Steps to configure unbuild orders in Viindoo¶

Unbuild means to separate and take out components of a product. In any enterprise, we may have to dismantle products in many various circumstances:

Businesses purchase materials to dismantle them into various components for usage or retail purposes.

In the manufacturing process, businesses want to dismantle the finished products into separated components due to not meet up quality standards, etc.

In this article, Viindoo will provide some instructions about how to unbuild a product into small components.

Requirements

This tutorial requires the installation of the following applications/modules:

Create manual unbuild orders¶

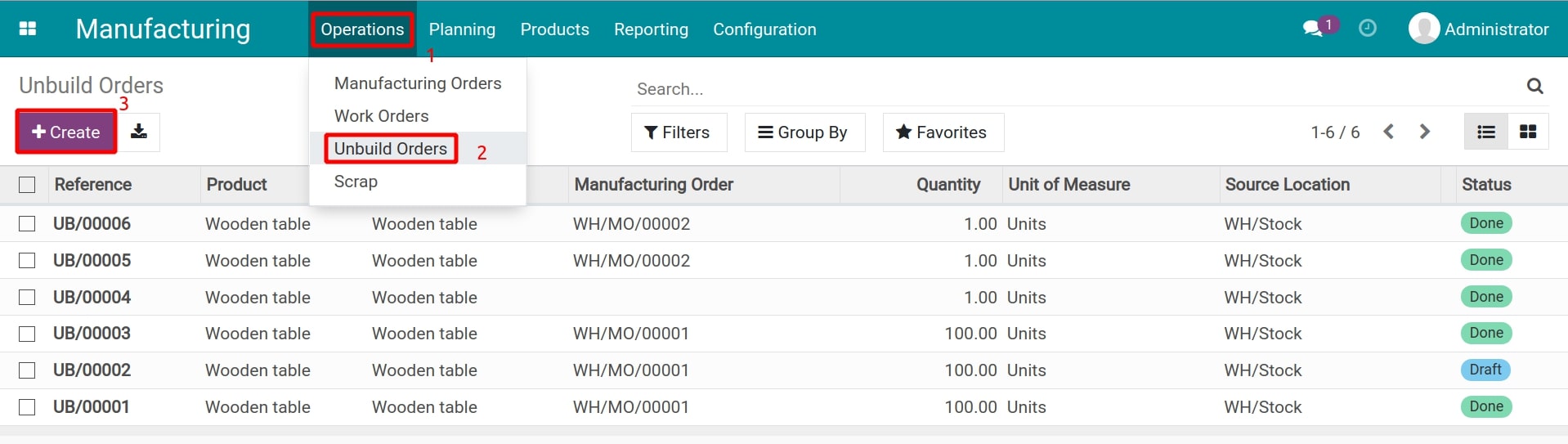

In the Manufacturing application, users can manually create unbuild orders by navigating to Manufacturing > Operations > Unbuild Orders, and choosing Create to create a new unbuild order.

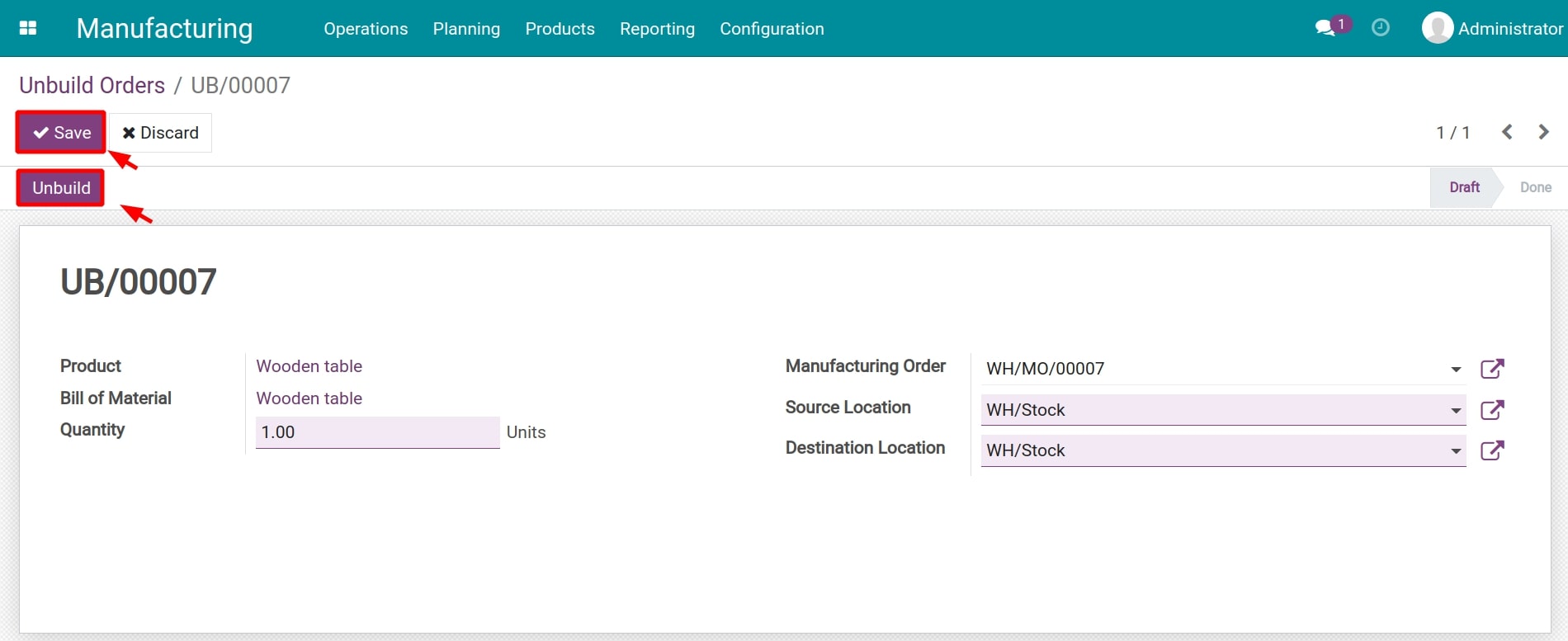

Then, add the following information:

Product: select the product that you want to unbuild;

Bill of Material: the to-be-dismantled product must have a Bill of Material for the identification of the components after the unbuild process;

Quantity: the number of units to unbuild;

Manufacturing Order: choose the manufacturing order for the unbuilt product (leave empty if this is a purchased product);

Source Location: the location where the unbuilt product is stored;

Destination Location: the storage location of components dismantled from the original product.

Then, press Save and Unbuild.

See also

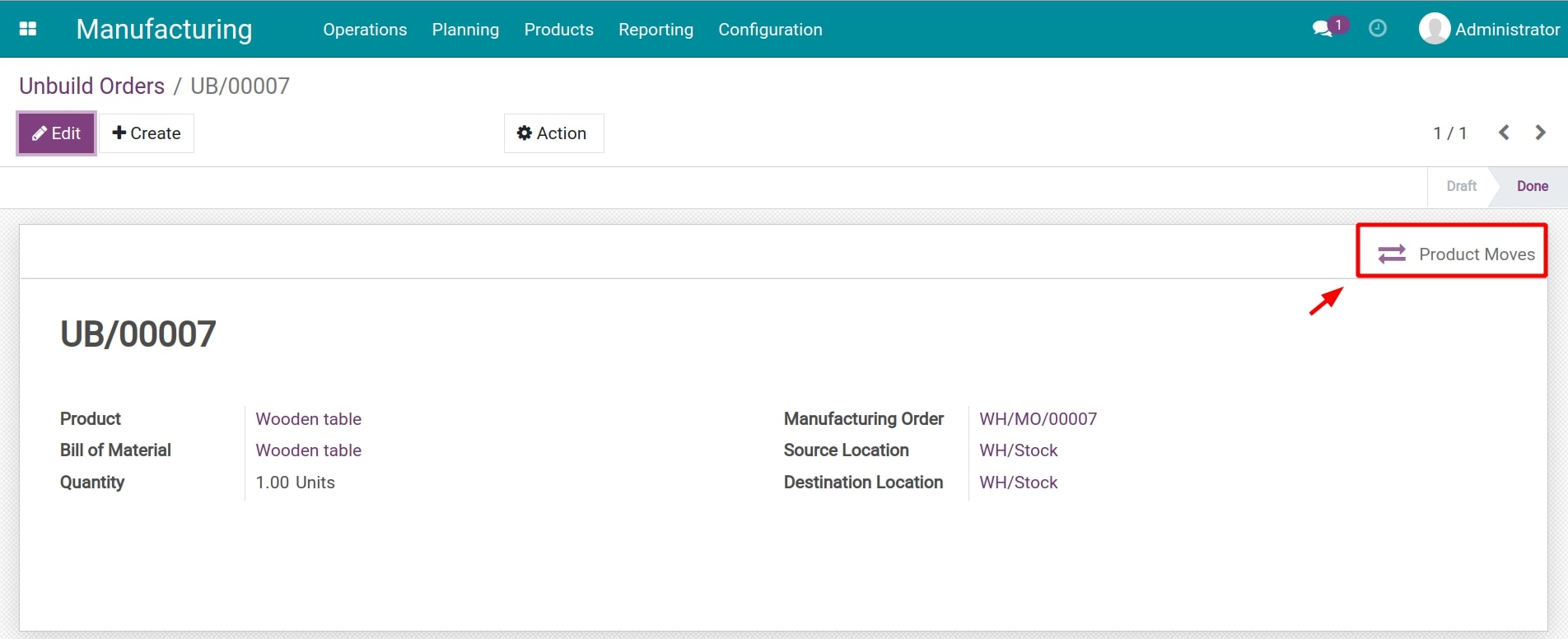

After choosing Unbuild, the status of Unbuild Orders will be changed to Done, simultaneously users can trace the transfers of the unbuilt products by clicking on Product Moves.

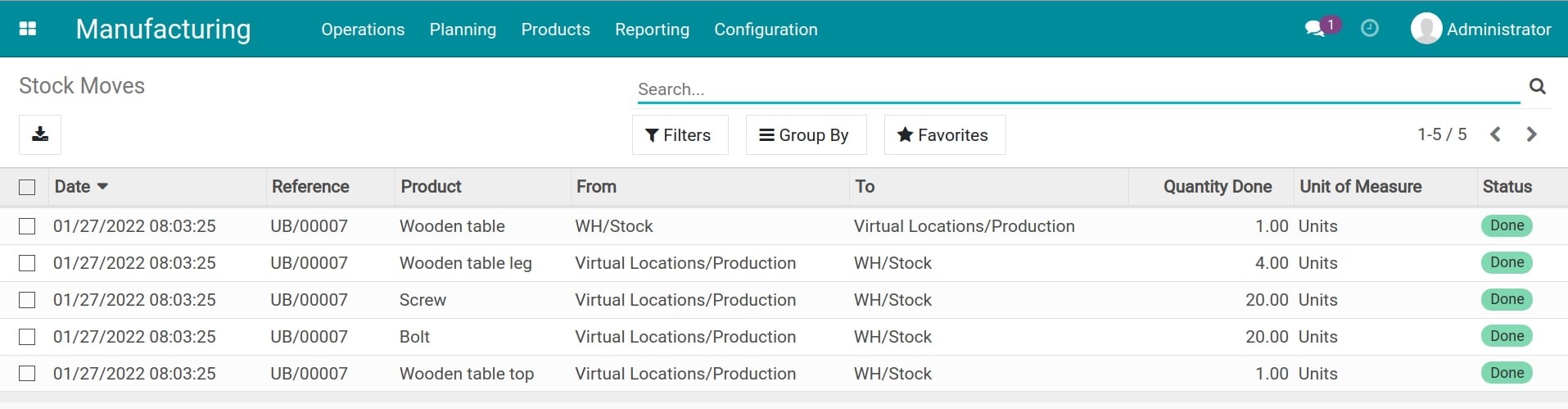

Here is some information about product moves:

Date of unbuilding (the Date column);

Reference of Unbuild Orders (the Reference column);

Product including the unbuilt product and its components generated after unbuilding (configured in Bill of Material) (the Product column);

Tracking the movement of the unbuilt product and its components (the From & To column);

The number of the products as the components generated from unbuilding process (the Quantity Done column);

Unit of the product (the Unit of Measure column);

Status of Unbuild orders: Draft or Done (the Status column).

Create Unbuild Orders from Manufacturing Orders¶

In Manufacturing Orders, the responsible person can make a unbuild order for the semi-finished and finished products which are not up to the quality standard.

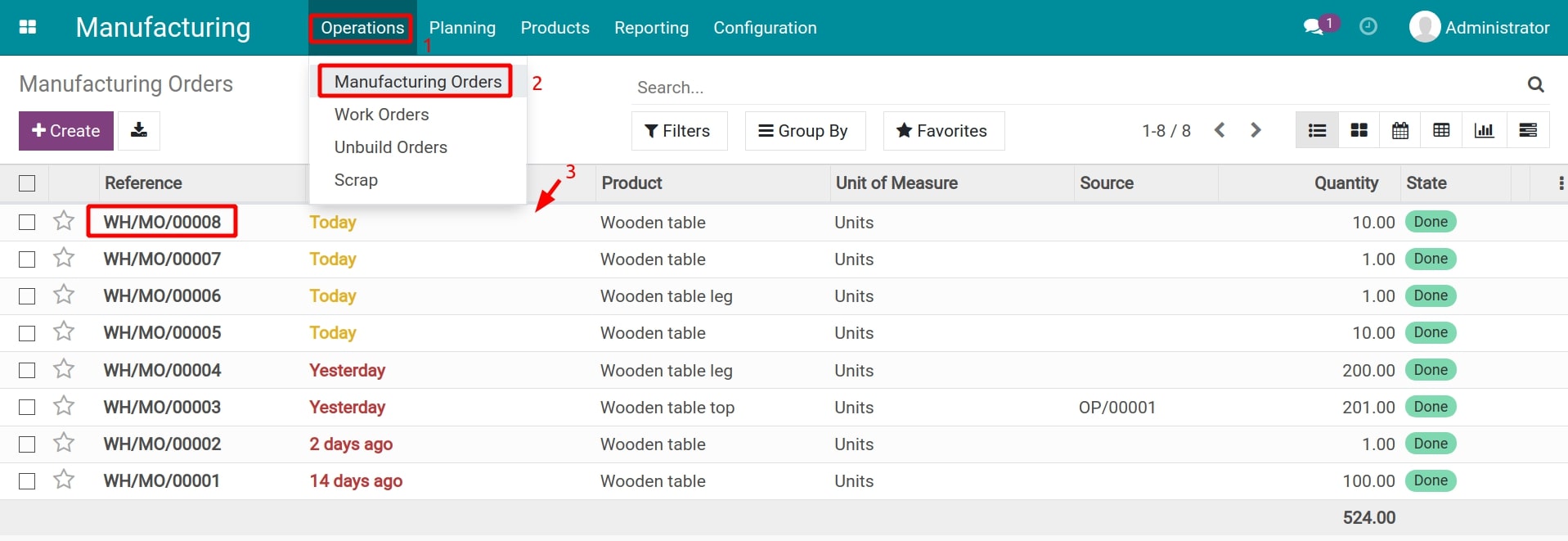

Navigate to Manufacturing > Operations > Manufacturing Orders, choose Manufacturing Orders where there is the product that needs to be dismantled.

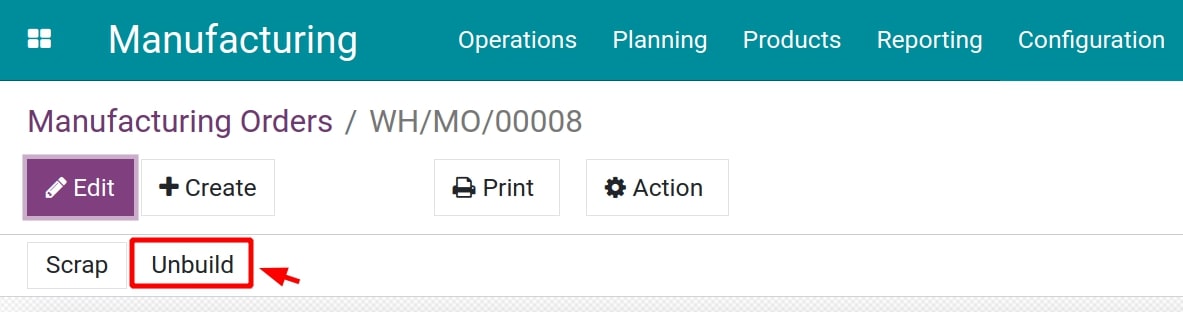

On the Manufacturing Order form, click Unbuild.

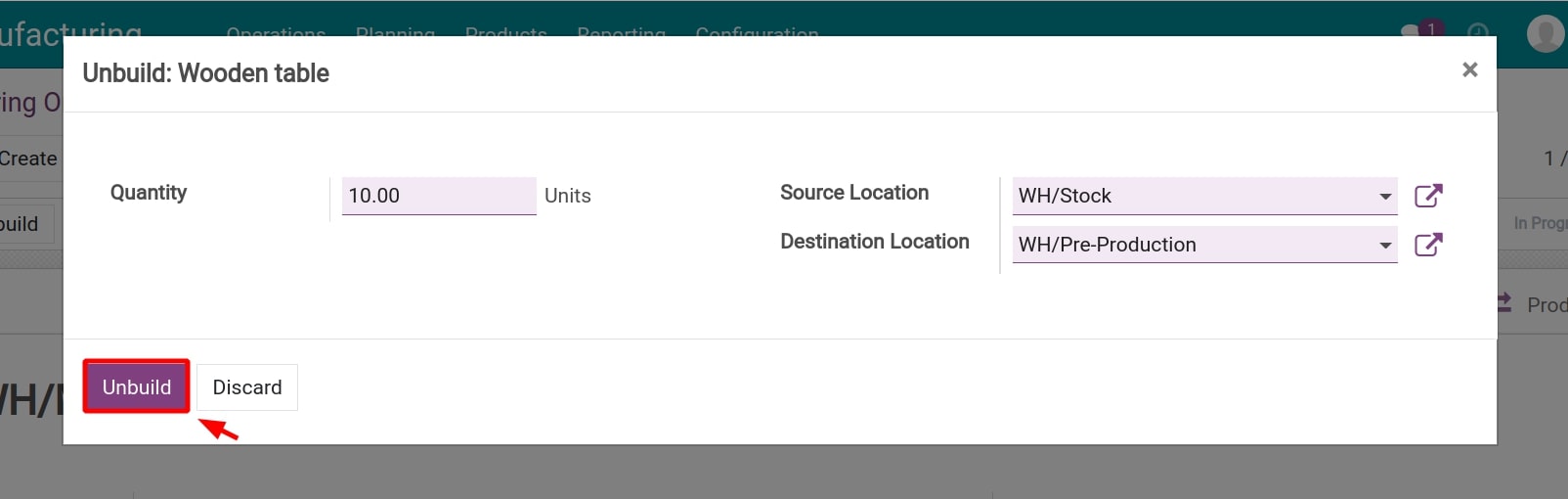

Users will be redirected to a new form that allows them to fill in the information about the products generated from this manufacturing order that need to be dismantled.

Here, add the necessary information of the Unbuild Orders similar to steps for the manual unbuild order, then press Unbuild to complete the product dismantling.

See also

Related article

Optional module