Steps to configure scrap orders in Viindoo¶

In the production and business process of a company, there might be situation where some products are damaged, fail to meet size or quality standards, expiration date, etc., and cannot be resold or unbuild for reuse. In such cases, we can consider them as scrap and remove them from the warehouse.

Viindoo Manufacturing Software assists users in managing scraps by generating quantity statistical data, traceability, and the moment that materials, semi-finished and finished products are transformed into scraps.

Requirements

This tutorial requires the installation of the following applications/modules:

Transferring products in the warehouse into scraps¶

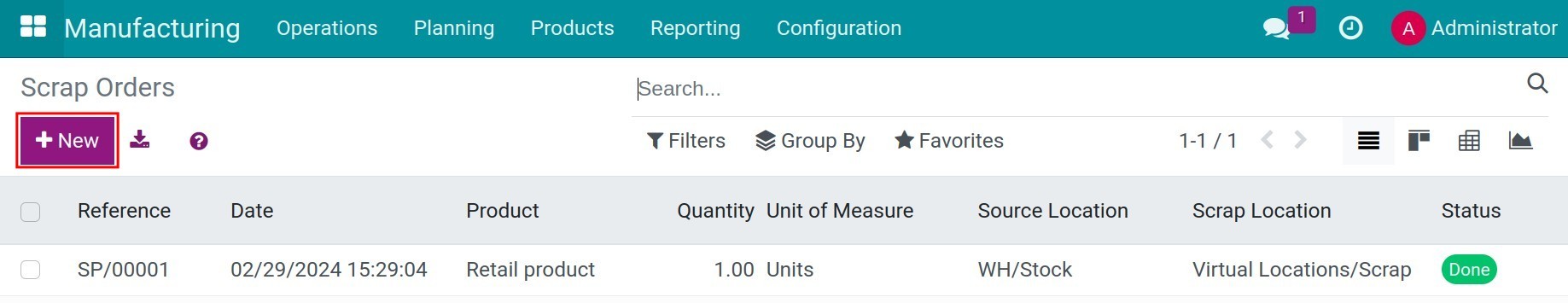

Navigate to Manufacturing > Operations > Scrap, select New to create a new Scrap Order.

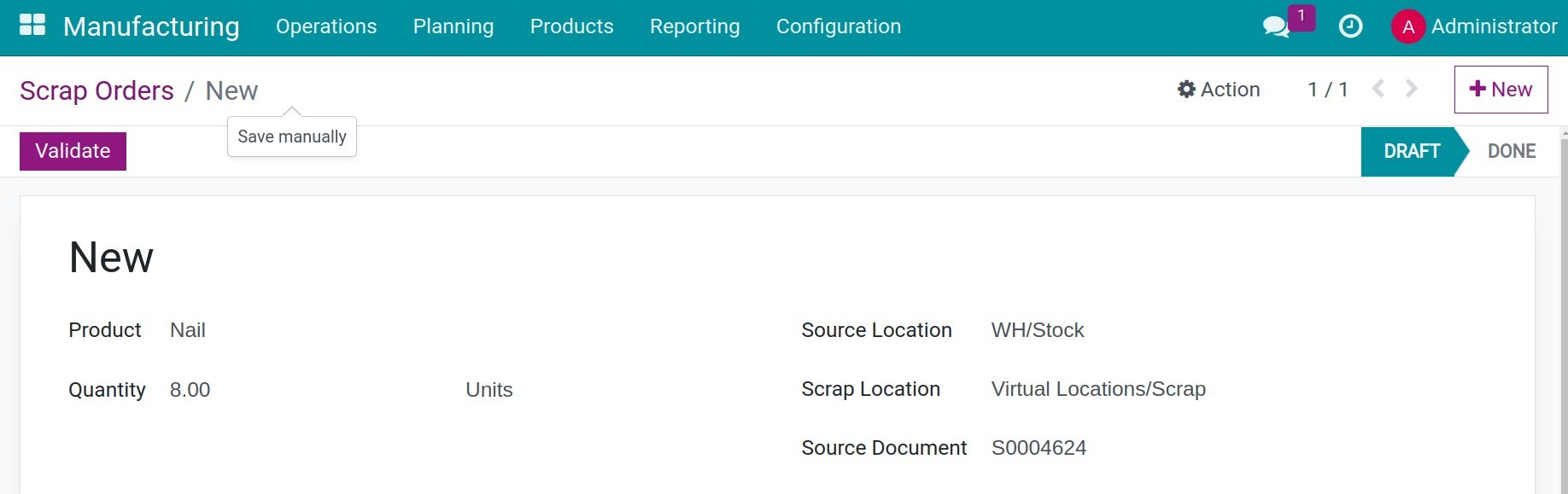

Then, fill in the following necessary information:

Product: choose the product that needs to be scrapped;

Quantity: the number of products to be scrapped;

Source Location: the current storage location of the chosen product;

Scrap Location: the location configured to store the scrapped products;

Source Document: the document which refers to these scrap orders, could be the manufacturing order reference, quality inspection documents, purchase orders, etc.

Note

By default, the Source location is the current warehouse of these products.

The Scrap Location is a virtual location where the products are placed for consumption. This means that the business no longer manages them in the warehouse. The products are considered to have disappeared, and they are recorded as an expense for the company. You can configure Scrap Location following this article: Accounting for Inventory Scrap.

Then, press Validate.

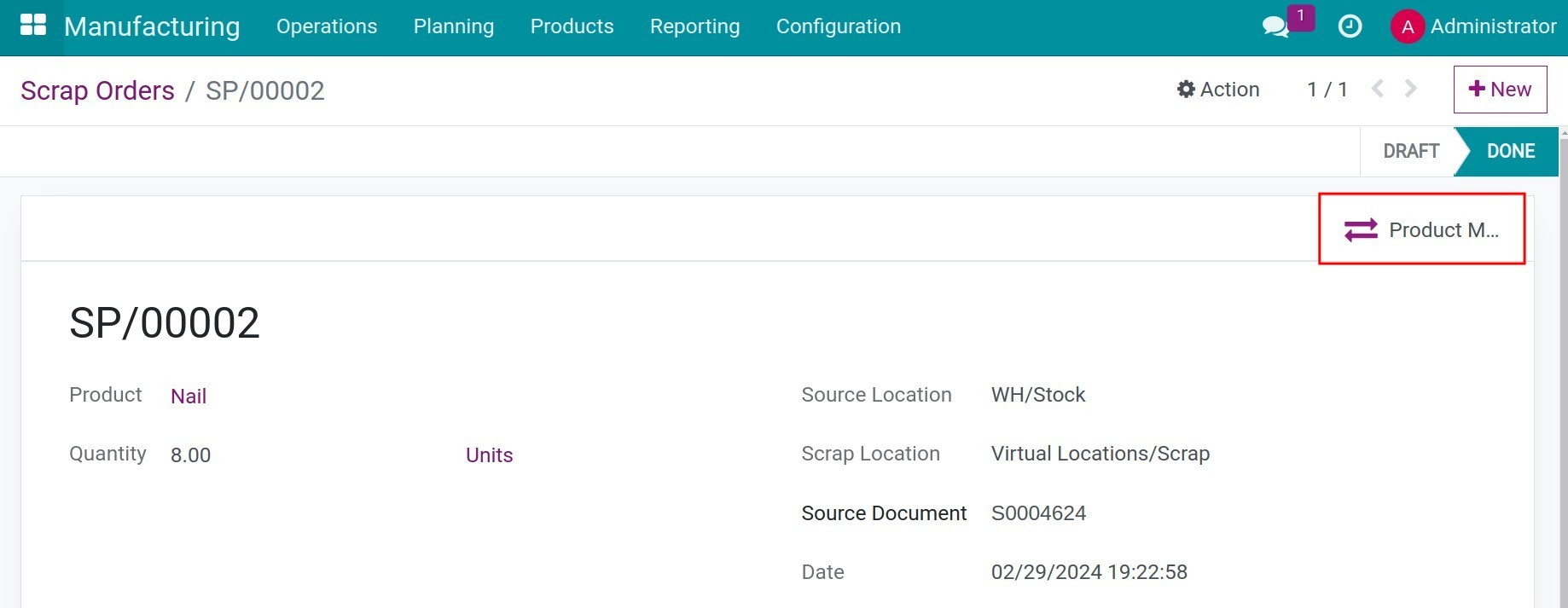

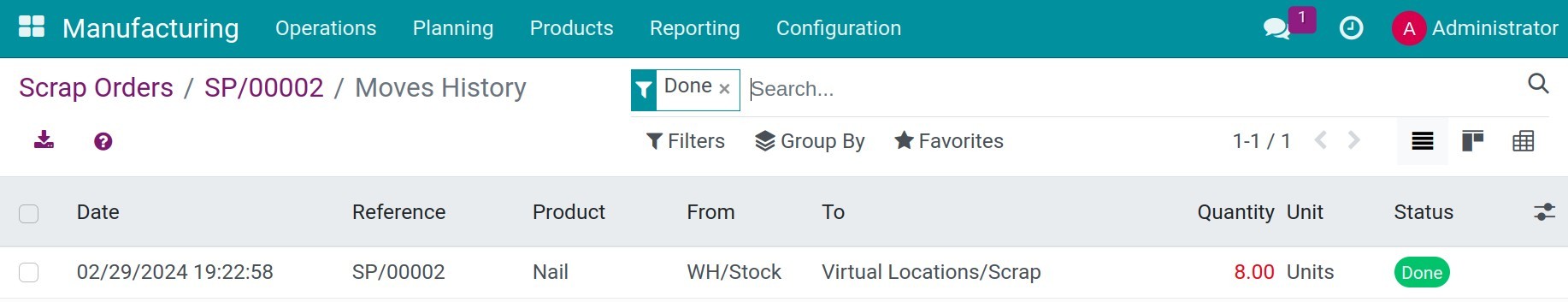

Once the order is validated, the scrap order status is changed to Done. You can track the movements of the scrapped products by clicking on Moves History.

Here is some information that we can track:

Date: Date of scrapping this product;

Reference: Reference of the Scrap Order;

Product: The scrapped product;

From and To: The locations where the scrapped product is taken from and moved to;

Quantity: The quantity of scrapped products;

Status: Status of the scrap order.

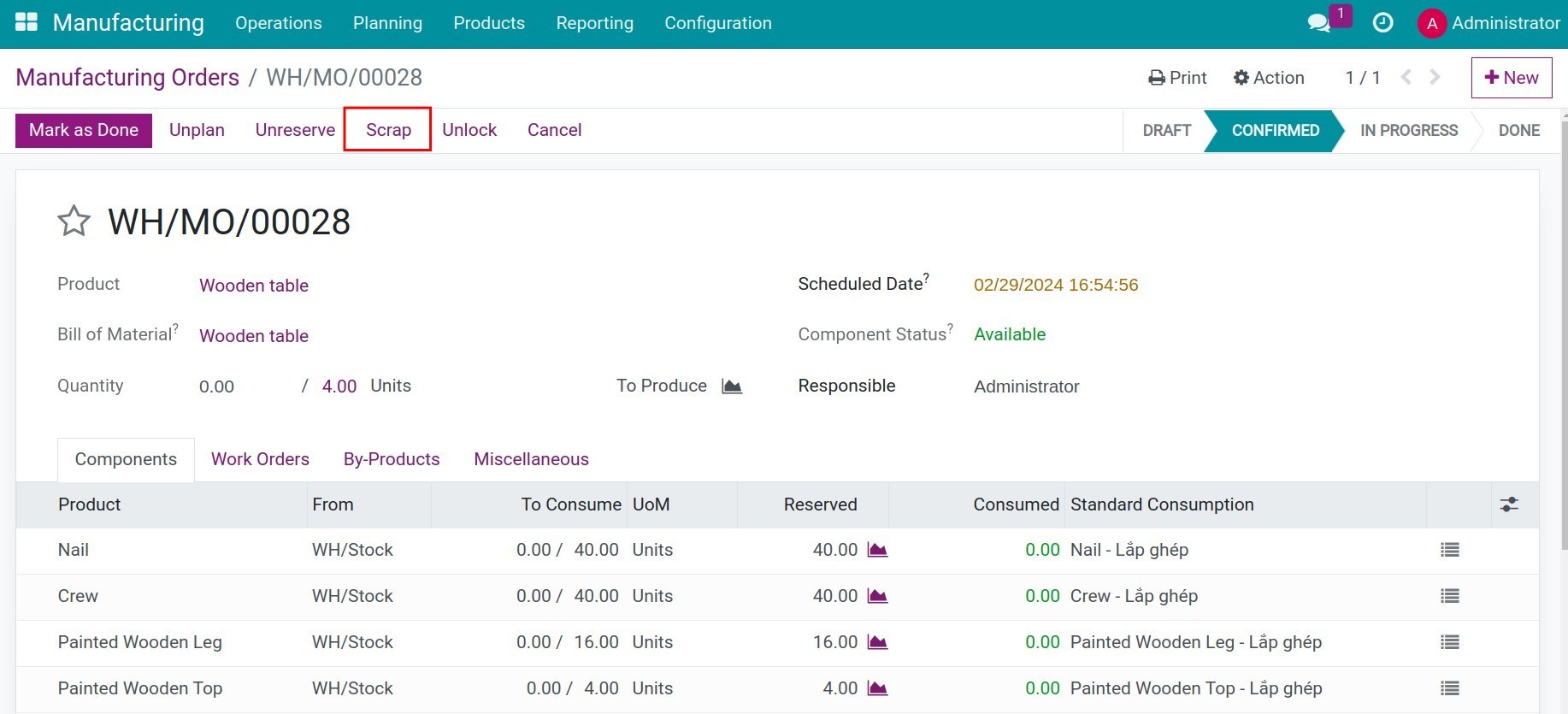

Transferring products in manufacturing into scraps¶

Assuming that during the Manufacturing process, certain raw materials or finished products become severely damaged or do not meet quality standards, the person in charge can directly convert them into scraps on the manufacturing order.

Navigate to Manufacturing > Operations > Manufacturing Orders, open the manufacturing order related to the product which you want to move to the scrap location and choose Scrap.

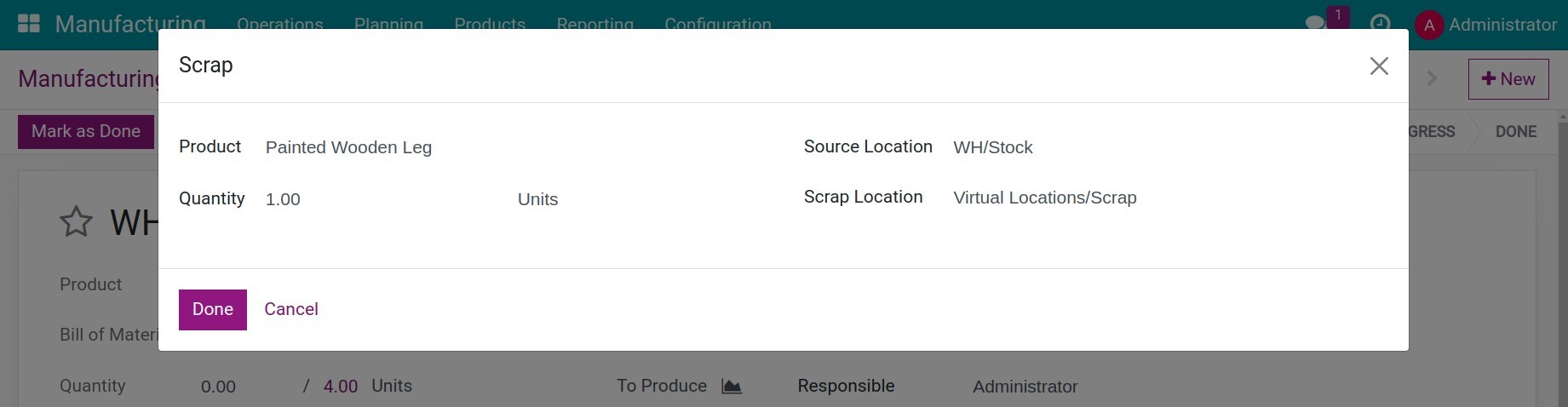

Then, you will be redirected to the interface to fill in the information about the product and scrap it from manufacturing operations.

Here, you can fill in information for the scrapped product similar to steps to create a Scrap orders for the products in the warehouse and choose Done to transfer the selected product to the scrap location.

Note

You can only create a scrap order for raw materials that have not been consumed in the manufacturing order or for finished products that have been completed and entered into inventory.

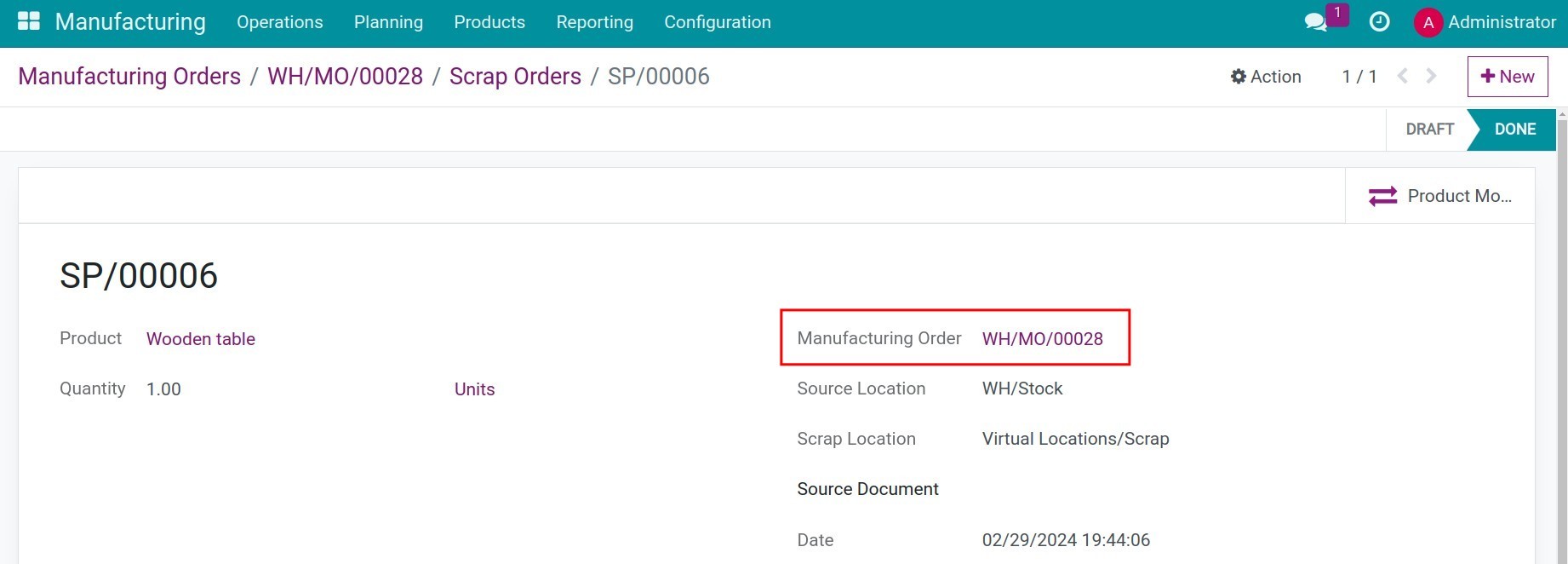

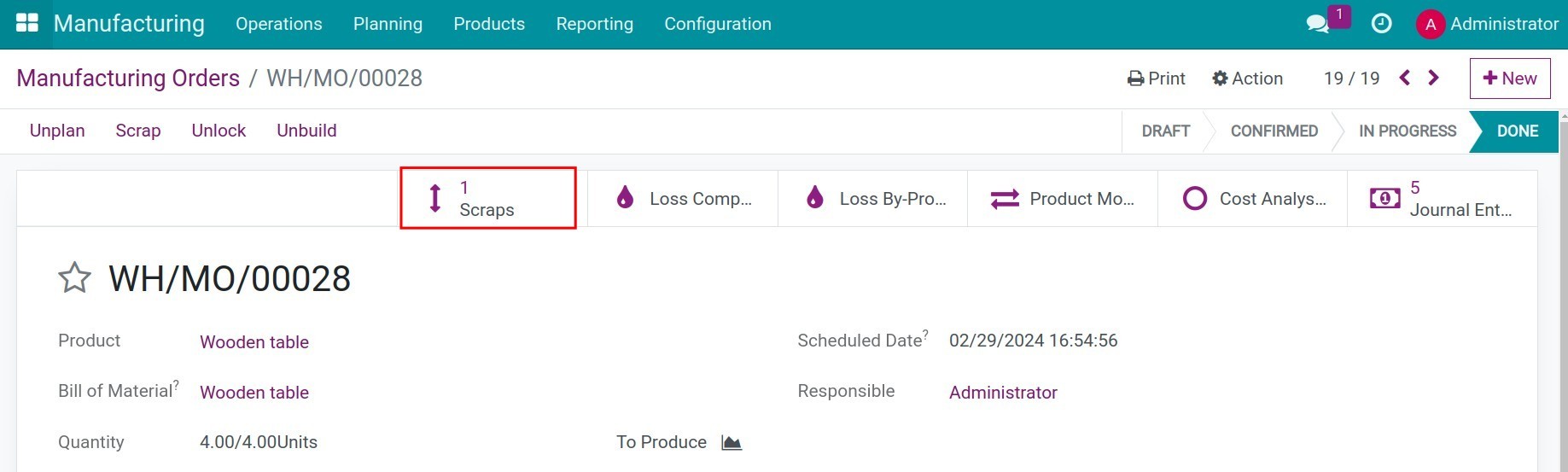

On the manufacturing order, you can press the Scraps button or access the Scrap menu to review related scrap order. At this point, the corresponding manufacturing order information is automatically linked to the scrap order.