Track your products with lots¶

Goods are produced in batches, each lot of products is numbered with a different set of numbers and symbols by the manufacturer to distinguish characteristics of each lot such as manufacture time, market, production stage, production process, etc.

Tracking goods by lot numbers with a strict process helps manage inventory effectively. The Viindoo Inventory app provides warehouse management solutions including convenient identification and traceability of goods, and schedule input-output-inventory actions for each products lot feature.

Requirements

This tutorial requires the installation of the following applications/modules:

Configure inventory management by lot numbers¶

To configure inventory management by lot numbers, you need to do as follows:

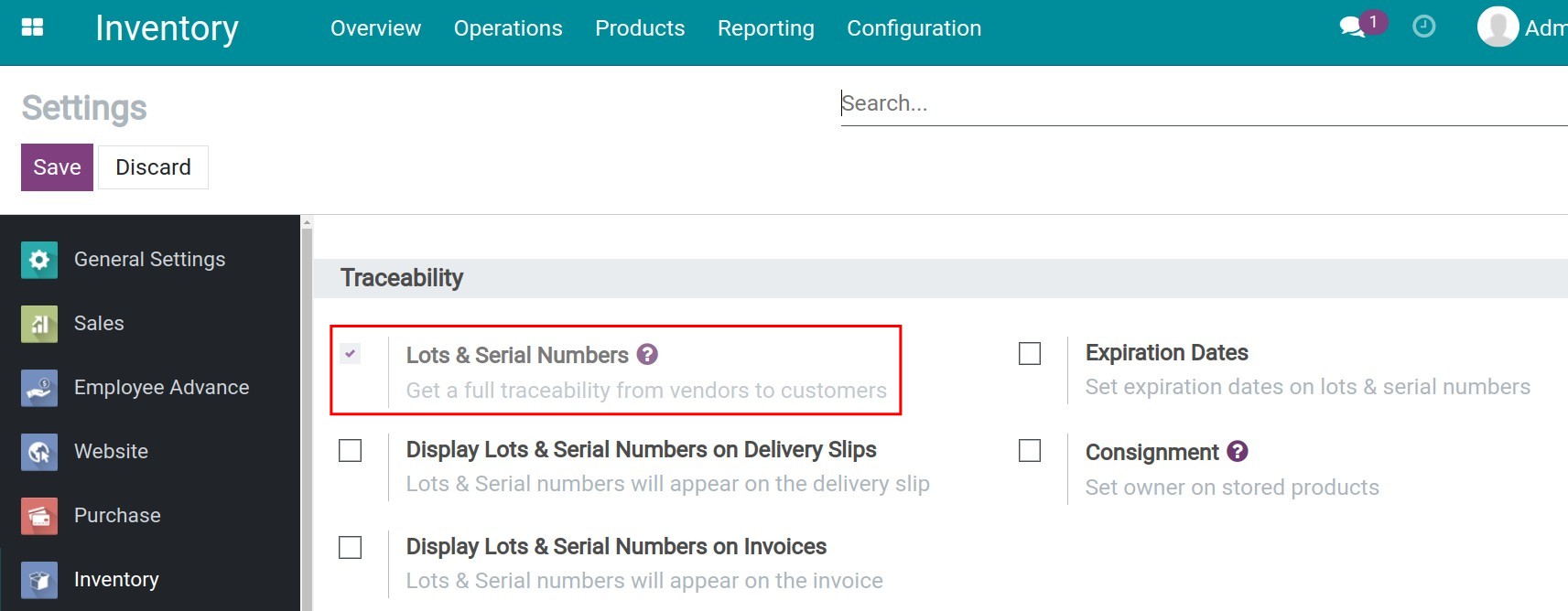

Activate Lots & Serial Numbers feature¶

You can manage goods by lot numbers by activating the Lots & Serial Numbers feature in Settings > Inventory > Traceability, tick Lots & Serial Numbers.

Then click Save to apply the settings.

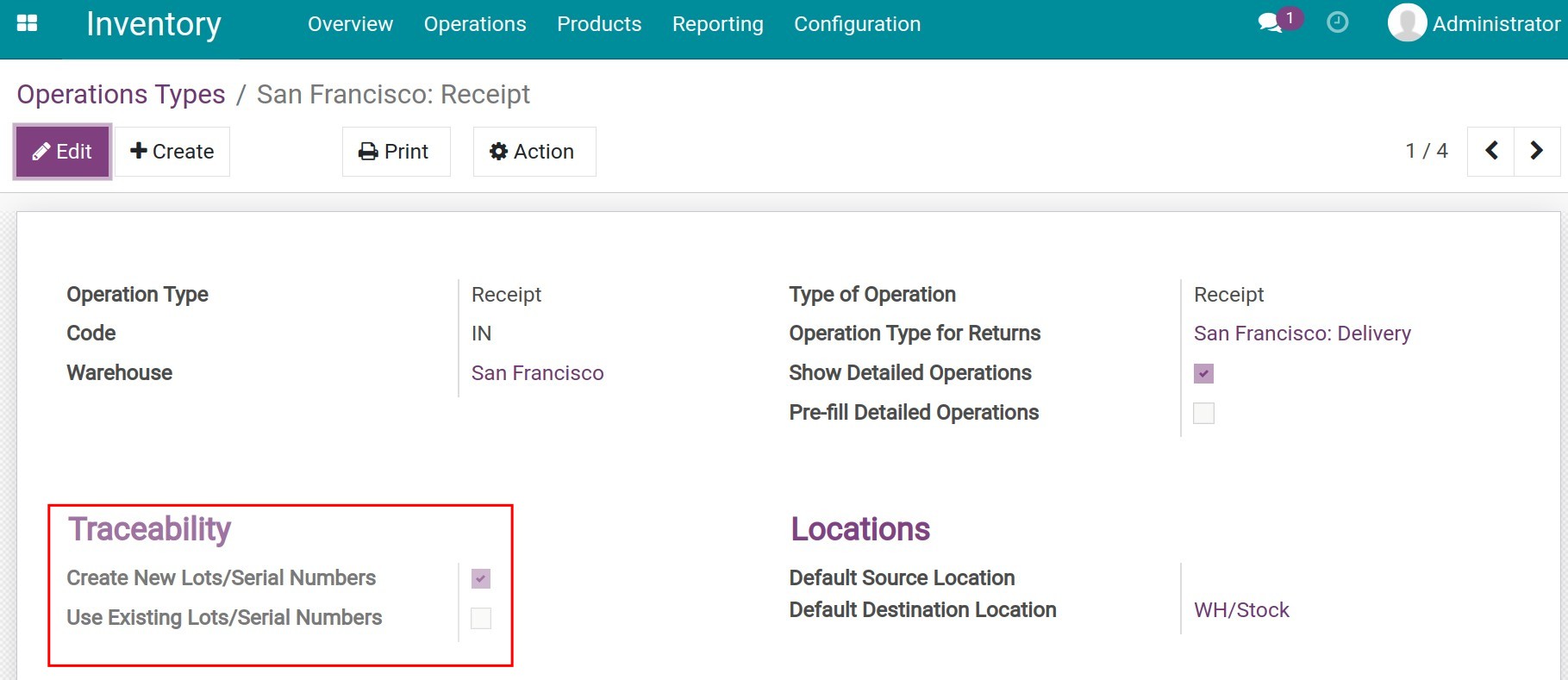

Configure lot numbers according to inventory management operations¶

Manage lot numbers for inventory management operations such as receiving, shipping, etc. in Inventory > Configuration > Operations Types.

Select an operation type and configure lot numbers as follows:

Click Save to apply the settings.

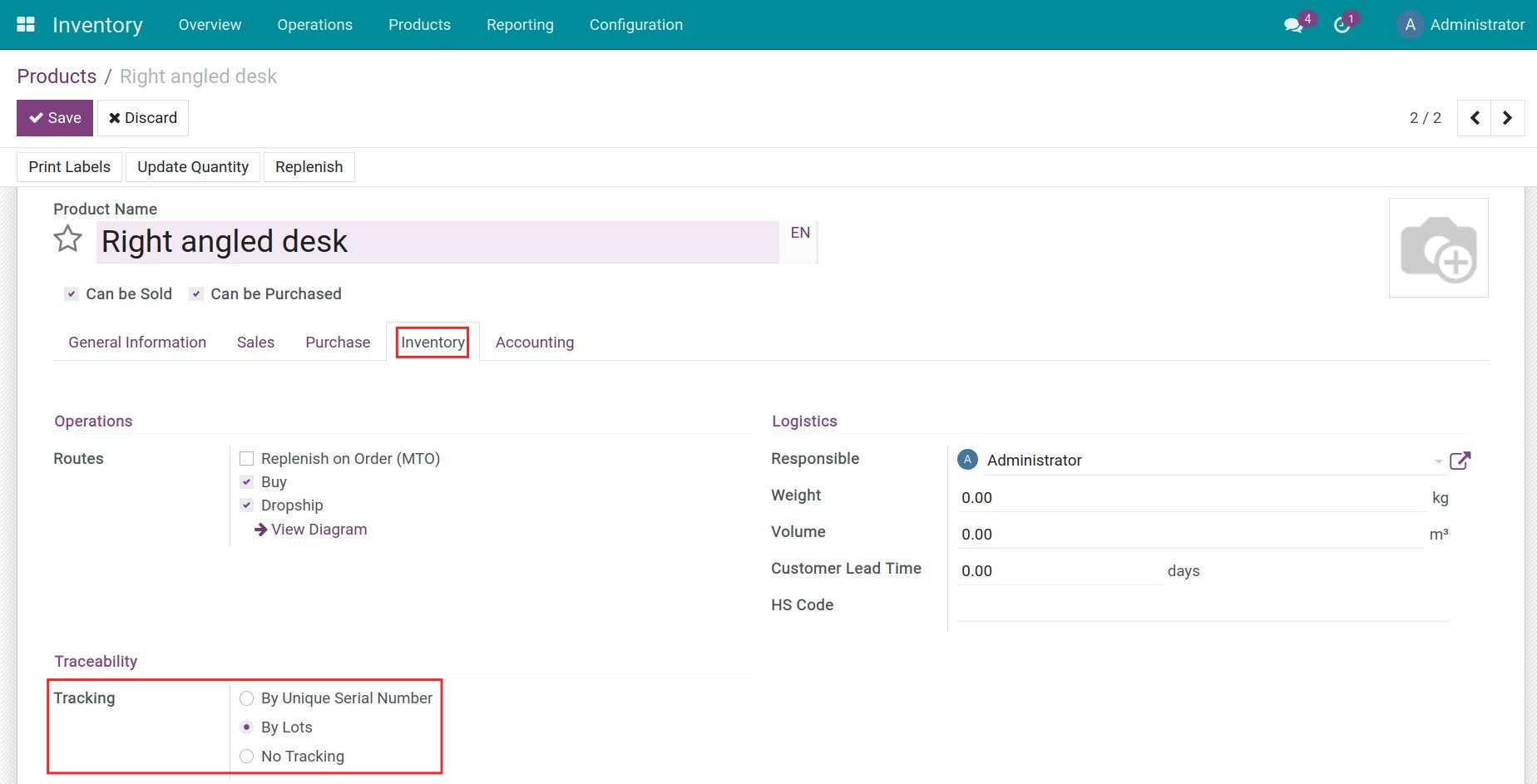

Configure product management by lot numbers¶

To manage products by lot numbers, navigate to Inventory > Products > Products and select a product that you want to set up.

In the product setup interface, switch to the Inventory tab, in Traceability, select By Lots.

Efficient inventory management with lot numbers¶

After configuring the Viindoo Inventory management software, the remaining work is to handle tasks related to inventory management by using the features.

Tip

Set up lot numbers methodically and systematically, this will help a lot in the management and operation of goods.

For example, with VNS0012, VN is the country code, S is the product code, and the number part is the product release date, etc.

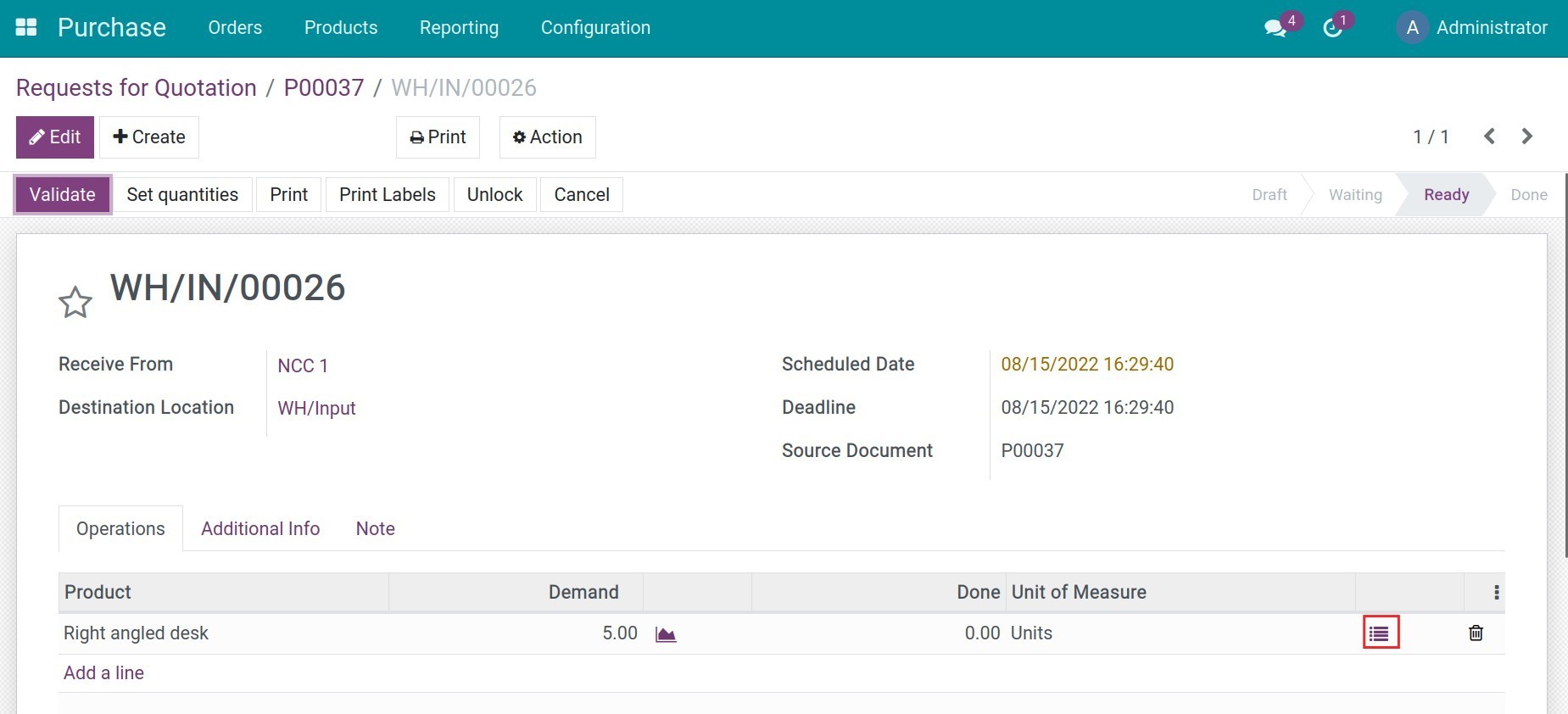

Create stock transfers¶

When there are receiving, delivering or internally transferring operations of goods, create stock transfers. Goods with lot numbers will be attached with lot number information to track the origin of goods.

Make a stock transfer, create a warehouse receipt by navigating to Inventory > Operations > Transfers, click Create.

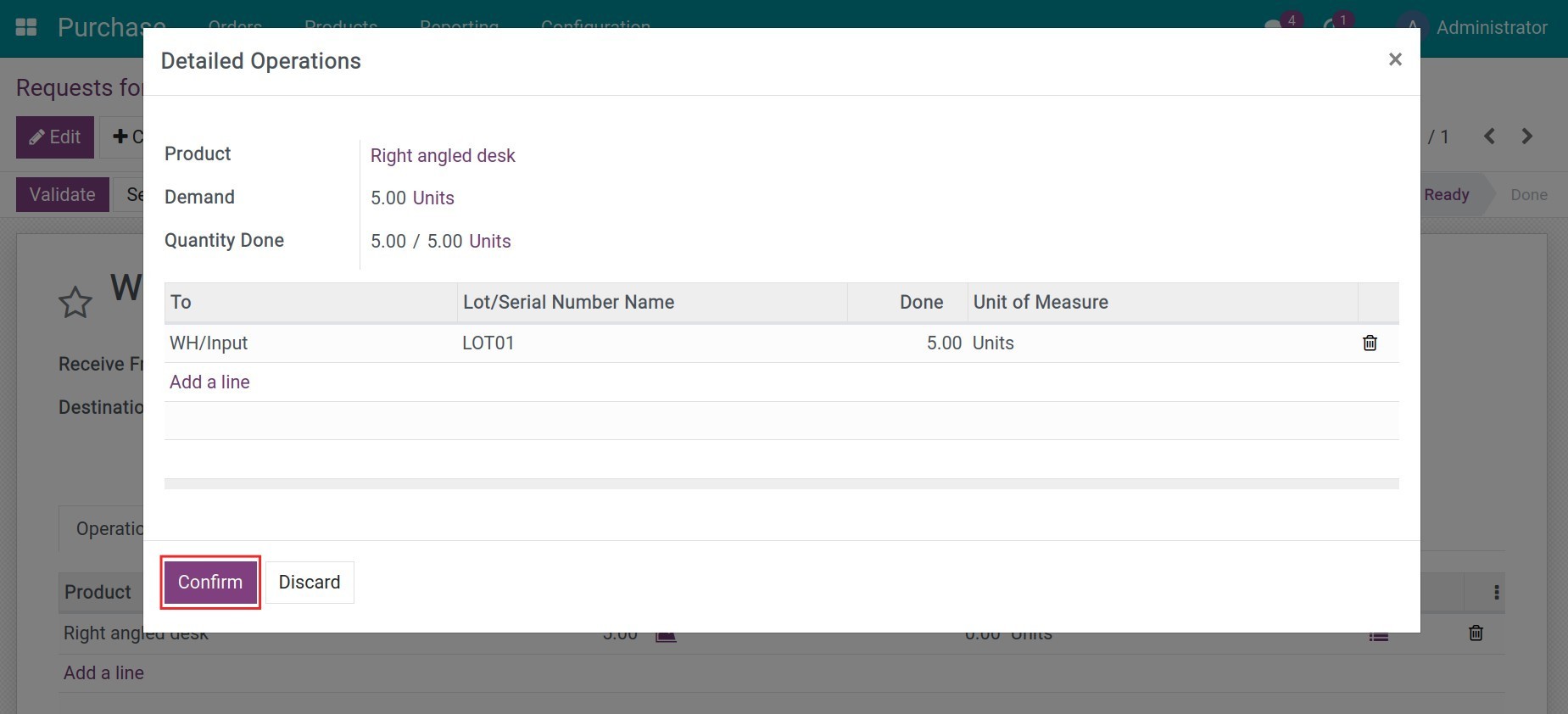

Click on the lot numbers icon to open the interface to assign the lot number to the product in the stock transfer.

Add the goods source, create a lot number or select an existing lot number, select the quantity and press confirm, the product with the set lot number will be attached to the created stock transfer.

Tip

Viindoo Inventory management software allows barcode scanners to get information and transfer it to the software. The software will do the job quickly and efficiently just by scanning the barcode.

Inventory Adjustments¶

When discrepancies arise between recorded and actual quantities, inventory adjustment features should be used.

For products with assigned lot numbers, it is necessary to correct the inventory corresponding to the lot number of the correct product.

Viindoo Inventory management software allows to use one of the following two methods:

Adjust on product interface¶

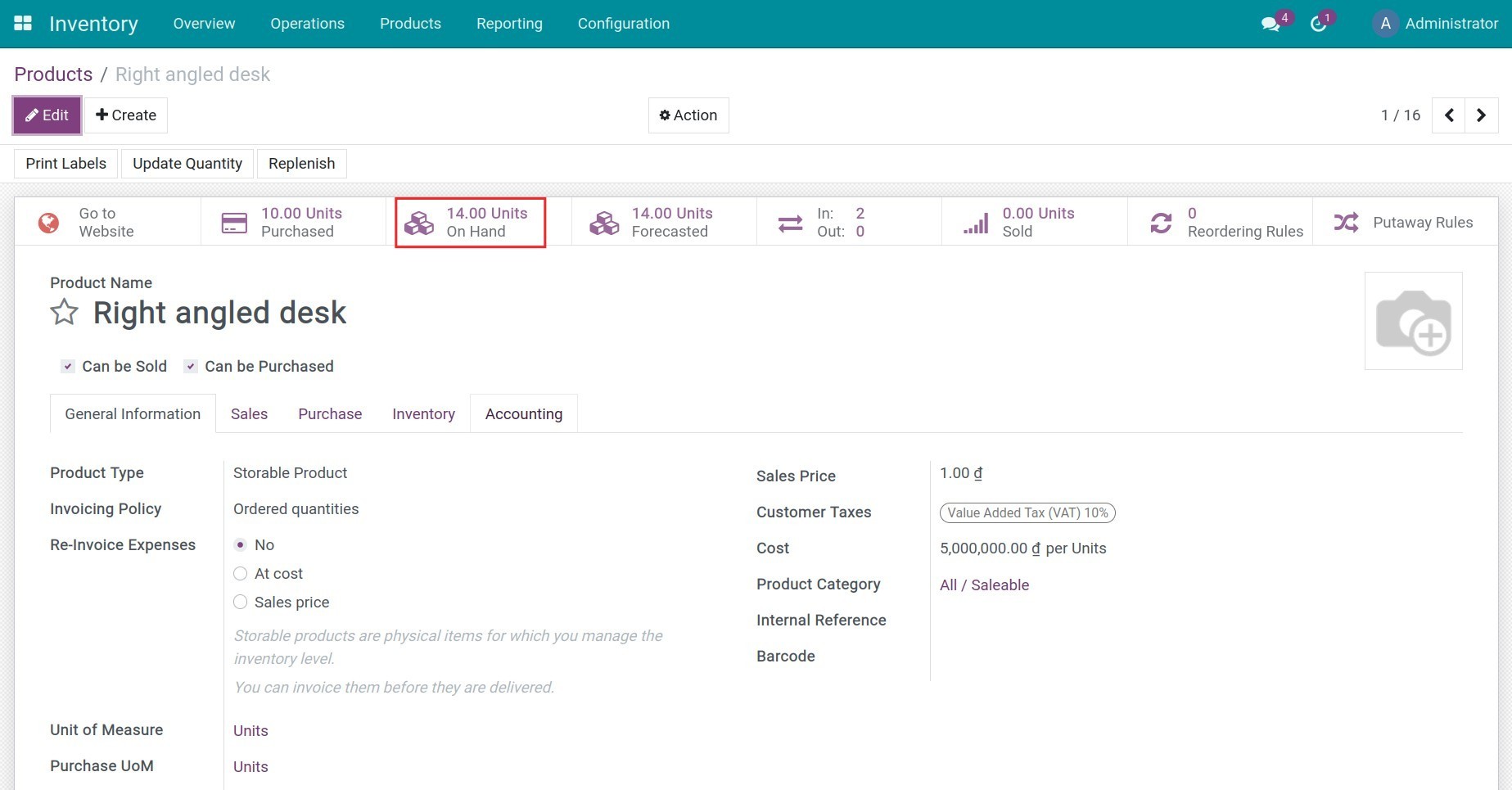

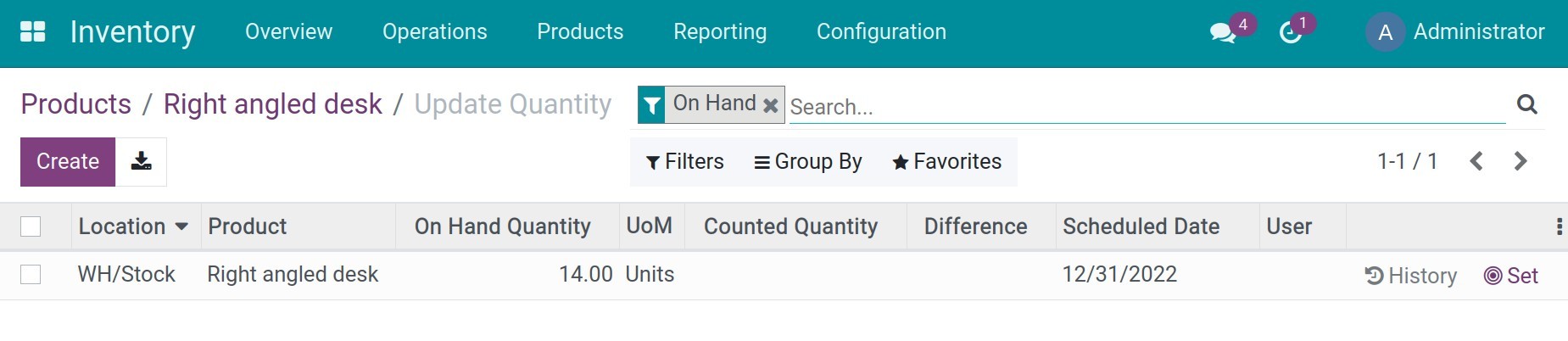

After performing the tally, navigate to Inventory > Products > Products, select the product and click On hand to adjust inventory.

Inventory adjustment information will be saved.

Note

When you need to do adjust the quantity of each lot, find the correct inventory line of said lot and edit the data. Press Create to add a new inventory line if that lot is not included in the inventory list.

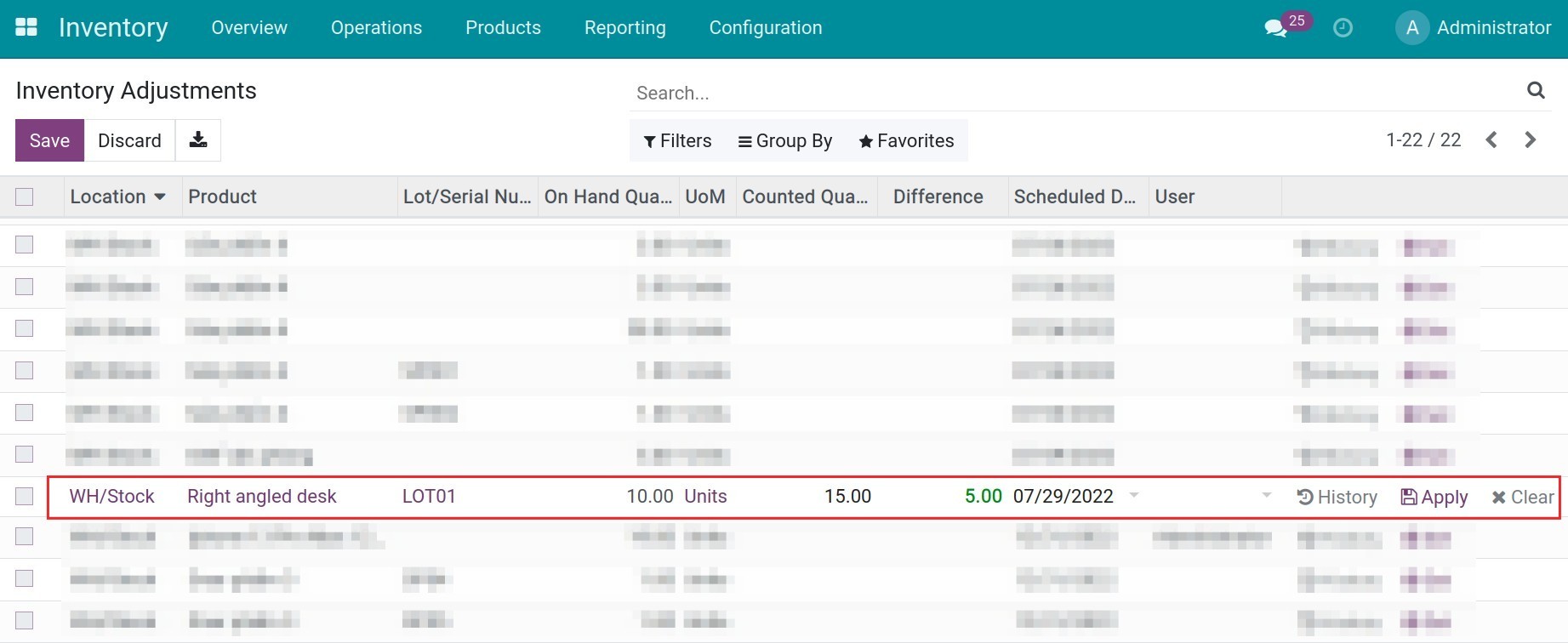

Adjust by the Inventory Adjustments feature¶

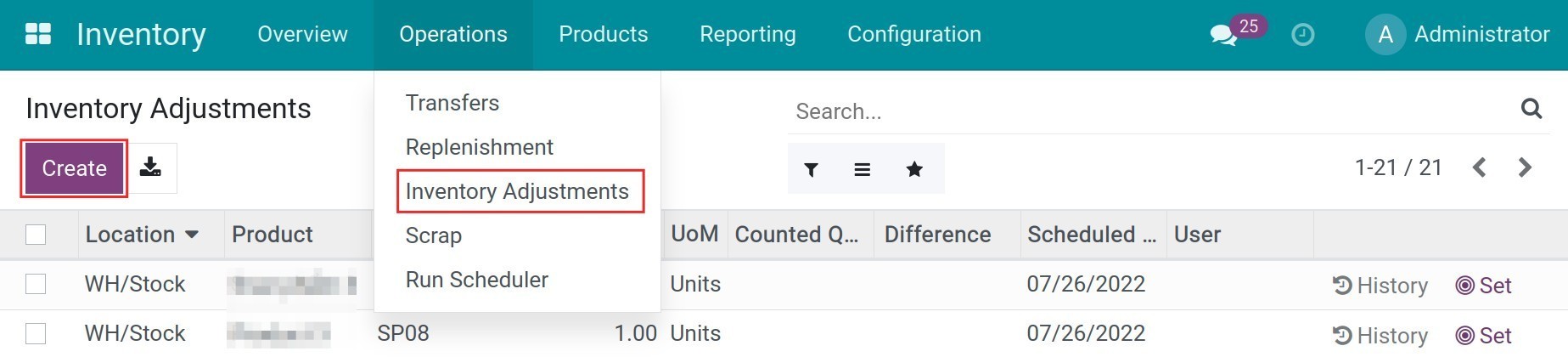

Navigate to Inventory > Operations > Inventory Adjustments, click Create to create inventory adjustment slip.

Perform counting operations and adjust inventory information corresponding to each product’s lot number, then fill the inventory information in the software.

Click Apply on each line, inventory adjustment information will be saved.

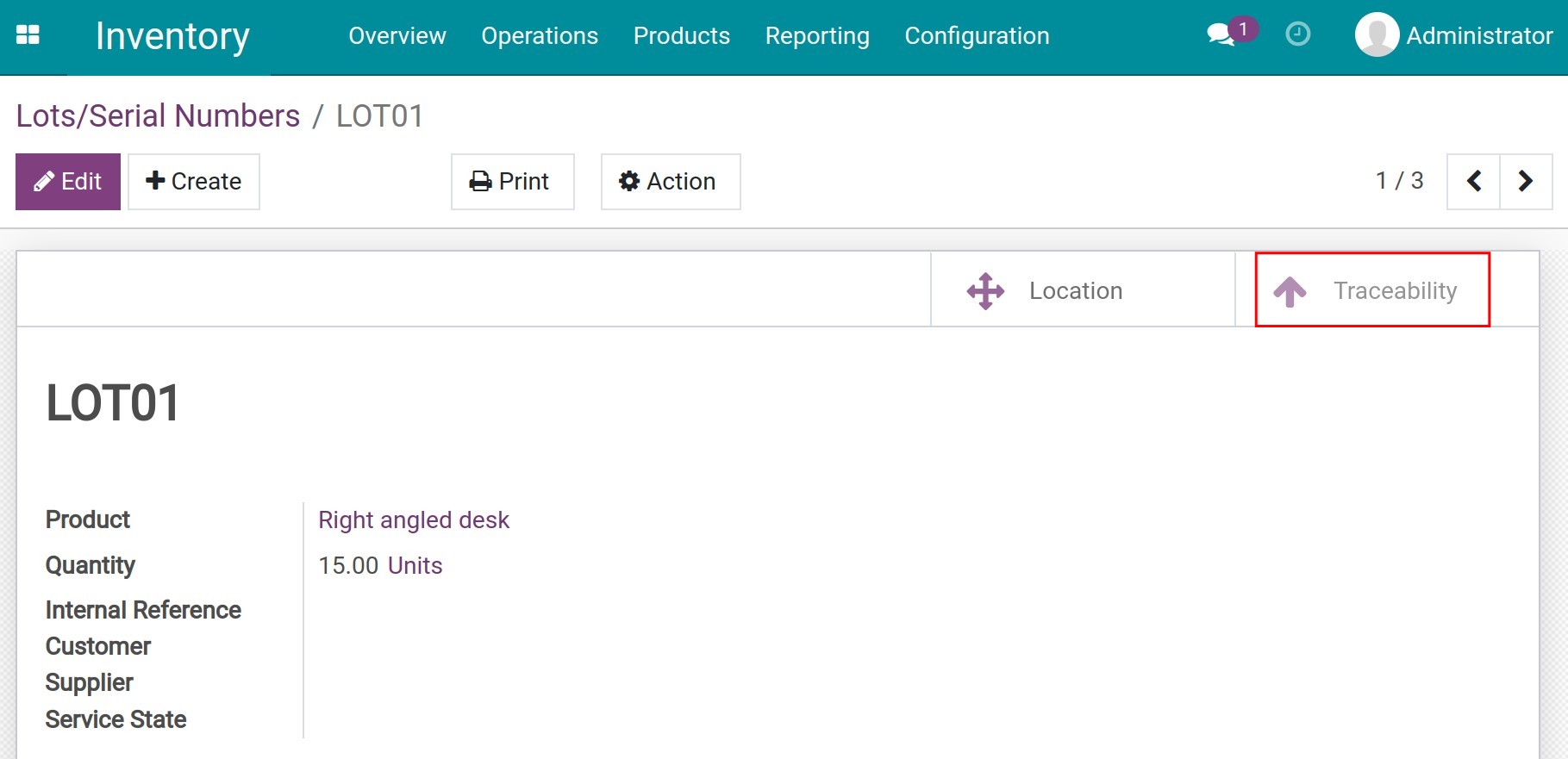

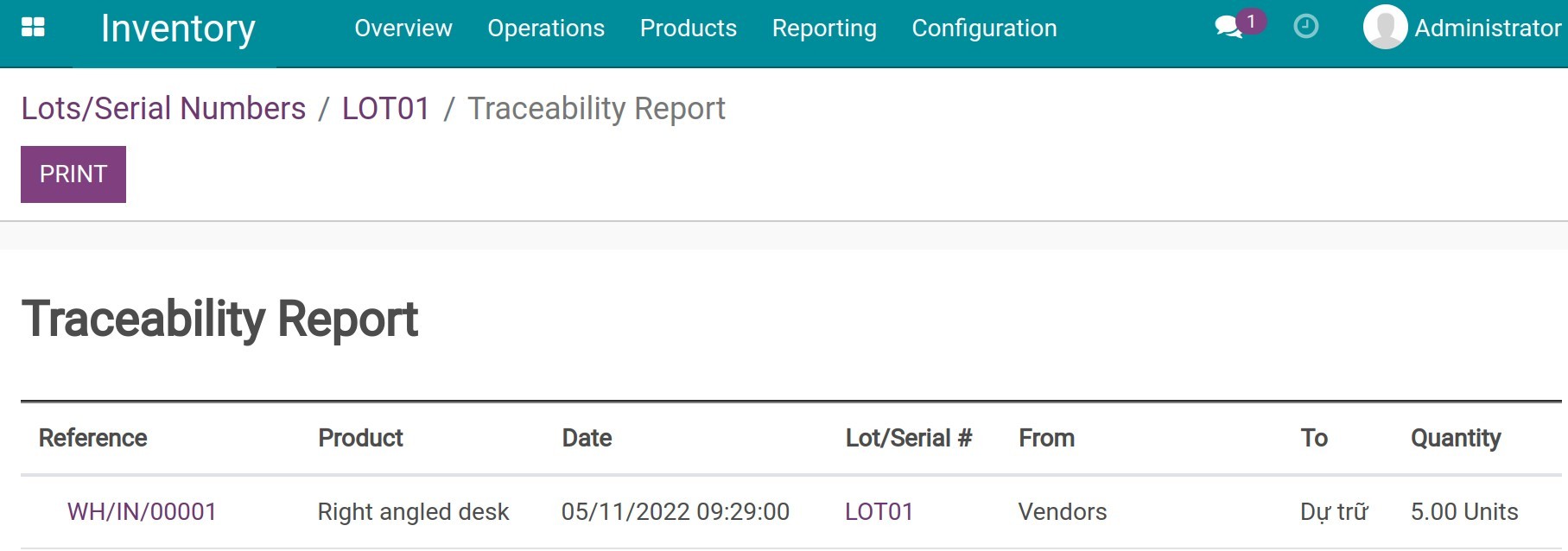

Tracking by lot numbers¶

You can trace products by lot numbers by navigating to Inventory > Products > Lots/Serial Numbers, select a lot and click Traceability.

The traceability interface will display the inventory changes related to this lot number.

See also

Related Article

Optional Module