Inventory inventory is a task performed regularly by most manufacturing enterprises. Choosing the wrong plan, method and inventory process will lead to loss and waste of the Enterprise's resources. Read this article by Viindoo to learn more about this issue!

1. What is inventory? Purpose of inventory count

Inventory counting is an on-site inspection of existing inventory to accurately determine the quantity, quality and value of actual inventory, thereby detecting discrepancies between the amount and quantity of inventory. actual data compared to the figures in the accounting books.

Inventory is also a type of business asset. In the process of doing business, it is inevitable that there will be loss or discrepancies in goods. Inventory will help businesses:

- Control goods strictly in terms of quantity, quality and value. This information helps managers make correct judgments about the business situation of the enterprise, thereby devising effective business strategies.

- Prevent phenomena of embezzlement, waste that leads to loss of assets, phenomena of violation of financial discipline, and enhance the responsibility of asset managers.

- Timely find discrepancies between books and reality to have solutions. For example, goods are lost over a long period of time, or poor storage conditions cause the quality of stored goods to decrease, etc. For each specific situation, we will have our own solution.

- Inventory also helps limit unnecessary waste by freeing up storage space and inventory management effort.

Inventory and inventory management play an important role in manufacturing enterprises

>>>> See more: Warehouse import and export management software

2. Inventory counting methods

2.1 Periodic inventory

Periodic inventory is a type of inventory with a specific time planned in advance, such as monthly, quarterly, semi-annually or at the end of a business's conventional period.

2.2 Abnormal inventory

Abnormal inventory is a type of inventory that is not planned in advance, possibly due to the needs of superiors or special reasons. Some examples of this case are when the warehouse keeper changes, when there are unusual incidents (theft, fire, explosion, etc.) whose damage has not been determined,...

2.3 Complete inventory

A complete inventory is a complete inventory of a business's inventory. This will usually be done at least once before preparing the year-end balance sheet.

2.4 Partial inventory

Partial inventory takes inventory of certain types of goods depending on management needs. For example: there is only a need to inventory a certain type of item, or when there is a theft in a warehouse.

3. Inventory process

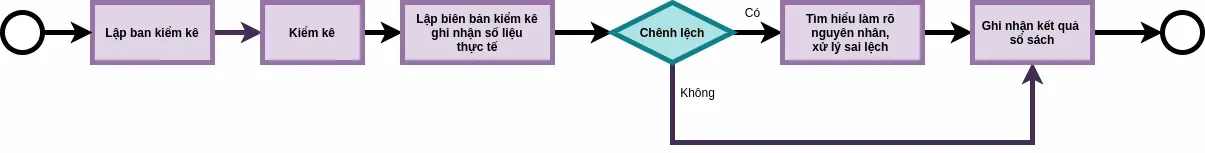

The inventory counting process will often be different according to each industry sector to ensure it is suitable for the business activities of the enterprise. The following is a common inventory process applied to most businesses:

>>>> See More: RFID in warehouse management

3.1 Preparation phase

Before conducting the inventory process, the warehouse manager needs to plan the assignment and notify this plan to relevant departments and personnel. Management must ensure that warehouse employees understand inventory procedures and plans. The plan can be announced via email or through a written decision from superiors

Warehouse managers must ensure that warehouse staff understand the inventory plan.

A standard inventory plan will include the following contents and activities:

- Priority order of areas that need to be inspected

- Method of synthesizing information and comparing results after inventory

- Develop effective inventory methods depending on the nature of the goods. For example, using your eyes to count or using a ruler to measure.

3.2 Stage of conducting inventory

After completing the preparation step, businesses can proceed with the inventory process with the following steps:

- Step 1: Warehouse staff are responsible for making a complete list of available goods at the time of inventory, this task can be done using the Warehouse Management Software that the business is using. The list of goods should be arranged to suit the order and area of the goods in the warehouse. This will make the steps of inventorying and comparing results easier.

- Step 2: Build inventory groups with 2 employees per group. These groups will be in charge of inventorying the actual quantity and quality of goods at the warehouse and making notes on the manifest created in step 1. Members of each group can independently note data to increase accuracy. accuracy. Any goods that have been inspected will have a sticker attached to mark them.

- Step 3: Compare the inventory results in the 2 members' declarations. This activity is intended to ensure the accuracy of the inventory process. If the data on both sides are inconsistent, re-checking must be done immediately.

- Step 4: After the groups have inventoried and cross-referenced, synthesize the results again. Then compare the results with books or inventory reports at the time of inventory. If there is a difference, the person in charge of daily inspection and warehouse management must explain the reason.

- Step 5: After explaining the reason for the difference between reality and books, businesses need to take notes as a basis for realigning data on books or systems.

- Step 6: Finally, prepare a report on the results of the inventory counting process. The content will include inventory activities, final conclusions and proposed methods to overcome problems of warehouses about to expire, warehouse storage areas in disrepair... followed by a signature for confirmation. Receive minutes from the parties participating in the inventory.

Effective inventory counting process

3.3 Sample, Excel inventory record

Here are some common inventory record forms:

1. If the enterprise accounts according to Circular 133/2016/TT-BTC:

- Form No. 04 – VT: Report of materials remaining at the end of the period

- Form No. 05 – VT: Minutes of testing of supplies, tools, products, and goods.

>>>> DOWNLOAD SAMPLE <<<<

2. If the enterprise accounts according to Circular 200/2014/TT-BTC:

- Form No. 04 – VT: Report of materials remaining at the end of the period

- Form No. 05 – VT: Minutes of testing of supplies, tools, products, and goods.

- Minutes of establishing the goods inventory council.

>>>> DOWNLOAD SAMPLE <<<<

>>>> See More: Inventory report

4. 5 kinh nghiệm kiểm kê hàng tồn kho hiệu quả

Việc kiểm kê tồn kho sẽ ảnh hưởng trực tiếp đến hoạt động kinh doanh của cả doanh nghiệp. Sau đây là 5 kinh nghiệm các doanh nghiệp có thể tham khảo để đạt được hiệu suất cao trong quy trình kiểm tra kho hàng.

4.1 Thống kê, theo dõi thông tin tất cả các hàng trong kho

Những nhân viên chịu trách nhiệm quản lý và kiểm soát kho hàng cần phải ghi chép đầy đủ các hoạt động lưu chuyển hàng hóa cũng như thông tin của các mặt hàng trong kho. Những thông tin này bao gồm số lượng hàng, mã số, nhà sản xuất, nơi xuất xử và SKU

Các doanh nghiệp cũng có thể ghi chú lại sự biến động của giá hàng hóa để xác định những yếu tố ảnh hưởng đến giá cả.

Nhân viên kho hàng cần phải ghi chép, báo cáo kiểm kê hàng tồn kho

>>>> Learn About: Inventory forecasting

4.2 Prioritize inventory goods

An effective way to count inventory is to give priority to items and goods available in the warehouse. With inventory in the warehouse, businesses need to divide inventory into different groups according to priority. Criteria for prioritization can be based on the price of the product or the sales potential of the product. For example:

- Group A: High-priced goods, difficult to sell, businesses need to import less

- Group C: Low import costs, better sales ability

- Group B: Goods with prices and sales speed lower than C, but higher than A

Prioritizing grouping will help businesses balance the number of goods that need to be imported into the warehouse as well as focus on products that are important to the business.

Criteria for dividing priority groups can be based on the price of the product or the sales potential of the product.

4.3 Use the 80/20 rule

Inventory management often has a rule that: 20% of the goods in the warehouse will bring 80% of the company's profits. Therefore, priority should be given to inventorying and managing inventory belonging to this 20% of expected goods.

The employee in charge of warehouse management needs to know the entire sales life cycle of these 20% of goods, for example how much profit is earned from these products per week, how much is imported and how much is sold.

Rule of businesses: 20% of goods in inventory will bring 80% of profits to the company.

4.4 Unify control processes

For a process to work effectively, the parties involved need to agree on how to work. The same is true for inventory control. Employees in charge of management, inventory, and warehouse supervision must agree on the inventory control process. If each employee applies their own method, it is easy to cause errors when working.

The parties involved in warehouse management need to agree on how to work.

4.5 Technology application in inventory

Currently on the market there are many application software to help businesses better inventory inventory. Using advanced technology will help prevent errors and confusion when employees have to manage a large amount of information about goods. Before using management software, businesses should consider their inventory and financial needs to choose the most suitable warehouse management software.

Business owners should consider their inventory and financial needs to choose the most suitable software.

Are you ready to experience?

Automate Supply Chain activities, warehousing, warehousing, inventory, warehouse accounting,... Avoid supply deviations, capital accumulation, and waste of Enterprise assets.

SIGN UP NOW hoặc Nhận tư vấn

It can be said that inventory counting is an important operation and is performed regularly throughout the warehouse operation process of the enterprise. If your business wants to learn more about effective inventory management solutions, contact us Viindoo Via hotline 02257309838 for detailed advice!