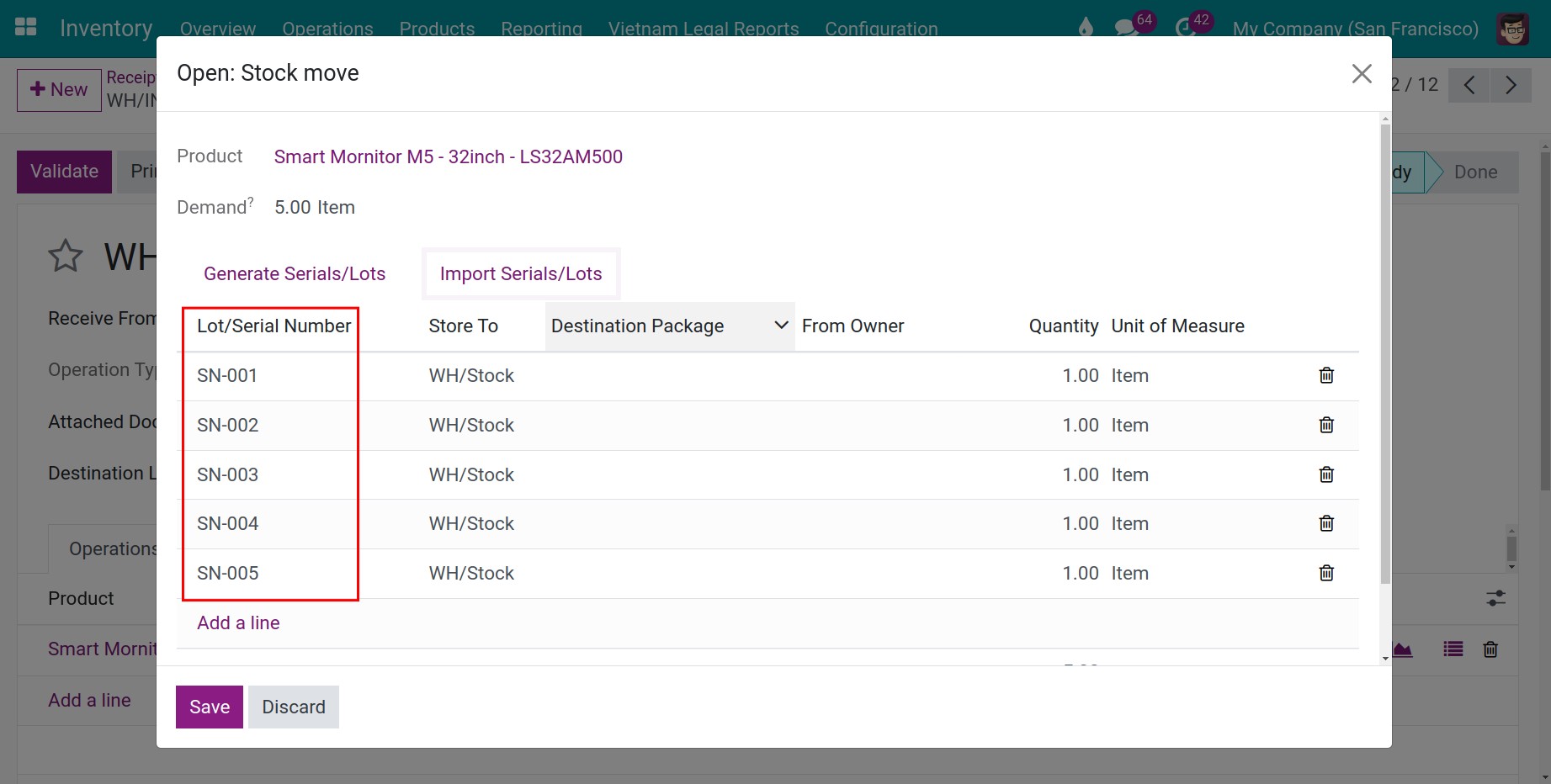

Copy and paste serial numbers from an Excel file¶

To copy and paste serial numbers, you open the sheet containing the serial numbers you want to import and copy the list. Then, paste the copied numbers into the Lot/Serial Number column.

The system will automatically create the lines you need.

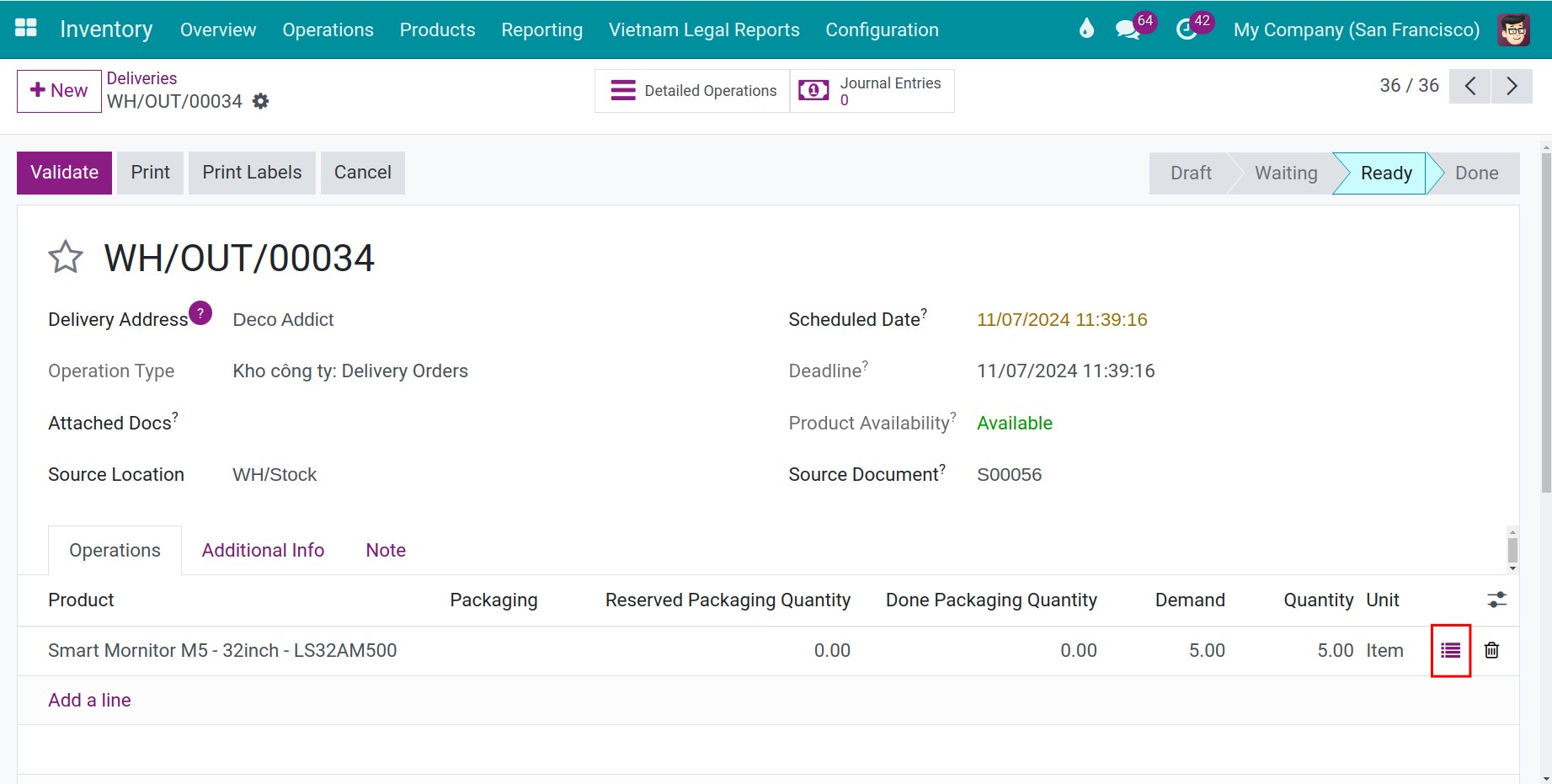

Delivery¶

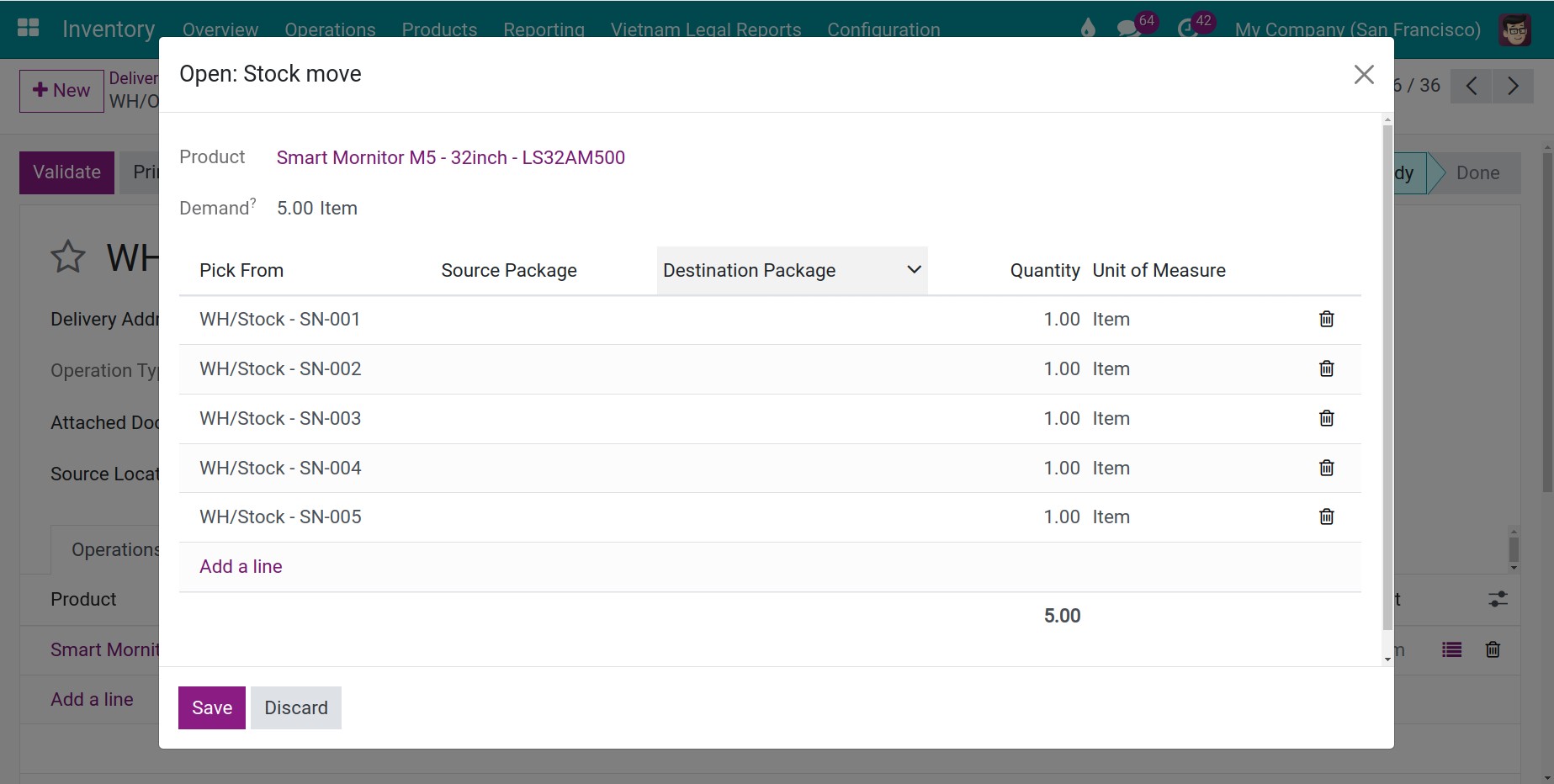

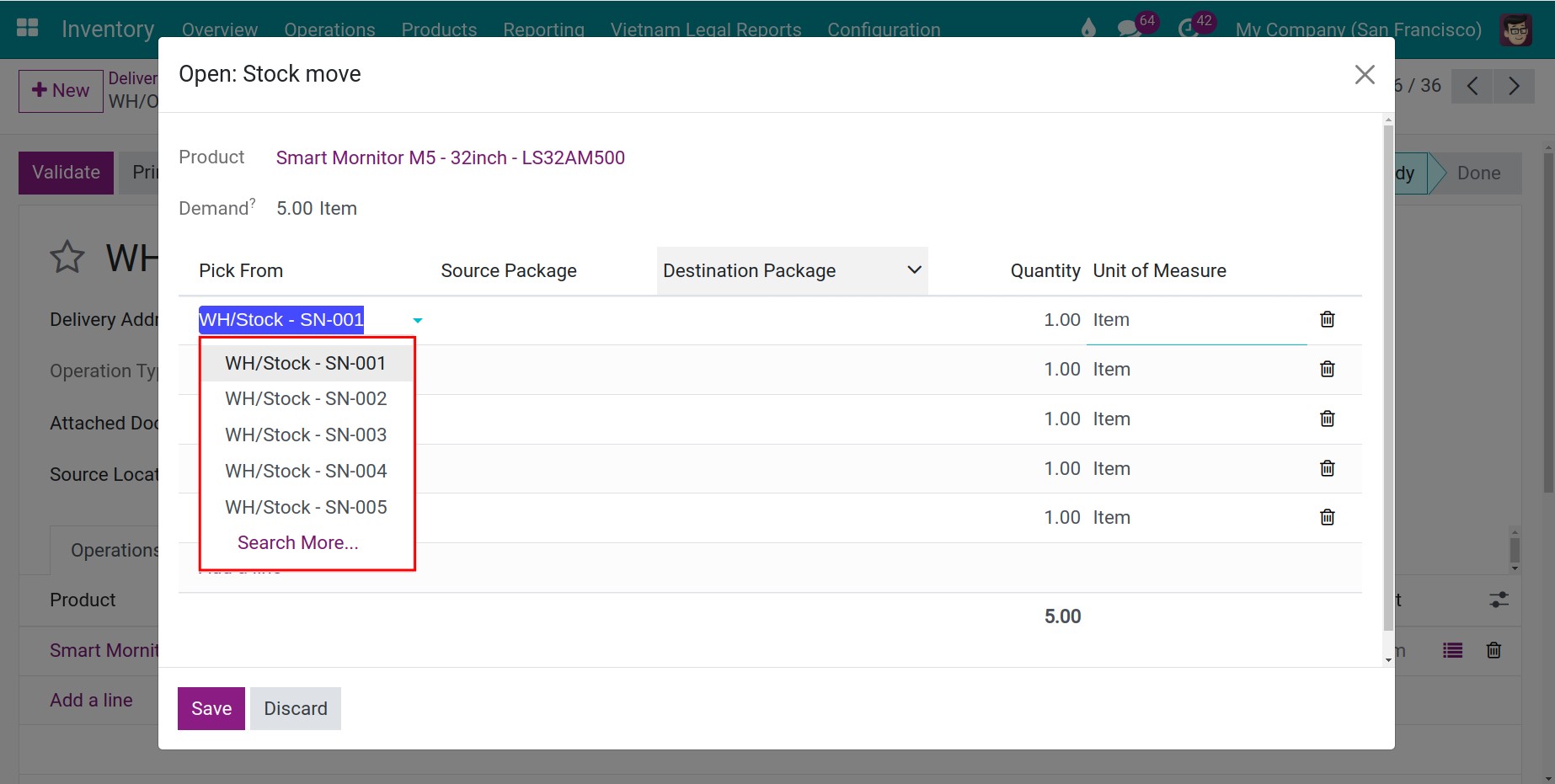

In order to track the serial number of the product upon the delivery, you click on the 5-line icon to open the Detailed Operations window at the delivery slip.

Here the system suggested products with corresponding serial numbers according to the Removal Strategy set up on the Product Categories.

In case you want to select products with certain serial numbers to deliver, you can change the serial numbers right at this interface.

Serial number traceability¶

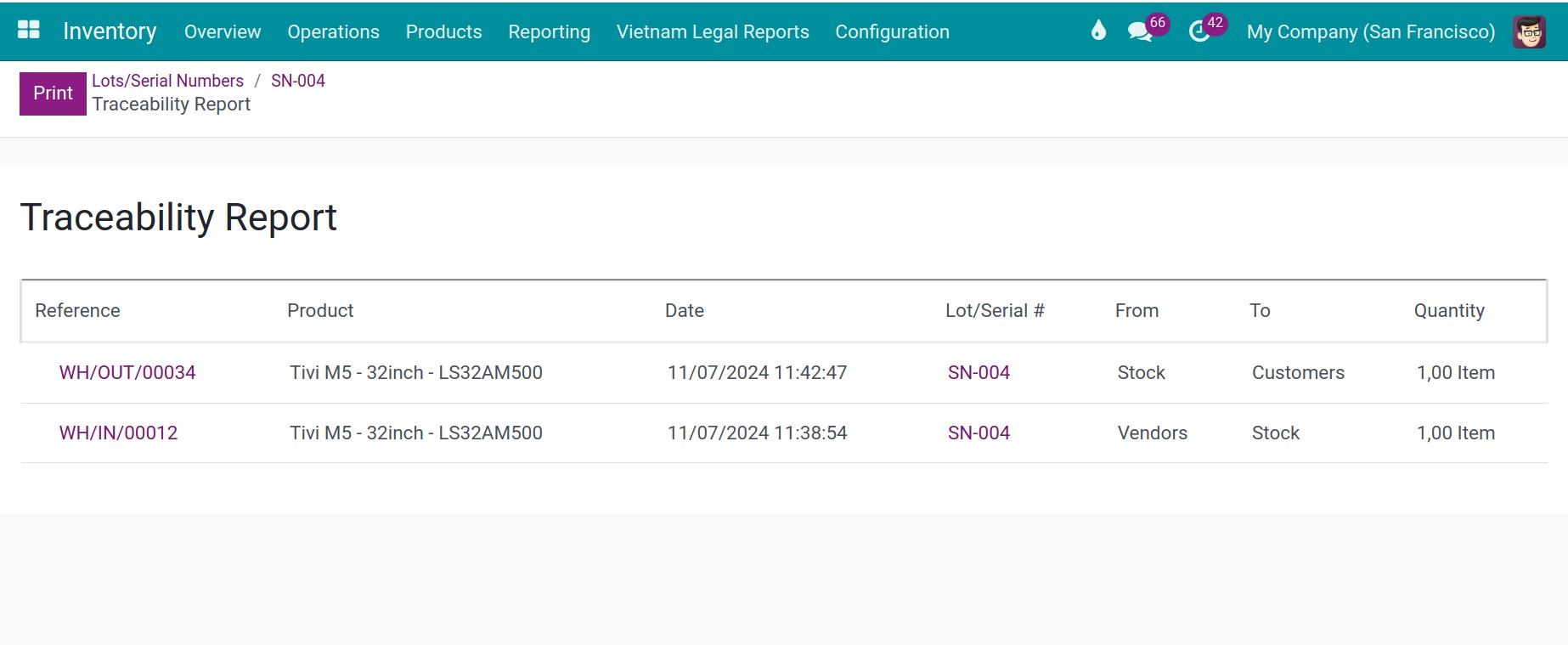

After configuring Viindoo inventory management software, you can easily trace back the product’s origin based on its serial number information.

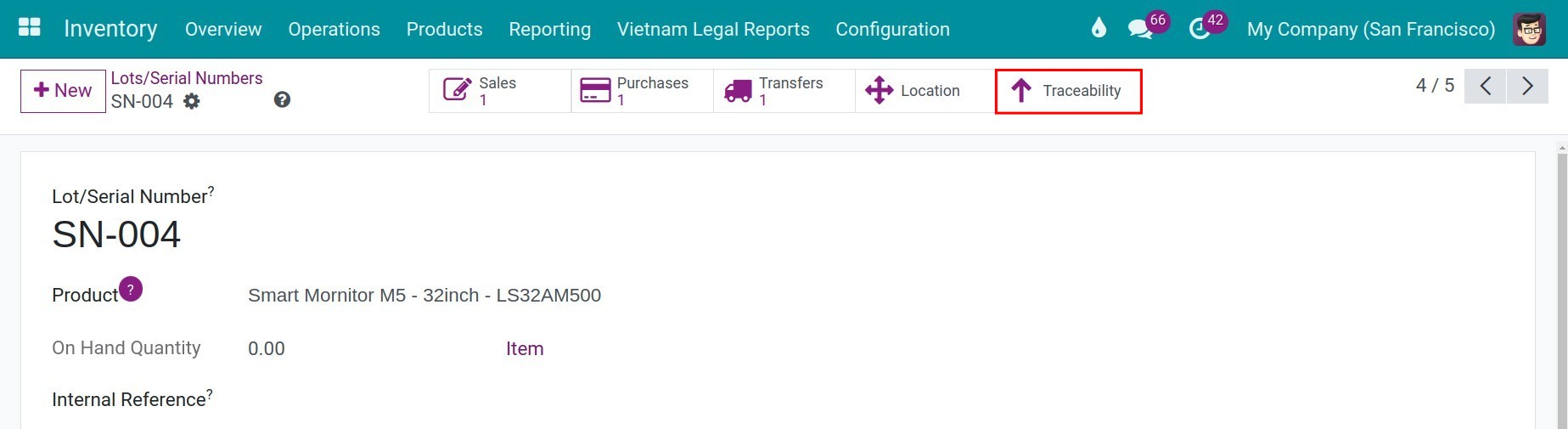

You can trace products by navigating to Inventory > Products > Lots/Serial Numbers and tapping on the corresponding serial number. Then, open Traceability. You will see the serial number information used here.

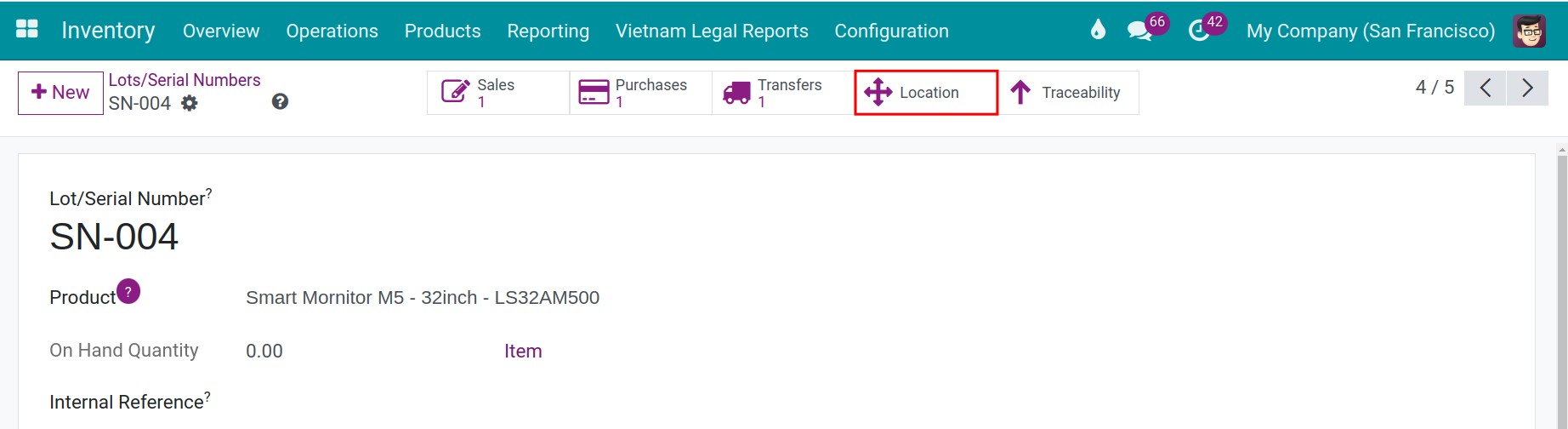

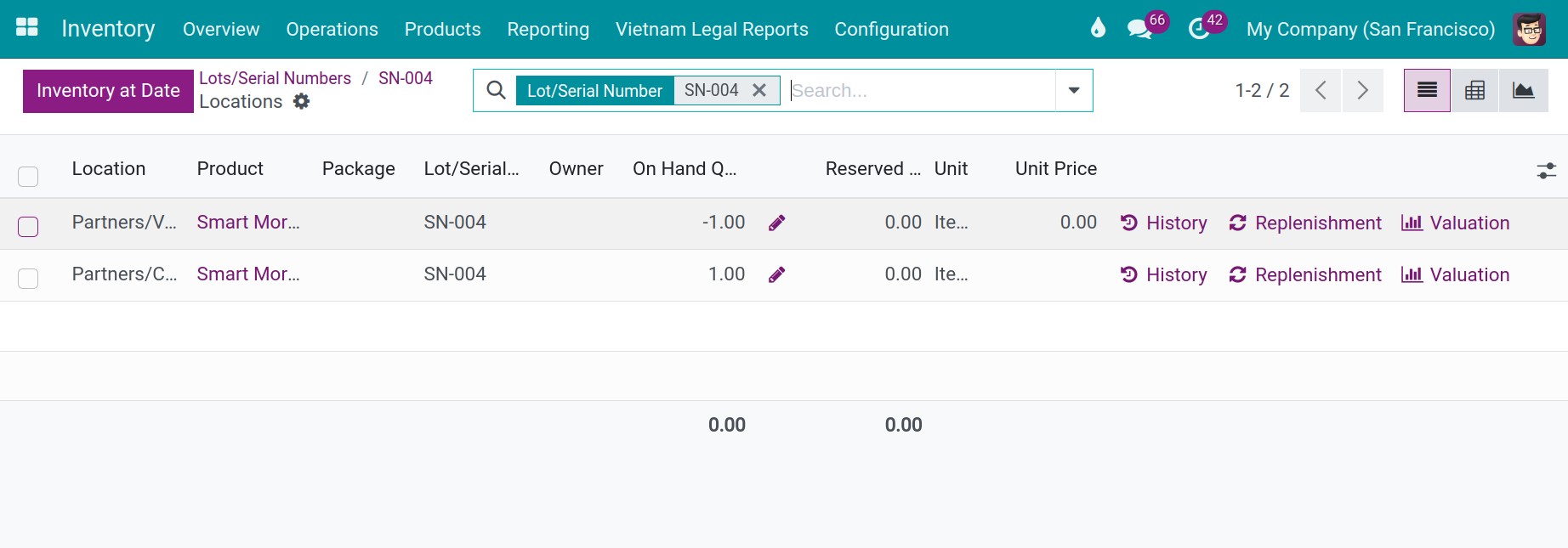

To be informed of the product’s location and stock quantity, you can click the Location button on the right corner of the serial number view.

The software will list the inventory location with the quantity corresponding to each serial number.

Tip

Providing serial numbers for every product is a time-consuming task. This should be used for items with warranties, after-sales services, asset management, etc. On the contrary, assigning serial numbers on toilet paper, and pens will not make sense.

Operation types¶

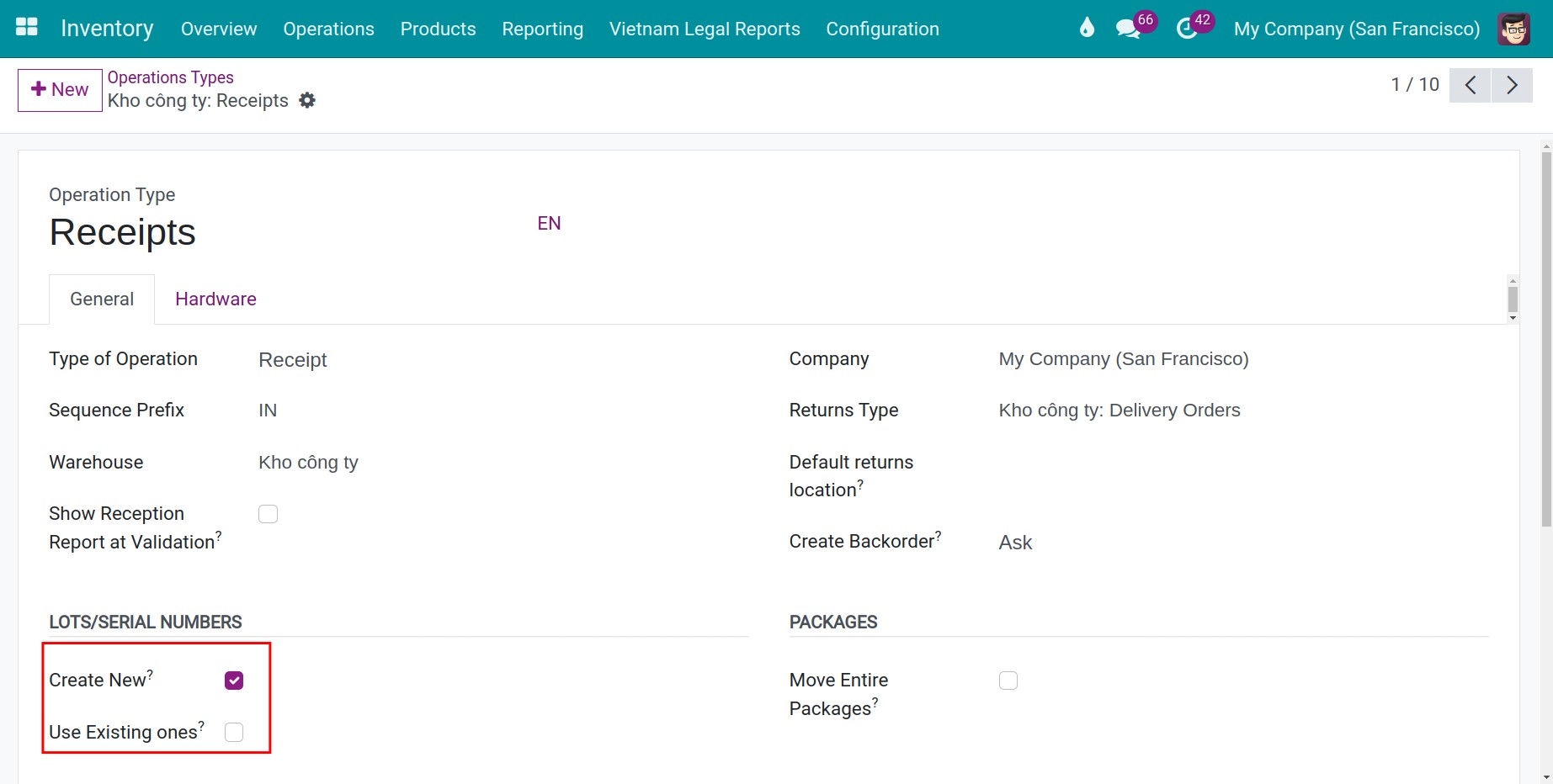

Create New Lots/Serial Numbers: If enabled, when you receive goods in stock, you will be allowed to create new serial numbers.

Use Existing Lots/Serial Numbers: If enabled, when you receive goods in stock, you can reuse the existing serial numbers in the system and can’t create new ones.

To set these options, go to Configuration > Operation Types in Inventory app.

For each type, you can create a new one or use an existing serial number. By default, the system selects to create a new serial number with the receiving operation type.

Tip

Create New Lots/Serial Numbers: Usually used in receiving or production operations.

Use Existing Lots/Serial Numbers: Usually used when transferring internally, delivery.

See also

Related Article

Optional Module