Create Quality Alerts¶

It’s quite important to check and warn the quality of products to eliminate errors in manufacture or stock transfers. The quality alert feature in Viindoo Quality app will support you to better control the product quality.

Requirements

This tutorial requires the installation of the following applications/modules:

Create Quality Alerts in Goods Receipts/Deliveries¶

Steps¶

Take the following steps to create a quality alert in goods receipts/deliveries:

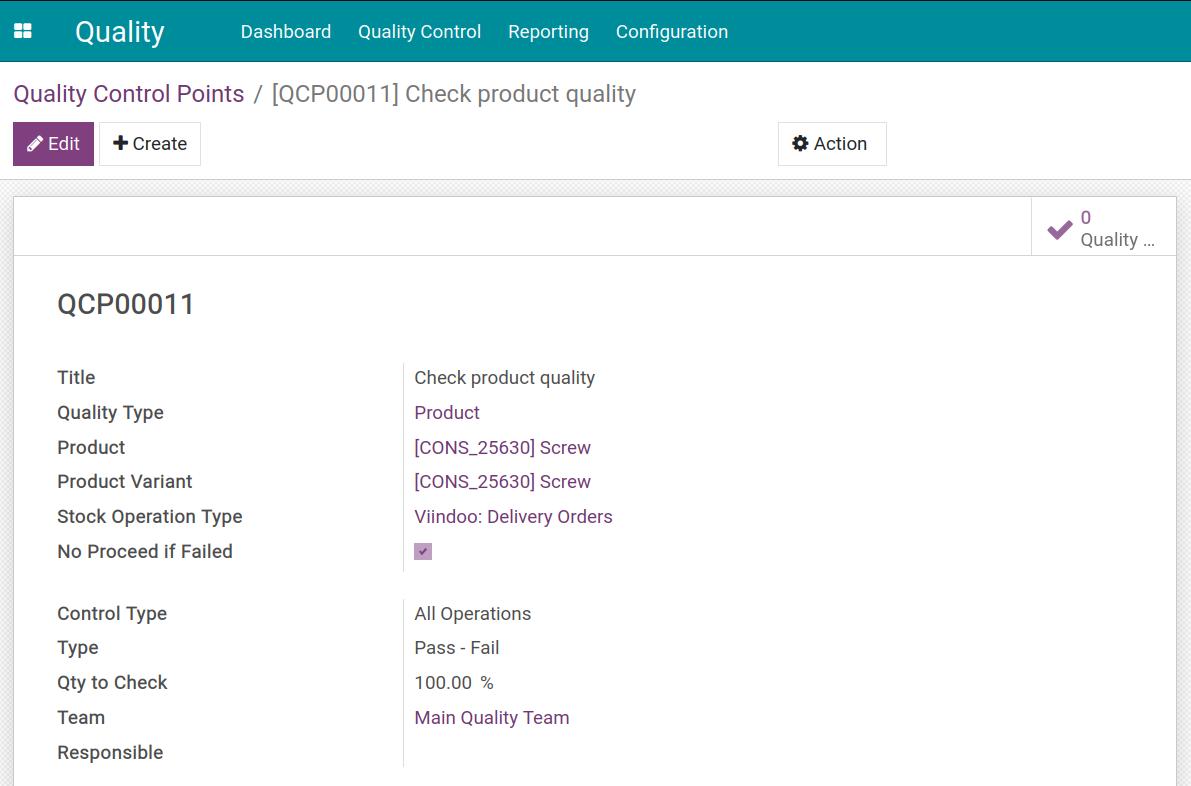

Configure the quality control point with a specific product and the Stock Operation Type is Receipt or Delivery.

Create purchase order/sales order, then create the receipt or delivery orders for the product.

Create a quality check to check the product quality on the receipt/delivery slip.

While operating a quality check, you can create a quality alert and propose suitable corrective/preventive actions.

Create Quality Alerts¶

Supposed that you have to make a quality alert for Screws when transferring them out of the warehouse:

Type: Pass - Fail;

Stock Operation Type: Delivery orders;

Product: Screw.

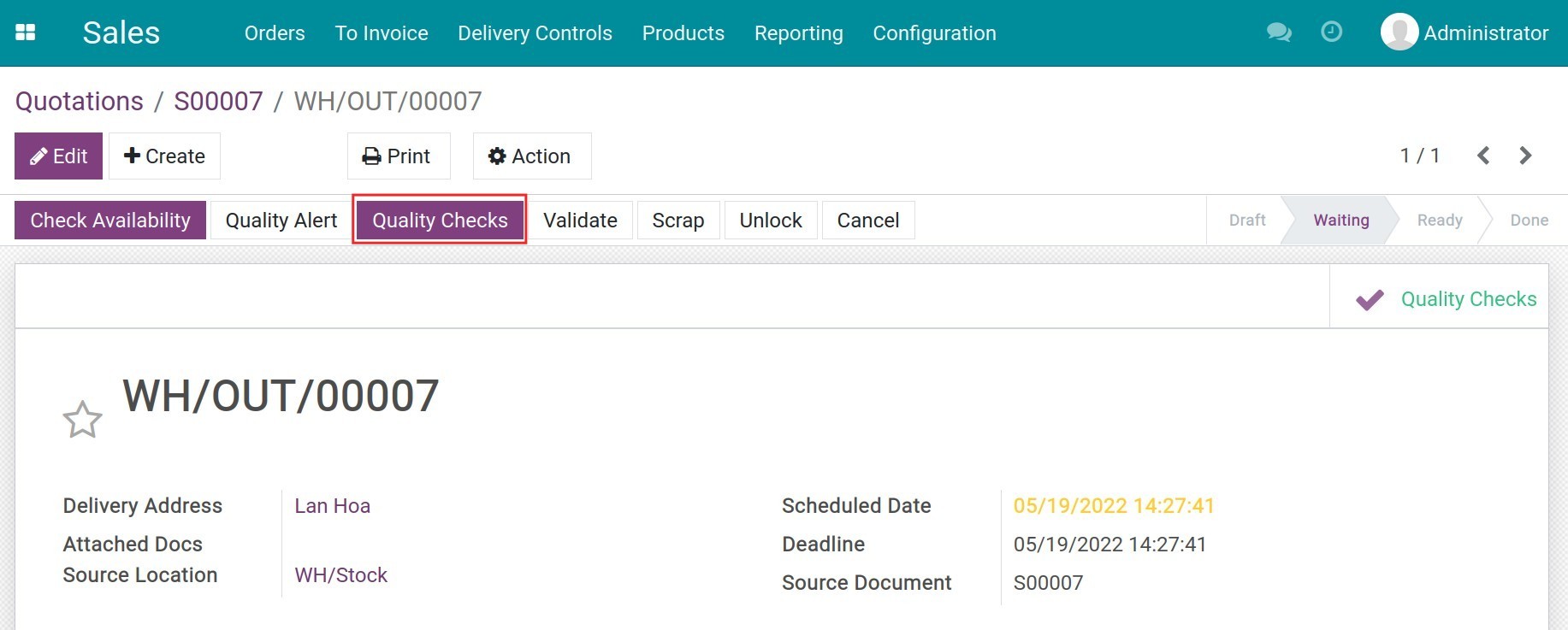

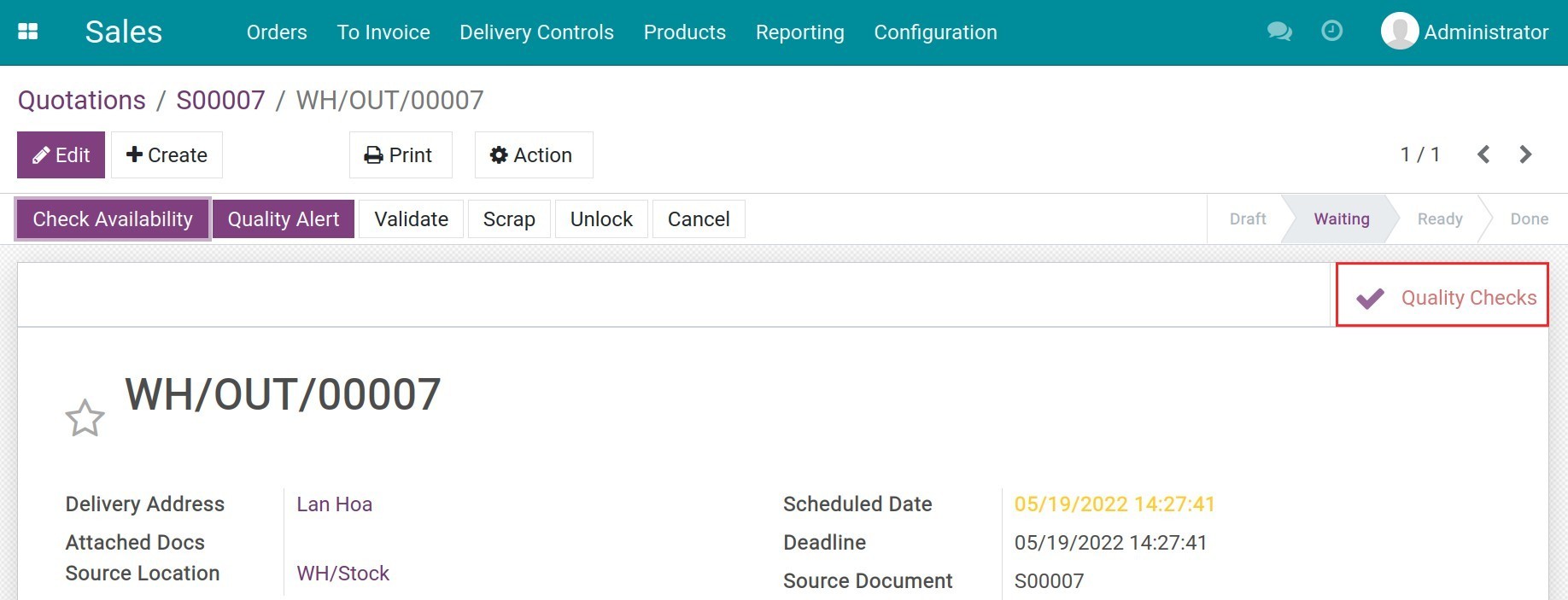

After confirming a sales order for the Screws, a delivery order will be generated. Click Quality Checks on the delivery order.

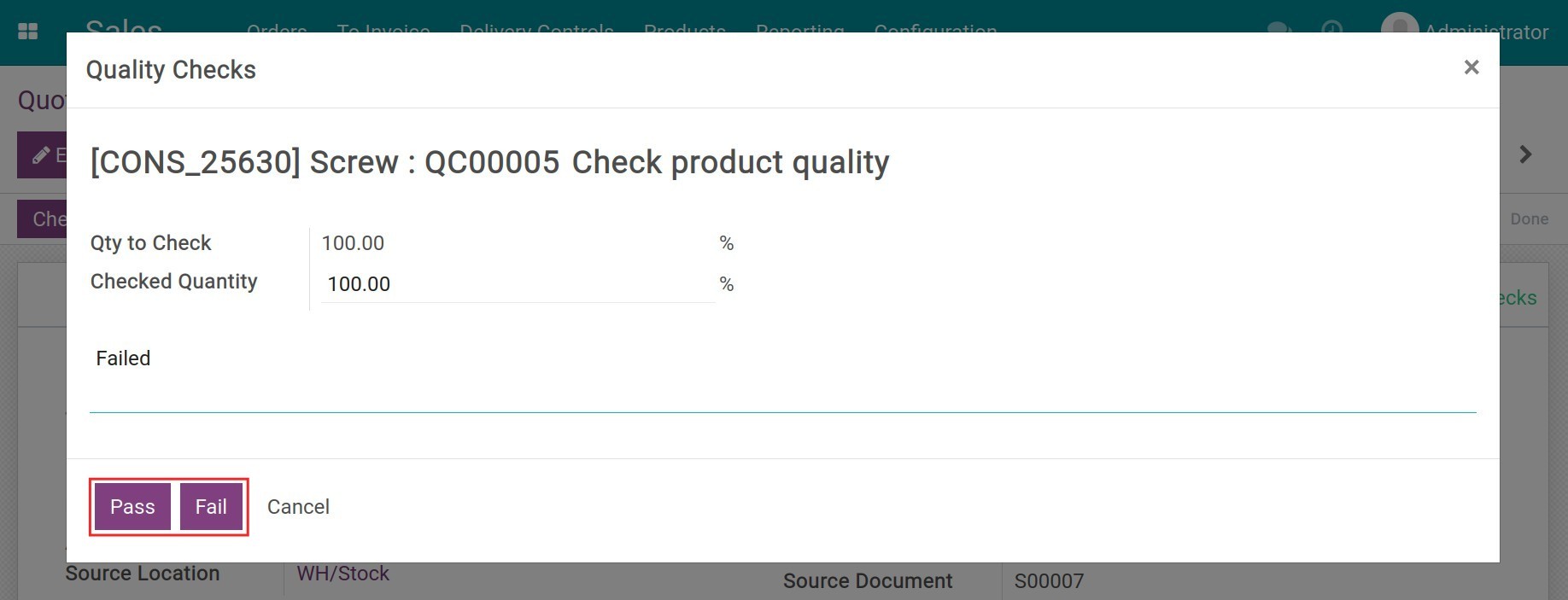

After clicking on that button, the Quality Check pop-up will appear to enter the result.

Now you enter the percentage of the checked quantity and leave some comments for this quality check.

If the product covered all the quality conditions, select Pass. Then, the quality check will turn to the Pass status and also turn green on the receipt/delivery slip. You can click on Confirm to confirm the delivery order.

If the product is flawed to the quality conditions, select Fail. Then, the quality check will turn to Fail status and also turn red on the receipt/delivery slip. In this case, you need to create the quality alert.

Tip

In case of pass, you can still create the quality alert as in the fail case.

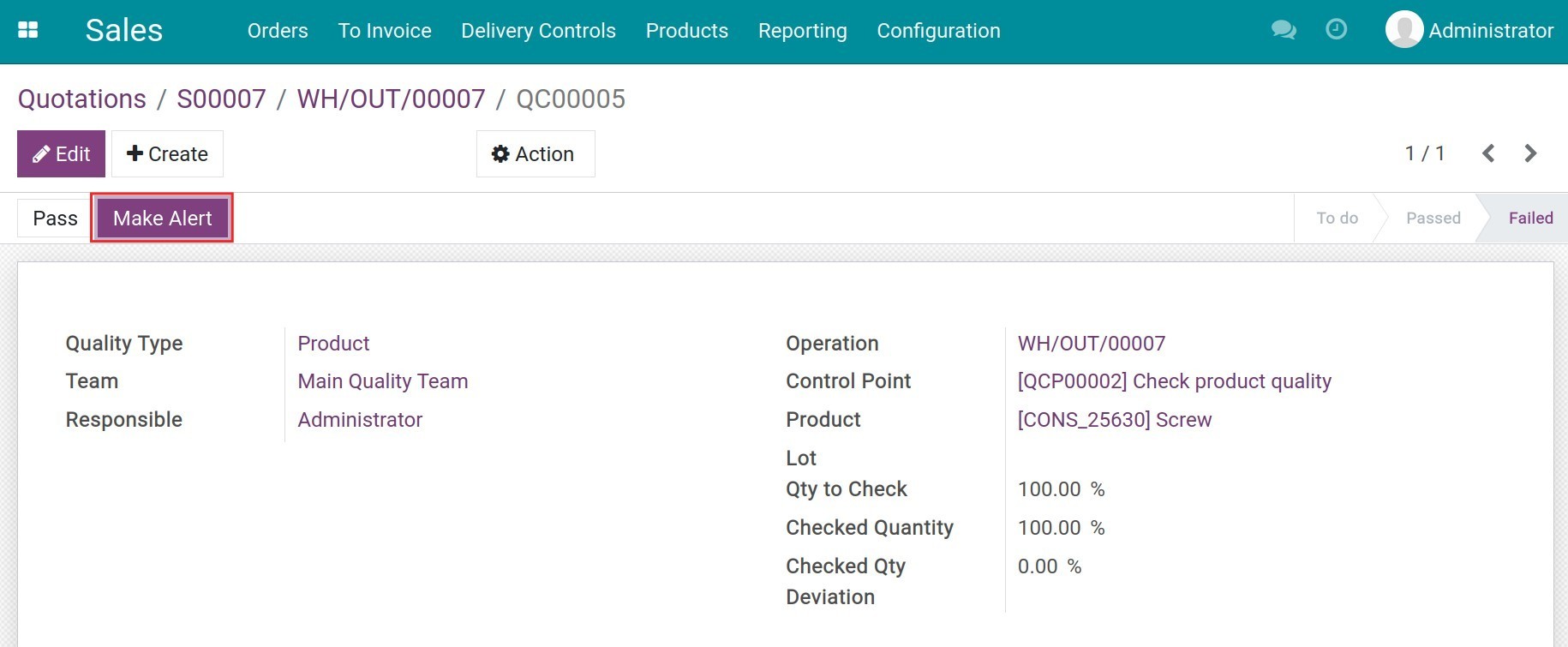

To create the quality alert, access the quality check, click Make Alert.

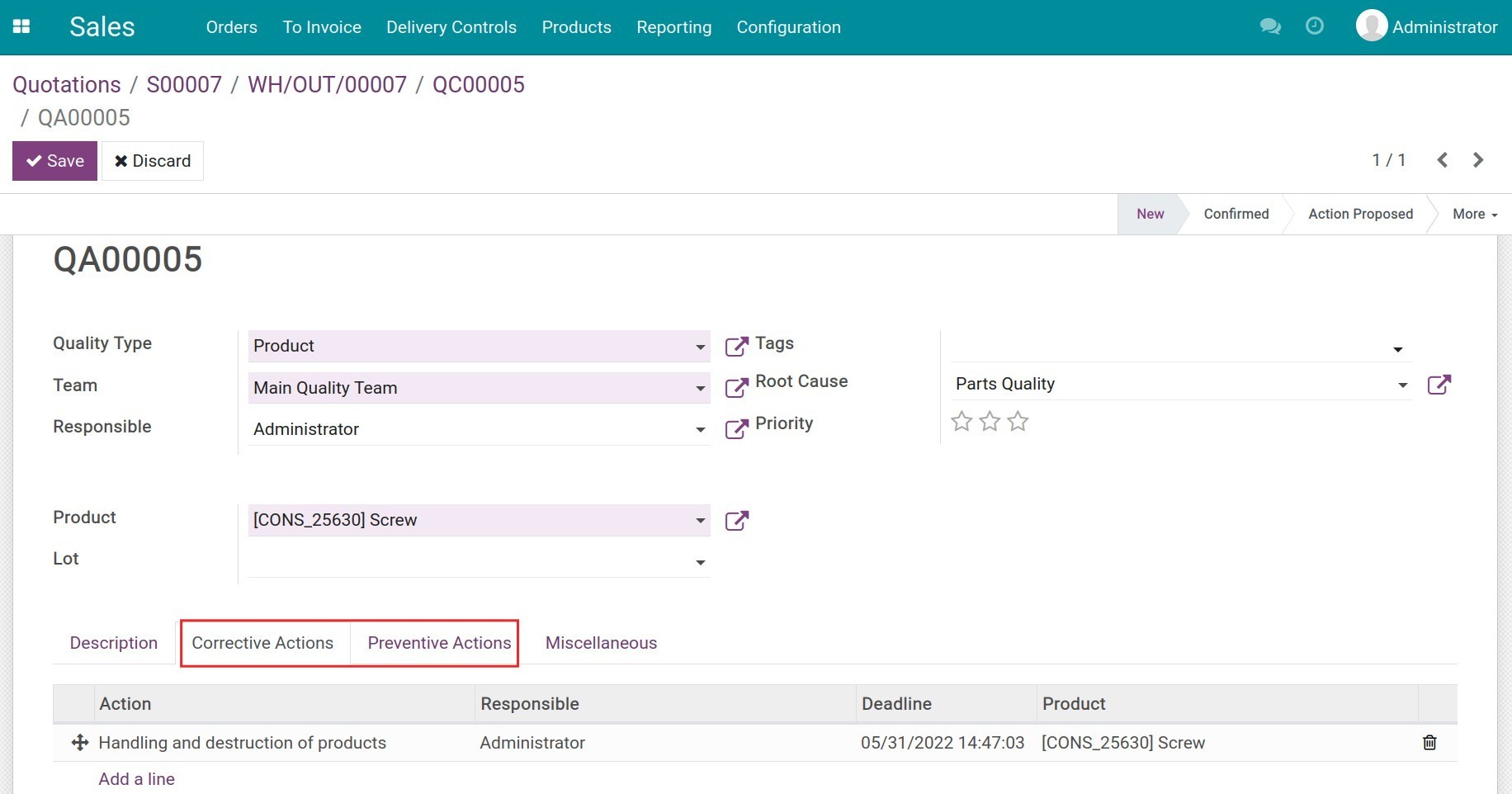

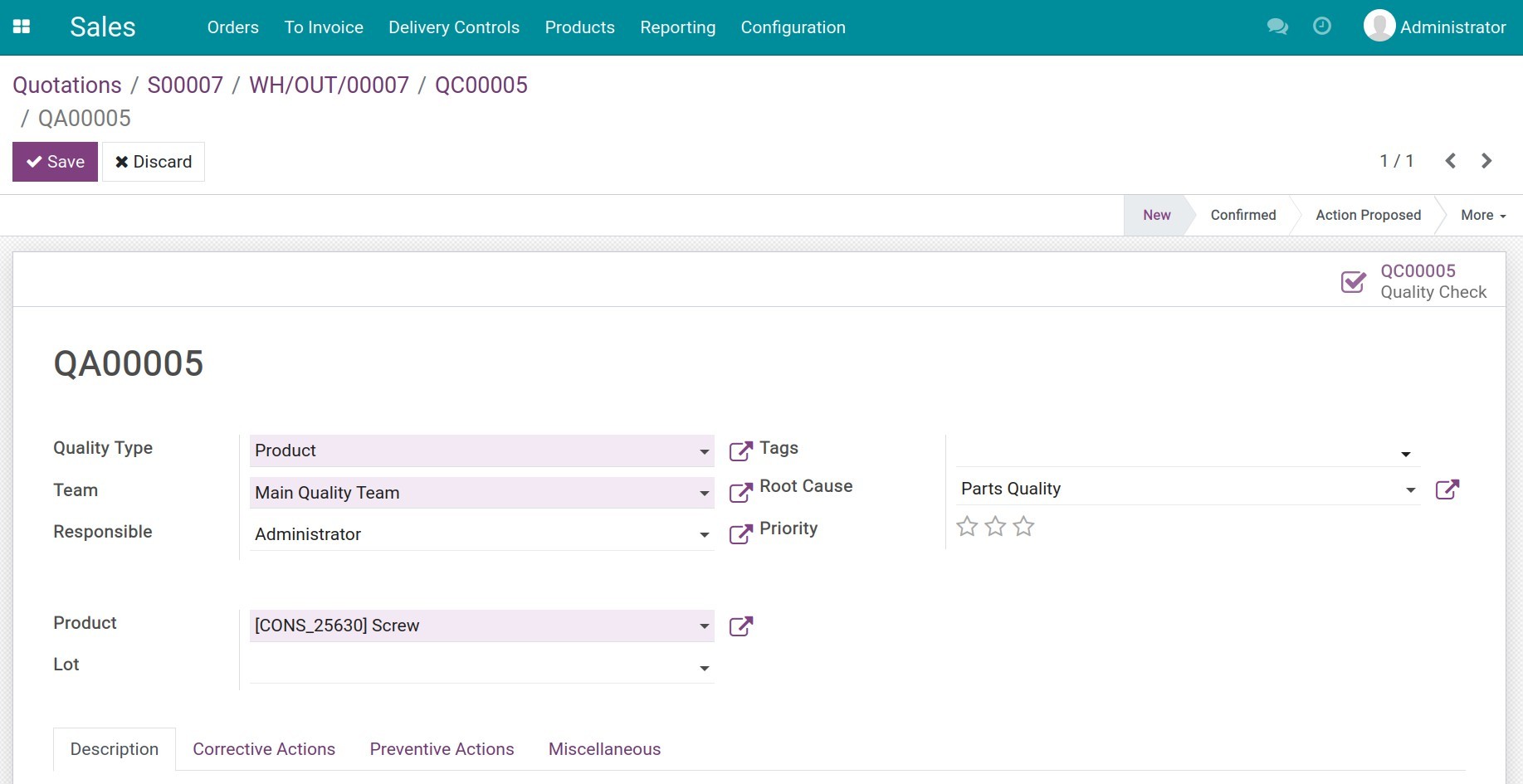

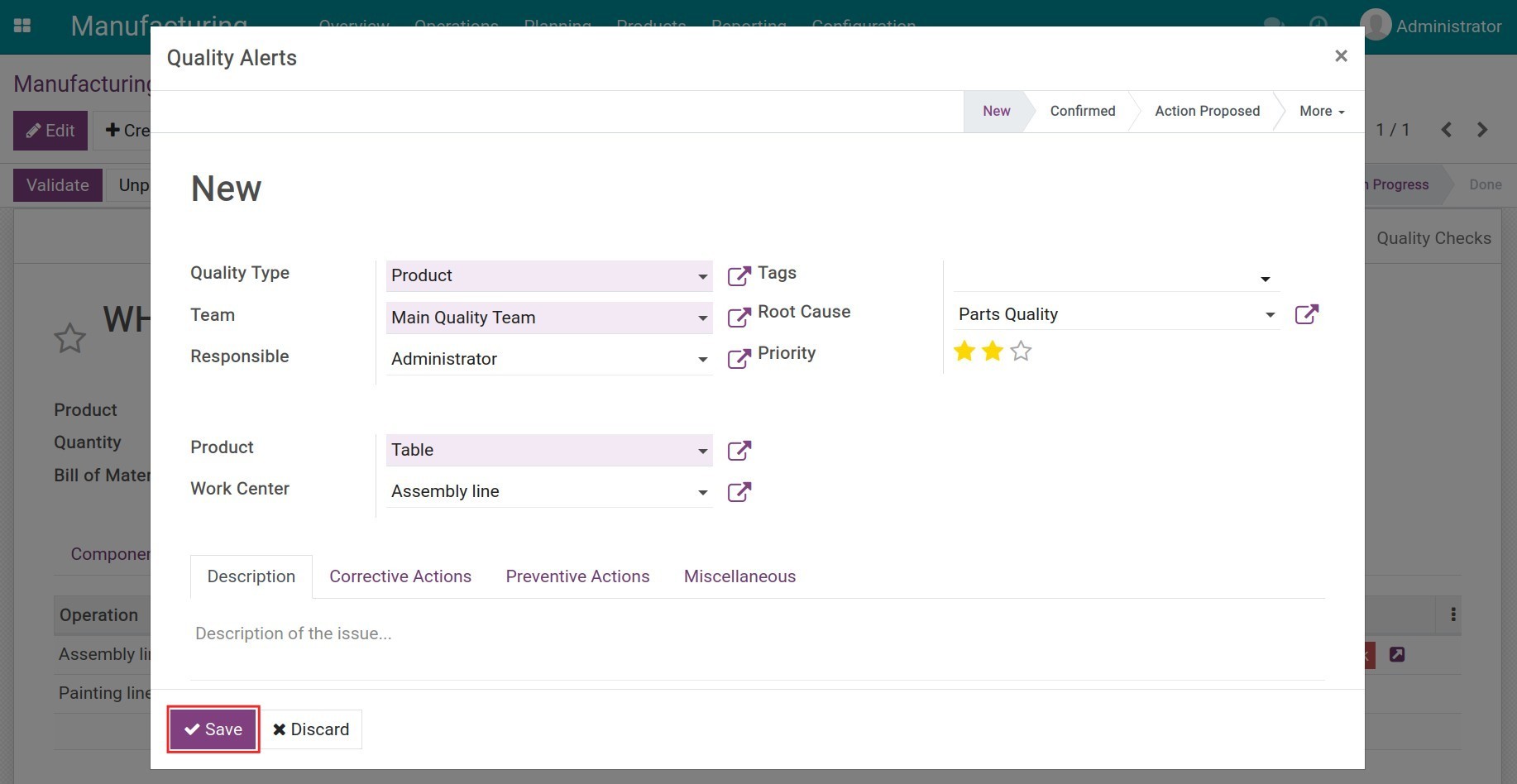

Fill in the following information:

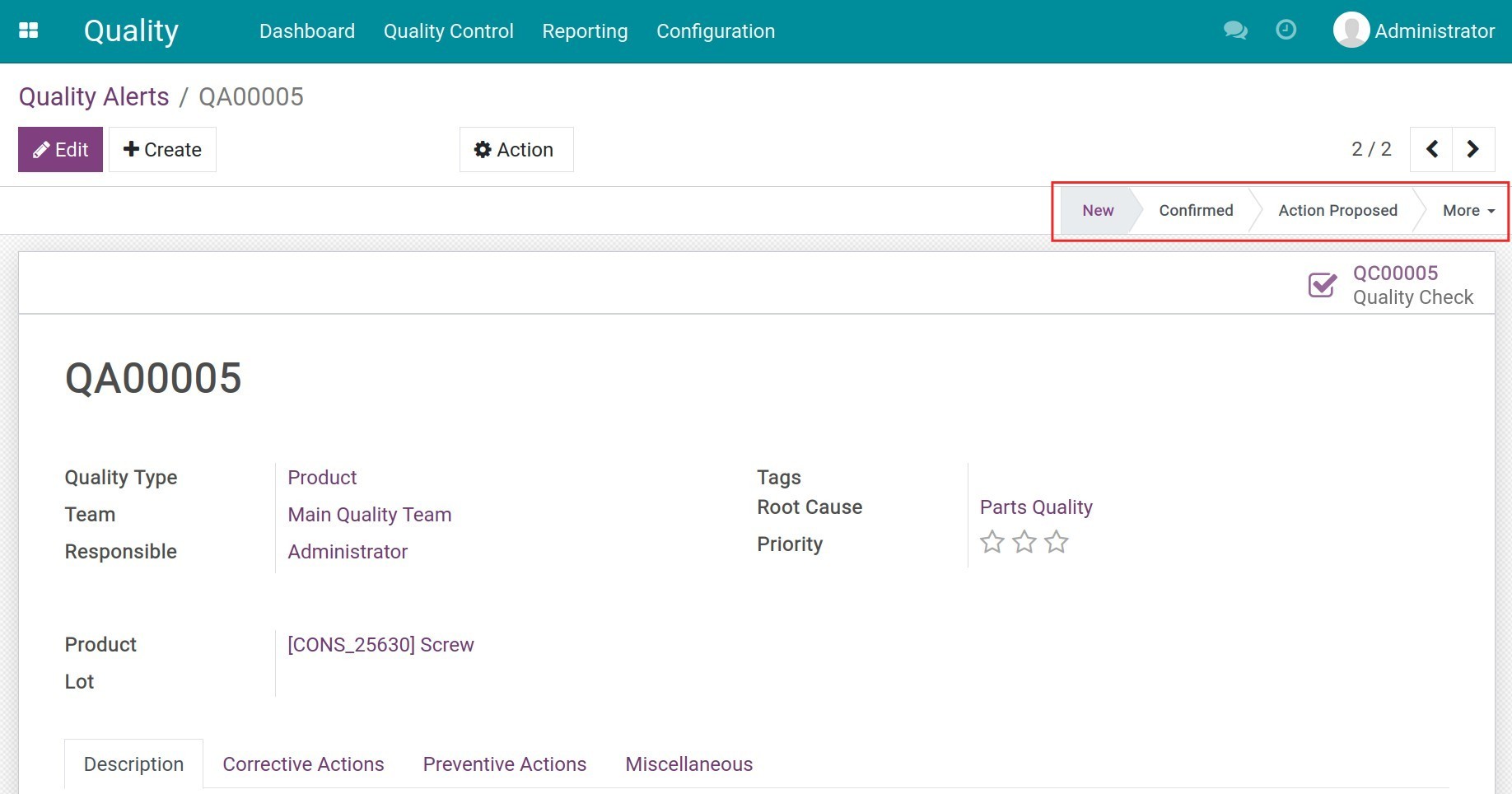

Quality Type: select the pre-configured quality type;

Team: select the responsible Quality team;

Responsible: the person in charge of the quality check;

Tags: to clarify different alerts;

Product: this field is auto-linked with products on the transfer sheet;

Product variant: this is auto-linked with product variant on the transfer sheet;

Lot: the lot number of products or product variant;

Work Center: this is used for the quality check in manufacturing;

Root Cause: the reason for the failure;

Priority: 3 stars for 3 levels: Low, Medium, and High;

Description: to describe details of the errors or the failure reason;

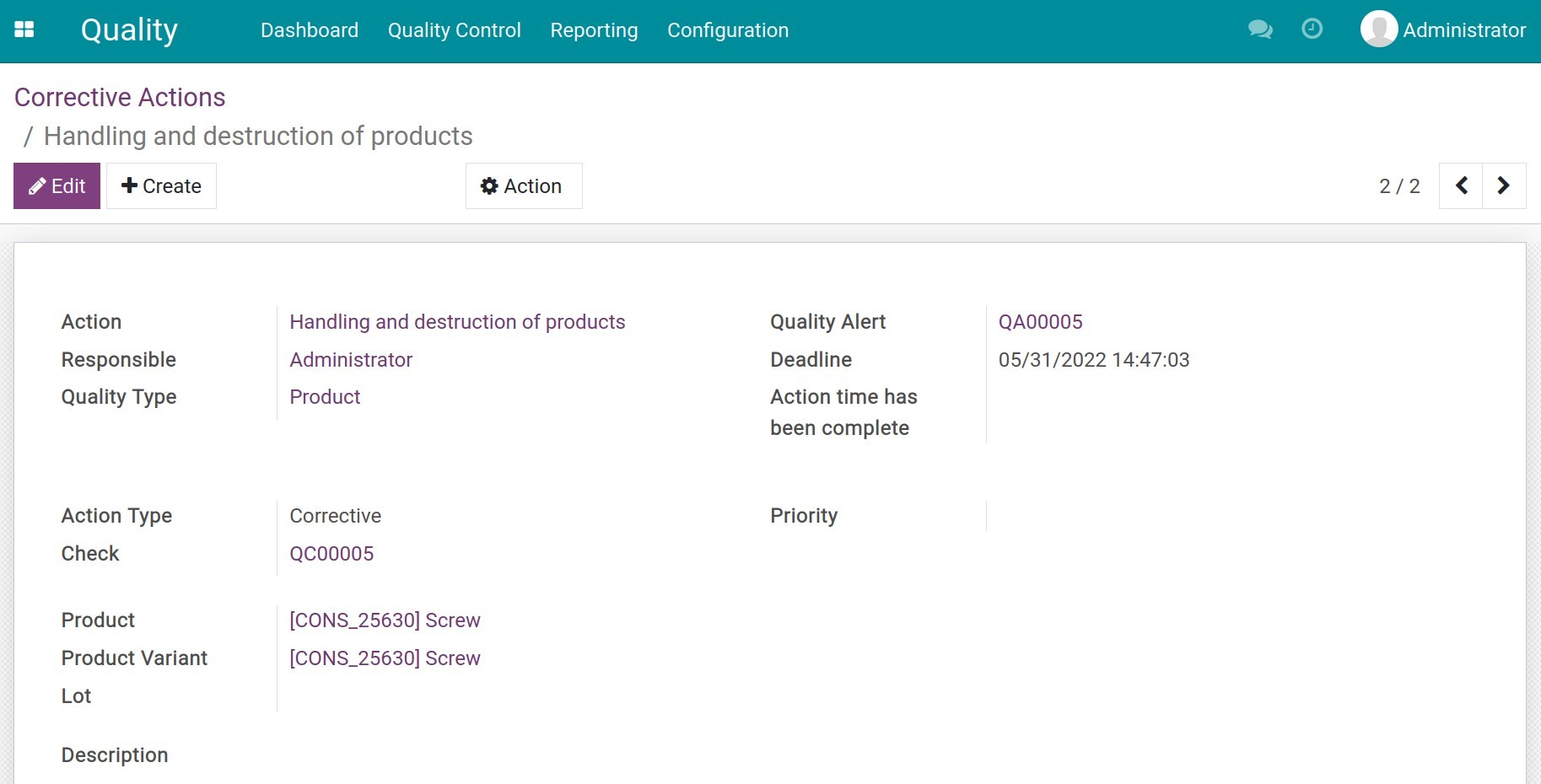

The Corrective Actions tab and the Preventive Actions tab: to create quality actions to solve the problems, including:

Action: select the needed action;

Responsible: the person taking this action;

Deadline: the date to finish the action;

Product: the product to be taken the action.

![alert actions]()

Click on Save to finish.

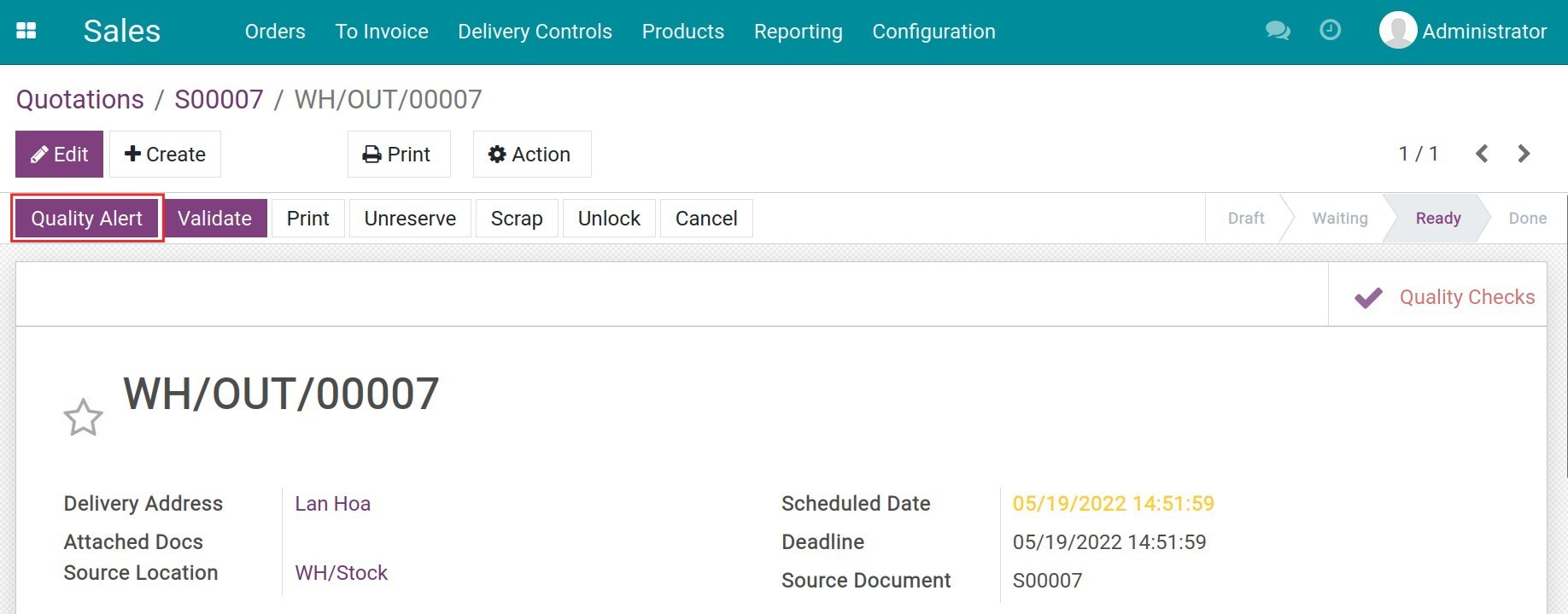

On the other hand, you can also create quality alerts right on the transfer sheet.

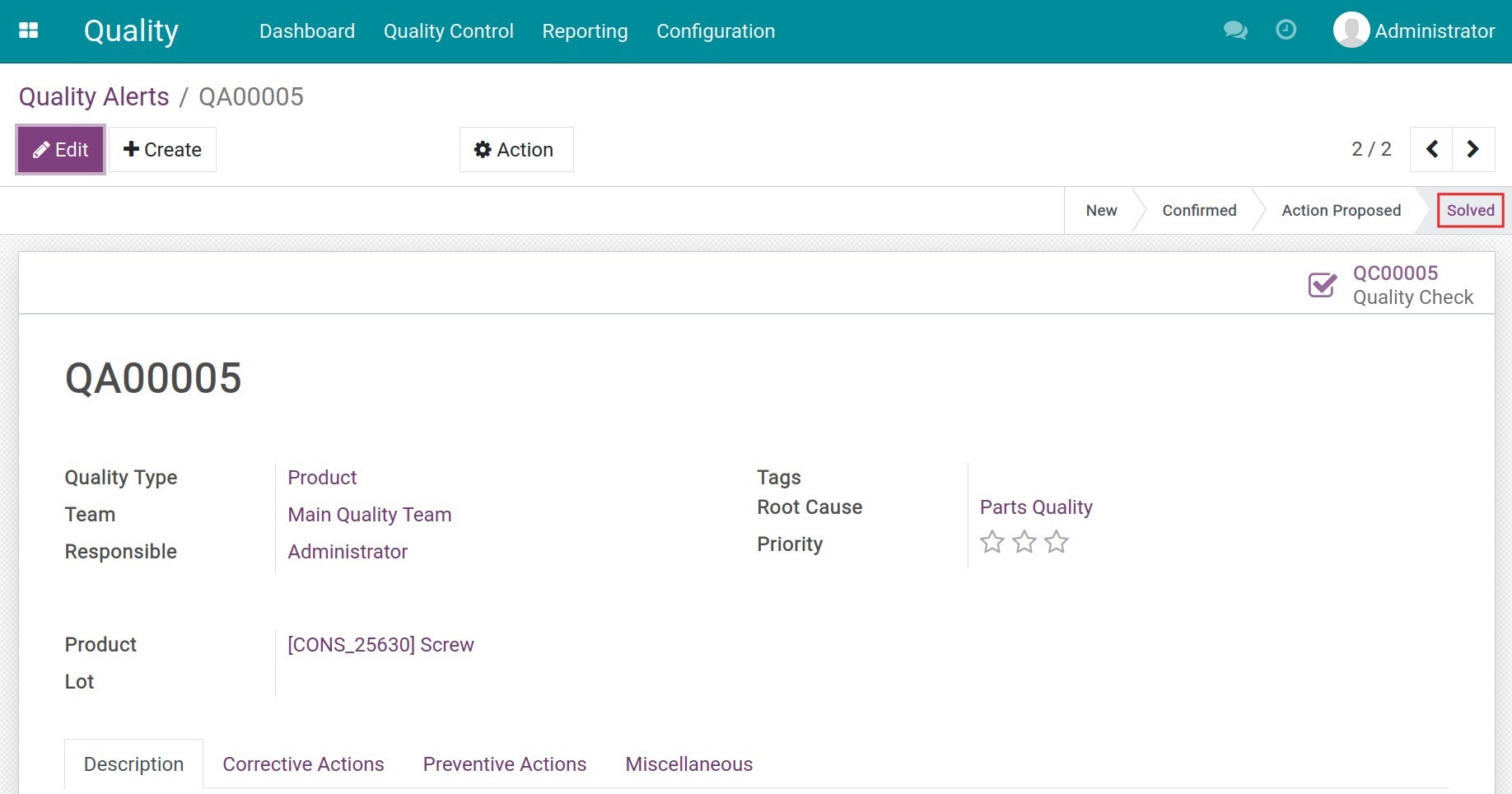

Solve the Quality Alert¶

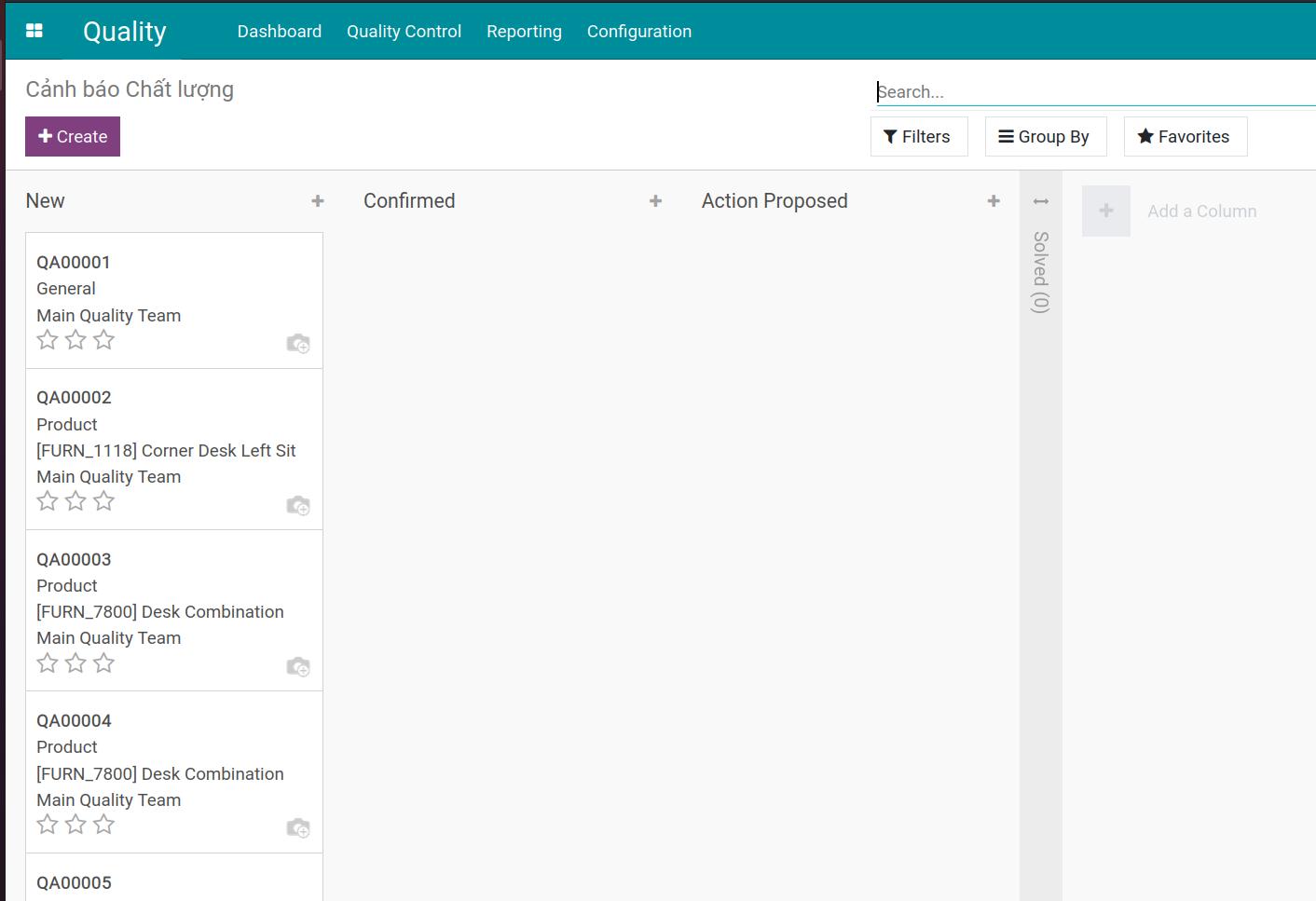

After creating the quality alert, you can check the list of quality alerts at .

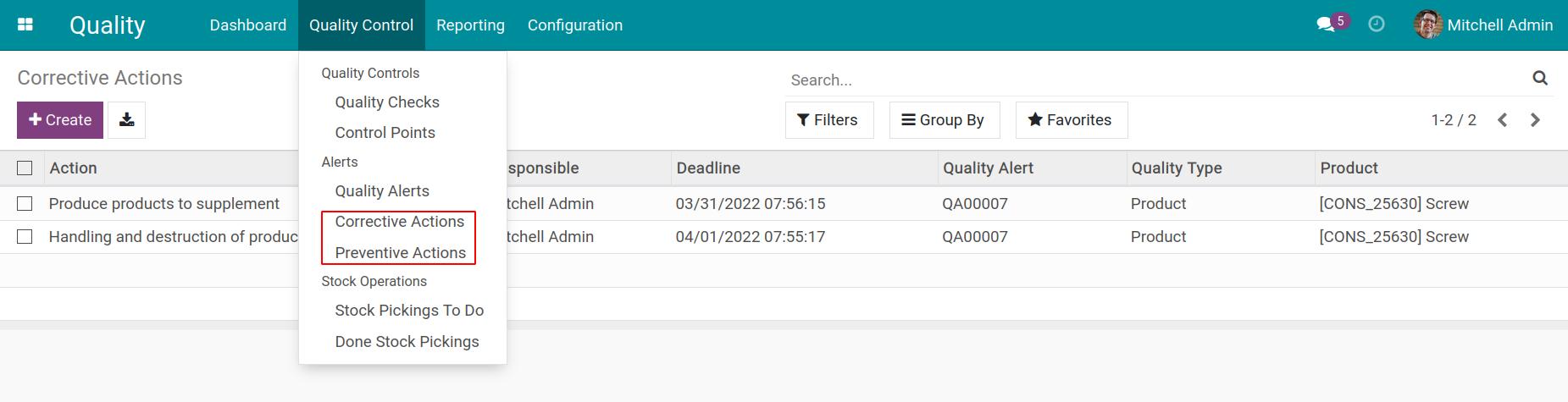

Go to or to check the list of actions.

Click on a specific action to get its detail.

When the quality alert is confirmed, you can move it to the next stage, Action Proposed.

After the alert is solved, you should move it to the Solved stage.

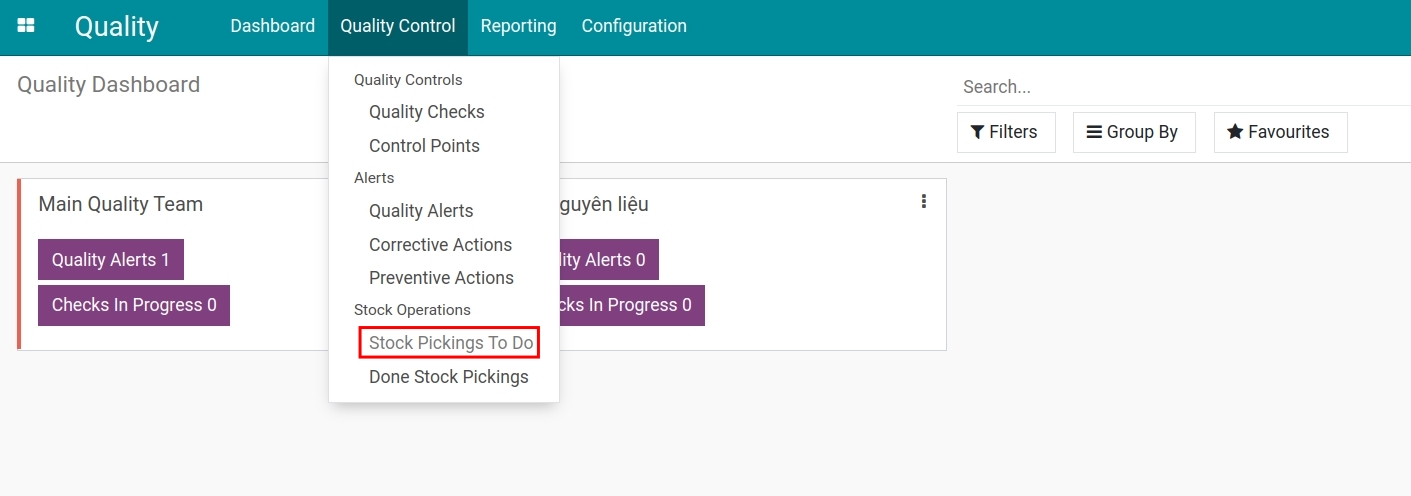

Once done, you can finish the stock operations by navigating to and selecting the ongoing operation.

Create the Quality Alert on a Manufacturing Order¶

Steps¶

Take the same steps as creating a quality alert on a transfer, including:

Configure the control point with a specific product and the Stock Operation Type is Manufacturing.

Create and confirm the manufacturing order of the product.

While operating the manufacturing, create a quality check to check the product or the by-product on the manufacturing order.

Create a quality alert and propose suitable corrective/preventive actions.

Create and Solve a Quality alert¶

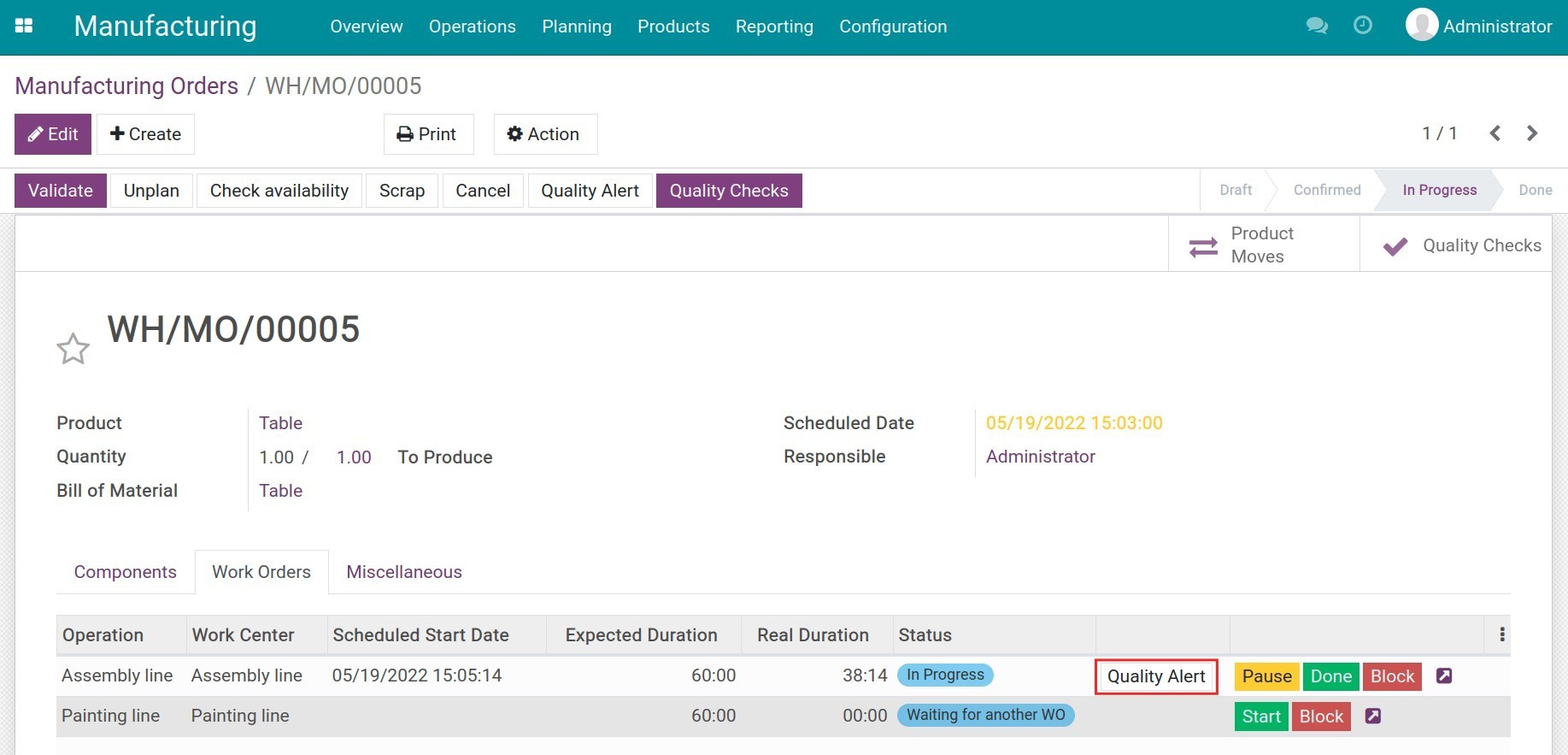

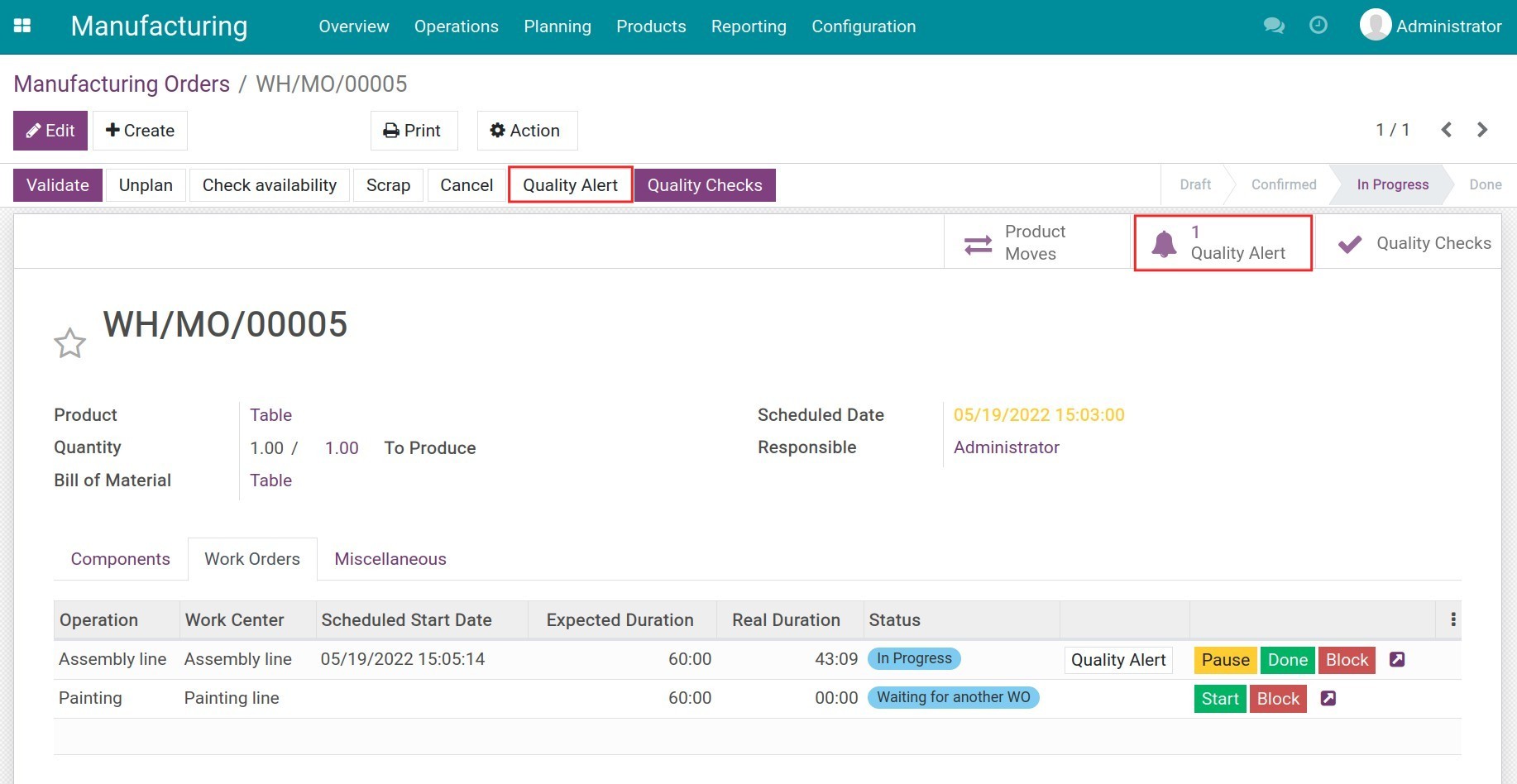

During the manufacturing process, when the materials don’t meet the requirements, you can create a warning by pressing Quality Alert.

Here you fill the information of the quality alert.

The quality alert will be displayed directly on the manufacturing order. You can also create a quality alert from a manufacturing order by clicking on Quality Alert.

Take steps to solve the quality alert on: Solve the quality alert on Receipt/Deliveries.

See also

Related articles

Optional modules