Create and use Alternative Work Centers¶

Work Centers represents production units that have the capacity to manufacture raw materials into semi-finished products or finished products. They could be either a group of workers or machinery. This feature supports manufacturers in efficient planning and productivity forecasting.

In daily production, it’s normal to have various manufacturing activities taking place at the same time. Work centers could be used simultaneously, affecting production efficiency by not taking full advantage of available production capacity. Viindoo Software provides the Alternative Work Centers to facilitate the optimization of business resources in these struggles.

Requirements

This tutorial requires the installation of the following applications/modules:

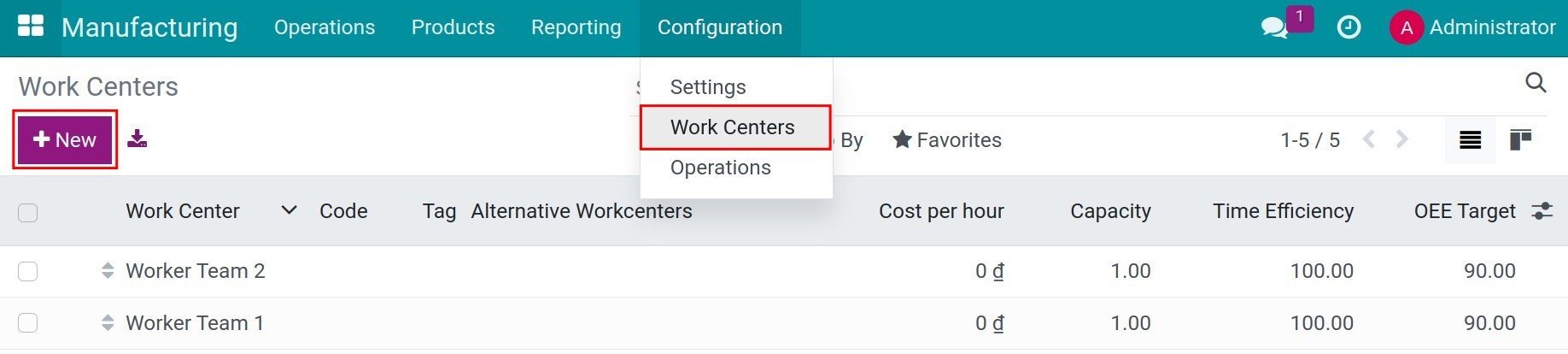

Configure Alternative Work Centers¶

Create new work centers, including the main work center and alternative ones.

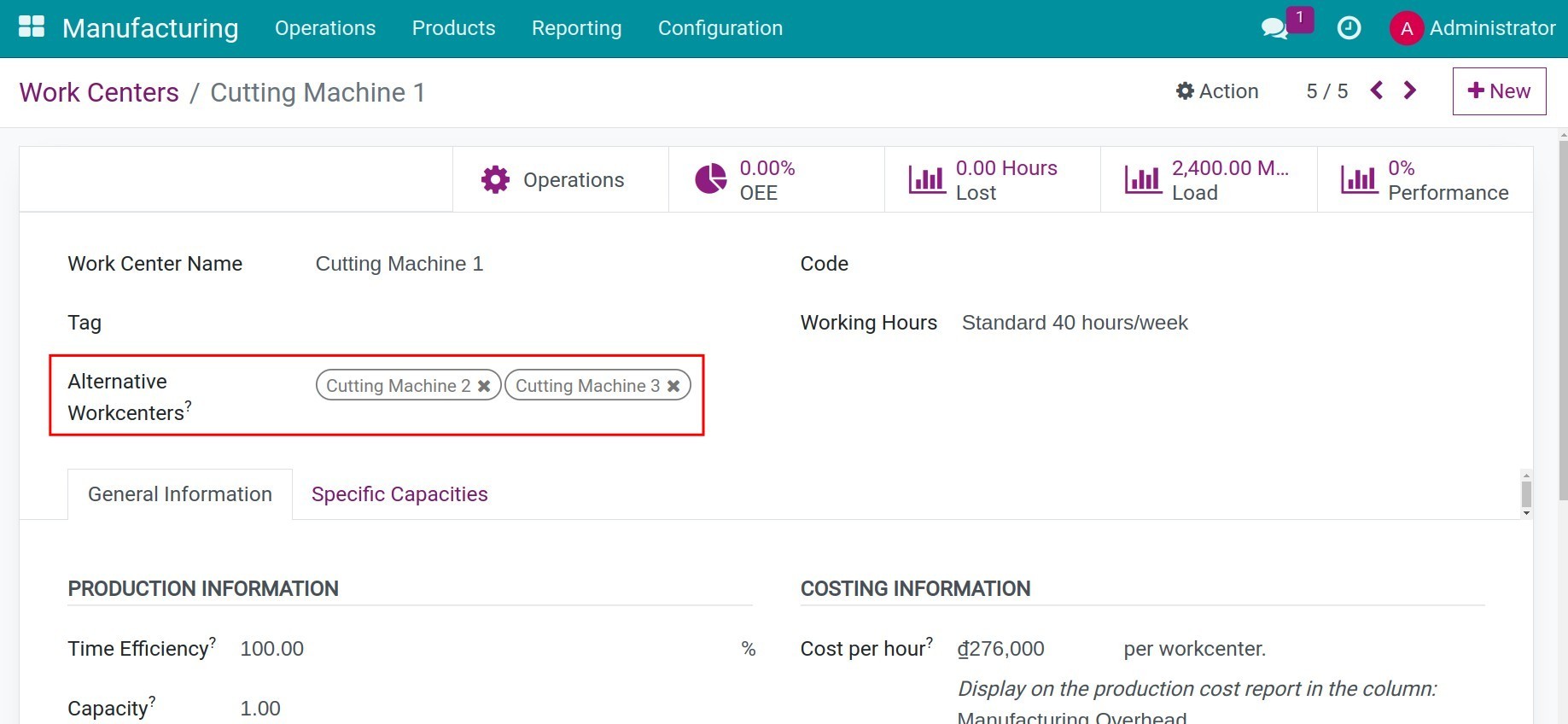

For example, in the manufacturing process of a Wooden table, if work center Cutting Machine 1 is engaged in another manufacturing order, it can be replaced by Cutting Machine 2 or Cutting Machine 3 if they are available. In this case, on the work center form of Cutting Machine 1, add Cutting Machine 2 and Cutting Machine 3 on the Alternative Workcenters field, then press Save.

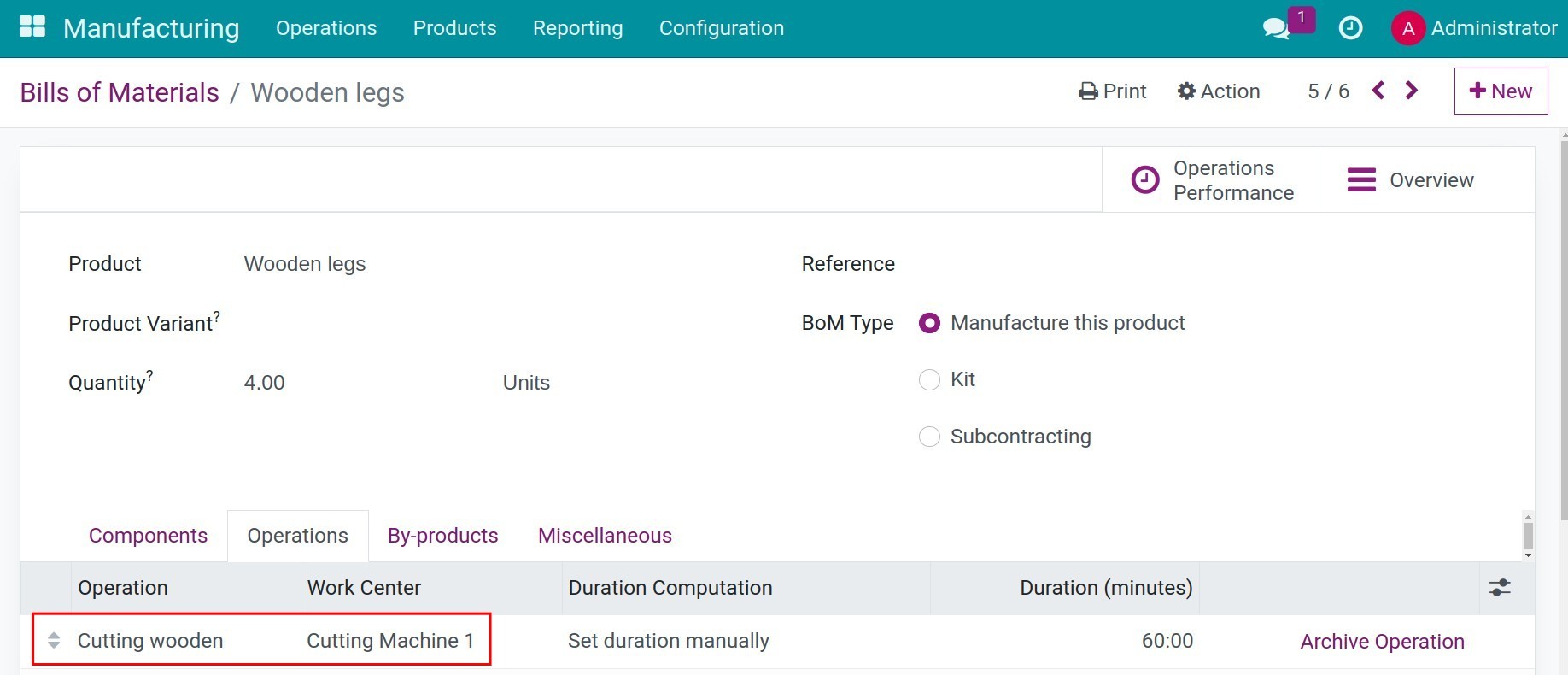

On the other hand, on the Bills of Materials of the Wooden legs below, you need to set the work center Cutting Machine 1 for the Operations.

Alternative Work Centers application in Manufacturing operations¶

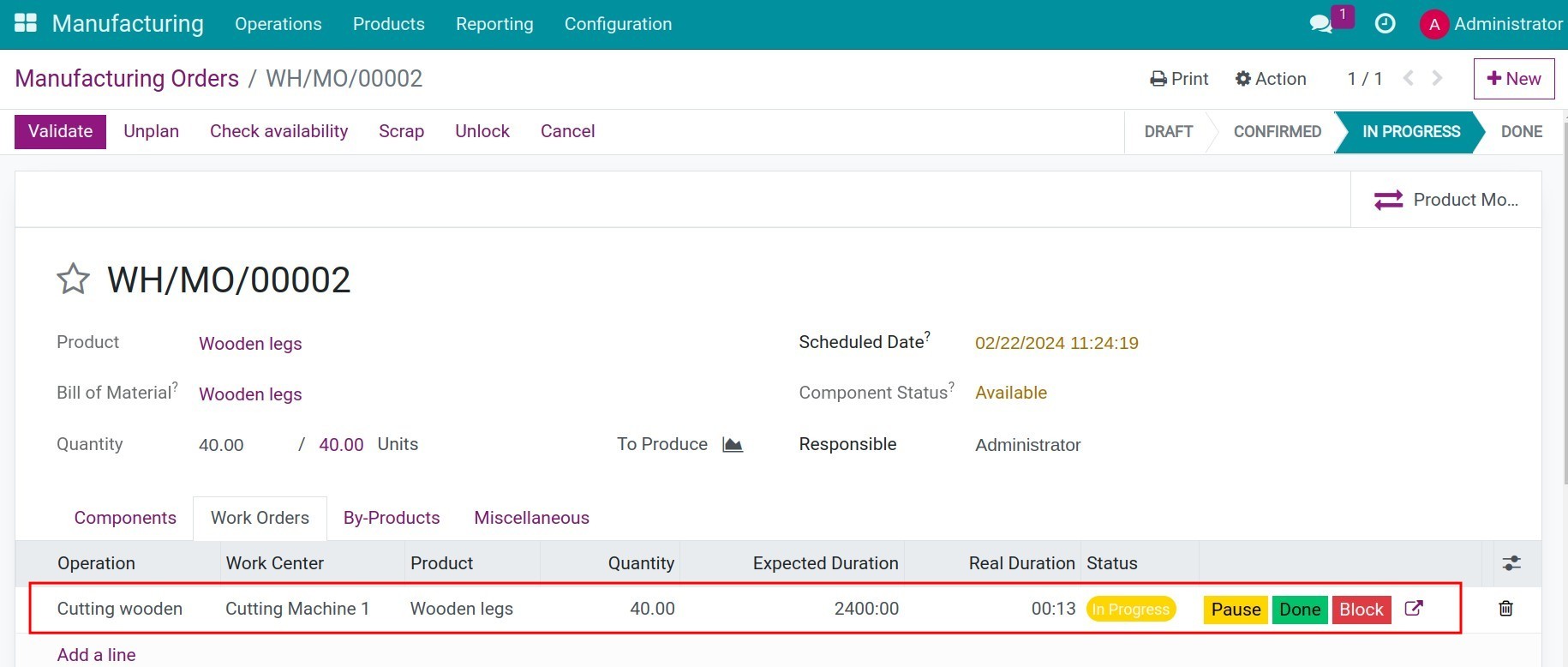

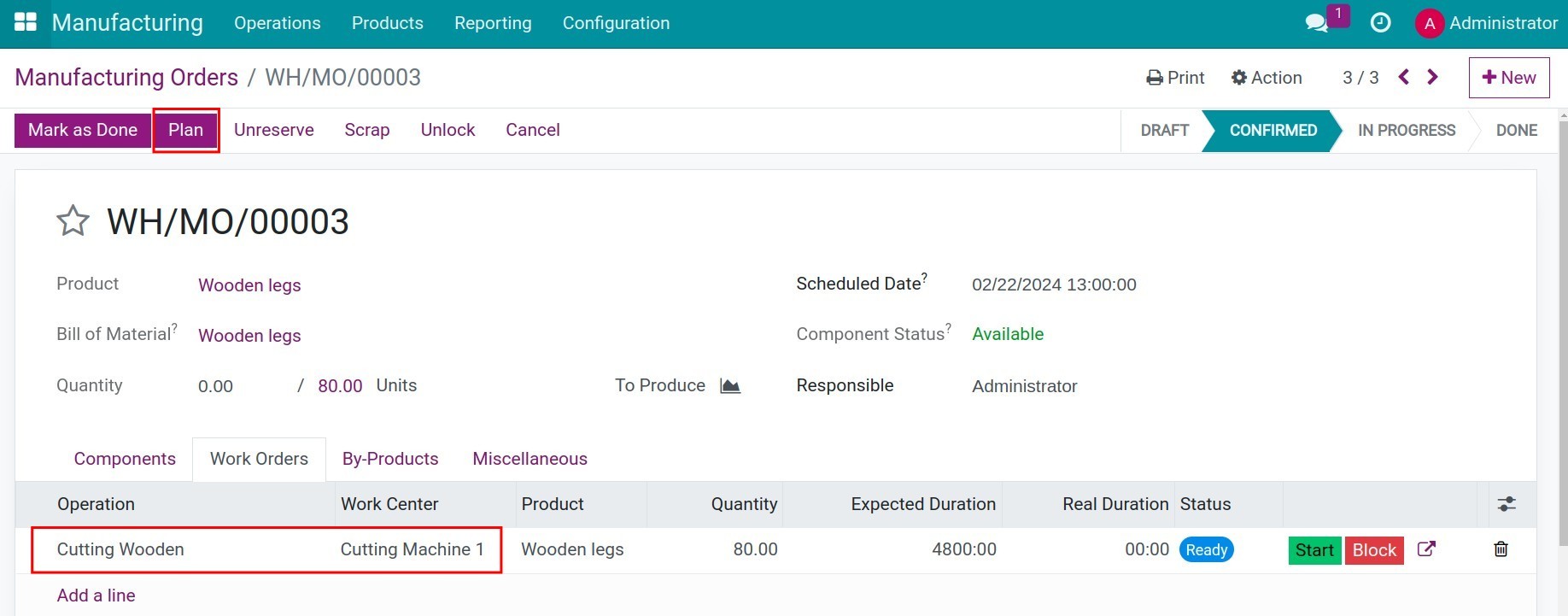

Create the first manufacturing order, using the work center Cutting Machine 1 and plan for it.

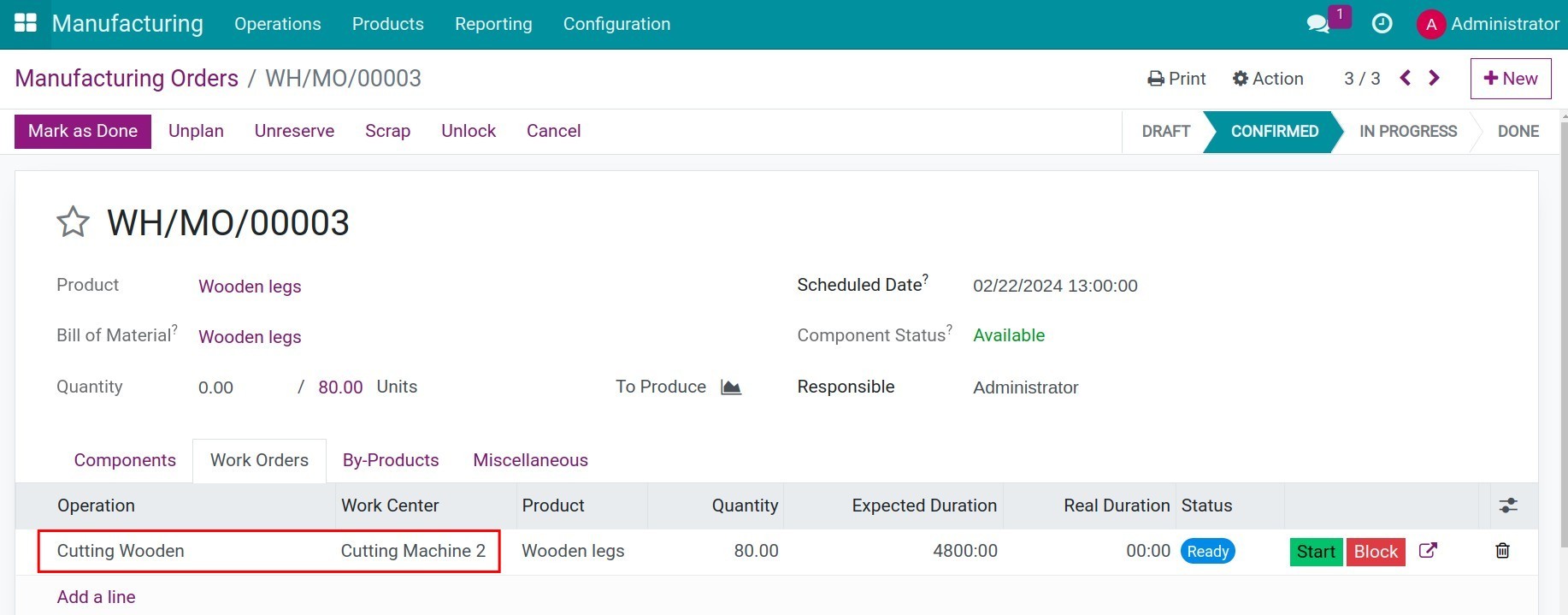

Create the second manufacturing order using the same work center as the previous order.

When you press Plan button, if Cutting Machine 2 or Cutting Machine 3 is available, it will automatically be substituted for the second manufacturing order.

So instead of having to wait for a work centers that are being used for another manufacturing order, the system automatically searches and substitutes it with available reserved work centers so that the manufacturing order can be executed immediately. This saves time for the manager (no need to manually check which resources are idle) and enhances production efficiency.

See also

Optional module