Unlock the potential of batch production with Viindoo Manufacturing Software. Learn how to optimize efficiency, reduce costs, and streamline operations in manufacturing. Discover the latest strategies and technologies for successful batch production implementation.

What is batch production?

Batch production is a manufacturing method where goods are produced in specific quantities or batches. This approach contrasts with continuous production and job production. In batch production, items are manufactured in groups, each representing a distinct batch, before moving on to the next set. Each batch undergoes the same or similar series of operations, making it suitable for standardized products or those with slight variations. This method offers benefits such as efficient resource utilization, flexibility to accommodate changes in demand or product specifications, and easier quality control. Batch production finds application across various industries like food and beverage, pharmaceuticals, automotive, and electronics. Manufacturers can balance economies of scale with product customization and flexibility. With advancements in technology, batch production continues to evolve, offering enhanced efficiency and quality control capabilities.

Batch Production

Batch Production How to optimize batch production with Viindoo Manufacturing Software

From advanced planning tools to real-time monitoring, Viindoo Manufacturing Software streamlines batch production processes, ensuring optimal resource utilization and timely delivery of high-quality products. Let's delve into Viindoo Manufacturing Software's capabilities and leverage them to maximize efficiency in batch production.

Planning and Scheduling

Planning with Viindoo Manufacturing Software

Planning with Viindoo Manufacturing Software Planning and scheduling are integral aspects of batch production, ensuring efficient utilization of resources and timely delivery of products. In batch production, planning involves determining the optimal batch size, sequencing production orders, and allocating resources such as raw materials and machinery. Scheduling, on the other hand, entails assigning specific timeframes for each batch's production and coordinating workflows to minimize idle time and maximize throughput.

Effective planning and scheduling in batch production help streamline operations, reduce setup times, and improve overall productivity. By forecasting demand and balancing workload capacities, manufacturers can optimize batch sizes and production schedules to meet customer requirements while minimizing inventory costs and production delays. Advanced planning and scheduling tools further enhance these capabilities by providing real-time visibility into production processes and enabling quick adjustments to changing demand or resource availability.

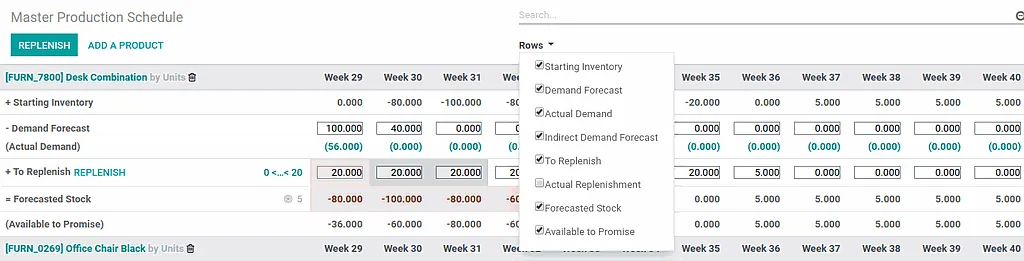

Viindoo Manufacturing Software provides a Master Production Schedule (MPS) feature that makes it easy to plan your supply based on your product’s forecasted demand.

Scheduling with Viindoo Manufacturing Software

Scheduling with Viindoo Manufacturing Software In summary, robust planning and scheduling practices are essential for optimizing batch production processes, maximizing efficiency, and staying competitive in today's dynamic manufacturing landscape.

Material Handling and Inventory Management

Material handling and inventory management are crucial aspects of batch production, ensuring smooth operations and cost-effectiveness. Material handling involves the movement, storage, and control of materials throughout the production process, from receiving raw materials to delivering finished products. Efficient material handling minimizes delays, reduces waste, and enhances productivity.

With Viindoo Manufacturing Software, you can:

- Define Bill of Materials for each manufactured product in Viindoo Manufacturing Software.

- Specify the list of raw materials, and their quantities required to produce one unit of the finished product.

Bill of Materials

Bill of Materials Inventory management is equally important, focusing on maintaining optimal stock levels to meet demand while minimizing holding costs. In batch production, where items are produced in specific quantities, effective inventory management is essential to prevent stockouts or overstocking, which can lead to production delays or excess inventory costs.

Inventory management

Inventory managementProduction Operations

Operations in batch production are fundamental processes that drive the efficient manufacturing of goods in predetermined quantities or batches. This method involves several key stages, each crucial for ensuring smooth production flows and high-quality output.

By optimizing operations in batch production, manufacturers can improve productivity, minimize waste, and consistently deliver high-quality products to meet customer demands. Leveraging advanced technologies and automation further enhances operational efficiency, enabling businesses to stay competitive in dynamic markets.

With highly automated production processes, managing the manufacturing operations and capacity is essential. Viindoo Manufacturing Software provides you with the tools for these manufacturing activities management.

Discover Viindoo Manufacturing Software

The All-in-one Software for Manufacturers. Provides all manufacturing reports and batch production strategy.

FAQs

Viindoo Manufacturing offers the Master Production Schedule feature, enabling management of production planning and scheduling

Inventory Management is a part of Viindoo Manufacturing , allowing you to easily monitor inventory levels of raw materials, components, and finished goods in the Viindoo Inventory module. Additionally, Viindoo Manufacturing allows you to track the consumption of materials during the production process

Yes. Viindoo Manufacturing offers packaging management for the production of finished products/by-products

Conclusion

Batch production stands as a cornerstone of modern manufacturing, offering a balance between efficiency and flexibility. Through meticulous planning, efficient scheduling, and optimized operations, businesses can meet diverse customer demands while minimizing costs and maximizing productivity. Leveraging advanced technologies and automation further enhances competitiveness in today's dynamic market. By embracing innovation and continuous improvement, companies can unlock new growth opportunities and maintain a leading edge in batch production.