Manage Semi-Finished Product in Manufacturing process¶

In reality, each manufacturing process goes through multiple stages. Between those stages, semi-finished products are created and used as input for the next stage. In Viindoo’s enterprise management software, these are referred to as Semi-finished product.

In this article, we will guide you on how to manage Semi-finished products within a complex manufacturing process.

Requirements

This tutorial requires the installation of the following applications/modules:

Configuration for the Semi-finished product¶

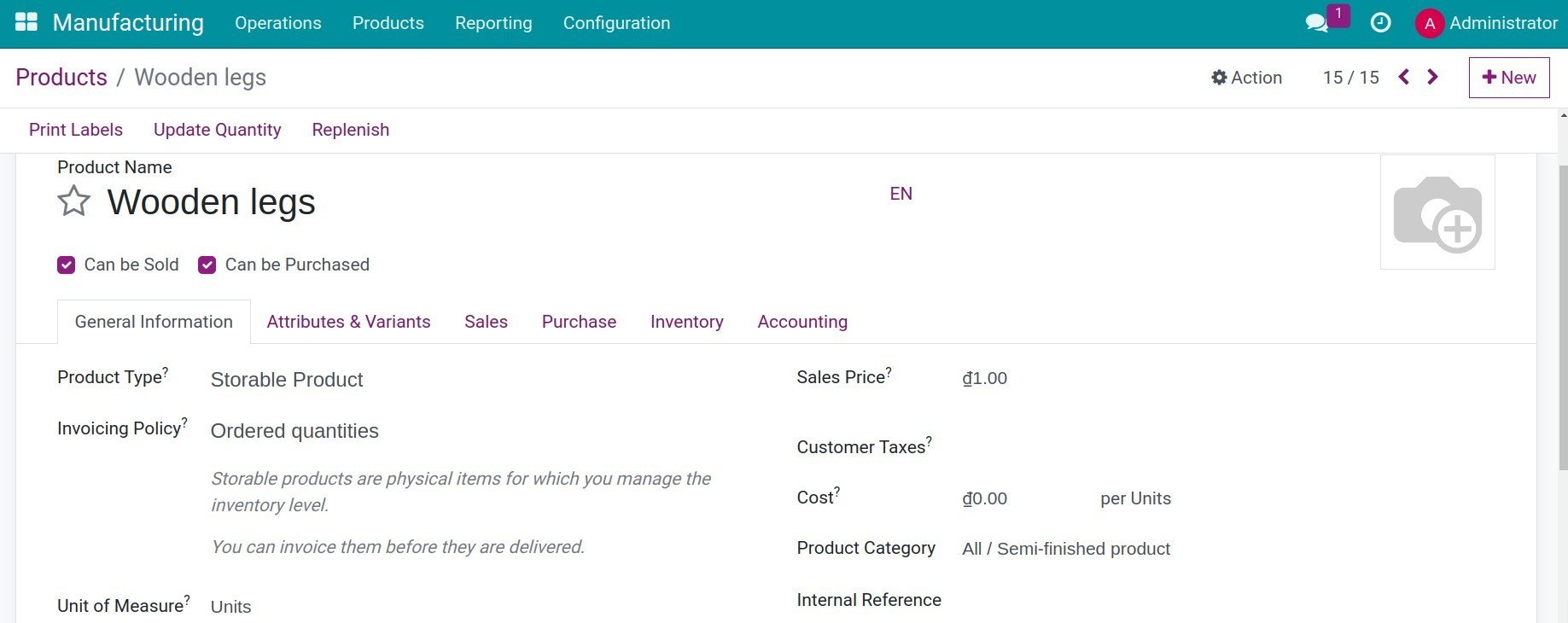

Access the Manufacturing application > Products > Products, click on the New button to create a product. Configure it as follows:

General Information tab:

Product Type: select Storable Product

Product Category: create a Product Category for Semi-finished products to configure Inventory Valuation rules and account properties.

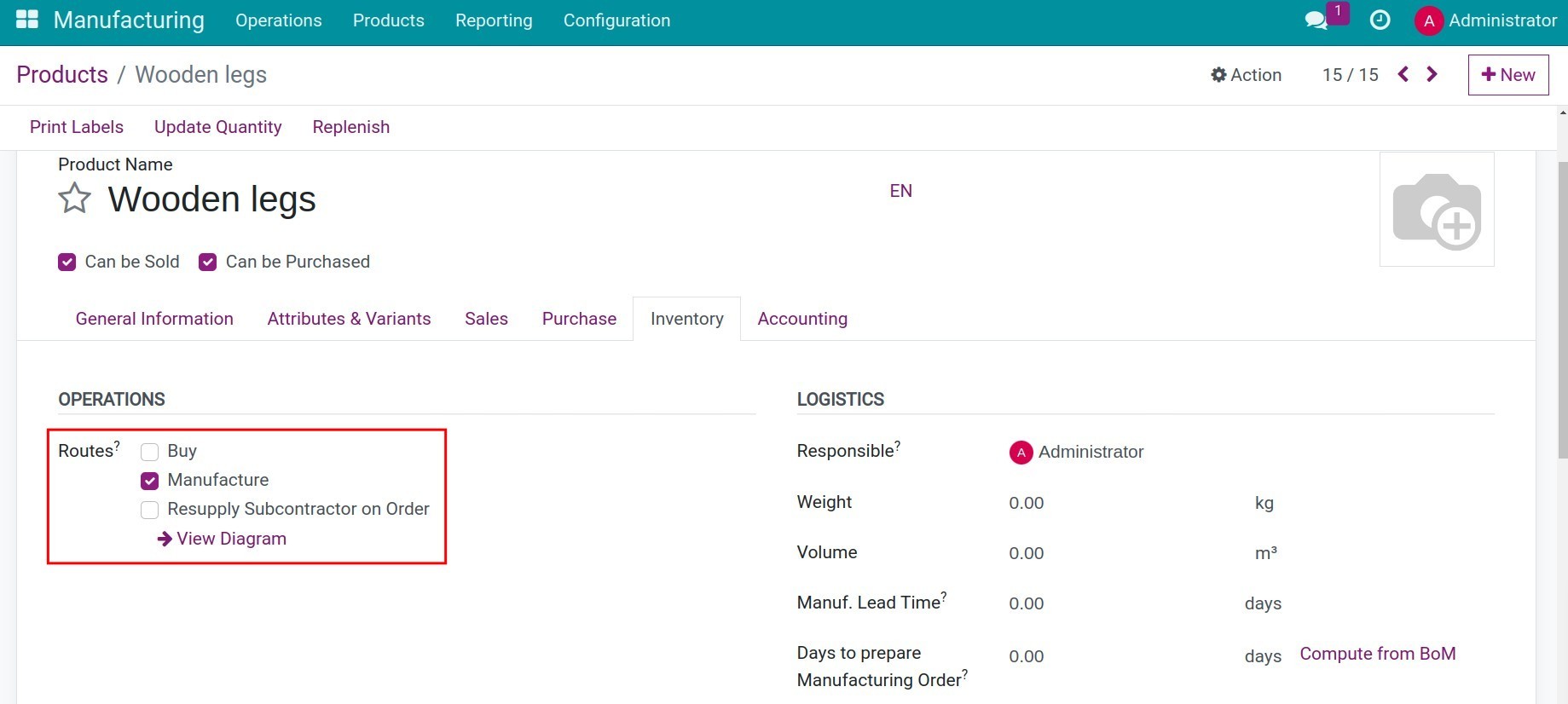

Inventory tab:

Routes: select Manufacture

Note

Depending on the manufacturing planning (Make-to-orders or Make-to-stock), additional supply routes can be activated, such as MTO) routes, inter-warehouse supply routes, etc.

Configuring the Bill of Materials (BoM) for Semi-finished product¶

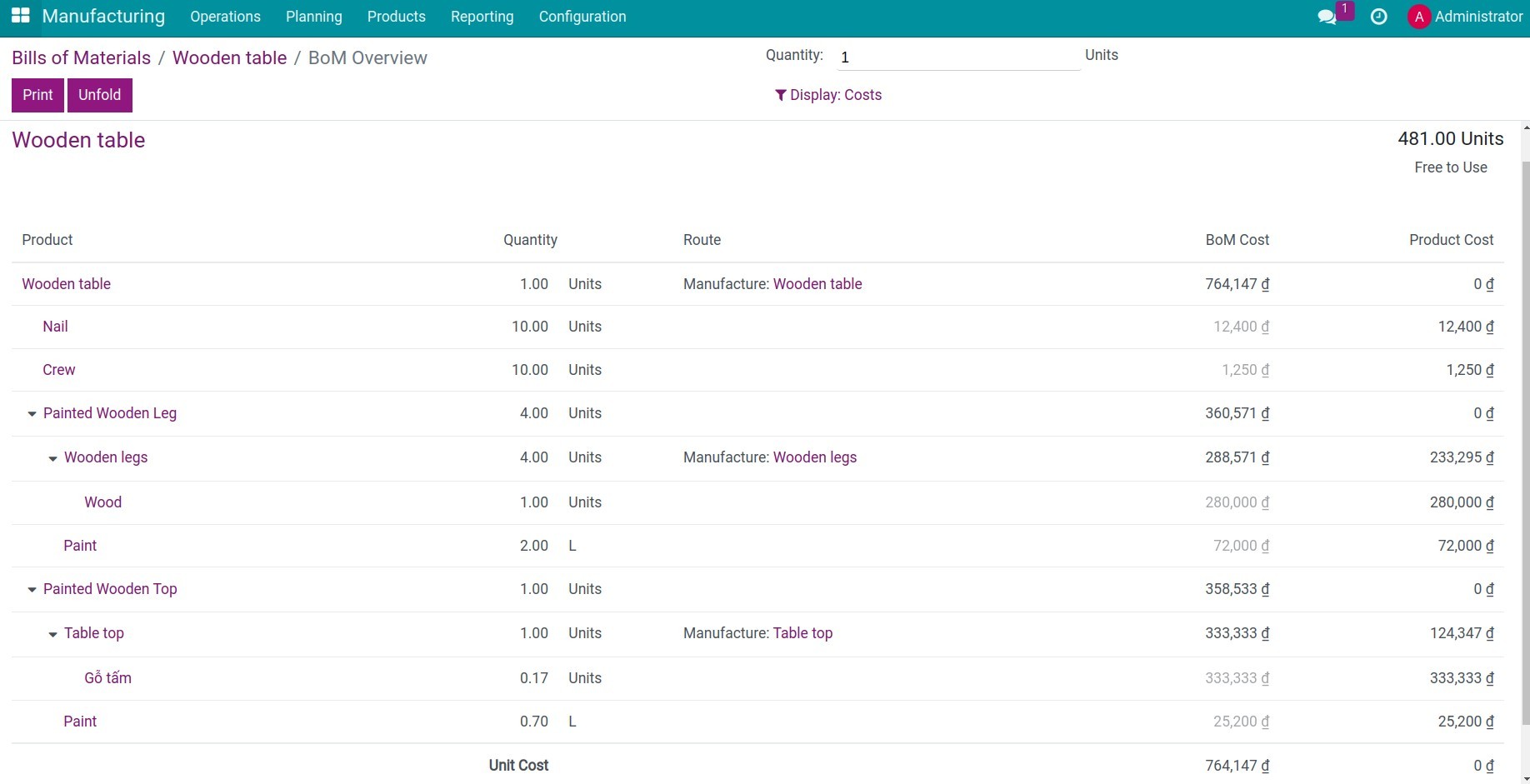

To better understand how to set up a Bill of Materials (BoM) for Semi-finished products, let’s analyze the following example:

The raw material Wooden Plank is used to produce Table Leg, while the raw material Wooden Board is used to produce Table Top.

The Semi-finished product Painted Table Leg is created by combining the Semi-finished product Table Leg and Paint. The Semi-finished product Painted Table Top is created by combining the Semi-finished product Table Top and Paint.

The Semi-finished product Painted Table Top, Painted Table Leg, along with Nail and Screw, are used to manufacture a Wooden Table.

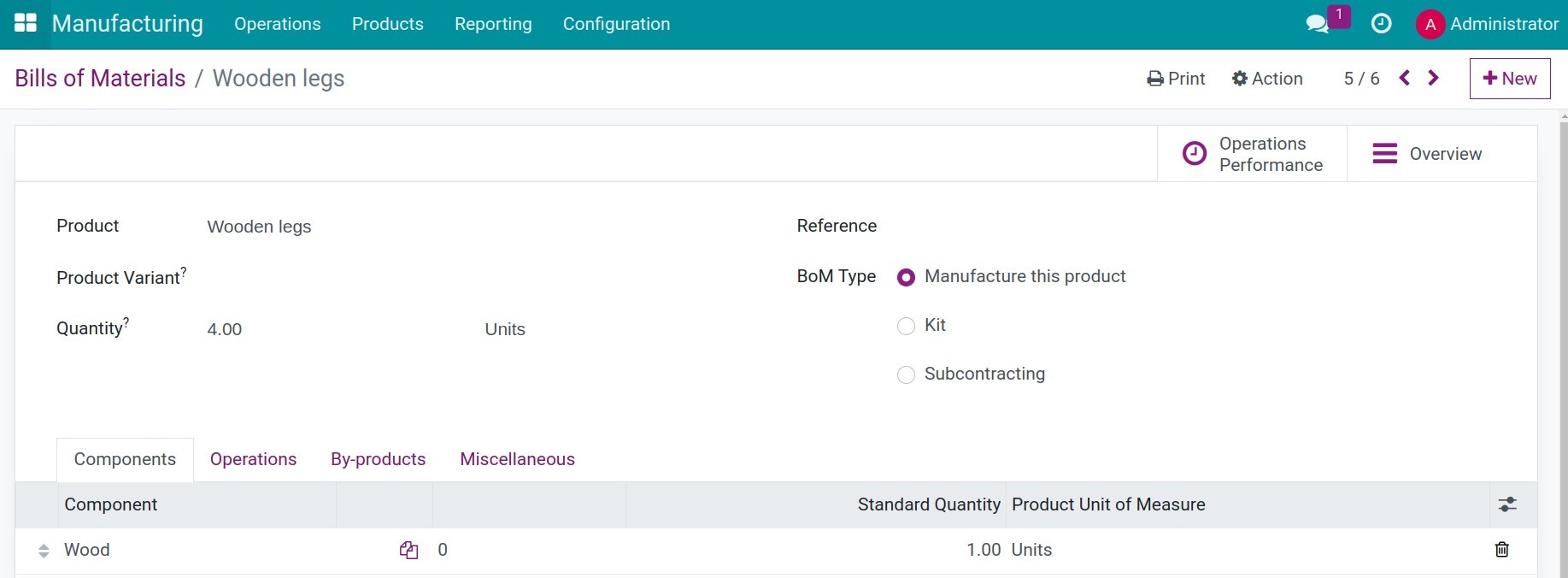

First, access the Manufacturing application > Products > Bill of Materials, create a Bill of Materials and configure it as follows:

General Information:

Product: select Semi-finished product in manufacturing

BoM Type: select Manufacture this product

Components tab:

Component: select their components. It can be raw materials or other semi-finished products from the previous stage.

Standard Quantity: Quantity of raw materials to be consumed.

Similarly, create the Bill of Materials for the Semi-finished products Table Top, Painted Table Leg, Painted Table Top, and the Finished product Wooden Table.

Afterward, open the Bill of Materials for the Wooden Table, click on the Overview button, and you will be able to view the complete breakdown of the materials required to produce the final finished product.

Manage the manufacturing of the semi-finished products¶

Based on the actual manufacturing process, manufacturing orders for Semi-finished products can be created in the following ways:

Proactively creating manufacturing orders when there is an urgent demand for Semi-finished products;

Automatically generated to ensure the Minimum/Maximum Inventory Rule (MTS);

Automatically generated when executing Make-to-Order (MTO) production;

Automatically generated when executing production according to the Master Production Schedule (MPS).

See also

Optional module