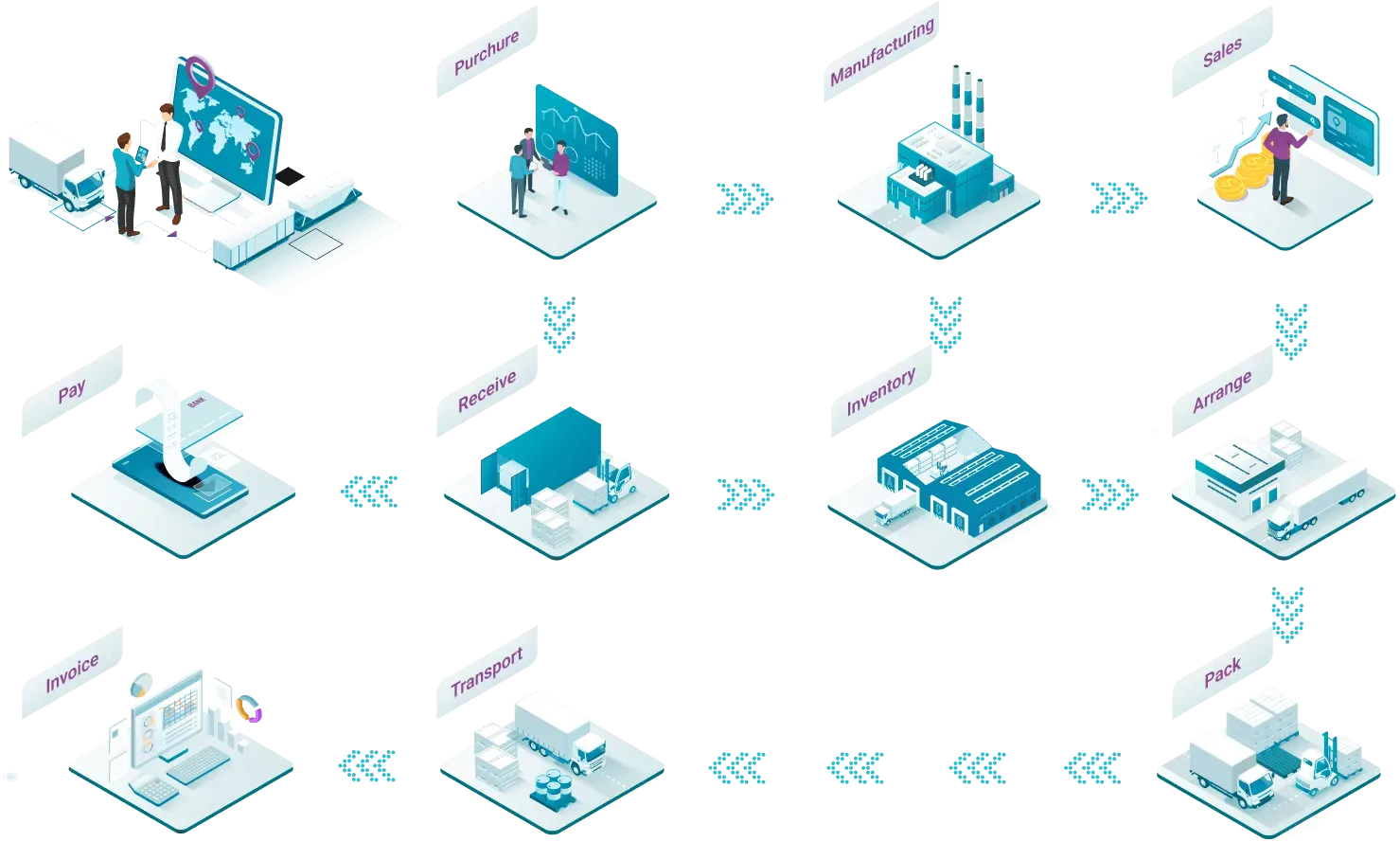

In enterprise management strategies, each planning area—finance, HR, production, marketing, sales, and R&D—functions as a vital organ within a single organism. No department can operate independently without the interconnection of the others. The cornerstone for effectively operating these plans lies in synchronization and precision during implementation.

In Vietnam, many enterprises still face challenges in transforming planning into a truly strategic tool. Production planning, in particular, is often perceived as an operational fragment; however, it serves as the pillar that ensures seamless alignment across plans and the realization of strategies.

The Reality of Planning in Vietnamese Enterprises

Despite reaching a significant scale, most Vietnamese enterprises still encounter common challenges in planning, particularly in production planning:

Departments often plan independently, leading to inconsistent information. For example, marketing and sales fail to update market demand, production plans face difficulties in adjustment, leading to financial losses from surplus or shortage. Lack of proactivity procurement, material shortages or price volatility disrupt production plans, causing delays or cost overruns.

Many enterprises still use manual methods or standalone tools that lack integration, outdated data, resulting fragmented, untimely, and unrealistic planning.

Lack of Long-term Strategic Forecasting: Production plans often focus on the short term, with weak connections to the company’s long-term development strategy.

Production Planning: The Bridge Between Strategy and Operations

In enterprise management structures, production planning is not merely about resource allocation and workflow coordination. It is the critical link between long-term strategies and daily operations. When implemented effectively, production planning ensures operational stability, facilitates strategic objectives, optimizes resources, and enhances competitiveness.

Serve Both Short-Term and Long-Term Goals

- Short-Term: Focus on daily operations

- Create detailed production schedules, allocating personnel and resources for each shift.

- Quickly adjust to fluctuations in demand or technical issues.

- Long-Term: Align with strategic vision

- Prepare production lines for new products or market expansion.

- Invest in modern technology and machinery to enhance future production capacity.

- For example, if a business adopts a strategy to develop eco-friendly products, production plans must adjust to incorporate recycled materials and optimize processes to minimize emissions.

Transforming Strategic Goals into Specific Actions

Every strategic goal must translate into actionable targets for execution. Production planning plays a direct role in realizing these goals:

- Output: Meets market demand based on forecasts from marketing and sales plans.

- Quality: Ensures products meet the quality standards promised to customers.

- Cost: Optimizes production costs to meet the profit targets in financial plans.

Example: If a business aims to capture 10% of a new market within the next year, the production plan must determine the additional product volume, evaluate production capacity, and coordinate the supply chain to ensure material readiness.

To achieve these objectives, businesses can consider production planning models to find one to balance operational capability, demand, cost, and quality,. Different models require different conditions for effective implementation:

- Make-to-Stock (MTS): Ideal for industries with stable demand, requiring accurate forecasting and efficient inventory management.

- Make-to-Order (MTO): Best for custom or low-volume production, demanding flexible scheduling and strong supplier coordination.

- Engineer-to-Order (ETO): Suited for complex, project-based manufacturing where design and production are fully customized.

- Lean Manufacturing: Focuses on eliminating waste and improving efficiency, suitable for high-volume industries like automotive and electronics.

- Just-in-Time (JIT): Aims for minimal inventory and real-time production synchronization, requiring a highly responsive supply chain.

Connecting and Synchronizing Departments

Production planning serves as the central hub where all enterprise plans converge and coordinate.

Linking Marketing and Sales Plans

- Marketing identifies market demand and drives campaigns to generate interest. Production planning ensures adequate supply at the right time.

- Sales forecast revenue and order targets, which production planning must meet promptly, avoiding shortages or surplus.

Linking Financial Plans

- Production planning dictates key costs, such as materials, labor, and operational expenses, directly impacting financial budgets.

- Finance provides funding for production plans while monitoring expenditure efficiency.

Linking Supply Chains

- Production planning defines material quantities and schedules, enabling supply chains to prepare and coordinate effectively.

- Any supply chain disruption impacts production, causing delays or operational breakdowns.

Optimizing Efficiency and Minimizing Waste

A robust production plan focuses not only on achieving targets but also on optimizing processes and resources, minimizing waste at every stage:

Reduce Waste in Operations

- Materials: Accurate planning minimizes excess inventory or material shortages.

- Waiting Time: Optimized production scheduling ensures continuous workflow without unnecessary downtime.

- Machinery and Energy: Efficient utilization of equipment and energy through rational coordination.

and more at 7 waste in production

Increase Flexibility in Response

In a volatile market, flexible production planning enables businesses to quickly adapt to changes in demand or supply

Key Deliverables of a Production Plan

A well-structured production plan must result in concrete outputs that guide execution, ensuring efficiency and alignment with business objectives. These outputs include:

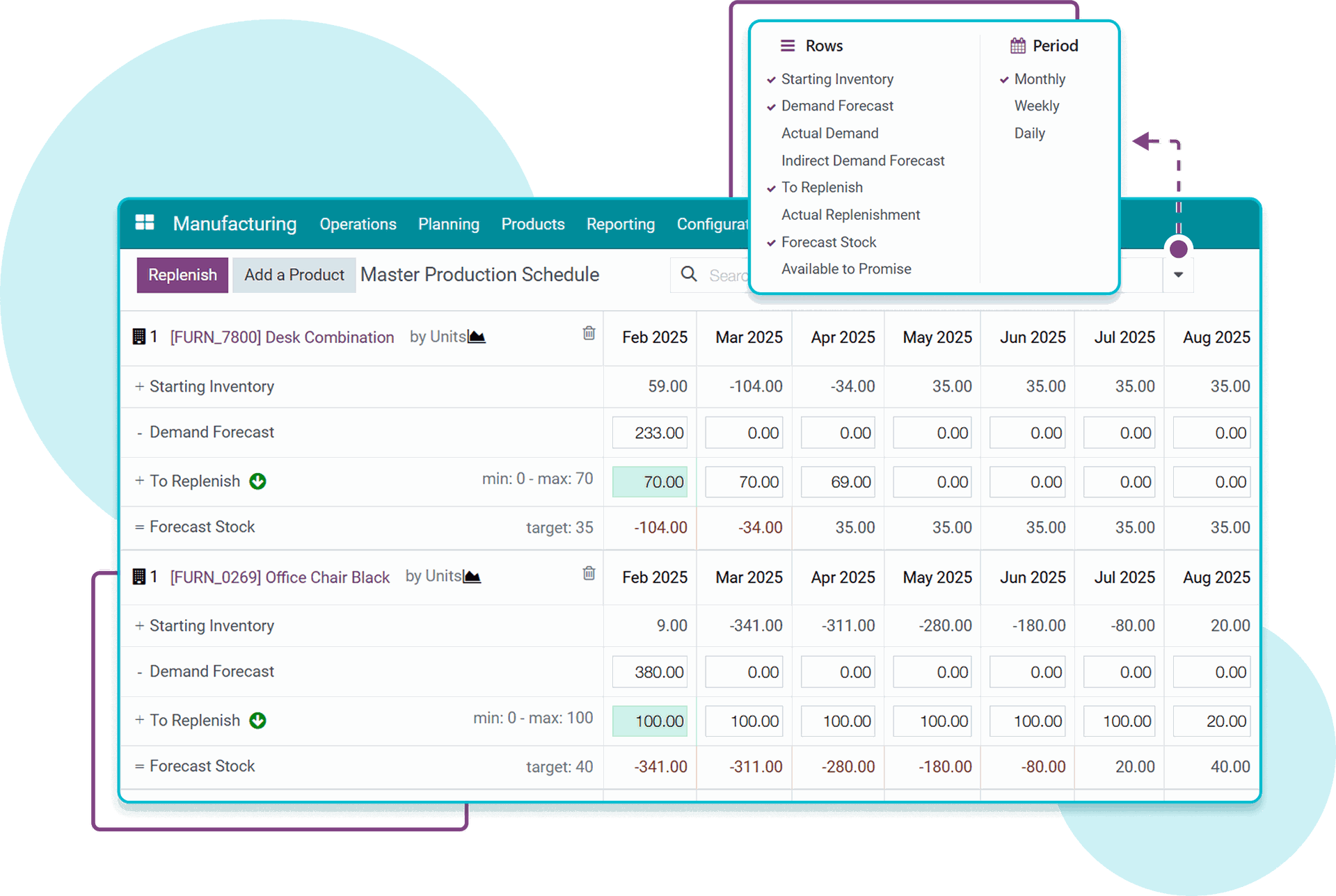

Master Production Schedule (MPS): Defines what products will be produced, in what quantities, and when, based on sales forecasts and inventory on-hand.

Material Requirements Planning (MRP): Determines raw material needs, supplier schedules, and reorder point to ensure safety stock, prevent shortages or overstock.

Workforce and Capacity Planning: Allocates human resources effectively, balancing workloads and minimizing idle time.

Production Routing and Scheduling: Specifies the sequence of operations, production stages, and machine utilization to optimize efficiency.

Cost Estimates and Budgeting: Forecasts production costs, labor costs, etc to align with financial planning.

By delivering these key components, production planning becomes a practical tool that bridges strategy and execution, ensuring smooth operations and business growth.

Viindoo ERP Solutions: Aligning Technology with Business Strategy

A grand strategy requires a management system flexible enough to adapt. For manufacturing enterprises, production plans serve as the guiding compass for all business activities. In this context, businesses need a technology system that can transform vision into actionable plans and ensure effective execution.

This is exactly the approach of Viindoo ERP—synchronizing People, Processes, and Technology to optimize production planning while ensuring operational flexibility.

Synchronizing People, Processes, and Technology

Unified Information Flow:

- Connects data across all departments, ensuring information is always synchronized.

- Automates the planning process, from demand forecasting and material allocation to production scheduling.

- Integrates data from marketing, sales, finance, and supply chain, ensuring cohesive planning throughout the organization.

Automated Workflows:

- Use supply routes and automatic recommendations, supply suggestions to ensure proactivity in production planning

- By automating repetitive tasks, the system enables employees to focus on strategic decision-making rather than manual data entry.

Collaboration Across Departments: Cloud-based access and automated notifications keep stakeholders informed, improving coordination in production planning and execution.

Enhancing Flexibility in Production Planning & Operation

Real-Time Plan Adjustments:

- Delivers instant updates on production progress, inventory levels, and performance, empowering managers to respond promptly.

- For unexpected order changes, supply chain disruptions, or equipment malfunctions, production schedules can be instantly adjusted based on real-time data & communication.

Dynamic Resource Allocation: The system optimizes workforce and machine utilization, reallocating resources as needed to maintain efficiency.

Greater Operational Visibility: Real-time dashboards in Viindoo ERP provide a holistic view of production performance.

Flexible Customization for Unique Business Needs

- Viindoo ERP is adaptable to different manufacturing models.

- Tailored solutions to fit the scale and operational characteristics of each business, from mass production to custom order manufacturing.

- Supports optimizing current processes to align with strategic goals.

Unlock the Full Potential of Your Production Planning

A strategic production plan, backed by the right technology and expertise, is the key to sustainable growth. However, implementing an effective system requires more than just software—it demands a deep understanding of manufacturing operations and a tailored approach to digital transformation.

At Viindoo, we don’t just provide ERP solutions; we work alongside businesses to implement ERP that align with their unique operational needs. Whether you’re looking to streamline processes, enhance agility, or integrate real-time decision-making, Viindoo can help you bridge the gap between strategy and execution.

📩 Let’s discuss how we can optimize your production planning for long-term success. Contact us today!

Expert Profile

Ms Jane Nguyen - USAID Project Expert - Chief Customer Officer, Viindoo

https://about.viindoo.com/people/jane-nguyen