Textile manufacturing has been a cornerstone of human civilization for

centuries, weaving fabrics from raw materials like cotton, wool, and

synthetic fibers. In today's fast-paced world, the textile industry

faces increasing pressure to meet growing demand while maintaining

efficiency and sustainability. Fortunately, advancements in technology

have ushered in a new era for textile manufacturers, offering innovative

software solutions to optimize processes and drive success. Let's

explore how Viindoo Software solution is revolutionizing textile manufacturing.

Revolutionizing Textile Manufacturing & Software Solutions

Revolutionizing Textile Manufacturing & Software SolutionsTextile Manufacturing: Challenges of operation optimization

Textile manufacturing involves a complex web of processes, from spinning

and weaving to dyeing and finishing. Managing these processes

efficiently is crucial for meeting production deadlines and maintaining

quality standards.

- Multi unit of measure required: One of the key challenge where the textile manufacturing has been faced is raw material's unit of measure. There is always change in units according to the norms of each product type. For example, a textile company purchases fabric dye chemicals in bulk, allocates them in bucket but calculates the production rate for a product in liters.

- Textile manufacturing involves a variety of complex processes, such as spinning, weaving, dyeing, and finishing. Therefore, manufacturing plan need to be flexible enough to adapt to changes in market demand, production constraints, or resource availability. And most current software solutions cannot meet the needs of businesses for flexible production planning when changes arise without affecting the production process.

- Subcontract manufacturing in the textile industry is very popular because the companies often face fluctuations in demand and may not always have the capacity to fulfill large orders on their own. Software solutions need to meet management demand when companies outsource excess production to third-party manufacturers when needed,

ensuring optimal utilization of resources and timely order fulfillment.

- Marterial loss management encompasses various techniques, methodologies, and strategies aimed at minimizing losses and maximizing resource efficiency. Measuring and tracking material loss is a complex in large-scale manufacturing environments and always changes arising from variations in production processes or human factor-related operational methods. Without comprehensive statistical data, textile companies cannot identify the

root causes leading to material wastage in production, nor can they

devise solutions to allocate resources or effectively plan the use of

excess materials to address the issue of unnecessary material

consumption.

- Each step in textile manufacturing requires various inputs, such as raw materials, labor, energy, and overhead costs. Managing and accurately attributing these costs to individual products or orders can be challenging, especially without the support of comprehensive software solutions.

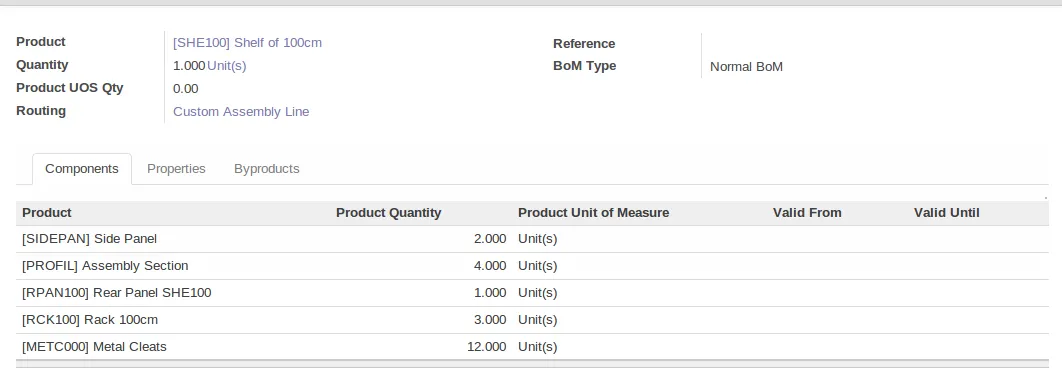

- Managing BoM with software can present several challenges because BoM can be highly complex, especially in industries with intricate

manufacturing processes or products with numerous components such as the textile industry. Managing

the relationships between different components, sub-assemblies, and

finished products can be challenging, particularly without robust

software solutions.

Optimizing the Textile Manufacturing with Viindoo Software

A software solution tailored for the textile industry streamline operations by providing tools for inventory management, production planning, quality control, and more. It enable manufacturers to track raw materials, monitor production schedules, and ensure consistent product quality, ultimately improving overall efficiency.

Necessary features help increase textile business operating efficiency

Viindoo provides solutions in textile manufacturing with comprehensive features. The differentiating factor we

bring is the Manufacturing Management Solution suite. Viindoo Manufacturing Software is a comprehensive and synchronized solution set

that helps textile businesses achieve synchronized inventory

management, finished goods management, production planning,

manufacturing management, purchase management, product lifecycle, and quality management to streamline their procurement processes and manage their suppliers more efficiently.

Viindoo SCM - The comprehensive software solution

Multi Units of measure

To solve the problem of coversion between units of measure mentioned above, Viindoo Inventory software helps multiple units of measure for each product so that textile companies no longer have to worry about the accuracy of these units of measure conversion.

>>>> Read more: Guidline for using the Different Units of Measure feature on Viindoo Software

Viindoo's Different Units of Measure feature

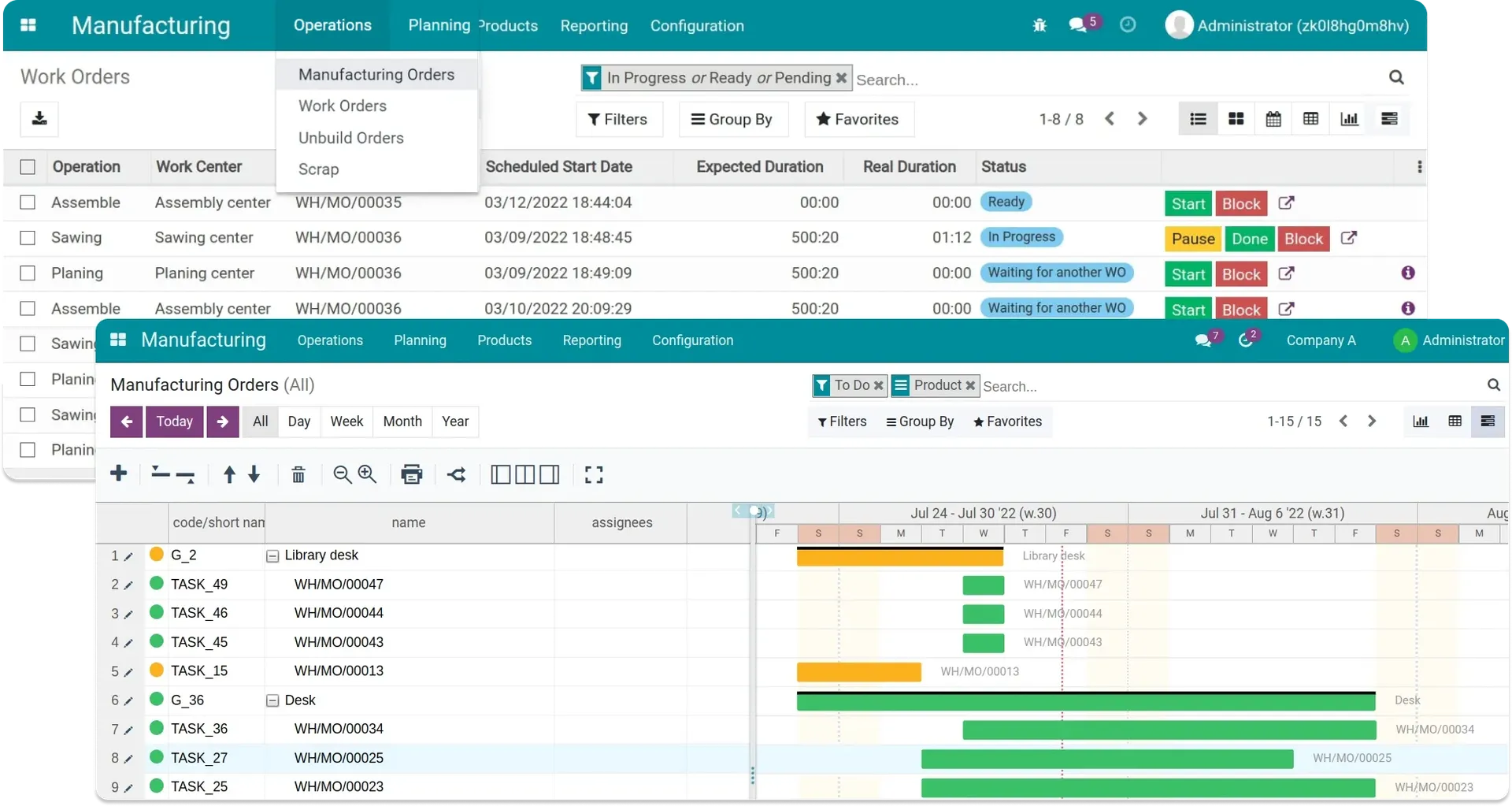

Split/Merge the Manufacturing Orders

For long-term production plans, Viindoo will help you divide them into suitable stages to manage detailabout schedule, costs, materials, and performance achieved for each stage. The Split Manufacturing Order feature will help minimize risks that may arise during operations by promptly capturing situations to make adjustments, remedies, and meet the overall plan completion deadline.

An easy-to-understand example of Viindoo's Merge Manufacturing Order feature is as follows: 1 finished product type can be used to produce 3 different product types. When manufacturing to order (MTO), the production order for the finished product will generate 3 manufacturing orders for the same finished product type. At this point, merging manufacturing orders shall minimize workload for warehouse staff, and the production department will also save costs for machine stop-start, etc.

Viindoo's Manufacturing Orders feature

Subcontract Manufacturing with Viindoo

The key factor in manufacturing processing activities is ensuring smooth connection and information transmission with sub-contractor to ensure the processing results. Businesses can monitor the entire subcontracting process, from supplier selection to quality control, ensuring timely delivery of high-quality products with Subcontract Manufacturing on Viindoo Software. It also offers textile companies the flexibility, scalability, cost savings, and

risk mitigation they need to thrive in today's dynamic business

environments.

>>>> Read more: Subcontract manufacturing management with Viindoo Software

Material Loss Management on Viindoo Software

Utilize Viindoo's inventory management feature to track raw materials, work-in-progress items, and finished products in real-time as a basic for dermination any discrepancies or losses promptly. Viindoo allows users to set up parameters to identify and quantify material losses at various stages of production. Whether it's through manual input or automated tracking sensors, the losses such as scrap, defects, or shrinkage can be recorded and categorised.

The analysis and results of the process of marterial loss management shall be complied into reports so that companies have an overview and easily make decisions for the streamline processes, reduce waste, and enhance overall efficiency in manufacturing operations.

Production Cost Calculation on Viindoo Software

Textile companies often source raw materials, such as cotton, wool, or synthetic fibers, from different suppliers, regions, or qualities. Fluctuations in raw material prices, currency exchange rates, or shipping costs can impact the overall cost of production. Viindoo Manufacturing can help users eliminate the difficulty of incorporate real-time data on raw material costs, reduce errors in cost calculations.

The user totally streamline the proocess of calculating production cost throught features such as tracking cost components, updating real-time costs, pricing based on material lists and intergrating data and analysis; serving management tasks and optimizing product costs, thereby improving profitability and making decision in operations.

>>>> Read more: How to Calculate Manufacturing Cost?

BoM Management Effectively with Viindoo solution

To structre a well BoM, the BoM Management solution of Viindoo allows users to keep track of different versions of BoM in environments where products undergo frequent updates or revisions. From there, risks of using outdated or incorrect BoM, the quality issues or delays in production are minimized to streamline the operations and enhance overall effeciency in the textile companies.

Beside, Viindoo software also provides the collaboration features among cross-functional teams, such as engineering, procurement, and

production, is essential for effective management to facilitate seamless collaboration, allowing

stakeholders to access and update BoM in real-time while maintaining

data integrity and security.

Managing BoM in textile manufacturing with Viindoo Software

Discover Viindoo Manufacturing Software

The All-in-one Software for Manufacturers. Provide all manufacturing features necessary for Textile companies.

FAQs

Viindoo's inventory management feature tracks raw materials,

work-in-progress items, and finished products in real-time, enabling

prompt identification of discrepancies or losses. Users can set up

parameters to quantify material losses and analyze data to minimize

waste and enhance efficiency.

Viindoo's subcontract manufacturing feature allows textile companies to

outsource excess production to third-party manufacturers, ensuring

optimal resource utilization and timely order fulfillment. It offers

flexibility, scalability, and cost savings, enabling companies to adapt

to fluctuations in demand efficiently.

Viindoo's BoM management solution helps textile companies keep track of

different BoM versions and collaborate seamlessly across

cross-functional teams. It minimizes the risk of using outdated or

incorrect BoMs, streamlines operations, and enhances overall efficiency

in production processes.

The Future Outlook of the Textile Manufacturing

Software solutions play a crucial role in optimizing textile manufacturing processes and enhancing overall efficiency. By leveraging these advanced tools, manufacturers can improve inventory management, streamline production planning and scheduling, maintain consistent product quality, optimize the supply chain, and effectively manage maintenance activities. As technology continues to evolve, the integration of software solutions will remain a key driver of innovation and competitiveness in the textile industry.

However, the textile industry still faces many challenges such as sustainability, supply chain management, and cost control, ... Along with the development of the textile industry, we expect to see many trends such as automation, sustainable materials, and digital printing shaping the future of textile manufacturing.

>>>> Read more: Case study of Cable Manufacturing