ONE platform for ALL Inventory demands

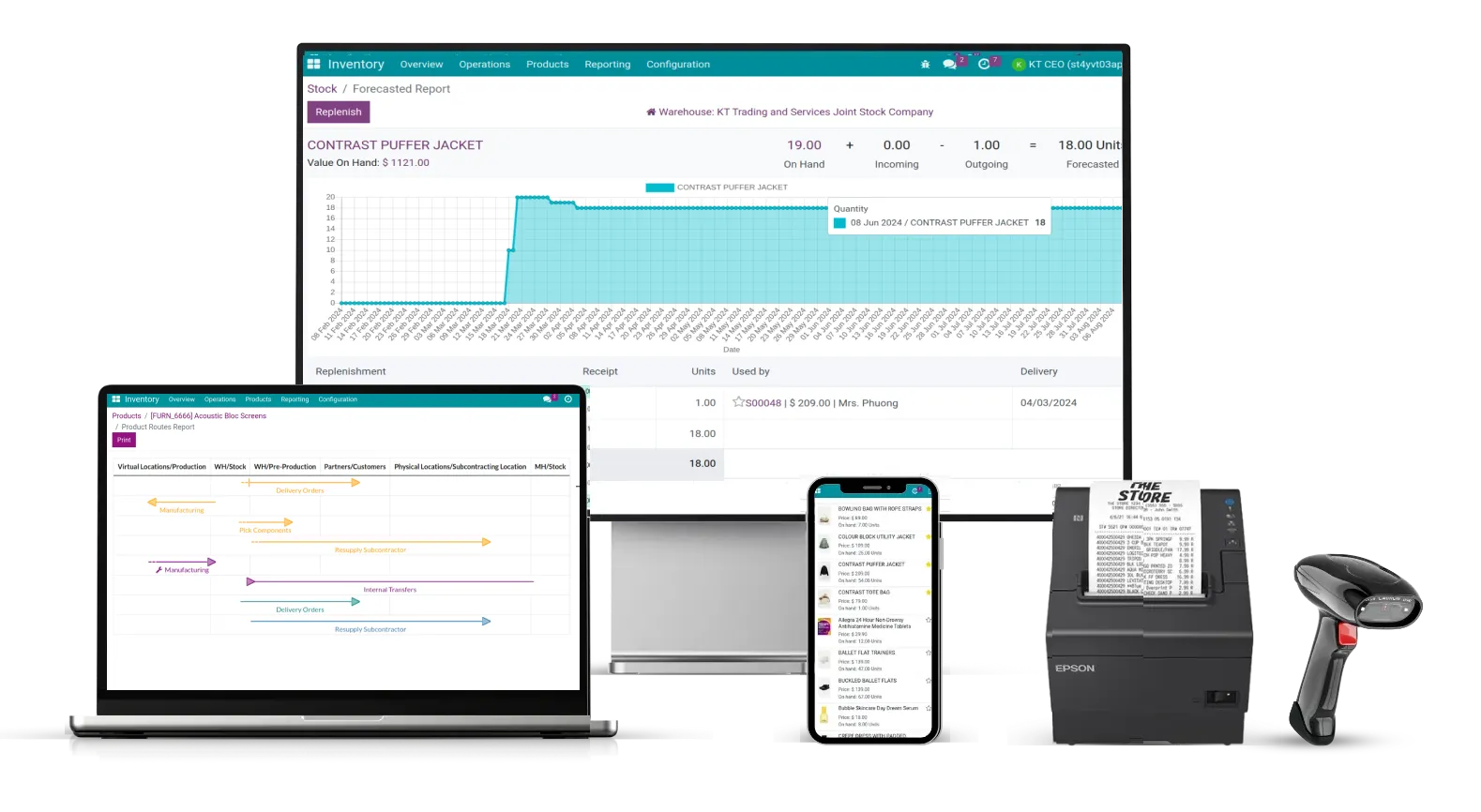

Any devices, any hardware

Laptops

Tablets

Mobiles

Inventory devices

All inventory management types

Multi warehouse

Lot, serial, batch inventory

Kitting, assembly

Dropshipping

Looking for consultancy? Meet our Viindoo experts

No more inventory chaos and delays

Ensure Inventory visibility and accuracy. Avoid stockouts, overstocking.

Real-time inventory

Gain visibility into inventory data from anywhere with an internet connection.

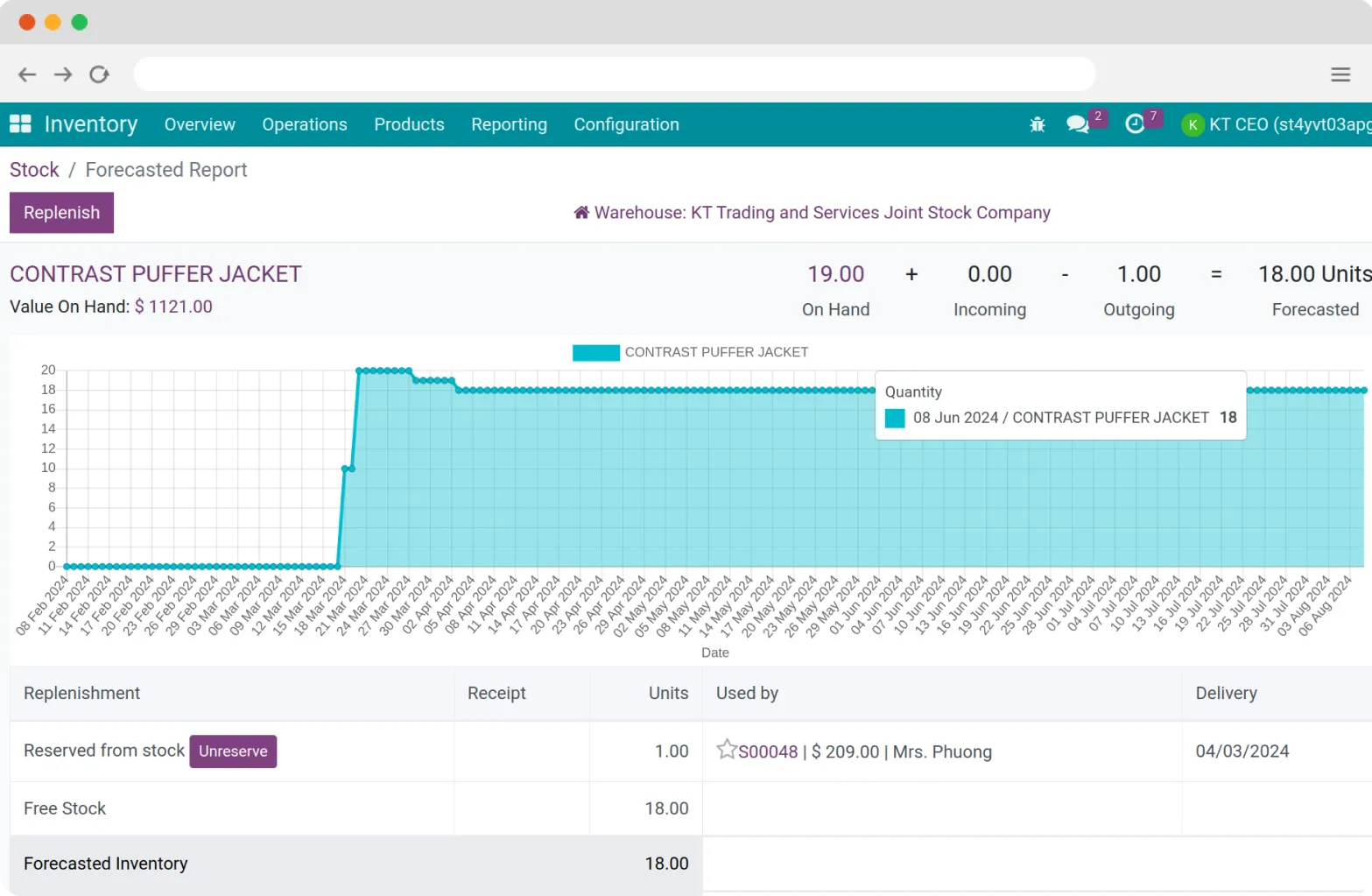

Intuitive & Automated Inventory Report

Real-time dashboards to monitor KPIs and optimize inventory levels.

Just in time Replenishment

Define min and max order quantities, reorder points, lead times, safety stock, and forecast models to calculate replenishment.

Automate Re-Ordering

Automate the re-ordering process to ensure timely replenishment of stock.

Reduce Inventory Costs

Minimize inventory costs and optimize inventory levels to minimize wastage.

Keep track of Warehouse Performance

Monitor warehouse performance to reduce errors and increase efficiency.

Speed up inventory operation

Leverage IoT technology to integrates inventory hardwares into your management software:

Barcode Scanners

Label Printers

Weighing Scales

Measurement devices

...

Key Features of Viindoo Inventory Management Systems

Control every inventory activities to enable sufficient and timely replenishment and delivery

Multiple attributes such as color, size, etc., are synchronized across teams including Purchase, Sales, Inventory, Accounting, etc

Rich-data products enable traceability of every item from supplier to customer.

Following two methods Lavoisier & Double-Entry Bookkeeping, all stock moves are recorded with source & destination location, qty, conversation history, transaction time, etc.

Automate stock in, out with multiple steps of processes.

Delivery schedule is calculated based on: on-hand qty, forecasted qty, lead time, etc to ensure timely delivery.

From components to set and from a set/semi-finished good/byproduct to components

Establish and execute cycle count schedule. Investigate stock discrepancies with transparent stock move report.

Automatic inventory processes of Drop-ship, Cross-dock, Suncontract.

Allow vendors, warehouse staffs, customers to place orders and manage inventory level in their preferred unit of measure with flexible conversion.

Oversee storage areas, such as shelves, aisles, cold storage rooms, and pallet racks

Manage all the warehouses, locations with hierarchical structure

Automatically propose internal transfers, ensuring quick and timely delivery of stock.

Monitor stock age, alert date of expiration, etc with intuitive report.

Record and classify every item to ensure optimal leverage and management.

Capture all the costs associated with your product including taxes, duties, and other fees.

Automatically create allocation journals to adjust receiving notes.

Multiple and automatic inventory valuation methods: Standard Price, FIFO, Average cost.

Integrate with Accounting to generate corresponding accounting entries.

Inventory performance report

Inventory Input-Output Report

Inventory Forecast Report

Inventory Valuation Report

Stock Age Report

etc

Define and perform quality tests during inventory receipt, shipping, kitting, production, or returns and automate quality check process.

Another concerns? Chat with us to discuss