Understanding the Scheduled Delivery Date computation¶

Whenever your business receives a sales order, planning for phases of purchasing, manufacturing, and packaging , etc. is an integral part for the sake of on-time delivery. You need to estimate and schedule the periods for each phase accordingly.

Viindoo Software assists you in scheduling delivery dates of products according to the usage purpose. This enhances the credibility of your business in the eyes of customers. It’s more likely that your customers will return to you when they are aware of your reputation.

Requirements

This tutorial requires the installation of the following applications/modules:

Definition and computation rule¶

In the product form, you can configure some information for customer lead time, manufacturing lead time, and delivery lead time. Moreover, the security lead time is also configured as a backup method to cope with the possible unexpected delays. Before taking a deep insight into the configuration and practical applications of each, here is a brief definition of each term:

Vendor’s Delivery Lead Time: the time for the vendor to deliver the goods. Expected Receipt Date on Purchase Order = Order date + Vendor’s Delivery Lead Time.

Purchase Security Lead Time: additional time to mitigate the risk of a vendor delay. When you work with a new vendor or the vendor who has inconsistent delivery lead time, it is essential to configure this feature. The expected delivery Deadline = Expected Receipt Date on Purchase Order + Purchase Security Lead Time.

Customer Lead Time: the number of days promised to customers (in days) from the time the sale order is confirmed until the product is ready to be shipped to the customer. The expected Delivery Date on Sales Order = Order date + Customer Lead Time.

Sales Security Lead Time: the pre-configured safety time to reduce the risks of delivery delays in sales. The Scheduled Date on the delivery order = The expected Delivery Date on Sales Order - Sales Security Lead Time.

Manufacturing Lead Time: the expected time it takes to manufacture a product. This lead time is set for each product and does not take the quantity into account.

Manufacturing Security Lead Time: the additional time to mitigate the risk of a manufacturing delay, which is useful in cases of bulk production orders. This is set for all the manufacturing orders. The Planned Date = the Delivery Order scheduled date - Manufacturing Lead Time - Manufacturing Security Lead Time.

Configuration and usage¶

Estimate the Leads time in Purchase¶

Vendor Delivery Lead Time¶

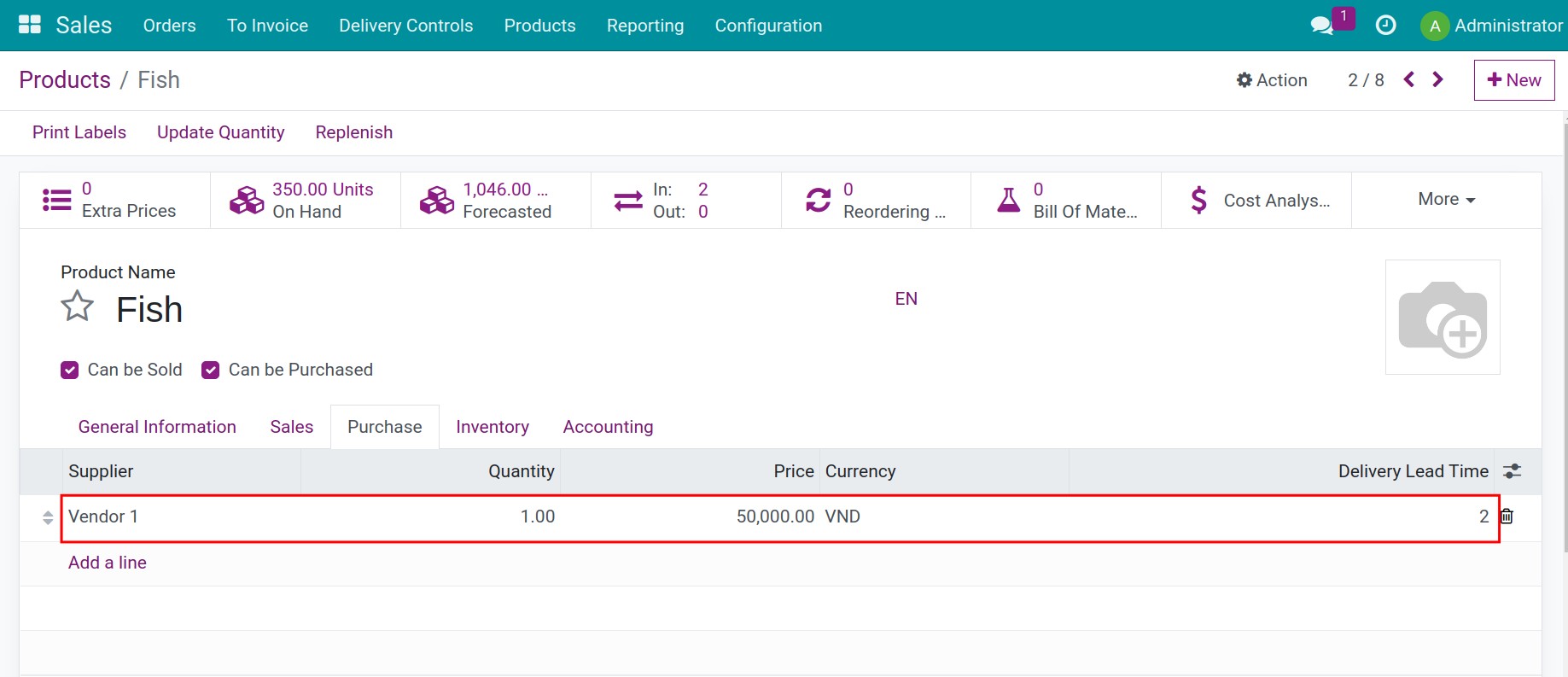

To set the delivery time of the vendor go to Purchase > Products > Products, and select any product.

In the Purchase tab, click Add a line, a new line is displayed, select the Vendor and the Delivery Lead Time there.

Note

A product can have various vendors with different delivery times configured. In case the same vendor has different delivery times, the system will prioritize the delivery time based on criteria in the following order: applicable period, quantity, and the sorting order from top to bottom of the vendor pricelists at the product’s configuration.

Purchase Security Lead Time¶

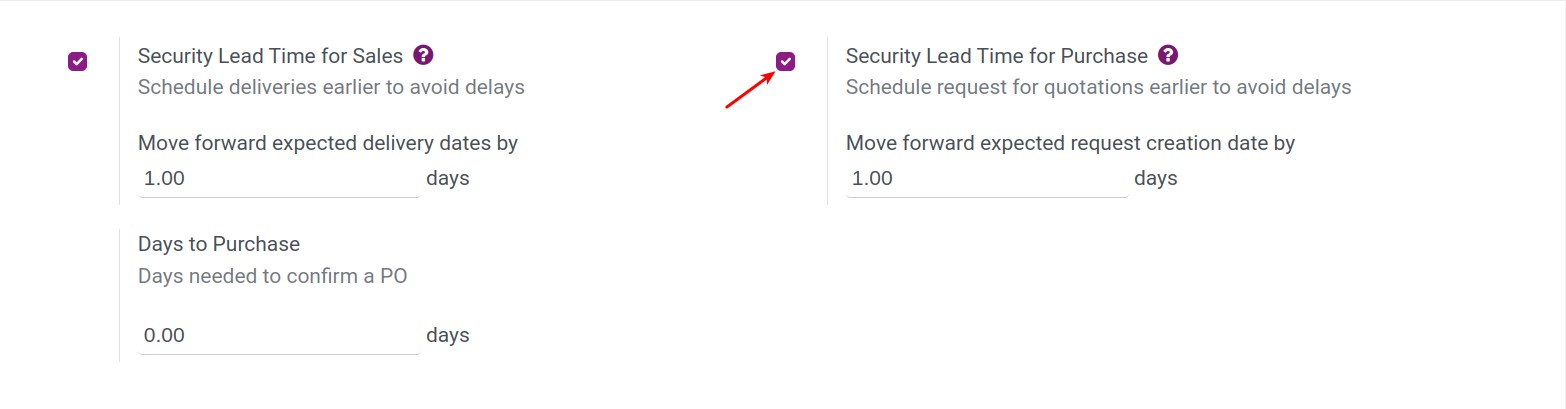

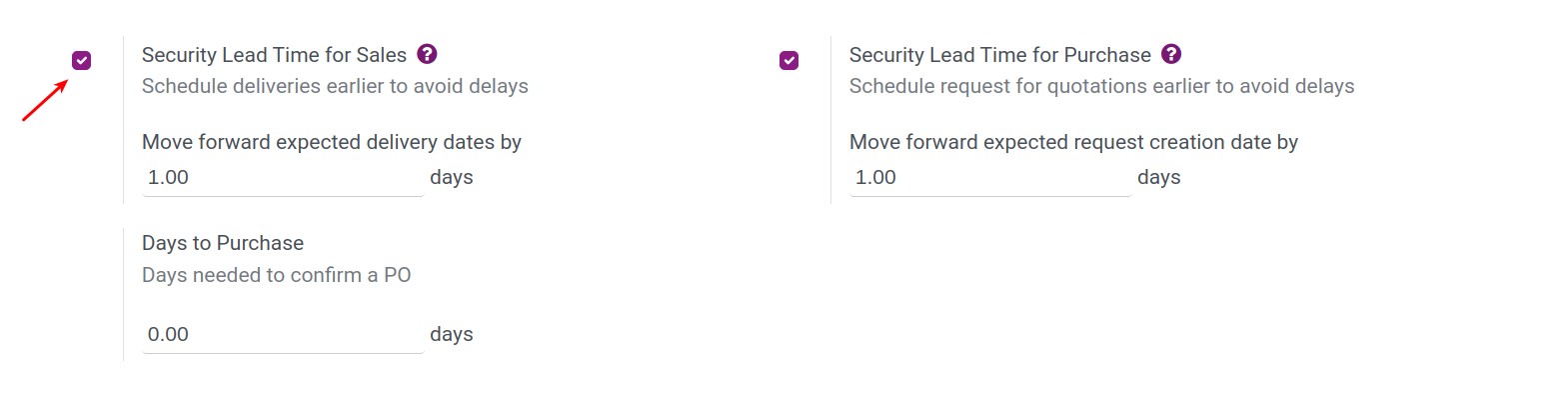

In order to set up purchase security lead time, go to Inventory > Configuration > Setting, find and activate Security Lead Time for Purchase. After that, you need to fill in the expected days and Save.

Application in Purchase¶

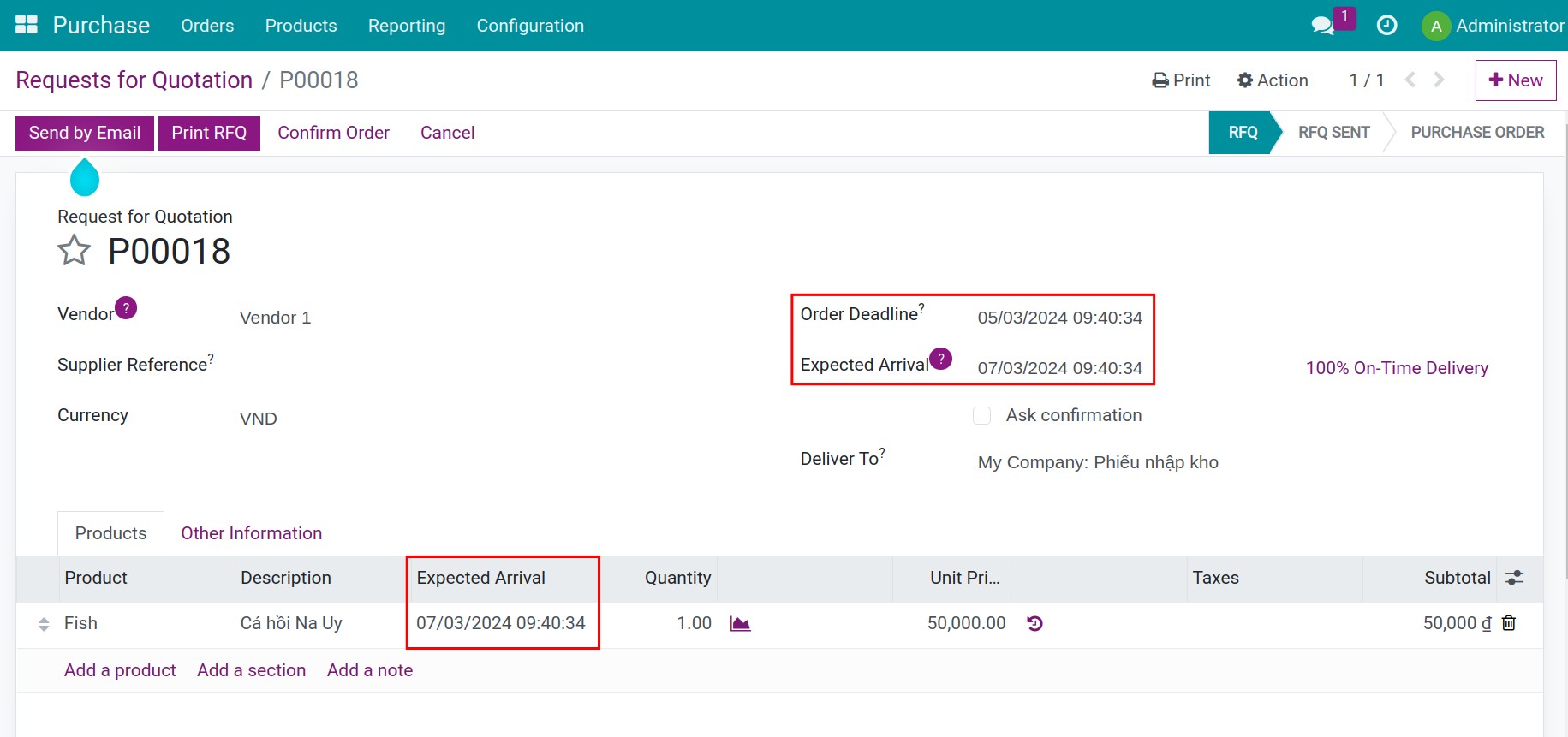

Suppose that you need to buy product A from vendor X with the following information:

A delivery Lead time of vendor X with the product as A: 2 days.

Purchase Security Lead Time: 1 day.

Order Date: March 05th, 2024.

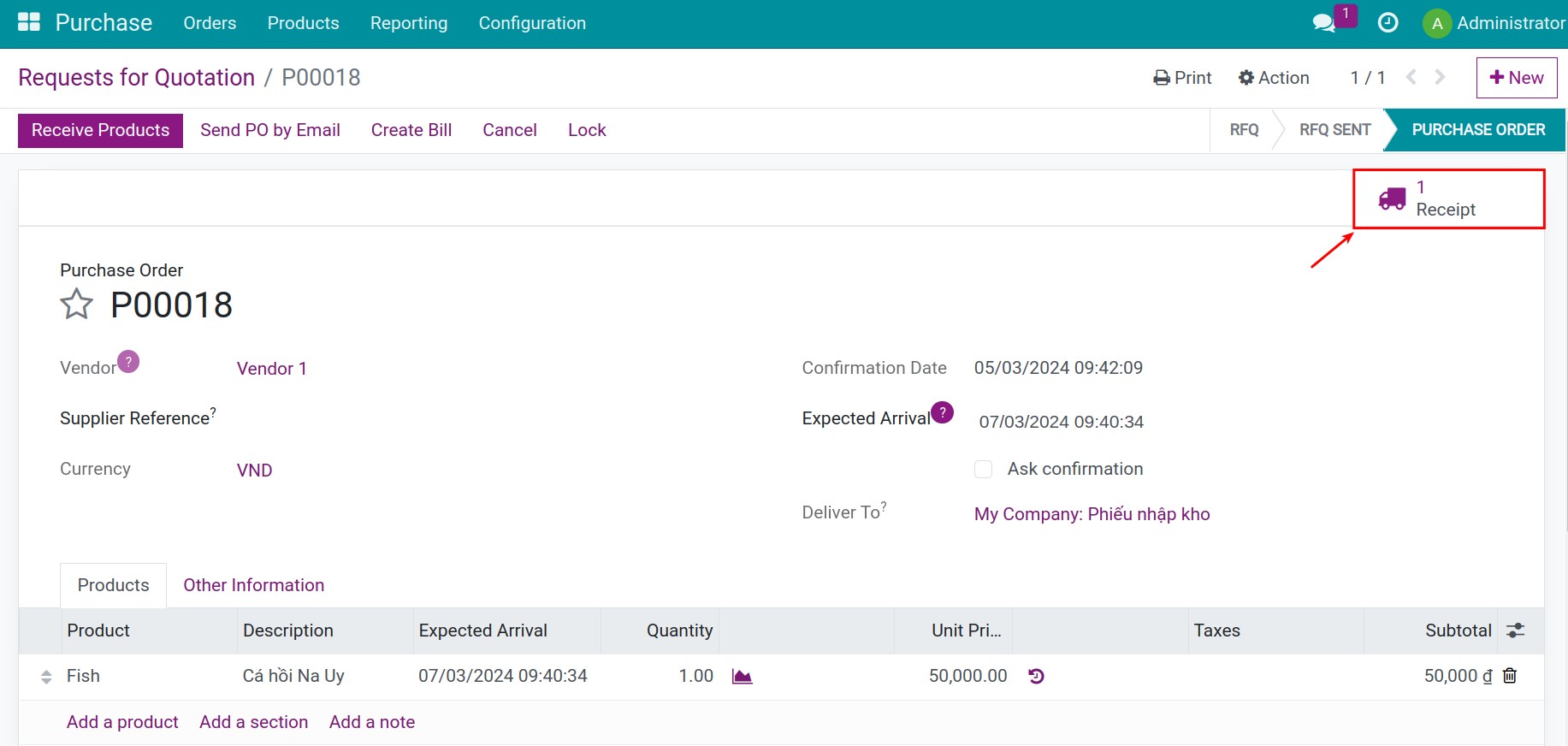

Make a purchase order from Vendor X with product A. scheduled receipt date will be automatically computed (March 7th, 2024) = Order date (March 5th, 2024) + Vendor Delivery Lead time (2 days).

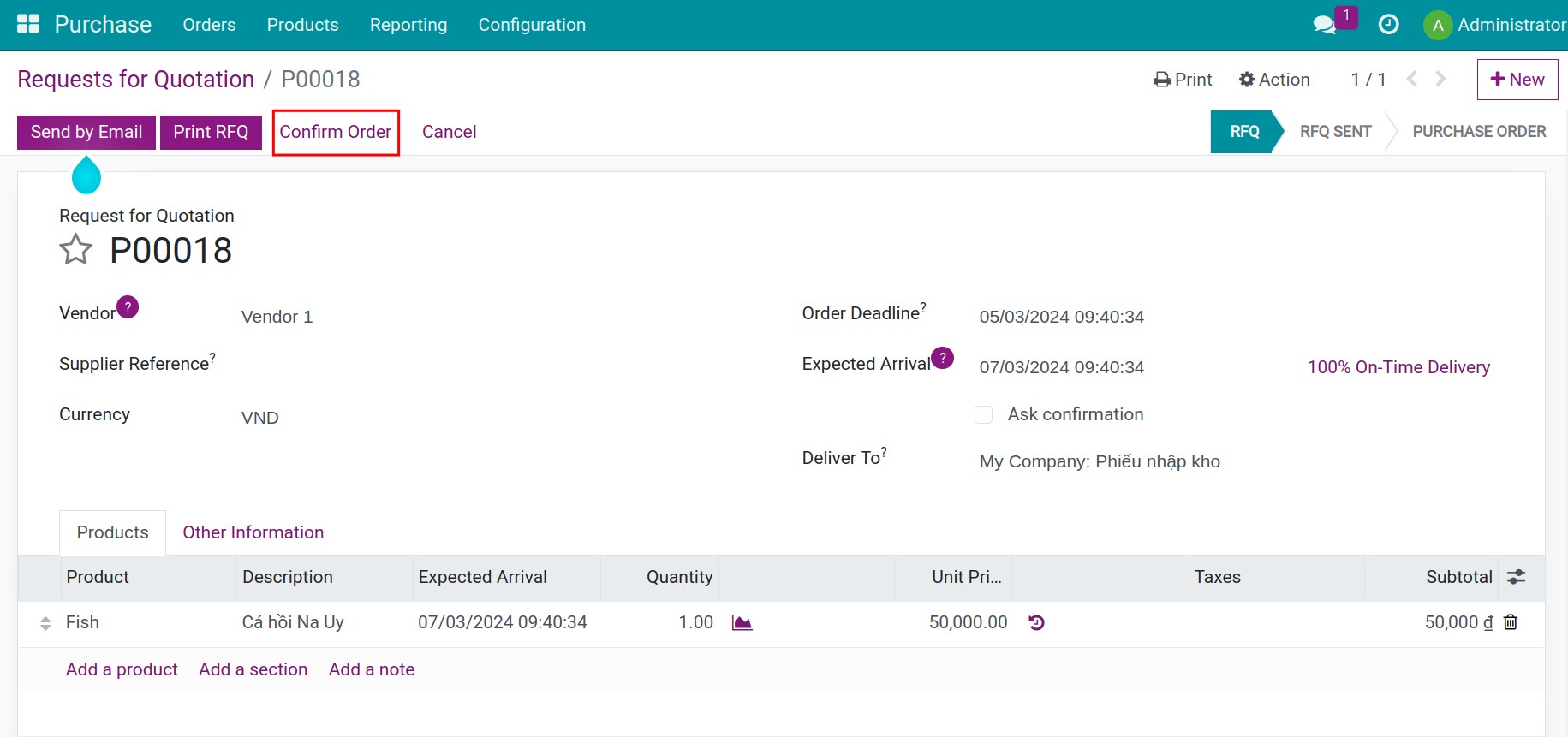

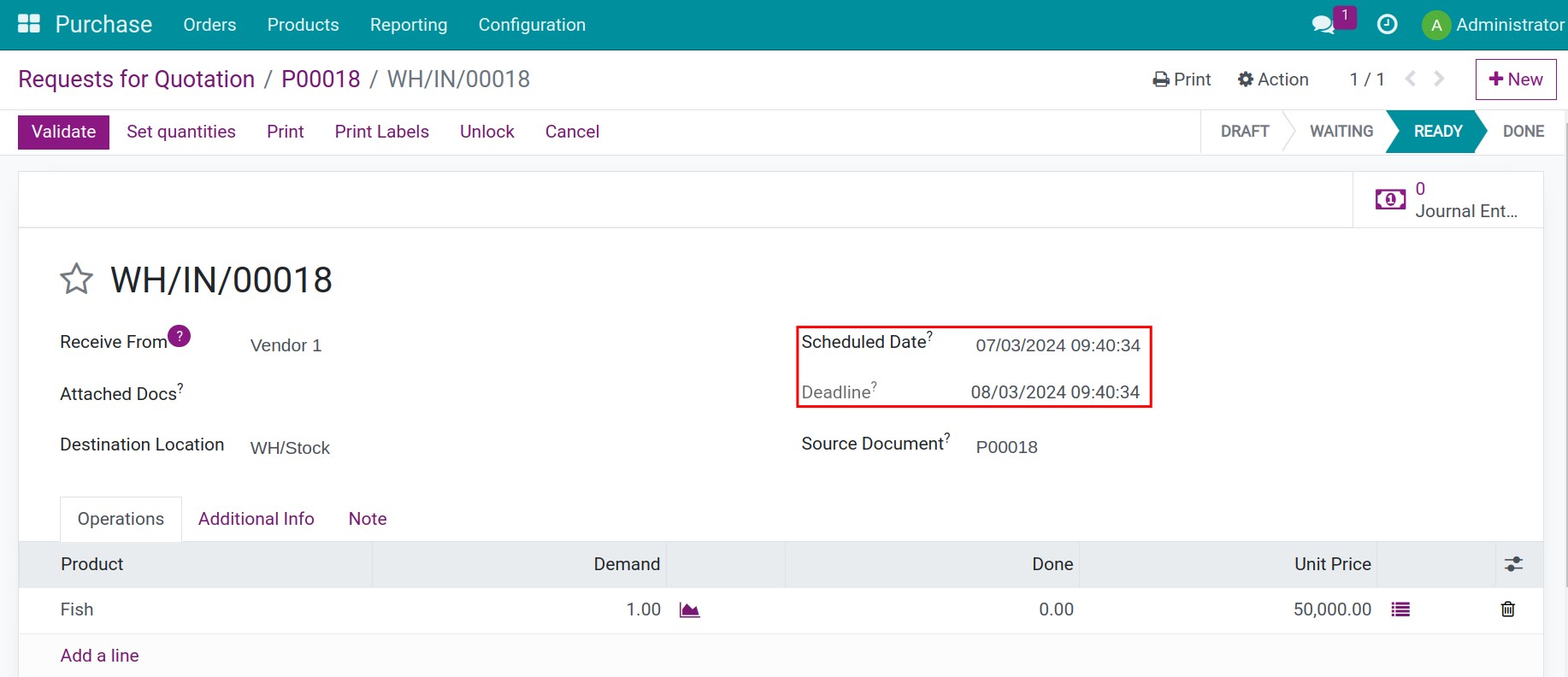

Once the purchase order is confirmed, a receipt slip is automatically generated. Deadline displayed on the slip (March 8th, 2024) = The Scheduled Date (March 7th, 2024) + Purchase Security Lead Time (01 day).

Estimate the delivery time in Sales¶

Customer Lead Time¶

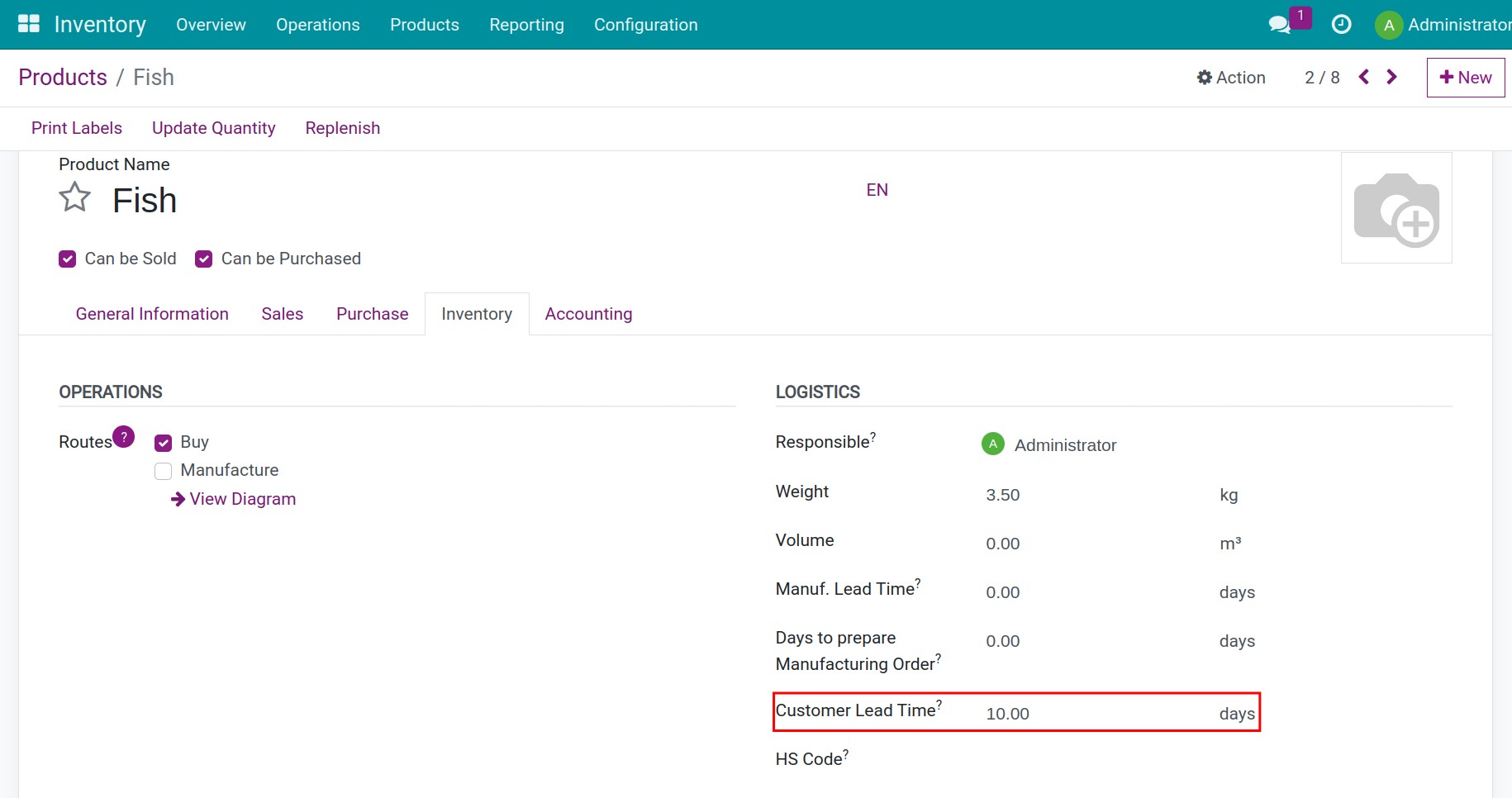

To set up the delivery date, navigate to Sales > Products > Products and choose any product. In the Inventory tab in Product form, fill in Customer Lead Time.

Security Lead Time for Sales¶

To set up this feature, navigate to Inventory > Configuration > Setting, check Security Lead Time for Sales, and fill in the expected days, then Save.

Application in Sales¶

For example, Customer A wants to order product A with the following information:

Customer Lead Time: 10 days.

Security Lead Time for Sales: 01 day.

Order Date: March 05th, 2024.

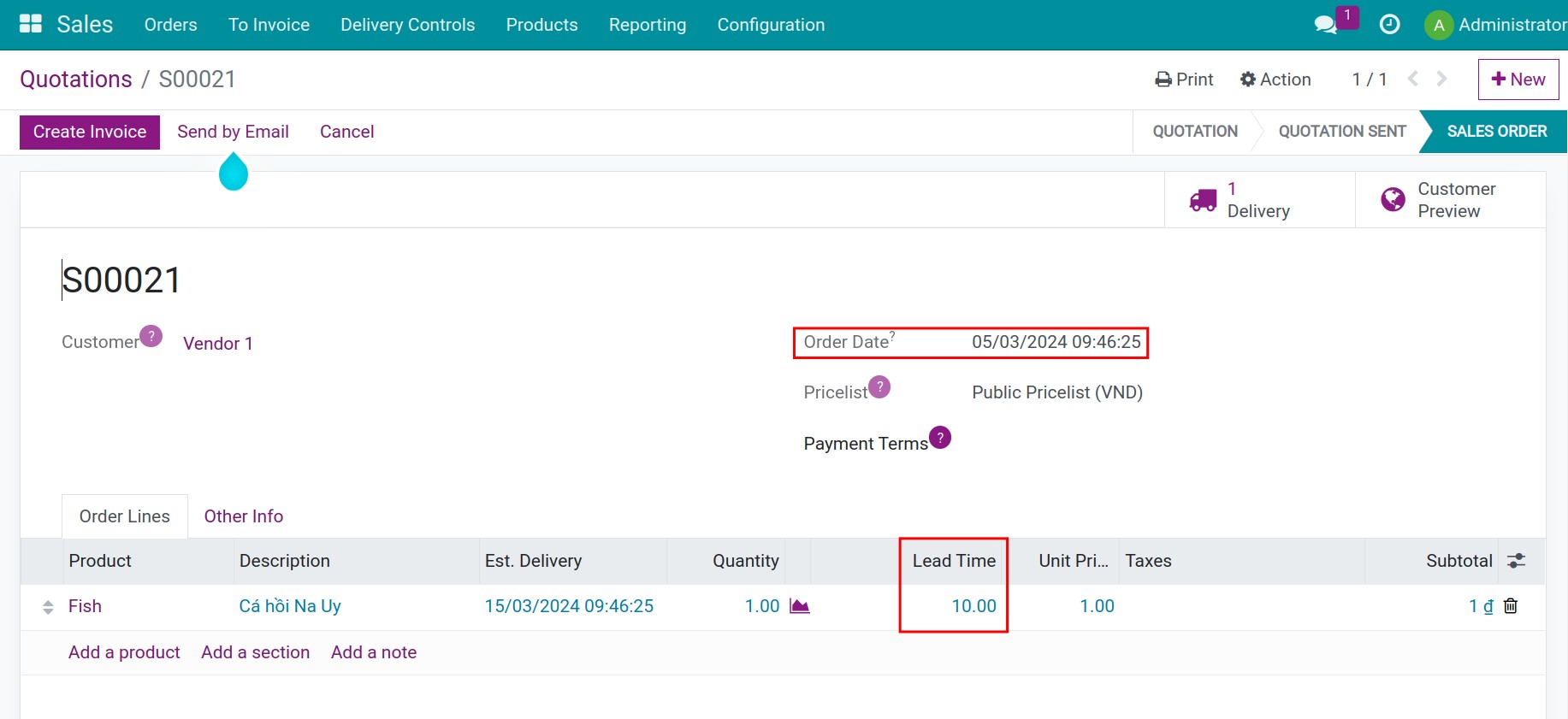

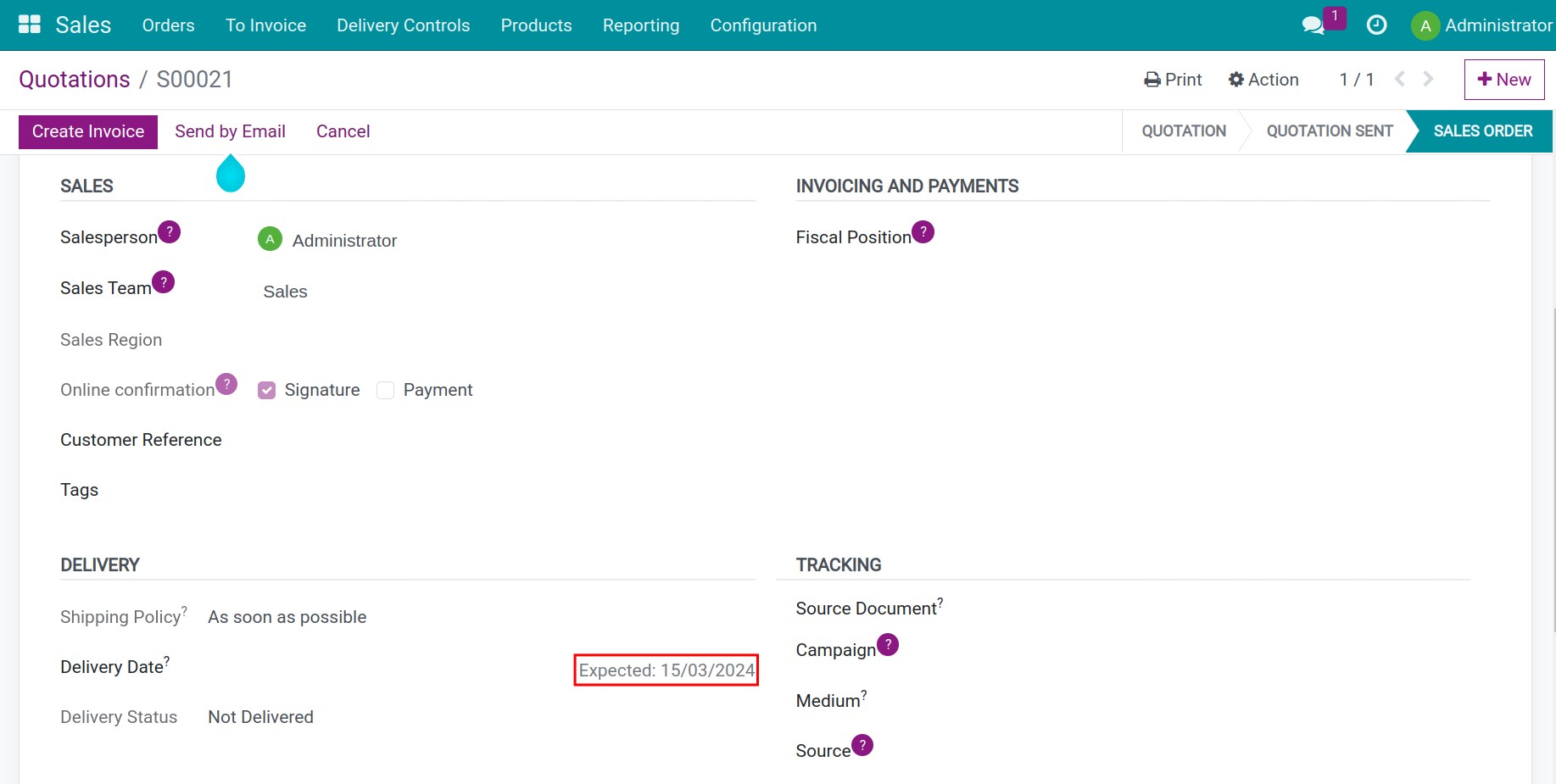

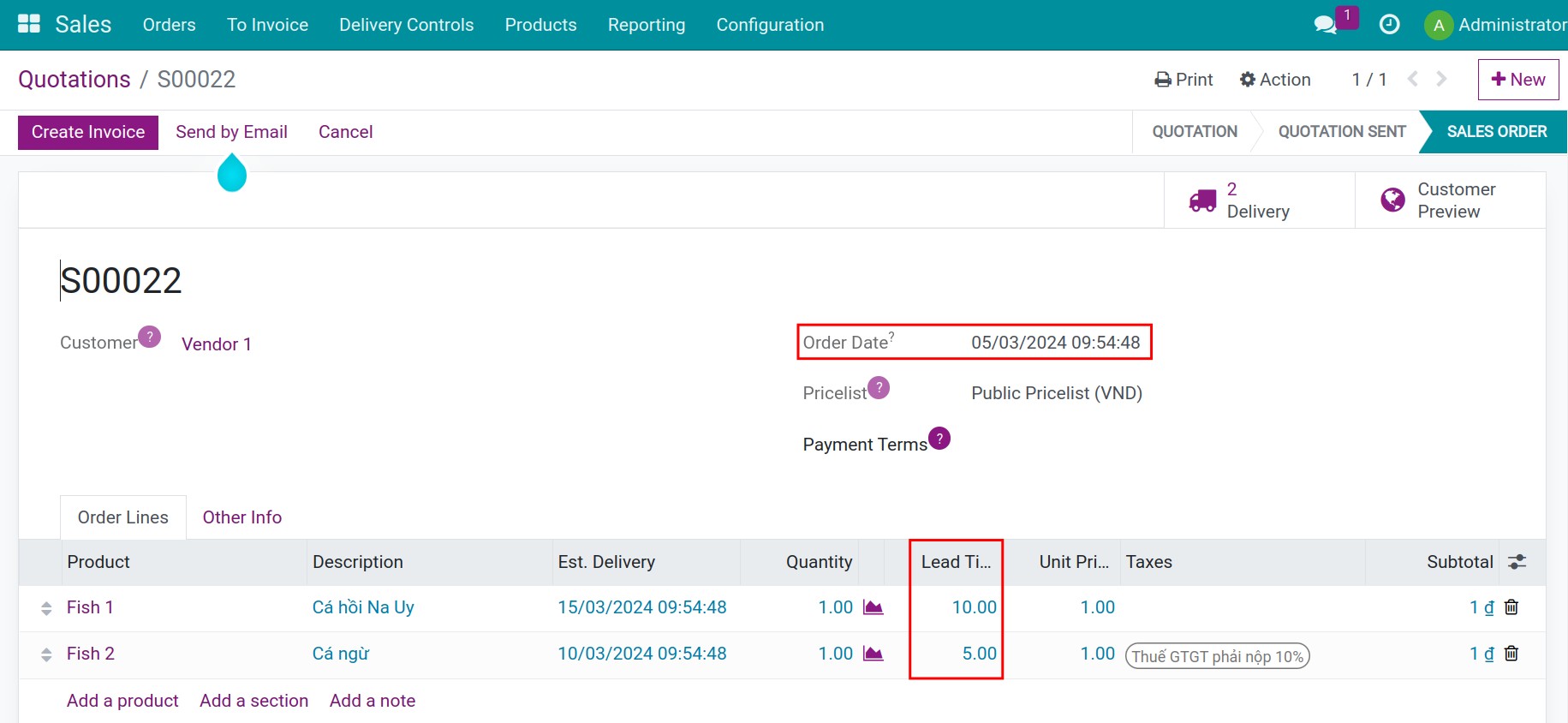

In the Sales app, create a sales order for Product A for Customer Z. In the Order Lines tab, the lead time is displayed as 10 days as configured customer lead time in Product A. In the Other Info tab, the Expected Delivery Date is automatically calculated based on the delivery time set on the product(March 15th, 2024) = Order Date (March 05th, 2024) + Customer Lead Time (10 days). There is also a Delivery Date that allows you to choose the delivery time at your will.

Note

In case there is no change in delivery date, the scheduled date is default as the expected delivery time.

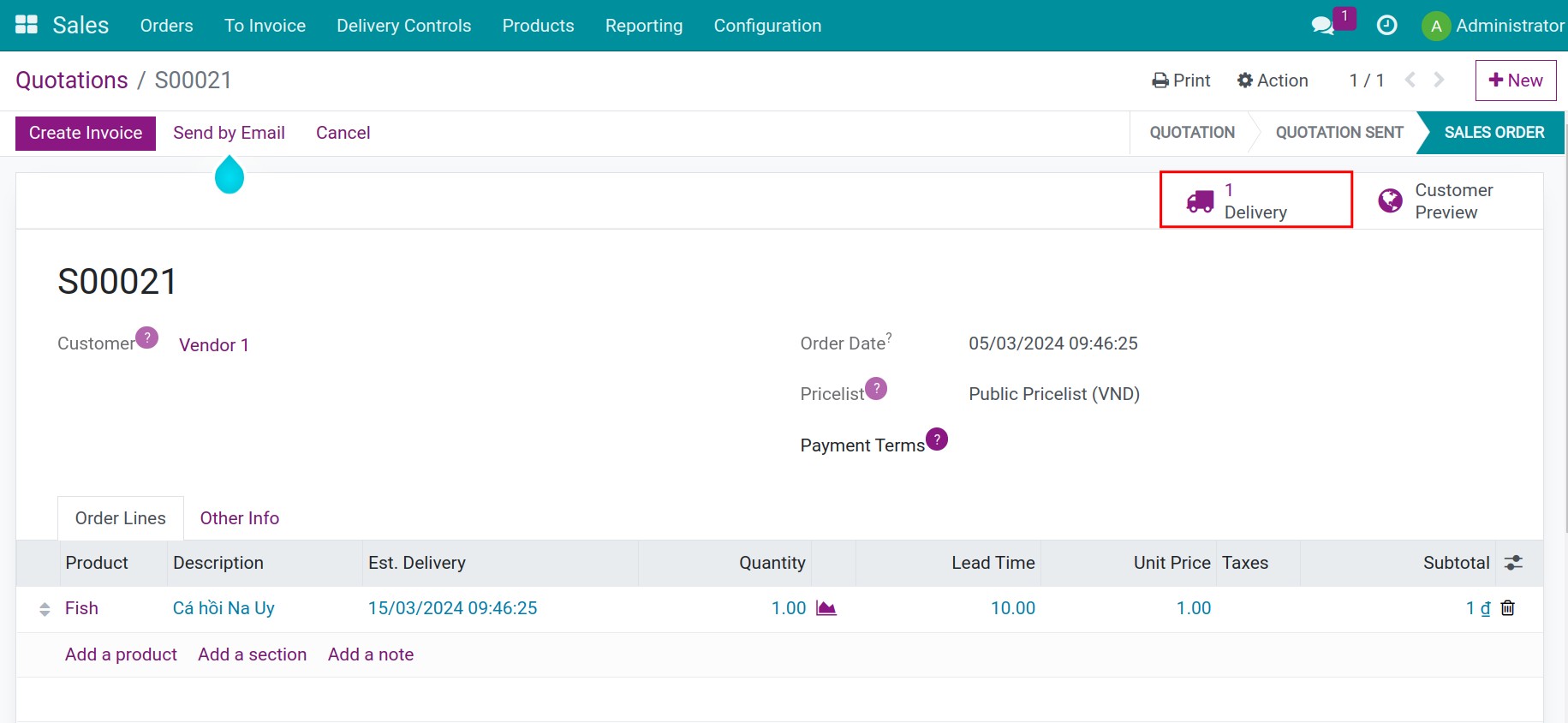

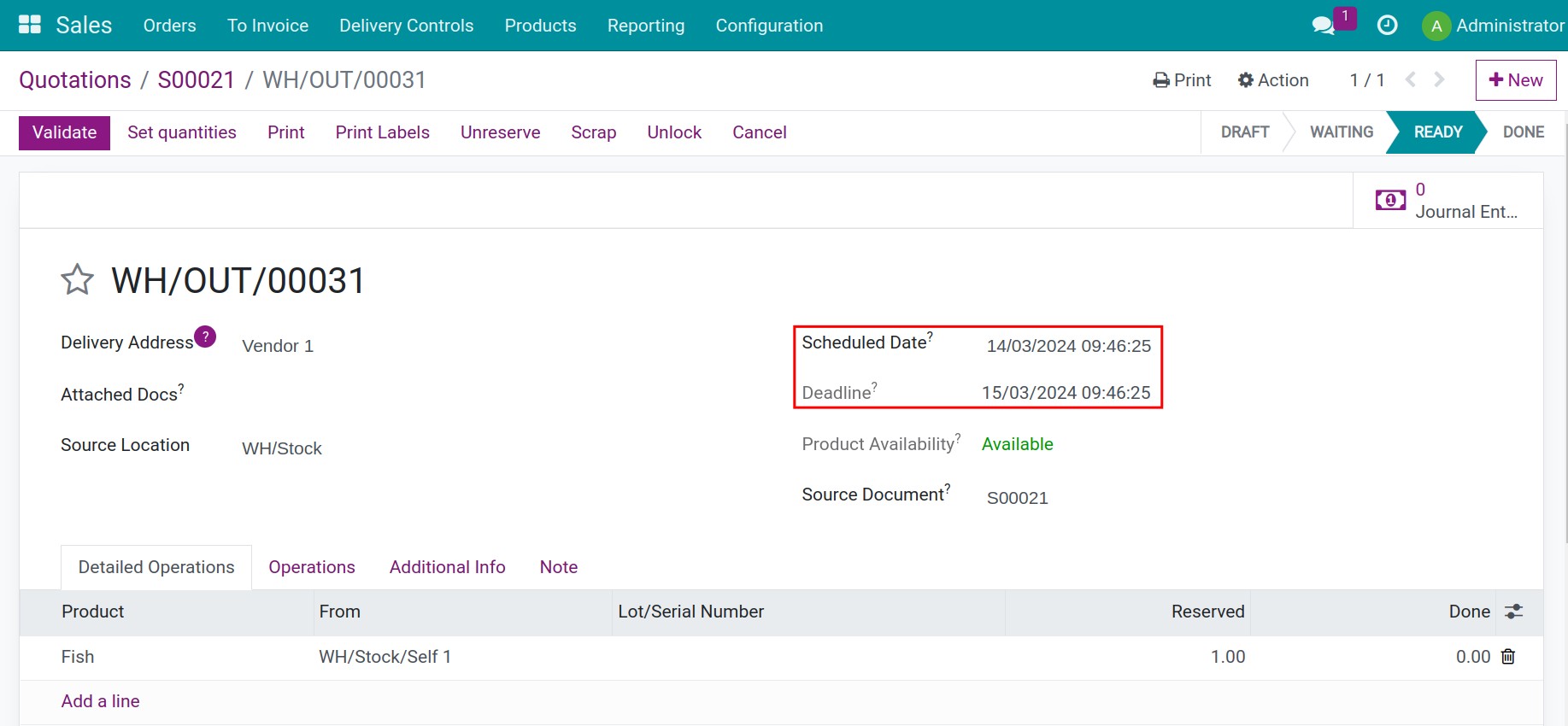

Once the sales order is confirmed, a delivery slip is automatically generated. In this slip, the deadline (March 15th, 2024) = The Scheduled Date. Scheduled delivery date on the delivery slip (March 14th, 2024) = Expected delivery date (March 15th, 2024) - Customer Lead Time (1 day).

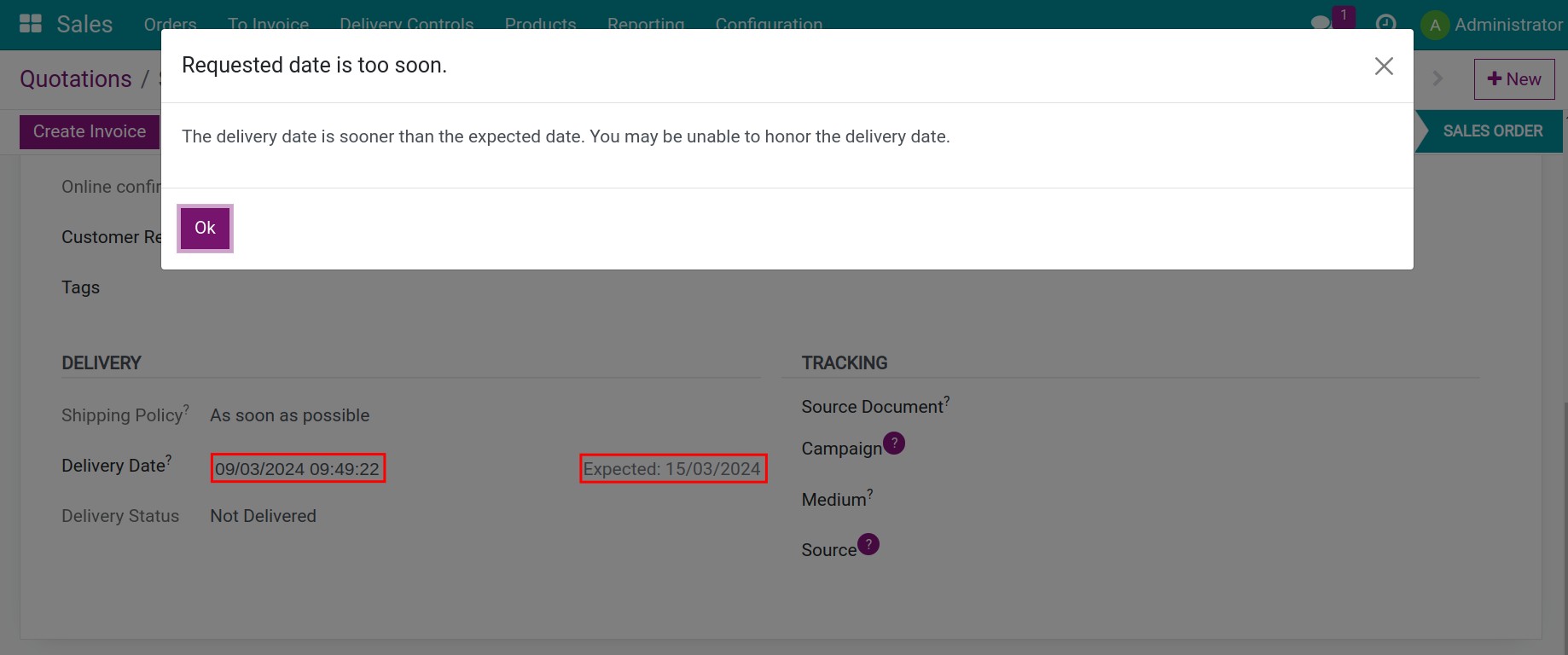

If the delivery date is earlier than the expected date, a warning message is displayed.

However, to make sure all of these work properly, security lead time for sales should be calculated and configured precisely.

Deliver several products¶

In reality, there are cases where a customer orders many products at once but wants to have them delivered at the same time or separately. For example, on March 05th, 2024, there is an order for products A and B. The delivery time for product A is 10 days, and for product B is 5 days.

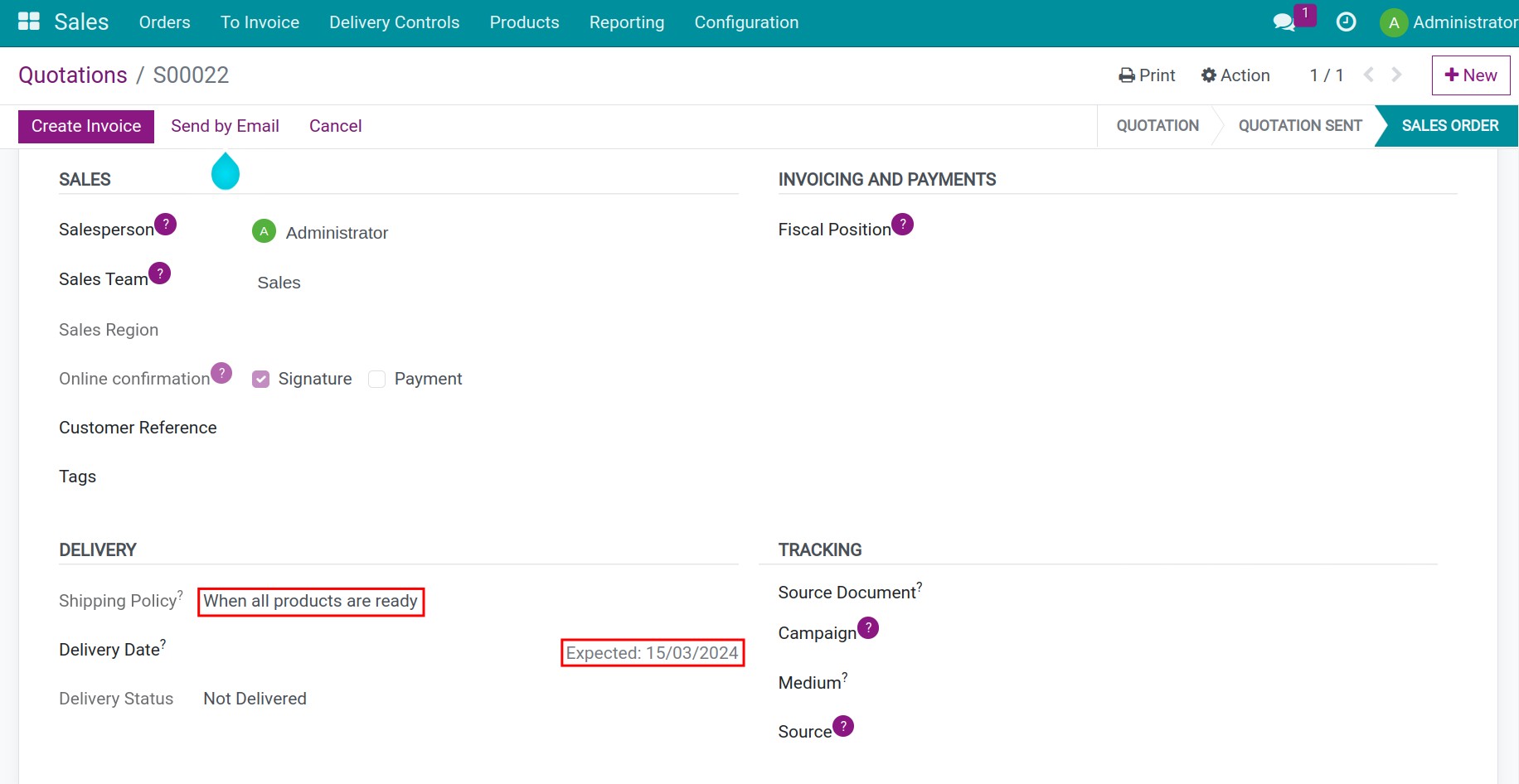

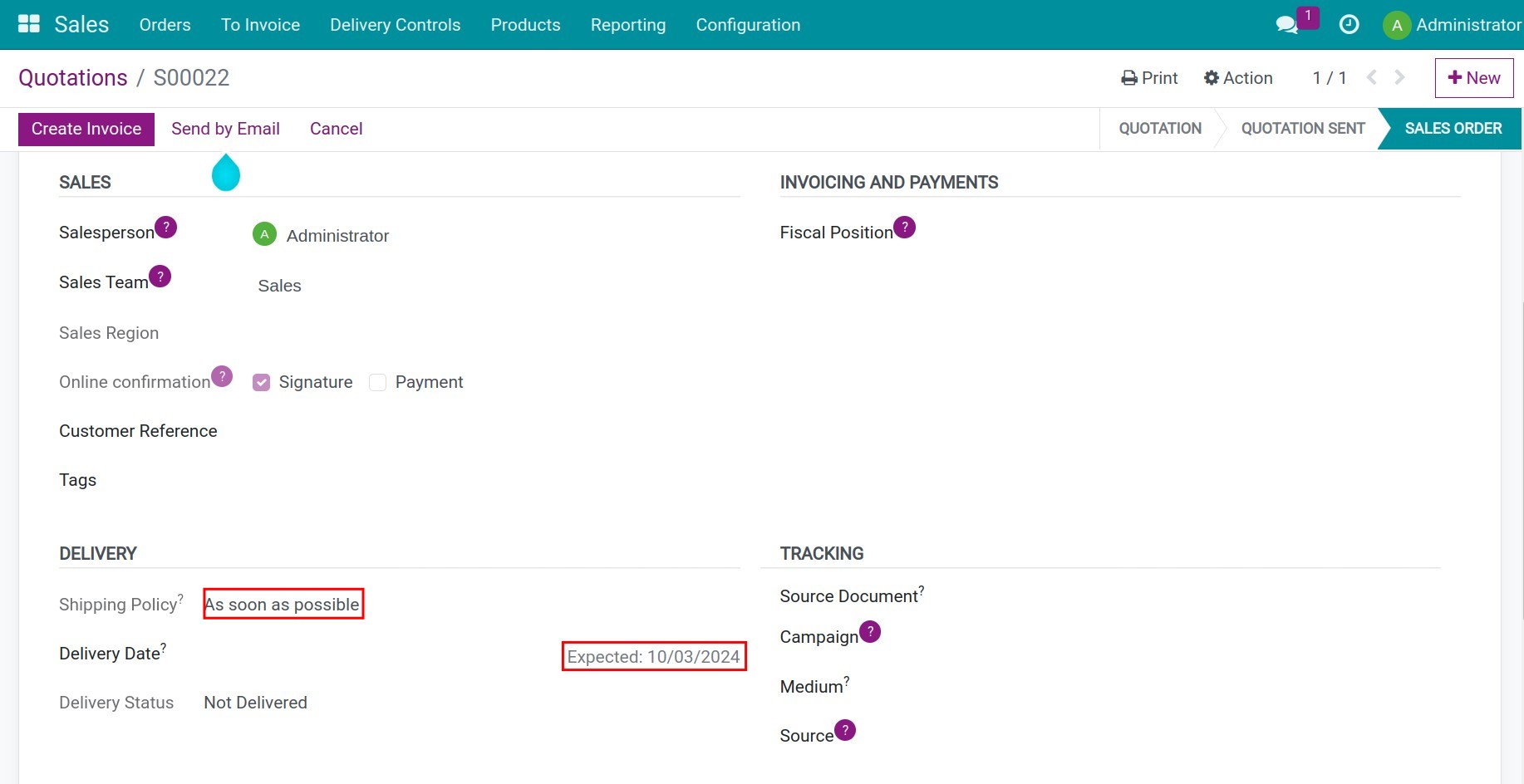

Viindoo provides you with two options for the shipping policy, which can be configured from the Other Info tab of your Sales order.

When all products are ready: deliver all products at the same time. A delivery slip is scheduled based on the product with the most lead days. In the above example, the expected delivery date will be calculated according to the delivery time of product A which is March 15th, 2024.

As soon as possible: separate delivery. The system relies on the product with the least customer lead days to calculate the delivery date. For example, B is the product with the least lead days. So, the expected date is on March 10th, 2024.

Estimate the Manufacturing time¶

Manufacturing Lead Time¶

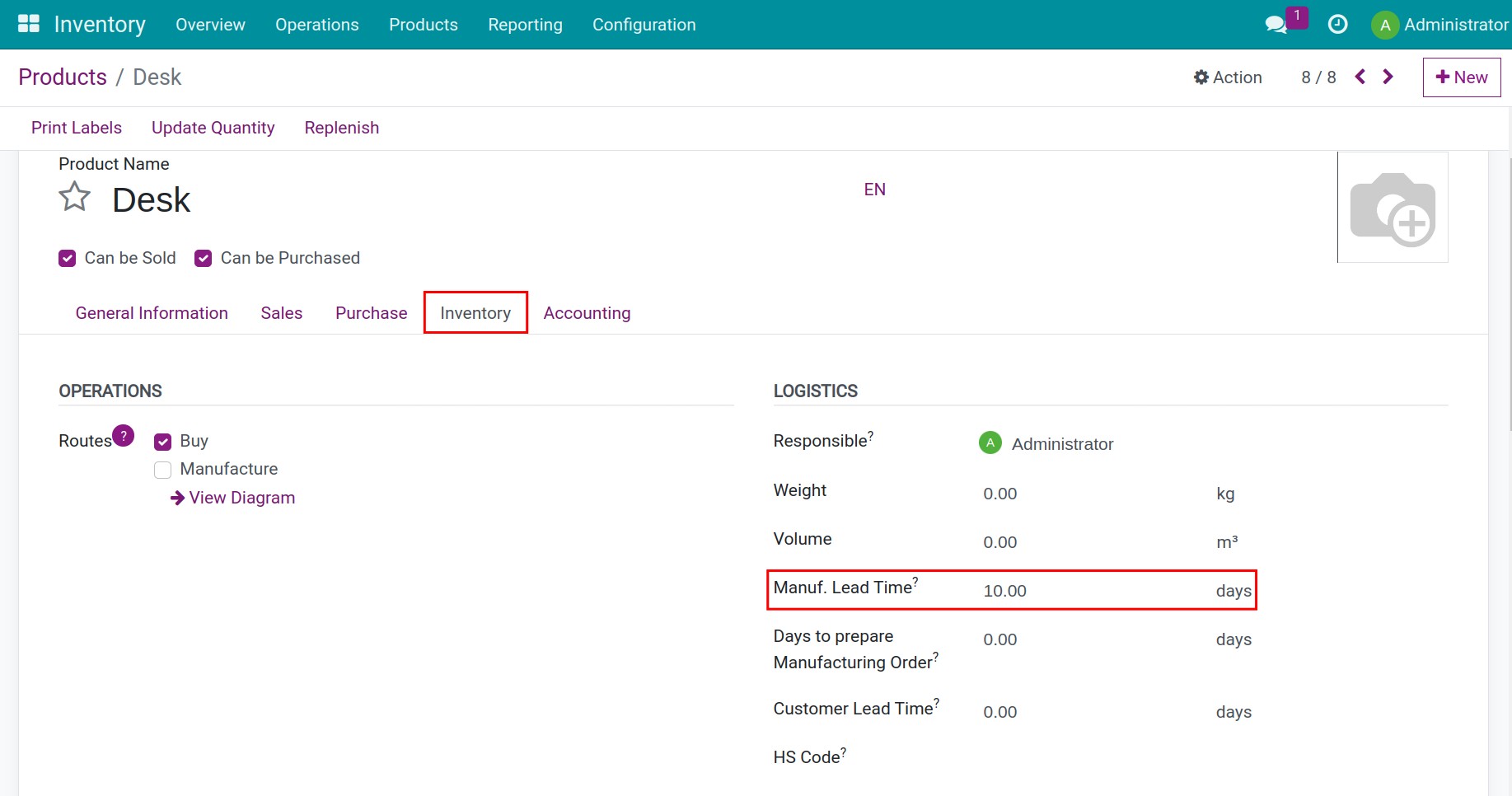

To set up this feature, in a product form, in the Inventory tab, fill in days in Manuf. Lead Time.

Manufacturing Security Lead Time¶

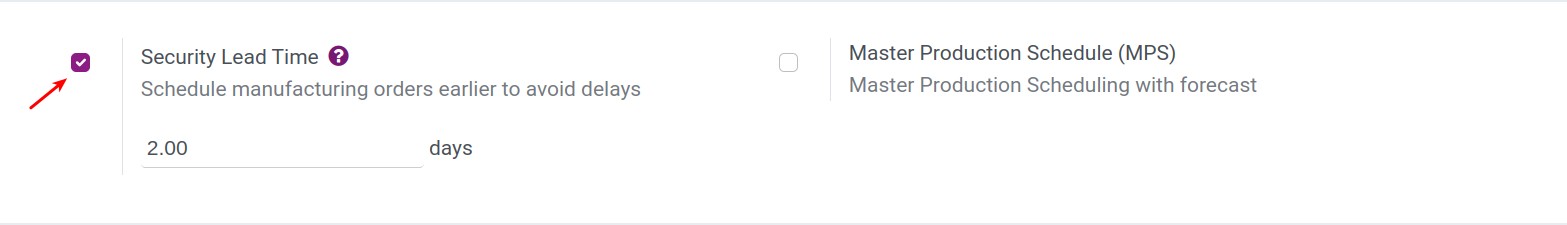

To activate the security lead time feature in the Manufacturing app, navigate to Manufacturing > Configuration > Setting, check Security Lead Time and fill in the number of expected days and Save.

Application in Manufacturing¶

It is supposed that you need to schedule the manufacturing date for product A for delivery to a customer on March 05th, 2024, as below:

Manufacturing Lead Time: 10 days.

Manufacturing Security Lead Time: 2 days.

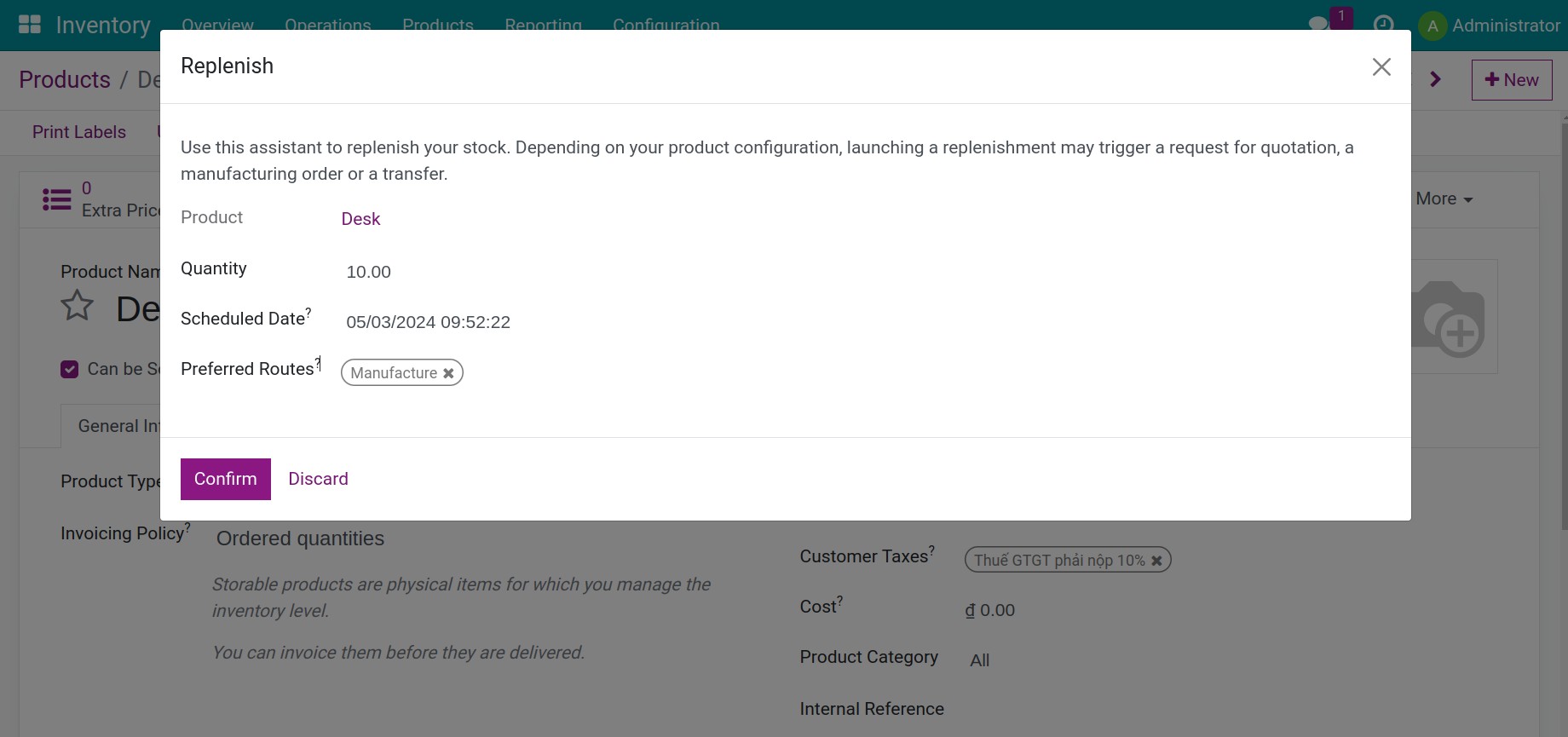

At the product form, click Replenish, choose the quantity, scheduled date on March 05th, 2024 and preferred routes Manufacturing.

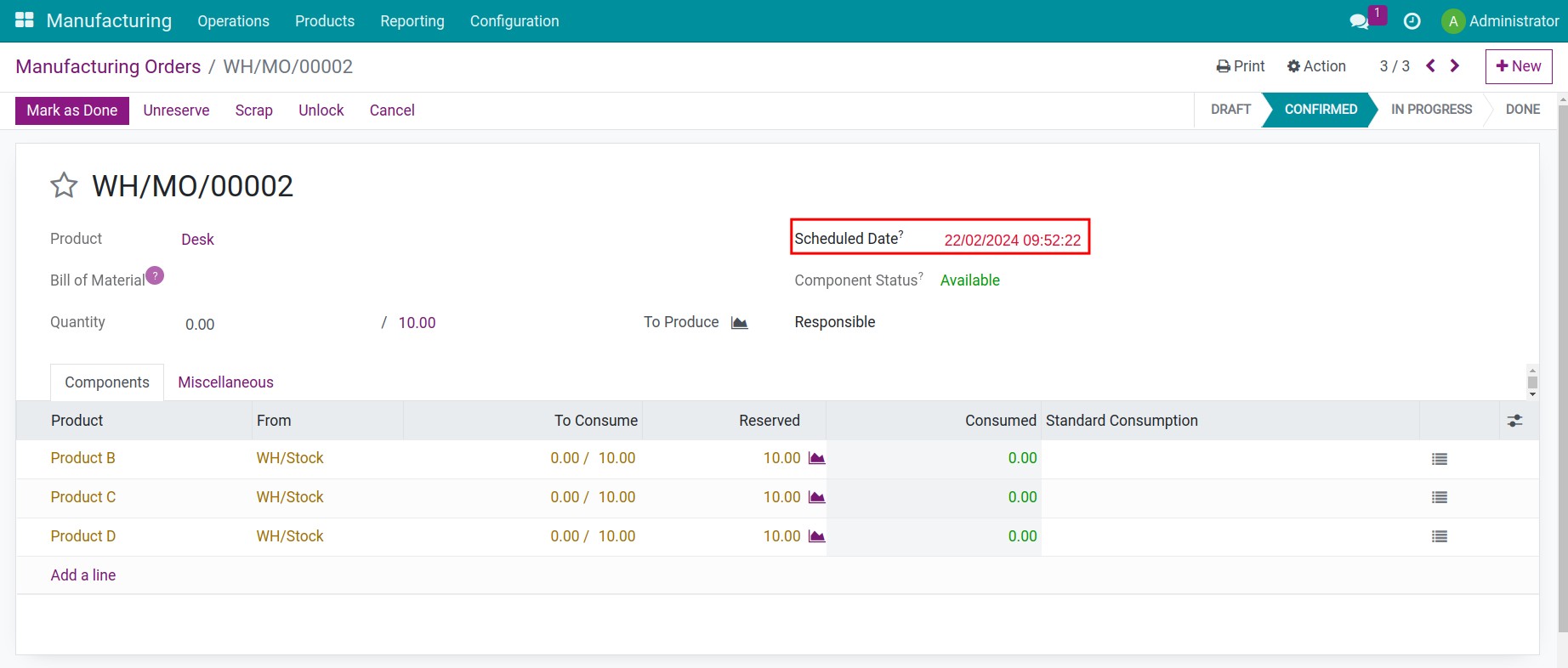

As information configure above, a manufacturing order needs to start on February 22nd, 2024, at the latest, which is the Scheduled Date of the manufacturing order = Scheduled Delivery Date (March 05th, 2024) - Manufacturing Lead Time (10 days) - Manufacturing Security Lead Time (02 days).

See also

Related Article

Optional Module