Introduction to Subcontracting in Viindoo¶

Subcontracting is a common operation in manufacturing enterprises. In which, the manufacturer sends portion or the entirety of necessary materials (which can be raw materials or semi-finished products) to a subcontractor who then takes care of a part or all of the manufacturing process.

Viindoo All-in-one Enterprise Management Software provides tools to support businesses in managing the subcontract operations efficiently with following features:

Create subcontracting requests from Manufacturing Orders, PLM;

Approve subcontracting requests;

Manage the subcontracting process according to Vietnamese accounting standards;

Perform subcontracting settlements and generate various subcontracting accounting reports.

This article shows you how to:

Activate the Subcontract feature;

Configure component materials and Bills of materials for Subcontracted product;

Steps in the Subcontract process.

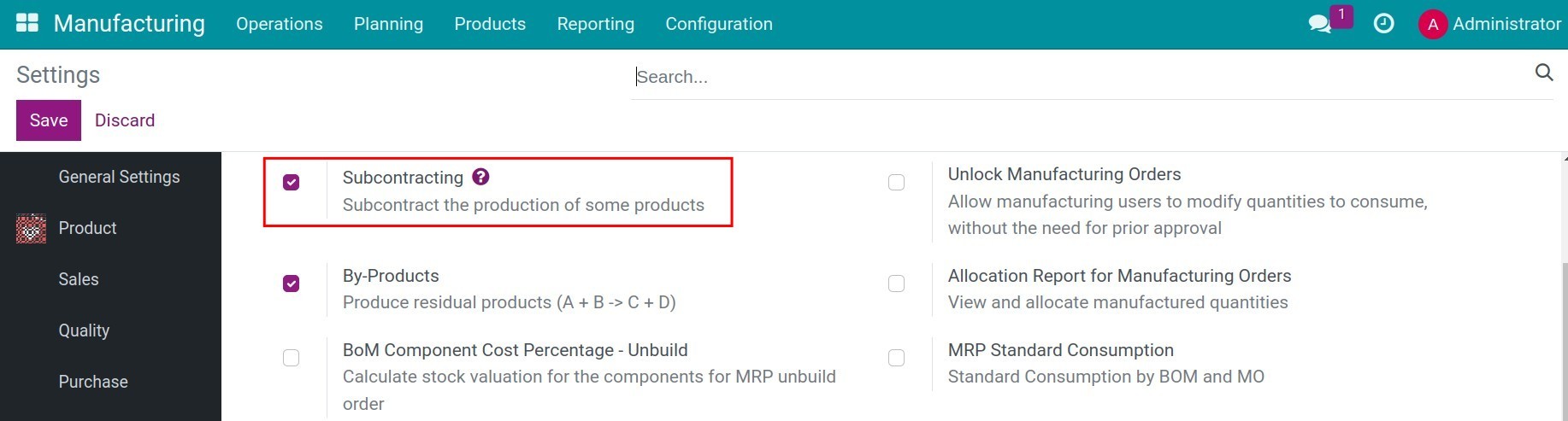

Subcontract feature activation¶

To enable the Subcontract feature, navigate to Manufacturing > Configuration > Settings, check on the Subcontracting feature and click Save button.

Subcontracted product configuration¶

Configure Accounting Accounts for the Subcontracting Process¶

First, you need to create product categories for the semi-finished and final products used in this process. Then configure the accounting accounts for these product categories accordingly. Refer to Subcontracting accounting in Viindoo to better understand and set up accounting accounts to suit your business needs.

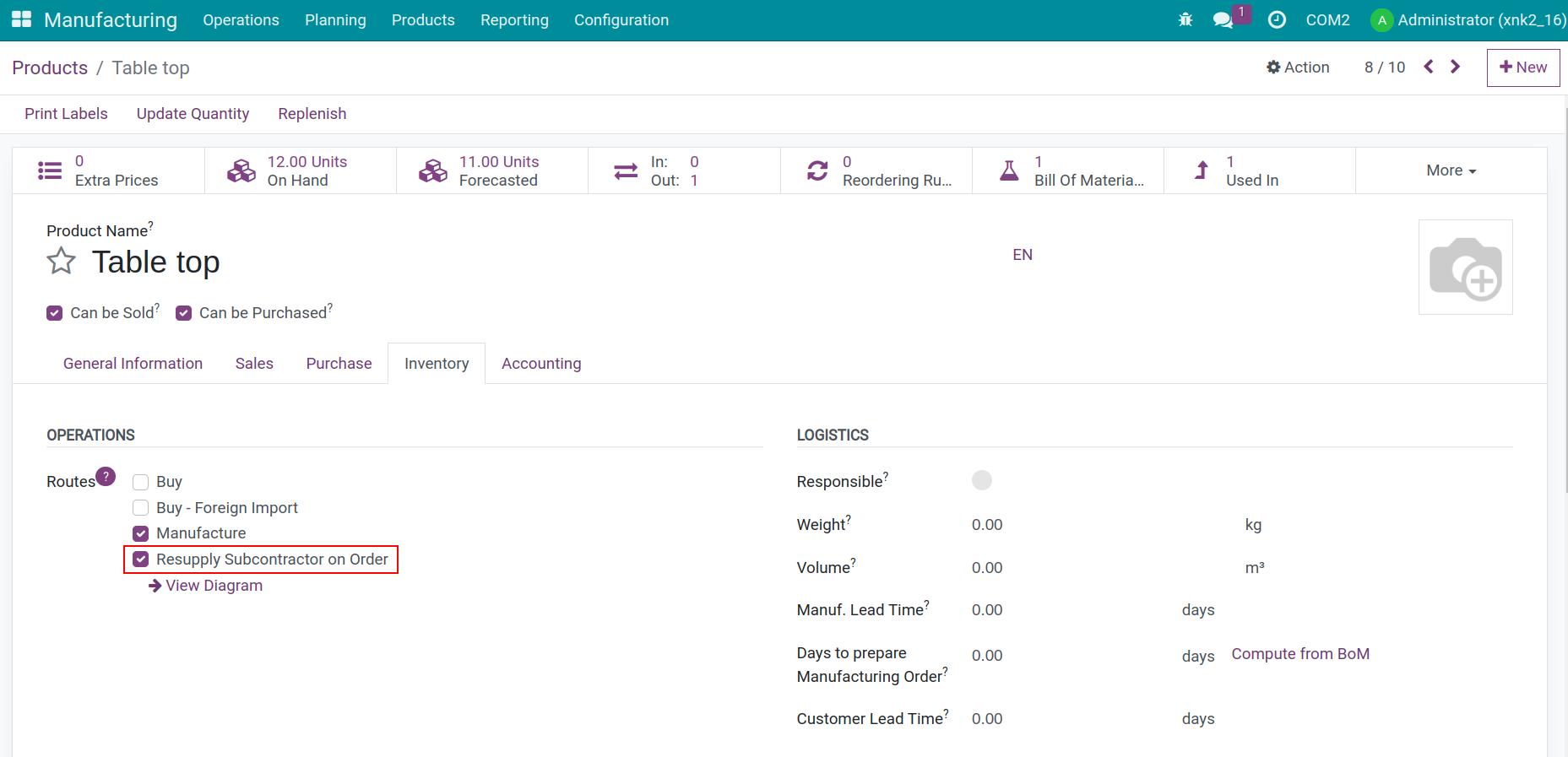

Configure component materials¶

On the Inventory tab of the products involved in the subcontracting process (includes the raw materials or semi-finished products that make up the product to be subcontracted, which will be sent to the subcontractor), activate the Resupply Subcontractor on Order routes.

For example, the product Painted Table Top, which needs to be subcontracted, has a Bill of Materials that includes:

Semi-finished product: Table Top;

Raw material: Paint.

So, the Table Top and Paint to have the Resupply Subcontractor on Order checked in the Product’s Inventory tab.

After this route is activated, Delivery Orders for sending materials will be automatically generated immediately when the manufacturer confirms the purchase order with the subcontractor.

Tip

You can also activate additional replenishment routes (make to order supply, supply based on minimum/maximum stock rule) to automatically generate subcontracting orders for subcontracted products when there is a demand from the manufacturer.

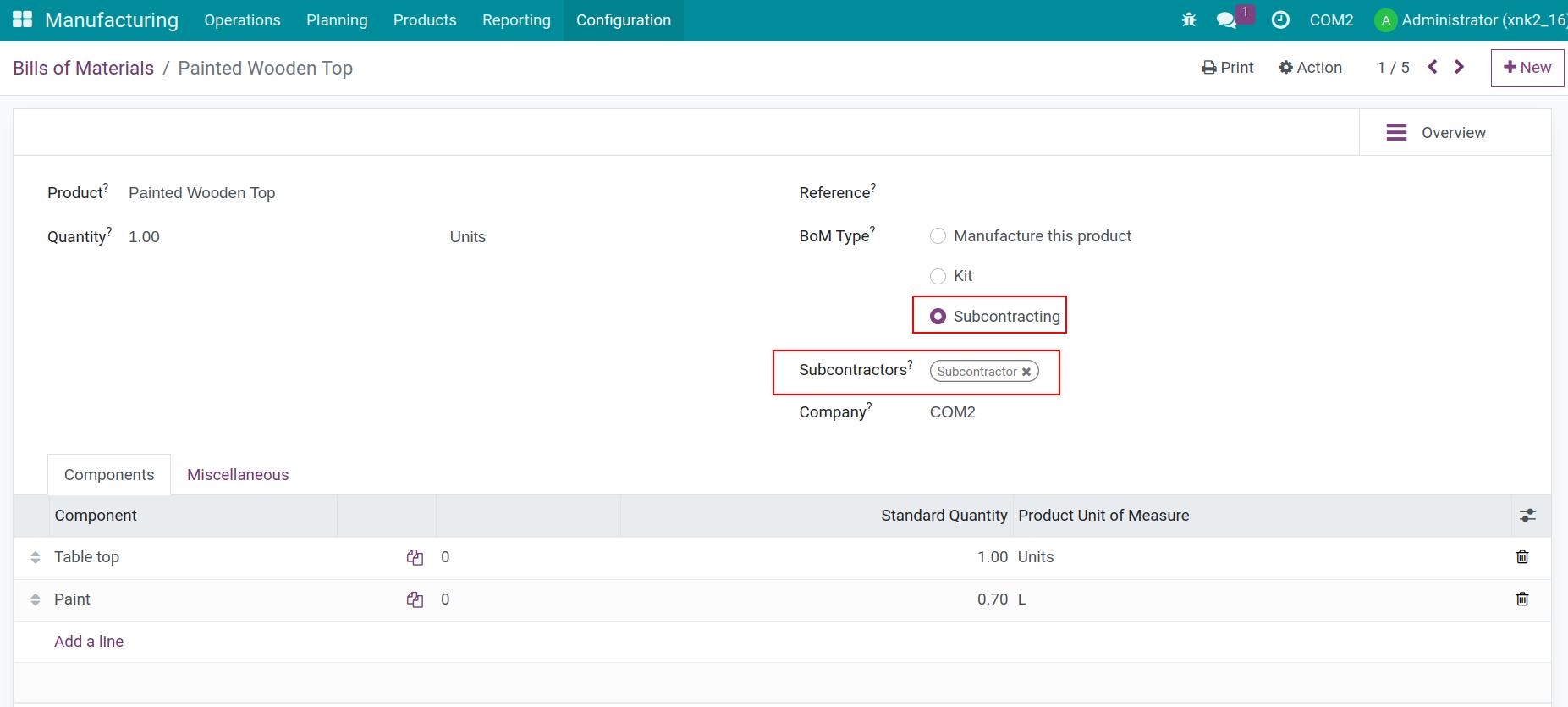

Configure the BOM for Subcontracted Products¶

For the Bill of Materials (BoM) of the subcontracted products, you need to select the BoM Type as Subcontracting and set up one or various subcontractors to produce this BoM. Then add necessary components and materials to the BoM.

Note

Since your business does not directly produce the subcontract products, there’s no need to track these production operations. Therefore, the system will not generate manufacturing orders for subcontracted products in the software.

The Materials configured in the Bill of Materials (BoM) will be the materials that your business will send to the subcontractor, without concerning the additional materials the subcontractor may require for production of the subcontracted finished goods.

Subcontracting process¶

In Viindoo software, to supply subcontracted products, the business needs to follow the following steps:

Step 1: Create a purchase order to buy the subcontracted products from the subcontractor or create Subcontracting Request.

Step 2: Transfer materials to the subcontractor by processing Delivery Orders to send materials from the business to the subcontractor (if necessary).

Step 3: Receive subcontracted products by processing the Receipt Orders to receive subcontracted products from the subcontractor to business’s warehouse.

Step 4: Record costs and subcontracts settlements with the subcontractor.

Step 5: Review subcontracting reports to evaluate the effectiveness of the subcontracting process.

This subcontracting feature can be easily applied in the manufacturing process.

See also

Related article

Optional module