Is your business struggling with Supply Chain Management?

Fragmented information, lack of connection, and ineffective communication among suppliers, partners, customers, etc. within the supply chain?

Difficulty in capturing and forecasting market demand to maintain optimal inventory levels that match customer consumption trends?

Inability to track the "flow" of goods in real time, resulting in delays in distribution and circulation when needed?

No optimal solution in place, leading to high costs and reduced price competitiveness?

Absence of standardized processes and plans for managing supply-demand balance, input materials, output products, and logistical support, leaving the business reactive and vulnerable to common supply chain risks?

Viindoo SCM - Design a Comprehensive Supply Chain Management Process

Overall strategy design

Viindoo SCM provides data on location, purchase history, website visits, etc. to address needs and design an overall strategy.

Sales process setup

An optimized, automated sales process ensures close order status monitoring, minimizing risks, and optimizing costs for your business.

Supplier network setup

Viindoo SCM ensures an uninterrupted supply chain by assisting businesses in building supplier networks and evaluating capacity to choose competitive suppliers.

Inventory management

Viindoo SCM enables businesses to manage import, export, stock, and supply efficiently, meeting customer needs and distribution strategies.

Technology platform

Viindoo SCM is an all-in-one solution for businesses to enhance performance, connect operations, and automate supply chain processes.

Standardize Supply Chain Operations with Automated Rules

SCM software helps save time & effort and optimize operations to improve efficiency across the supply chain.

Set rules to activate replenishment requests:

- Make-to-order

- Make-to-stock

Automate replenishment process in multiple methods:

- Buy from suppliers;

- Manufacture or Outsource;

- Stock transfers among warehouses;

- ...

Record all landed costs and automatically create allocation journal entries to a djust stock price.

Support multiple inventory valuation methods:

- Standard Price;

- FIFO;

- Average cost

Enable automatic deliveries with logistics methods like Drop-ship and Cross-dock.

Manage your Supply Network in real-time

Collaborate with your suppliers and partners for seamless supply chain processes, including ordering, forecasting, inventory management, and supply and demand monitoring.

Transparency, flexibility, and maximum value creation for the Supply Chain

Enhance logistics control.

Enhance collaboration efficiency throughout the supply chain.

Enhance the ability to control and evaluate efficiency at each stage in the supply chain.

Increase transaction volume through accelerating real-time data exchange

Increase sales with effective customer-responsive implementation.

Minimize inventory.

Reduce operating costs across the supply chain from transportation, and distribution, to warehousing, and more.

Reduce product costs and improve profits for businesses.

Minimize risks and respond quickly to changes in the market and consumer needs.

Improve customer service and increase business competitiveness.

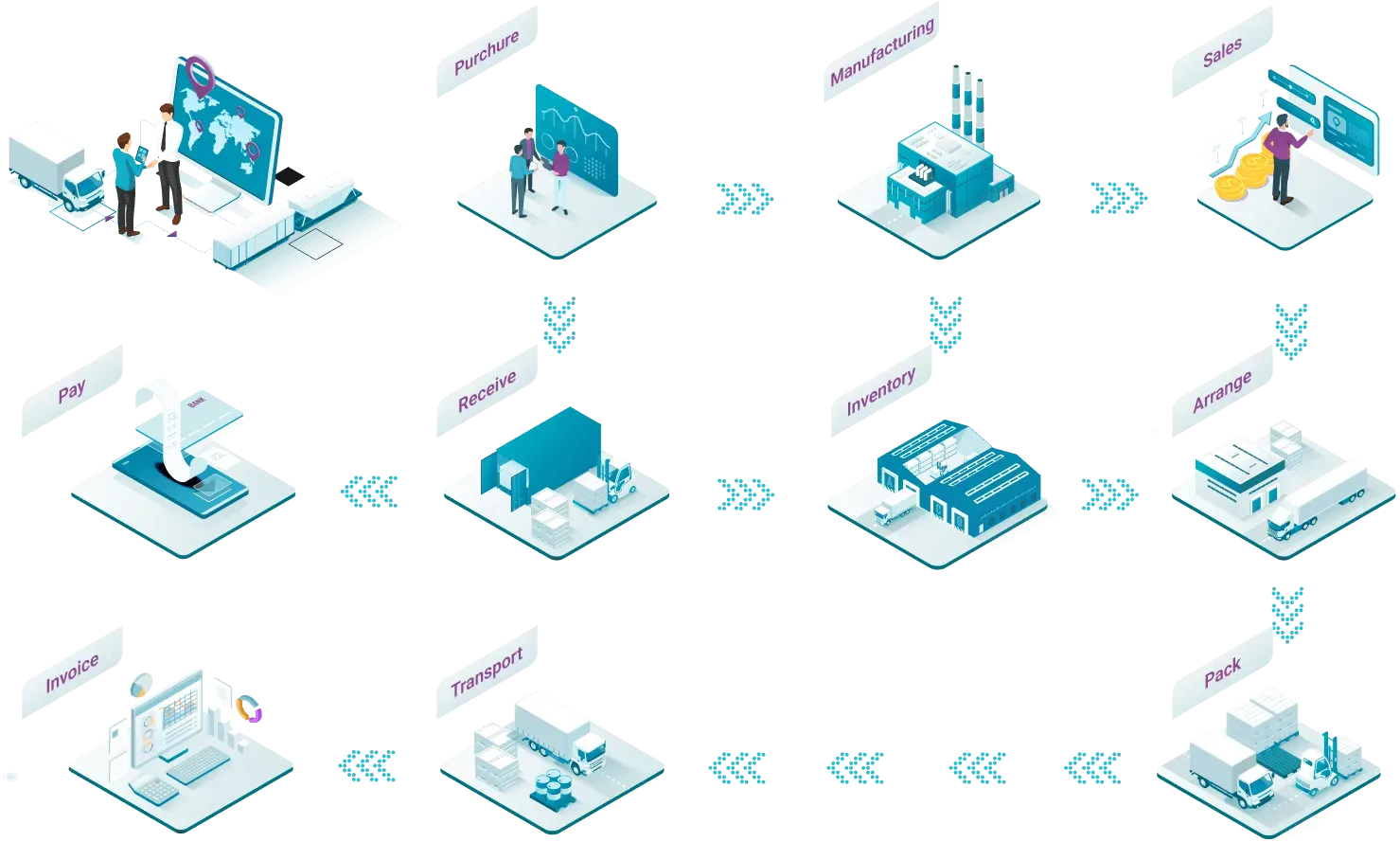

Connect every aspect of your Supply Chain

An open system that integrates all operations on a single unified platform!

Order quantities based on demand

Automated replenishment

Organize the supply chain

JIT manufacturing

Automated inventory valuation

Setup control points

Manage employee contracts

Viindoo is used and trusted by scalable enterprises