Instructions

Instruction video: Manufacturing Quality Control

Example: Your company purchases raw materials to produce round tables. To manufacture 1 round table requires 4 table legs and 1 table top. You need to perform the quality check of the incoming raw materials and the finished round table when the production is completed. Here are some steps to follow:

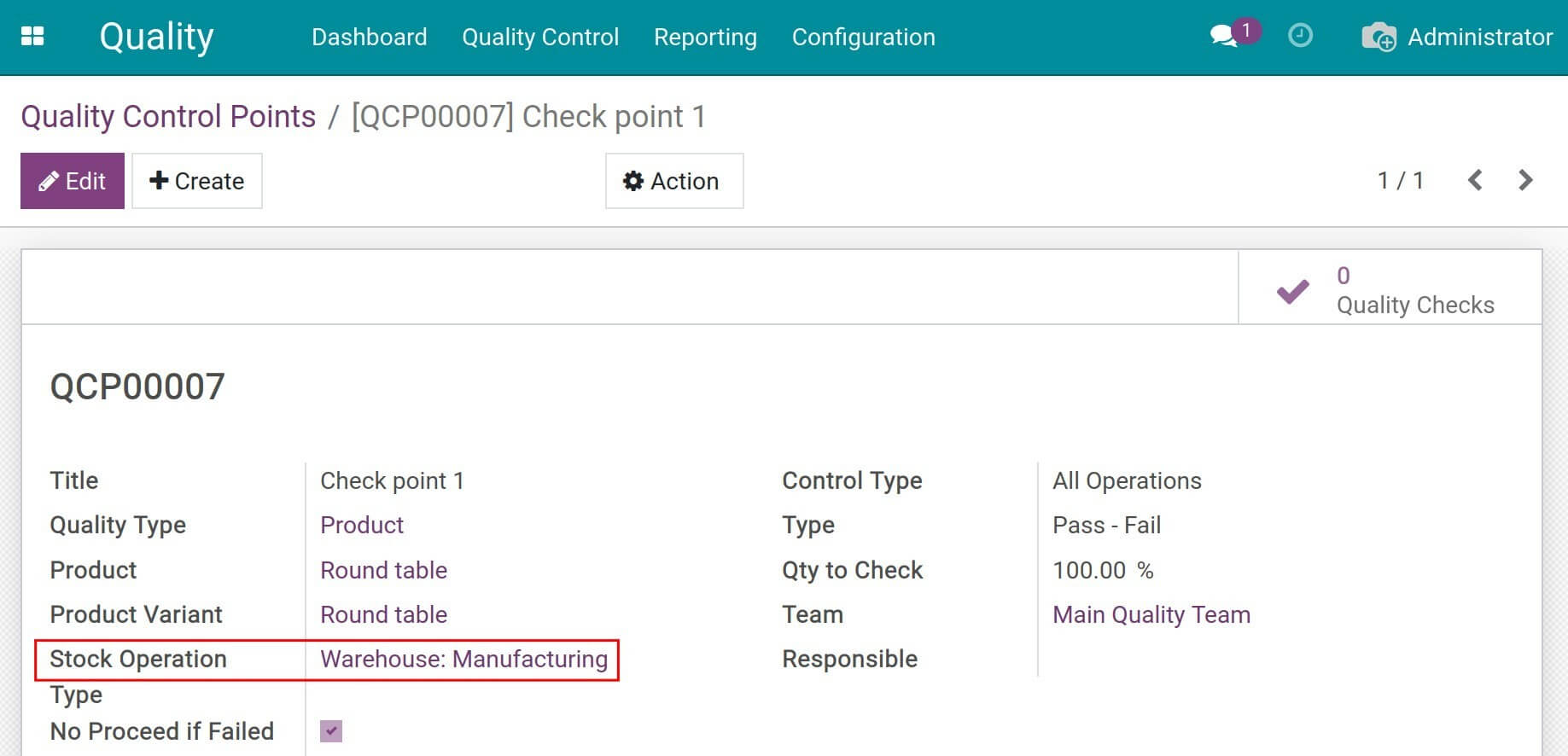

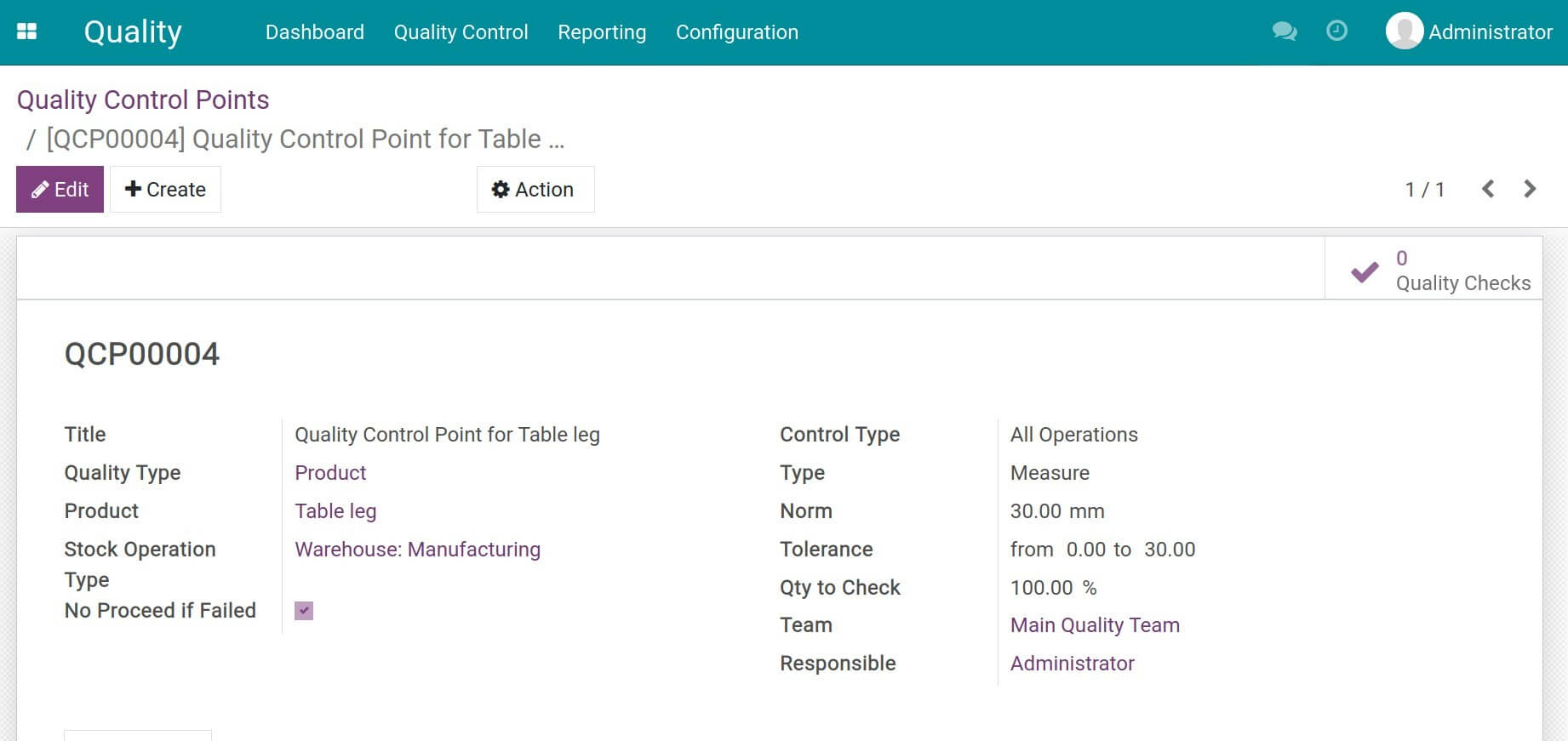

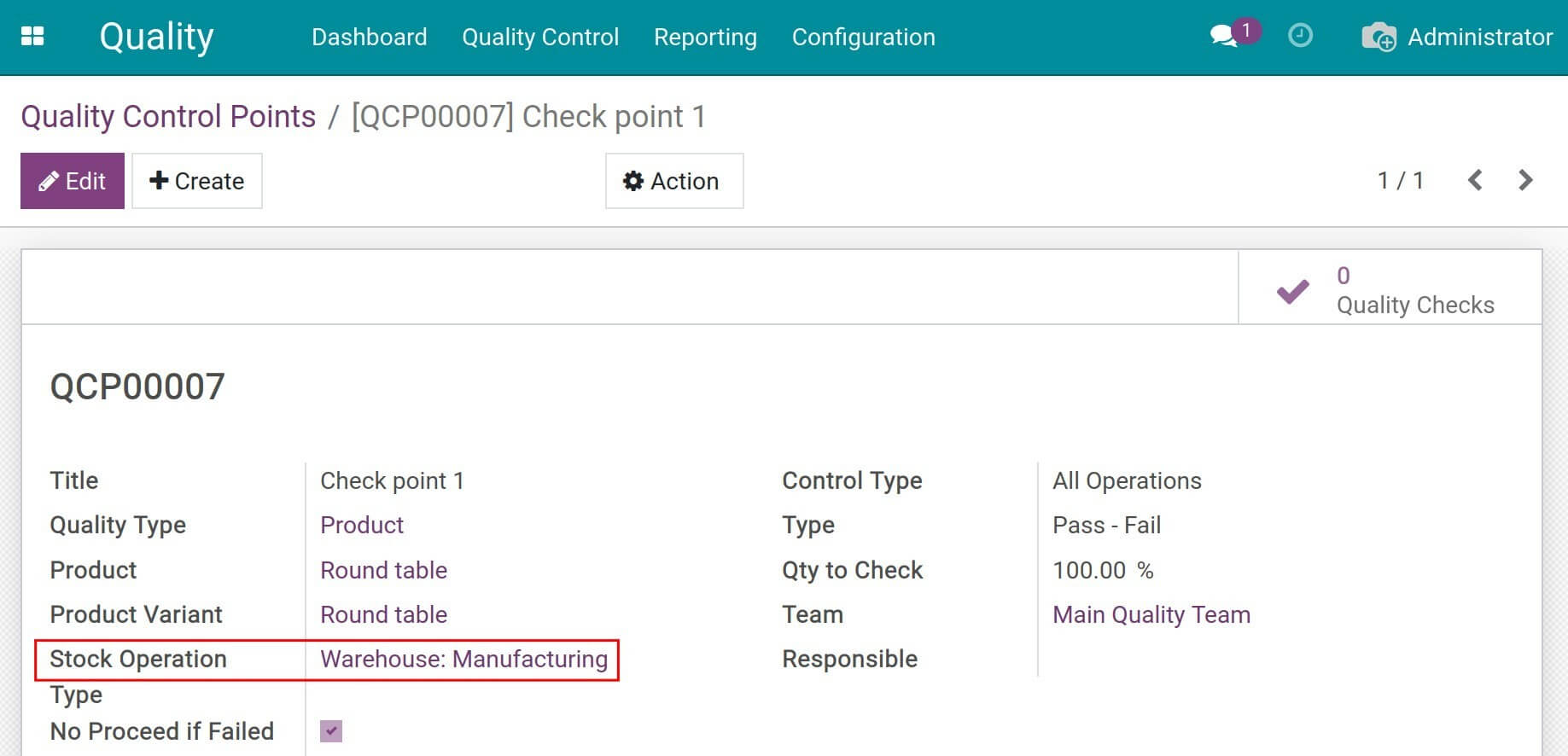

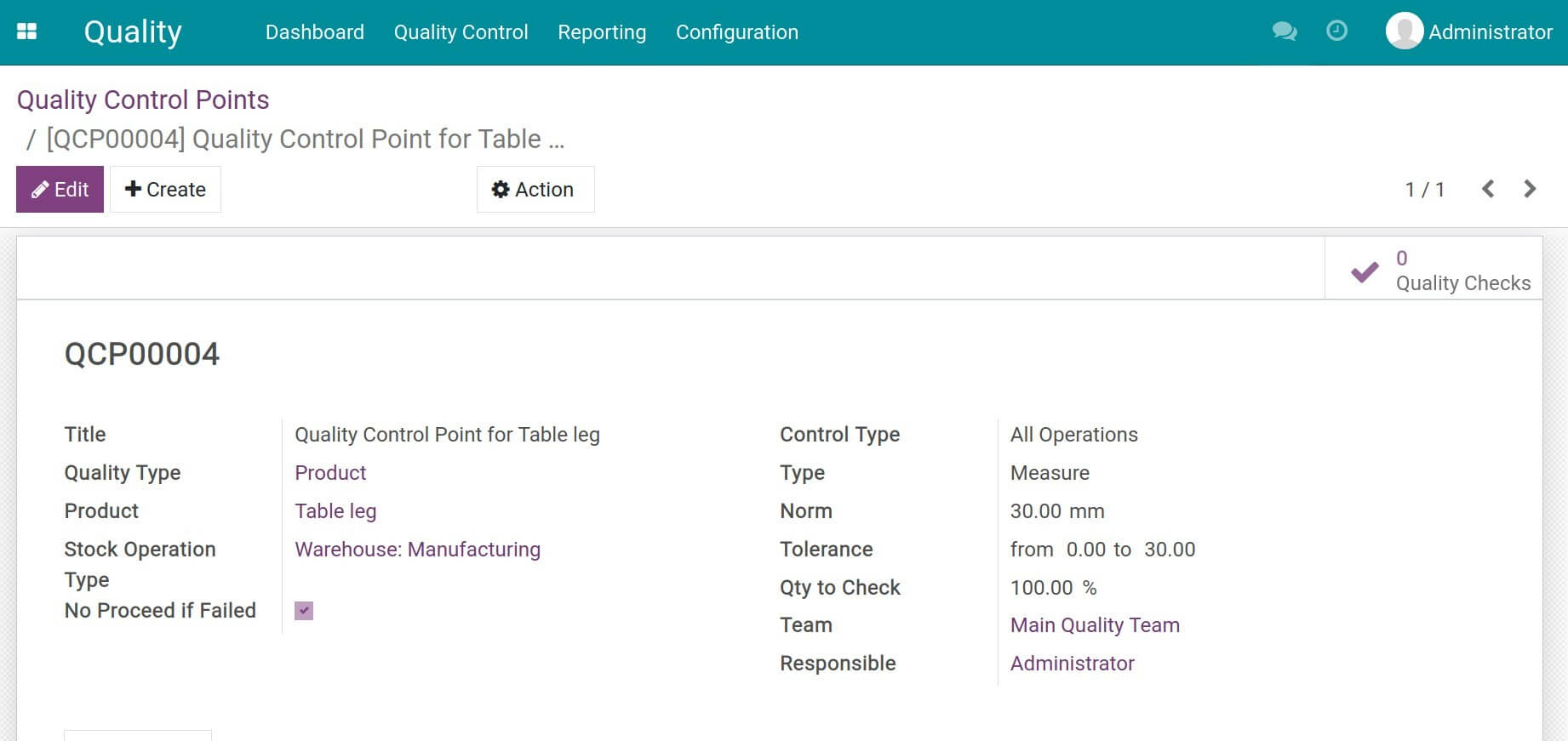

1. Create quality control points for manufacturing

Navigate to Quality > Quality Control > Control Points, and press Create to set up control points for the quality control.

Note: When this module is installed, the to_quality_stock module will be automatically installed at the same time.

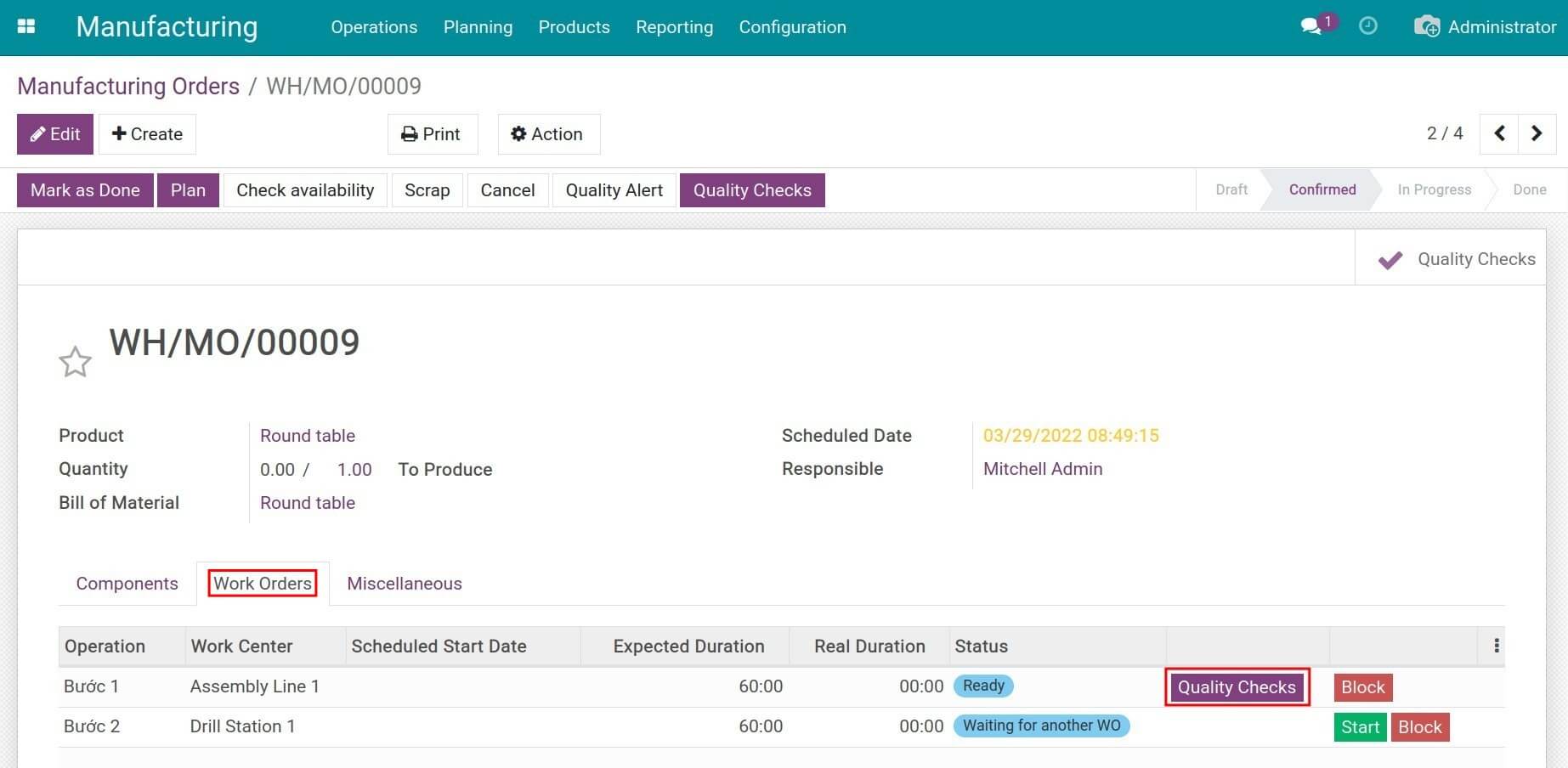

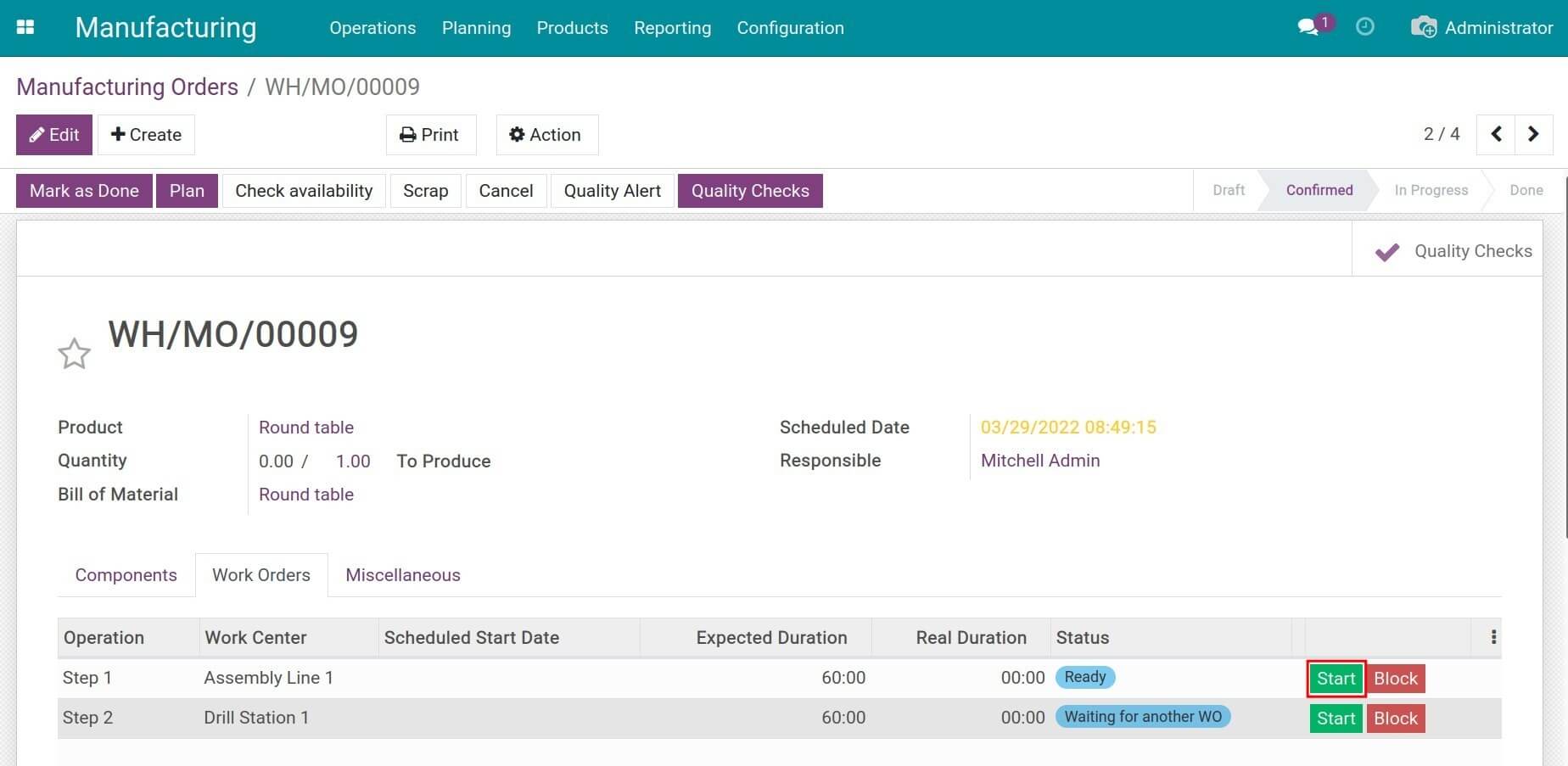

2. Process a manufacturing order and create quality checks

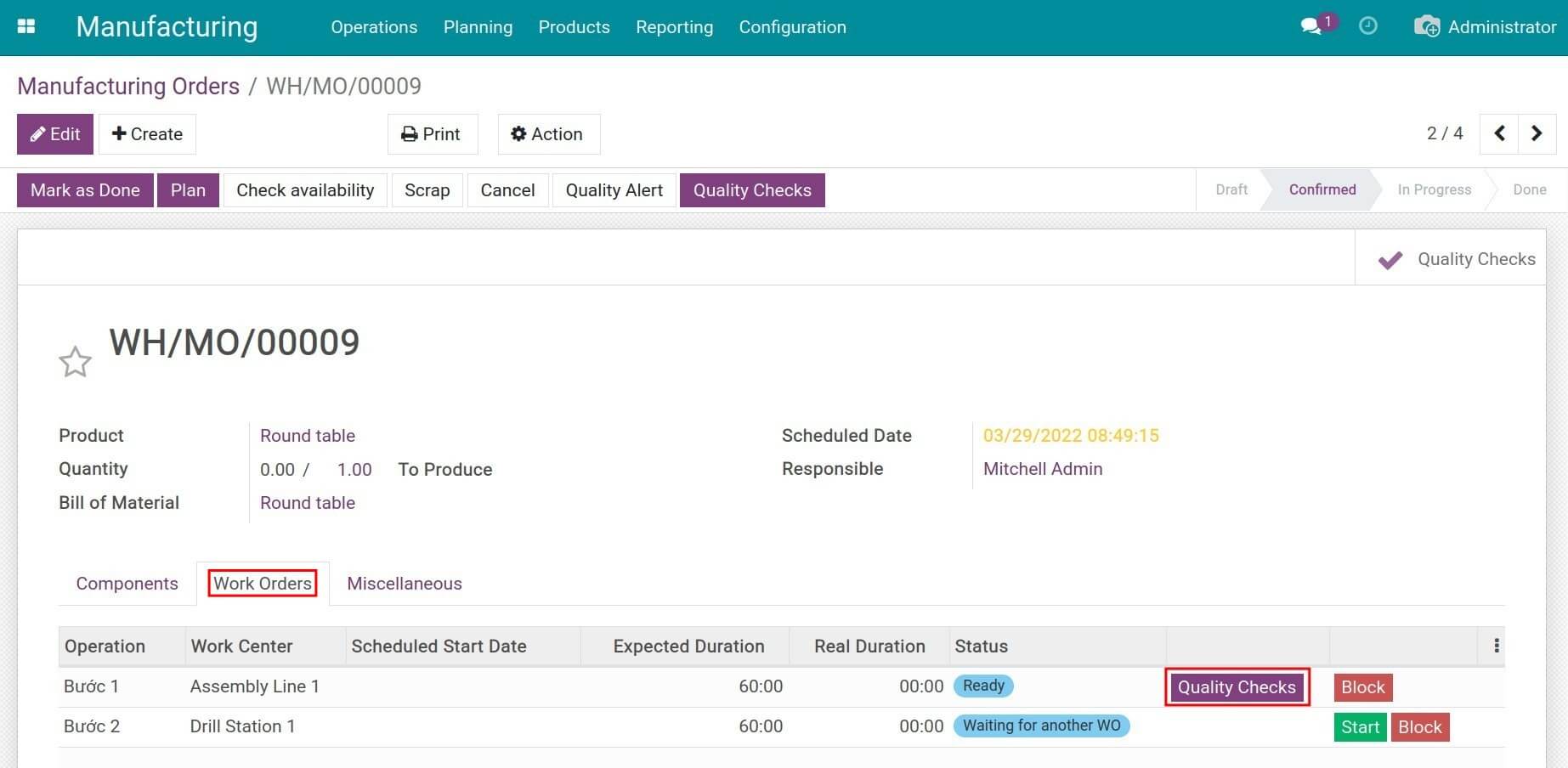

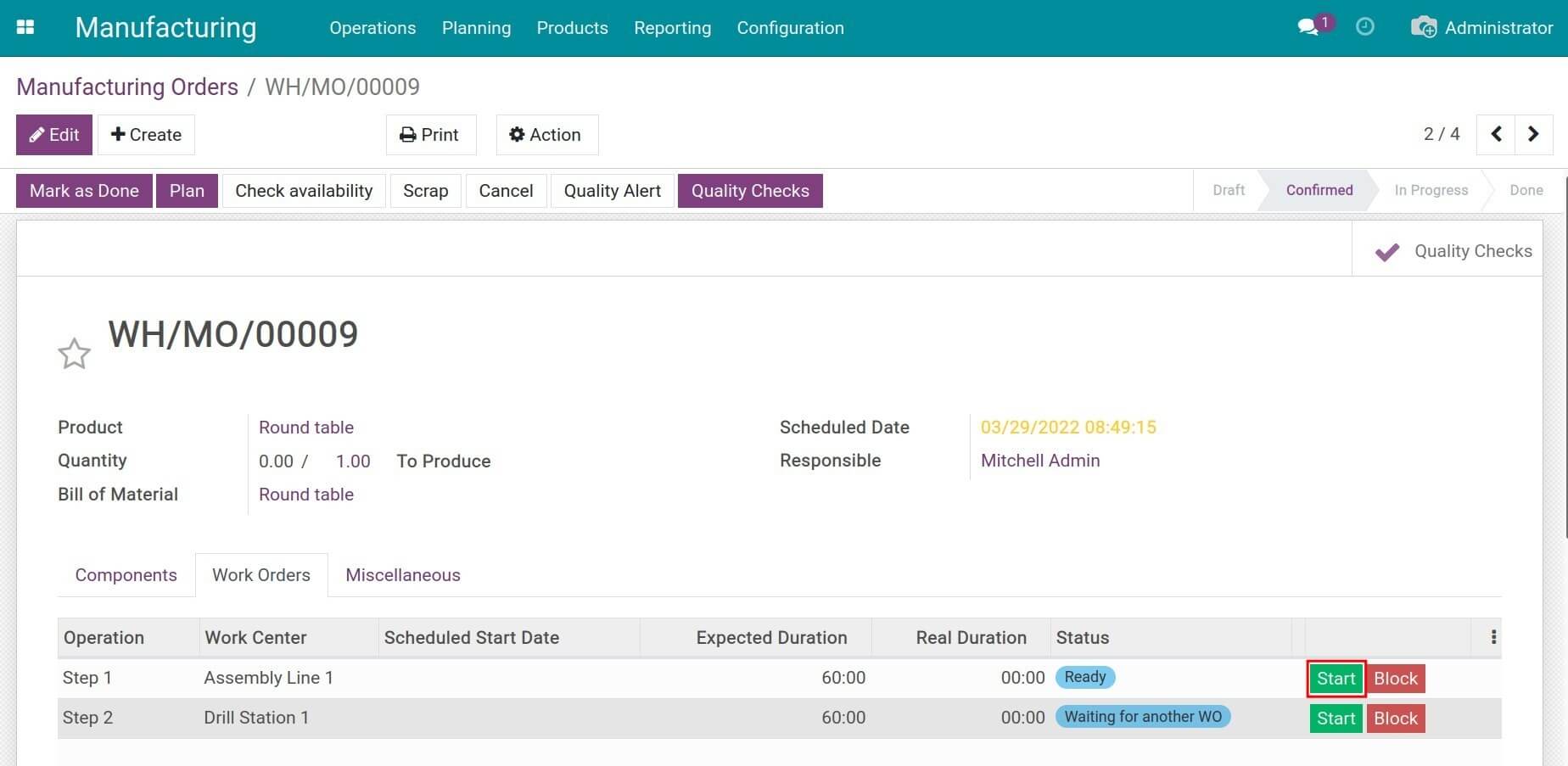

Configure the bills of materials and the alternative work centers, create and confirm the manufacturing order. After the manufacturing order is confirmed, the system will automatically recognize and display the Quality Checks button on each line in the Work Orders tab.

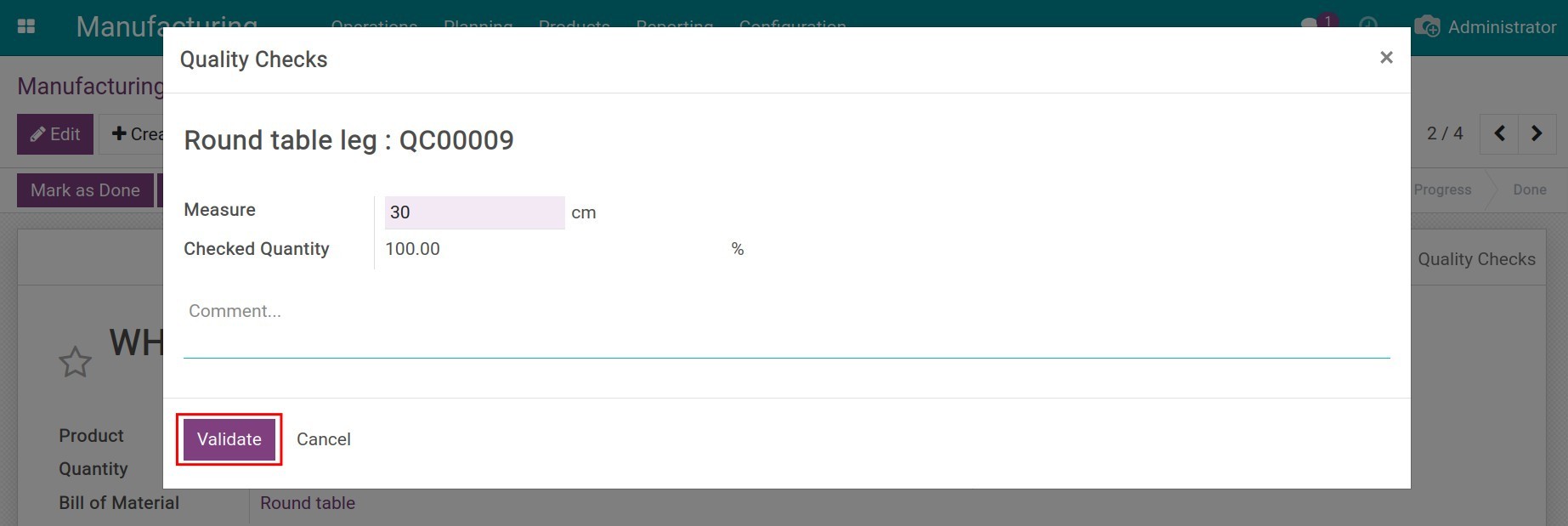

3. Evaluate materials quality before production

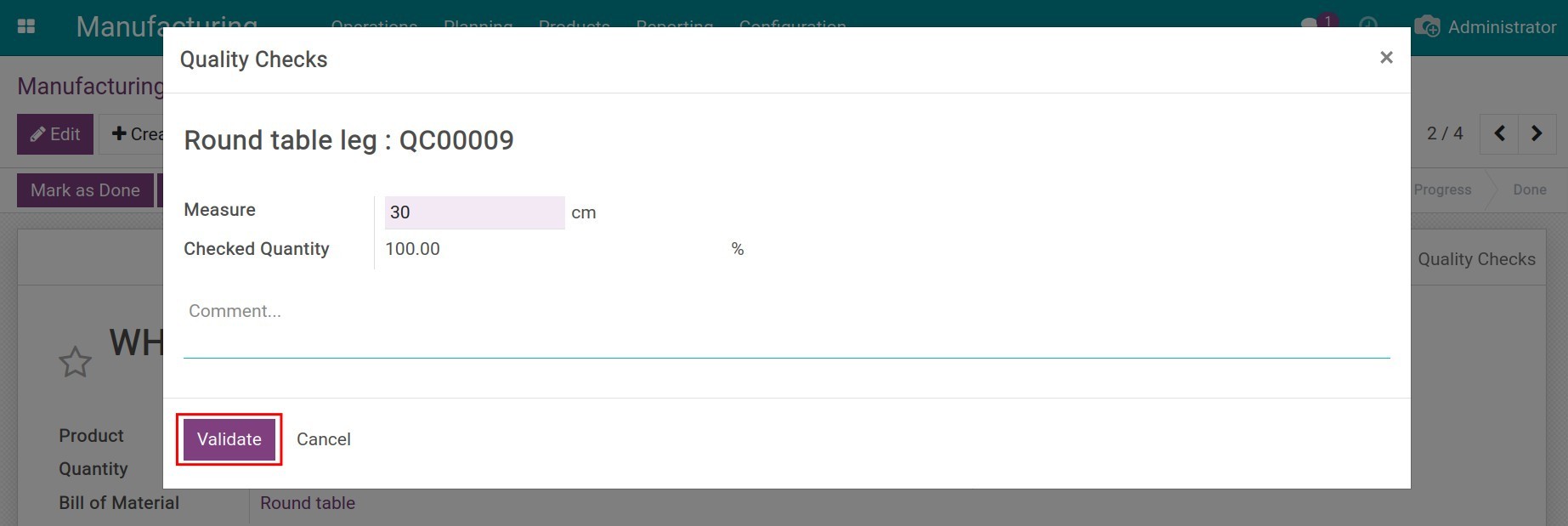

Press Quality Checks and add the measurement, fail or pass evaluation for the materials.

In case the measurement is in the tolerance range set up on the Control points, the quality check is automatically marked done and the Start button to initiate the production.

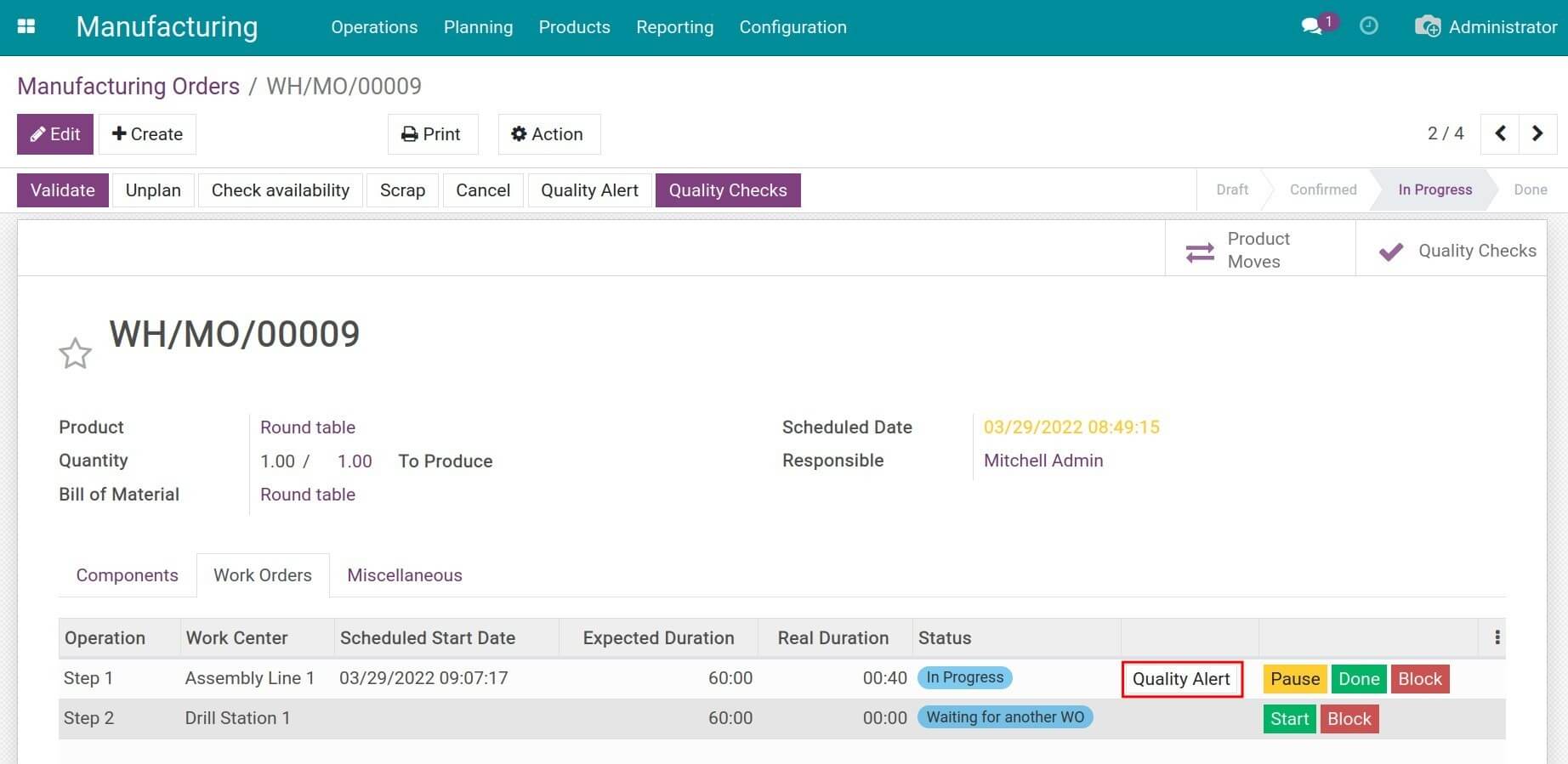

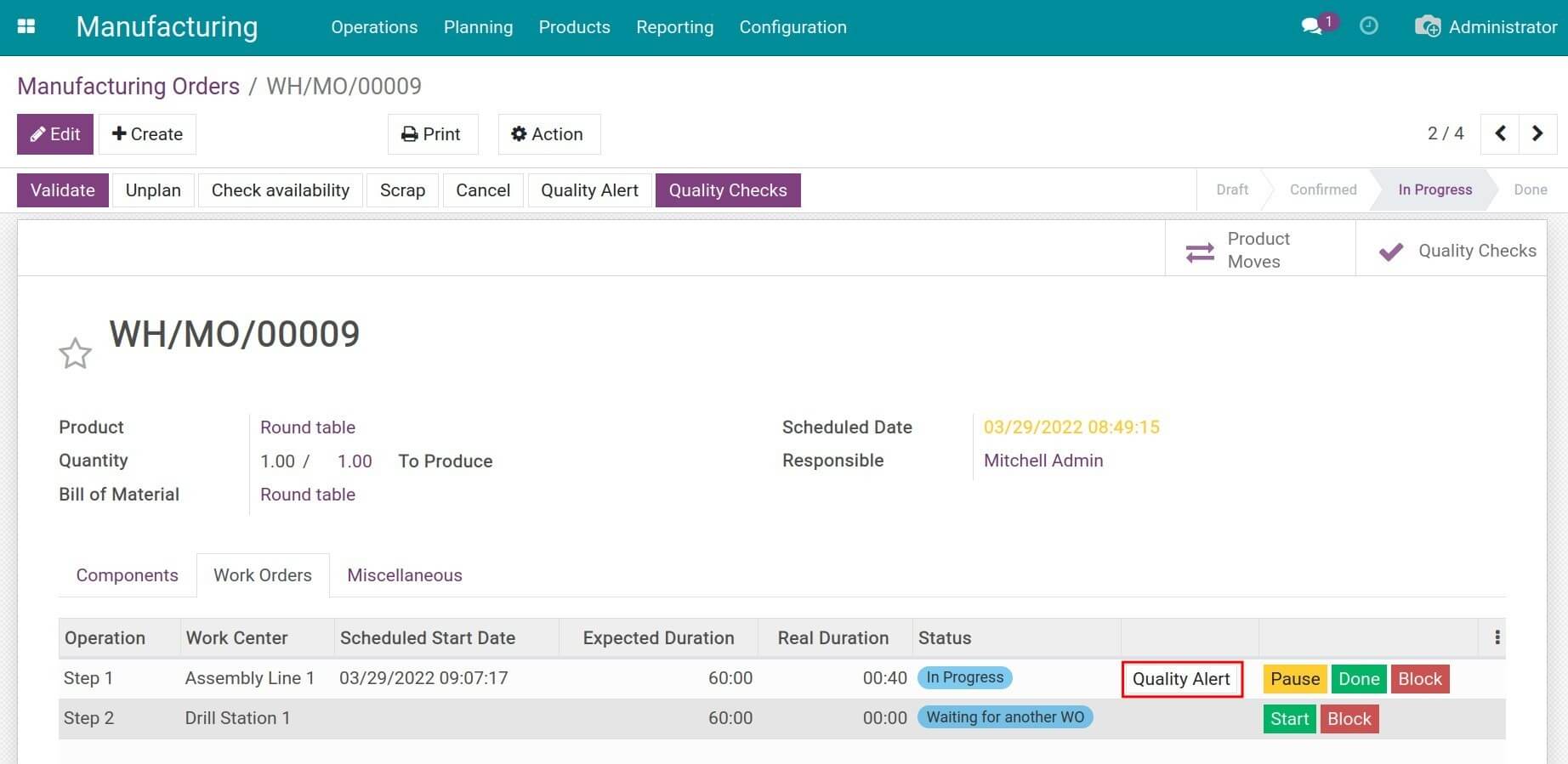

4. Create and process quality alert

During the manufacturing process, you might encounter situations where materials don't meet the requirements, you can create an alert by clicking on Quality Alert.

Note: Once the work centers finish the production, you can perform similar steps to evaluate the quality of the finished products before sending them to the warehouse.