Manufacturing productivity encompasses a wide array of factors that influence the efficiency of production processes. In this piece, Viindoo delves into the realm of elevating manufacturing productivity through the lens of effective resource planning – a cornerstone in the manufacturing landscape. The judicious allocation and adept utilization of resources, encompassing human capital, equipment, materials, and time, stand as paramount drivers for amplifying both output and profitability. Let's take a closer look at how adept resource management fundamentally bolsters the fabric of manufacturing productivity.

What are resources in manufacturing?

In manufacturing, a resource refers to any element, material, tool, or asset that is utilized in the production process to create goods or provide services. Resources are essential components that contribute to the overall production of a product. They can be categorized into various types based on their nature and usage. Some common types of resources in manufacturing include:

What are resources in manufacturing?

What are resources in manufacturing?

Raw Materials: These are the basic components used to create a finished product. Raw materials can be natural resources like minerals, metals, wood, or synthetic materials like plastics and chemicals.

Labor: The workforce involved in manufacturing processes is a crucial resource. This includes skilled and unskilled workers, operators, technicians, engineers, and other personnel responsible for assembling, operating machinery, quality control, and other tasks.

Equipment and Machinery: Manufacturing often requires specialized machinery and equipment to transform raw materials into finished products. This can include machines like CNC (Computer Numerical Control) machines, injection molding machines, assembly lines, and more.

Facilities and Space: The physical space where manufacturing processes take place is also a critical resource. This includes factories, warehouses, and other facilities required for production.

Time: Time is an essential resource in manufacturing. Efficient management of time can lead to increased productivity, reduced lead times, and improved overall performance.

Information and Data: In modern manufacturing, data and information are crucial resources. This includes data related to production schedules, inventory levels, quality control, and other aspects of the manufacturing process.

Capital and Finance: Adequate financial resources are required to invest in equipment, facilities, raw materials, and other elements of the manufacturing process.

...

Why is resource planning important in enhancing manufacturing productivity?

Comprehensive Resource Assessment

Conduct a detailed assessment of existing resources within the production process, encompassing human expertise, machinery, raw materials, and time.

Identify key resources with significant impact on productivity and product quality.

Resource Planning and Allocation

Develop a comprehensive plan outlining how resources will be allocated and utilized throughout the production process.

Determine timing, quantity, and usage of resources to ensure efficient and non-wasteful utilization.

Process Optimization

Analyze and streamline production processes to eliminate unnecessary steps and optimize the movement of resources.

Ensure a logical sequence of work to prevent time and resource wastage.

See more: Streamlining Manufacturing Process: Overcome Pain Points

Workforce Training and Development

invests in training and development programs to enhance the skills and capabilities of the workforce.

Ensure employees possess the necessary knowledge and techniques for efficient and resource-effective task execution.

See more: Strategies for Implementing Skill-Based Training in your business

Equipment Maintenance and Preservation

Implement regular maintenance and upkeep of production equipment to ensure consistent and uninterrupted operations.

Employ data-driven maintenance methods to predict maintenance needs, minimizing downtime.

Efficient Material Utilization

Determine methods for efficient material usage to reduce waste and production costs.

Monitor and track material consumption to ensure efficient usage and minimal material losses.

Monitoring and Measurement

Employ monitoring and measurement of resource utilization to identify weaknesses and improvement opportunities.

Establish resource performance metrics to ensure optimal utilization and achievement of targets.

Continuous Improvement and Innovation

Encourage innovation and creativity in resource utilization to discover opportunities for process enhancement.

Foster an environment that motivates employees to contribute novel ideas for resource utilization.

Robust Resource Management Framework

Develop a structured resource management framework to ensure planned and efficient utilization of resources.

Define responsibilities and delegation of authority for effective resource management.

Data-Driven Decision-Making

Utilize data and analytics to make informed decisions about resource allocation and utilization.

Leverage insights to fine-tune strategies and enhance resource efficiency.

Efficient resource management is a dynamic interplay of processes, technology, and human commitment, all working in harmony to ensure optimal resource utilization and continuous productivity improvement in the manufacturing realm

Applying ERP for Optimizing Resources to Enhance Productivity

The Enterprise Resource Planning (ERP) system has become a powerful tool in improving manufacturing productivity through effective resource management. By integrating and automating processes, ERP helps optimize the utilization of human resources, equipment, and raw materials to achieve the best possible production output. Below is an overview of how ERP can be applied to efficiently manage resources and elevate manufacturing productivity:

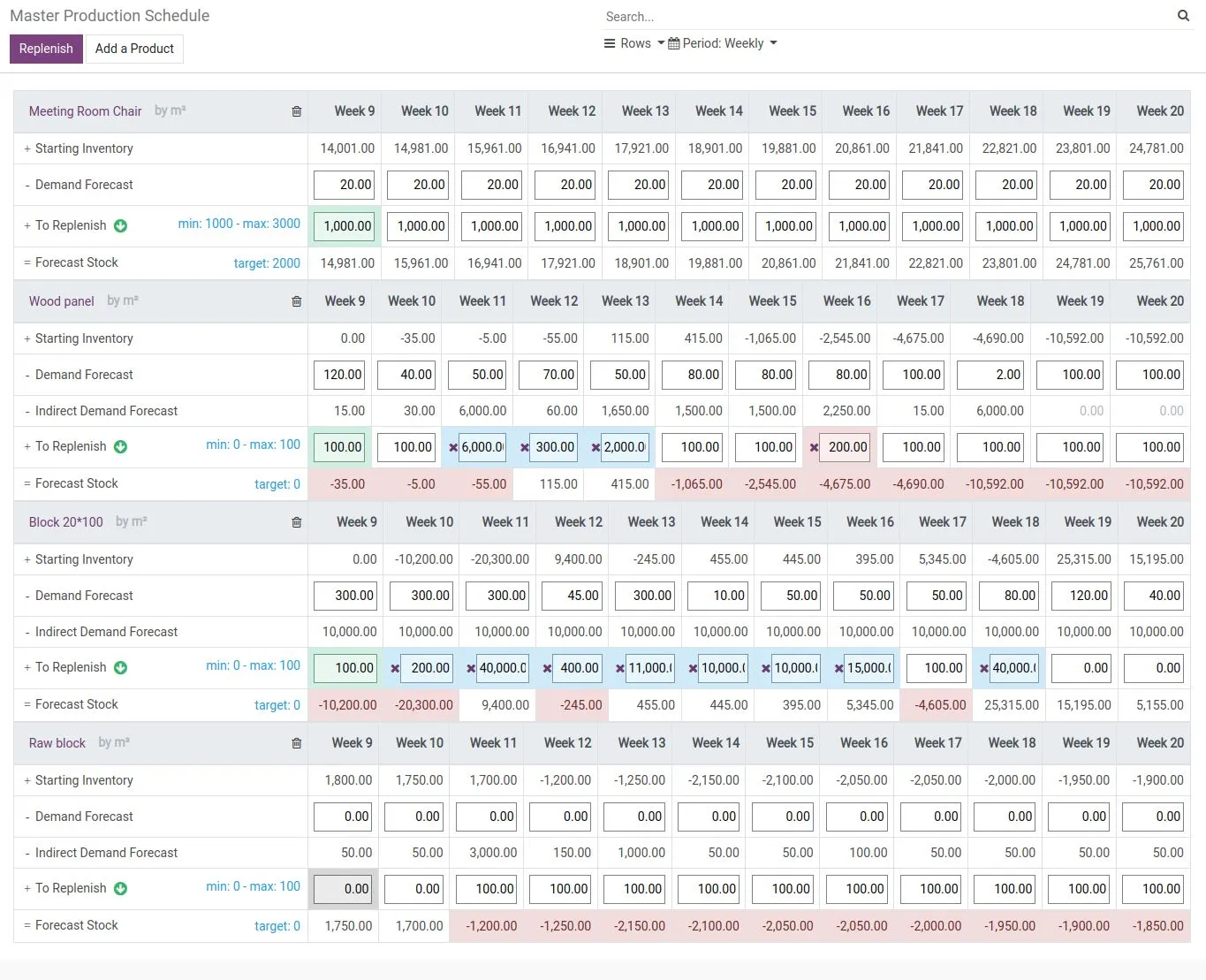

ERP's Master production schedule report helps effective resource planning in manufacturing

Data-Driven Decision-Making

- ERP enables organizations to track employee information, skills, experience, and work schedules.

- Efficiently schedule work shifts based on skills and work requirements.

- Monitor workforce performance and production output to optimize task allocation and engagement.

- ERP enables organizations to track employee information, skills, experience, and work schedules.

Equipment and Asset Management

- ERP facilitates tracking of equipment status, usage, and maintenance.

- Schedule regular maintenance and inspections to ensure uninterrupted operations.

- Manage inventory levels and forecast material requirements to maintain smooth production.

- Some specific features: Digitalize equipments information Automatic maintenance plan ensures seamless equipment operation, visualize the whole maintenance activities in many interfaces: Kanban, Calendar, Pivot, etc. follow each stage of maintenance activities. Retrieve information anytime

Streamlining Production Processes

- ERP integrates data and processes, from planning to delivery, optimizing the production workflow.

- Optimize production schedules, monitor production progress, and receive alerts in case of issues.

- Manage production lines and choose process optimizations to increase productivity.

Performance Tracking and Measurement

- ERP generates reports and metrics to monitor production performance and product quality.

- Monitor real-time data to address issues promptly and ensure continuous improvement.

Supply Chain Management

- ERP integrates procurement, shipping, and scheduling from suppliers.

- Monitor inventory and forecast material needs to ensure a stable supply.

- Maintain strong supply chain linkages to avoid production disruptions.

See more: Viindoo SCM - Supply Chain Management Software

Data Integration

- ERP establishes strong connectivity between departments and operations, facilitating automatic data sharing.

- Prevent errors and reduce manual data processing time.

See more: Viindoo MRP - All-in-one Manufacturing software

Quality Control

- ERP allows tracking and managing product quality through testing and validation data.

- Identify and address quality issues promptly to meet specifications and standards.

>>>> See more: Viindoo Quality Management Software

The implementation of ERP in resource management is a crucial part of the strategy to enhance manufacturing productivity. This system not only optimizes resource allocation but also fosters better coordination, data-driven decision-making, and continuous improvement throughout the production lifecycle

Conclusion

In the increasingly competitive landscape, enhancing manufacturing productivity has become a top priority for businesses. Effective resource management and the implementation of an ERP system have demonstrated their crucial role in achieving this goal.

Enhancing manufacturing productivity through the application of ERP is a highly effective approach. This system aids in optimizing resource utilization, refining workflows, and enhancing collaboration between departments within the business.

Through data and process integration, ERP minimizes errors and reduces manual data processing time, thereby boosting operational efficiency. Monitoring and measuring performance becomes more streamlined, providing a clearer view of the production process and identifying areas for improvement.

Moreover, ERP supports efficient resource management, maintains robust supply chain linkages, and ensures compliance with quality standards. Overall, ERP implementation empowers businesses to elevate productivity, improve operational effectiveness, and gain a competitive edge in today's challenging market landscape.

>>>> See more:

- Manufacturing report: How to utilize to overcome pain points

- Production capacity planning: Definition, types, and best practices