Manage semi-finished products¶

To simplify the manufacturing process in your company while using multi-level BoM (Semi-finished products), the Viindoo Manufacturing app provides the Semi-finished products feature which triggers the automatic production of semi-finished products right when a manufacturing order for the final product is confirmed.

Requirements

This tutorial requires the installation of the following applications/modules:

Configurations for semi-finished products¶

In order for the automatic production process of semi-finished products to be triggered when needed, you need to:

Create new semi-finished products that is the components of the finished products. See more at Steps to create a new product.

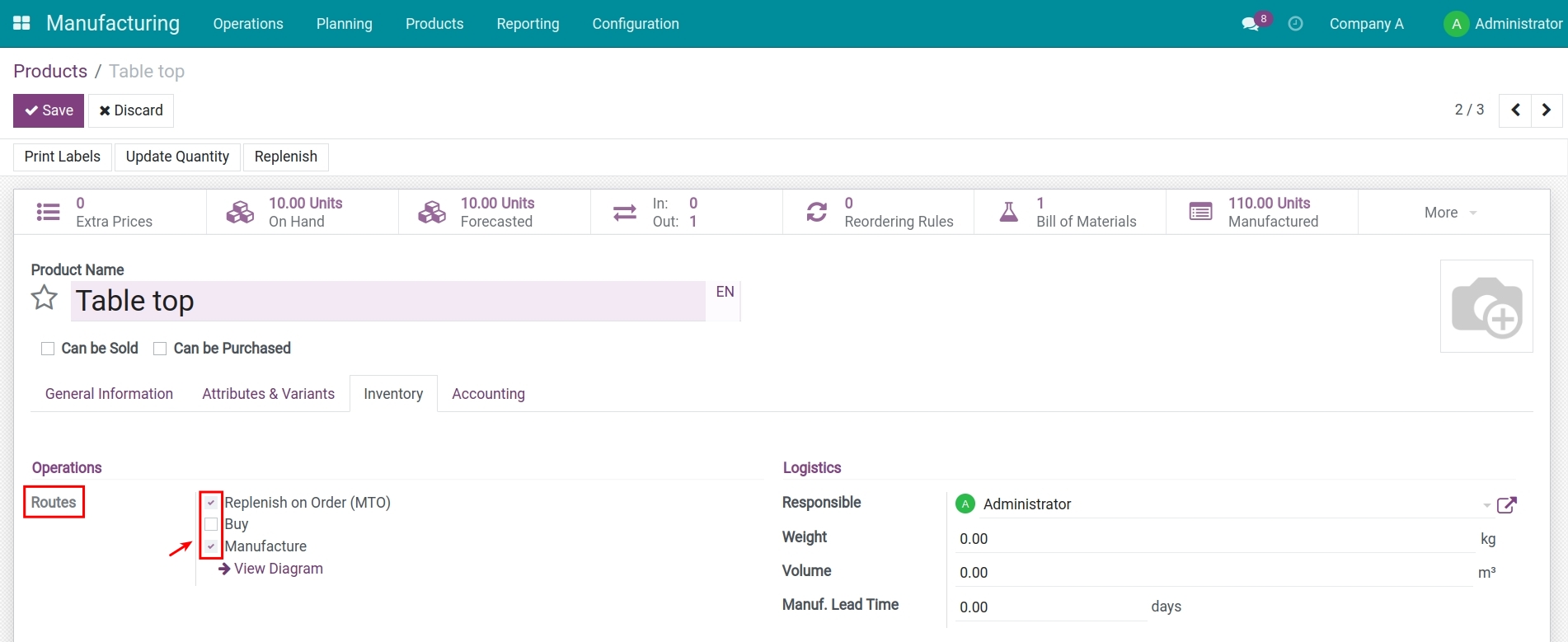

Choose one of two configurations for the semi-finished products is the Replenish on Order (MTO) rule or Make to Stock (MTS) rule.

In the example below, we will use the routes Replenish on Order (MTO).![Activate routes for semi-finished products in Viindoo MRP software]()

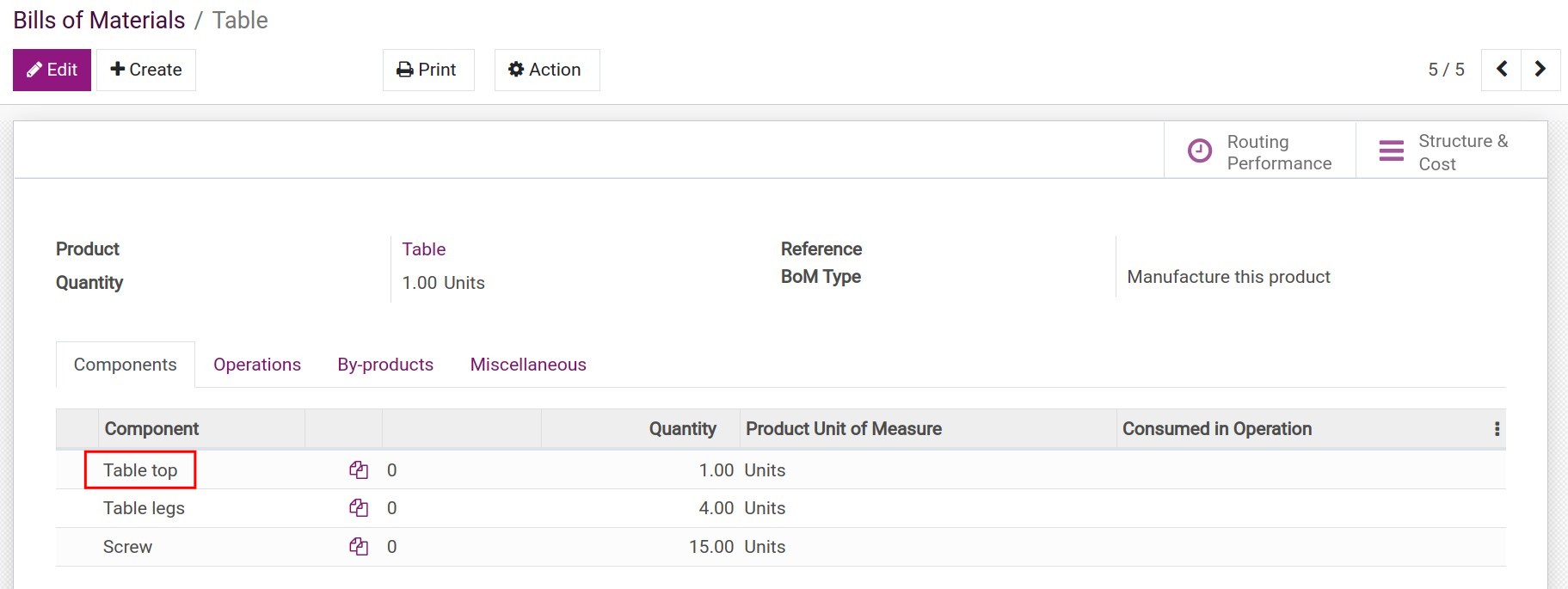

Besides of configuring the Bills of Materials (BoM) for the final products, you also need to create BoM for its semi-finished products (which include components and necessary operations of the manufacturing process).

The BoM for main product:![Create BoM for main products in Viindoo Manufacturing software]() The BoM for semi-finished product:

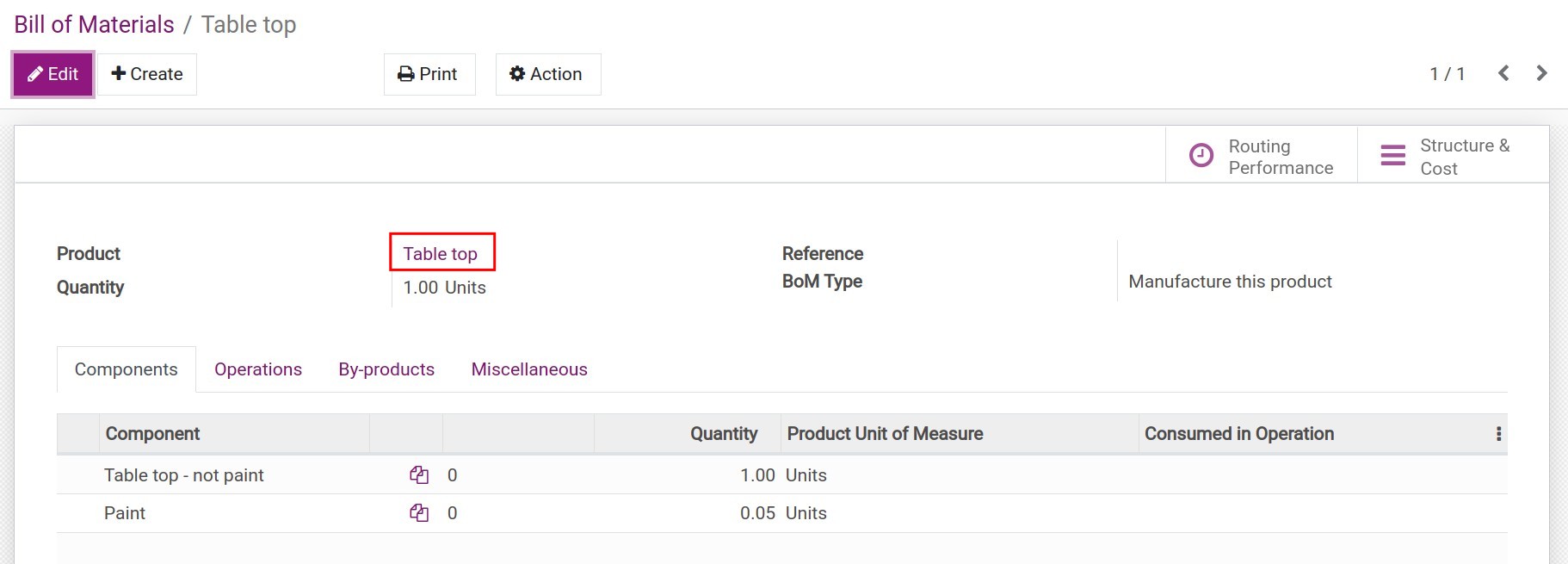

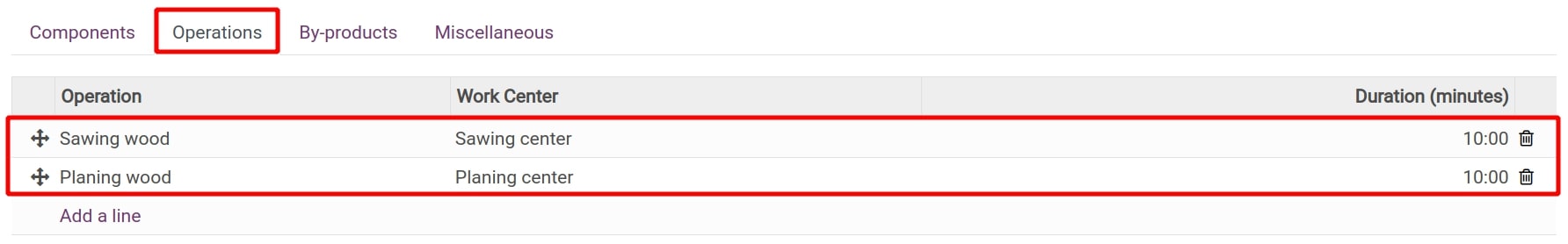

The BoM for semi-finished product:![Create BoM for semi-finished products in Viindoo Manufacturing software]()

![Manufacturing operations for semi-finished products in Viindoo MRP app]() With other semi-finished products, you also need to create respective BoMs for each one of them.

With other semi-finished products, you also need to create respective BoMs for each one of them.

Manage the manufacturing of the semi-finished products¶

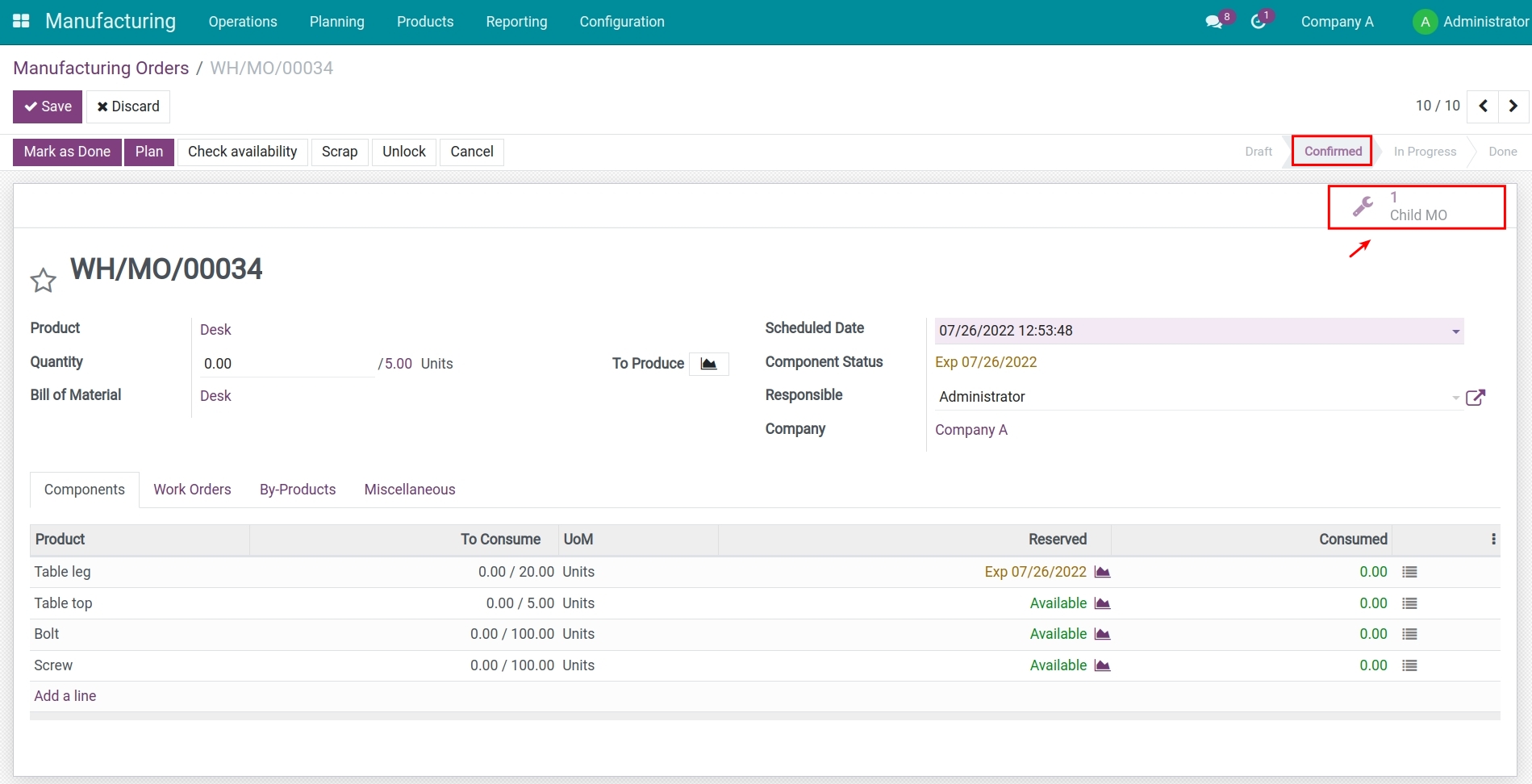

With the above configuration for semi-finished products, when a manufacturing order is confirmed for a final product, the child manufacturing orders for its semi-finished products will be generated.

You can navigate to the icon on the top right corner of your screen to see all the child manufacturing orders of these semi-finished products.

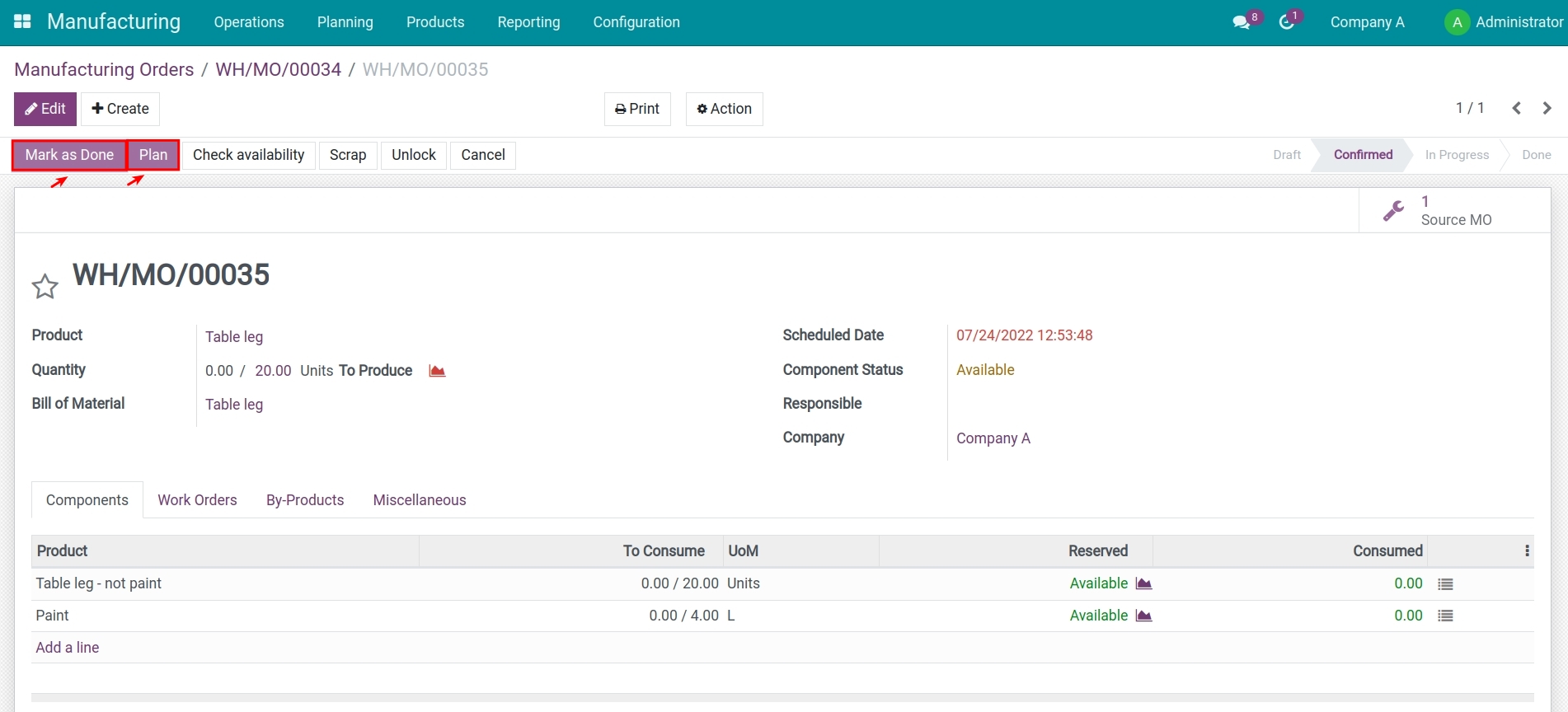

On the manufacturing order of the semi-finished products, you can choose Plan to make a production plan or select Mark as Done to record the finished production.

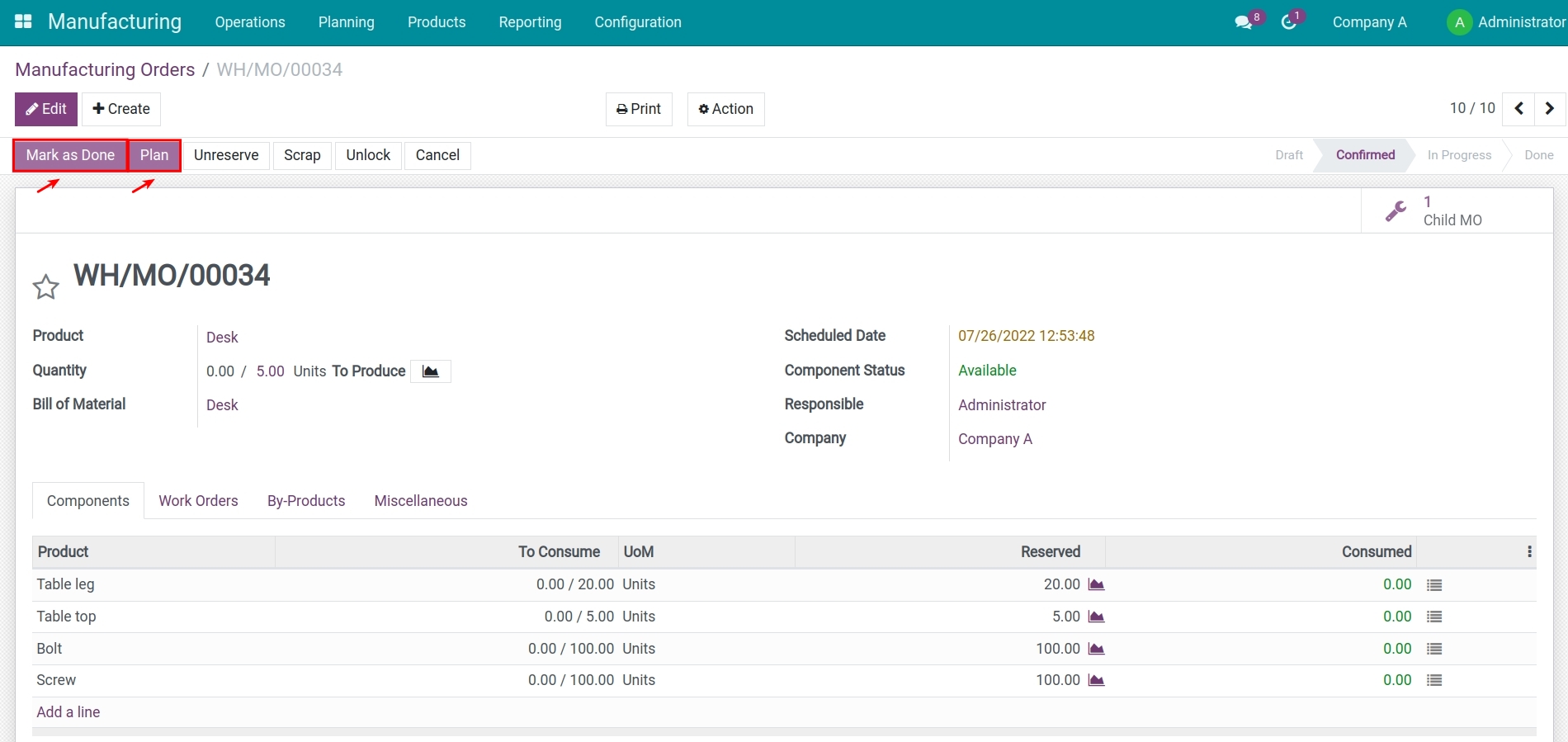

Once the semi-finished products are recorded, go back to the Manufacturing Order view of the final product, you will see the status of all the semi-finished products used as components for this product changed to Available.

Press on Check Availability to reserve the semi-finished products and raw materials quantities needed for this manufacturing order. The Component status will be changed to Available.

This is when you can start making a production plan or mark as done for the manufacturing of the final product.

See also

Optional module